Exposure device and method

An exposure device and exposure method technology, applied in the field of photolithography, can solve the problems of inconsistent deformation of flexible substrates, poor exposure accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

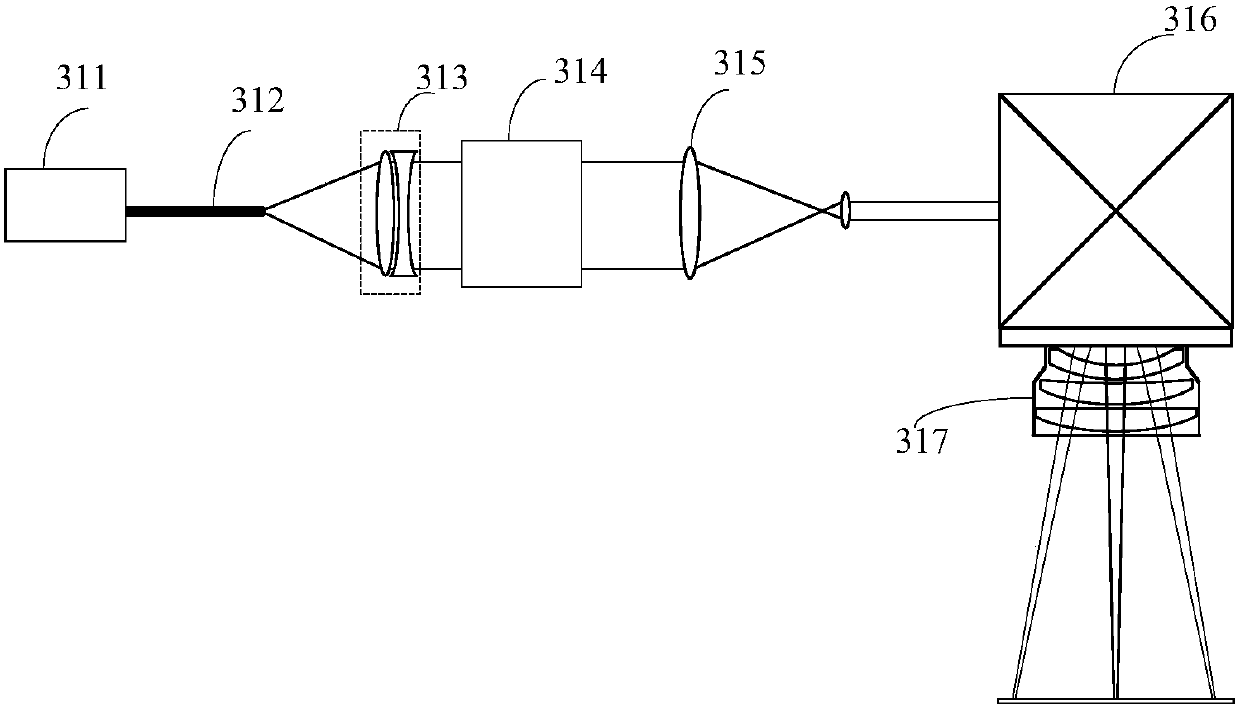

[0082] Such as Figure 10 As shown, different from Embodiment 1, in this embodiment, the first exposure system 31 and the third exposure system 41 include a first light source 311, a beam expander assembly 315, a shaping assembly 314, a scanning Vibrating mirror assembly 316 and field lens 317; The first light source 311 is a laser light source, and the collimated light beam sent is adjusted by the beam expander assembly 315 after the diameter of the beam, and then enters the shaping assembly 314 to form the required spot shape, and the light spot shape can be It is a rectangular spot, and of course it can also be in other shapes. The shaping component 314 is DOE (Diffractive Optical Elements, diffractive optical element) or ROE (refractive Optical Elements, refractive optical element).

Embodiment 3

[0084] Such as Figure 11 As shown, different from the above-mentioned embodiment 1-2, the first exposure system 31 and the third exposure system 41 include a first light source 311, a beam expander assembly 315, a shaping assembly 314, and a focusing lens 318 arranged in sequence along the optical path. , the objective lens 319 and the scanning galvanometer assembly 316, the first light source 311 is a laser light source, the output collimated beam passes through the beam expander assembly 315 to adjust the beam diameter, and then enters the shaping assembly 314 to form the required spot shape, and then adjusts The focus lens 318 adjusts the focus of each point of view in the entire field of view, so that the light beams of each point of view are focused on the plane, and finally after being imaged by the objective lens 319, it is reflected to the focal plane by the scanning galvanometer assembly 316, and the flexible substrate 1 to make the exposure. The shape of the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com