Electron beam resist composition and preparation method

A technology of electron beam lithography and composition, applied in the field of photoresist, can solve the problems of poor thermal stability, dry etching resistance, low sensitivity, etc., and achieve the effects of improving sensitivity, improving resolution, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

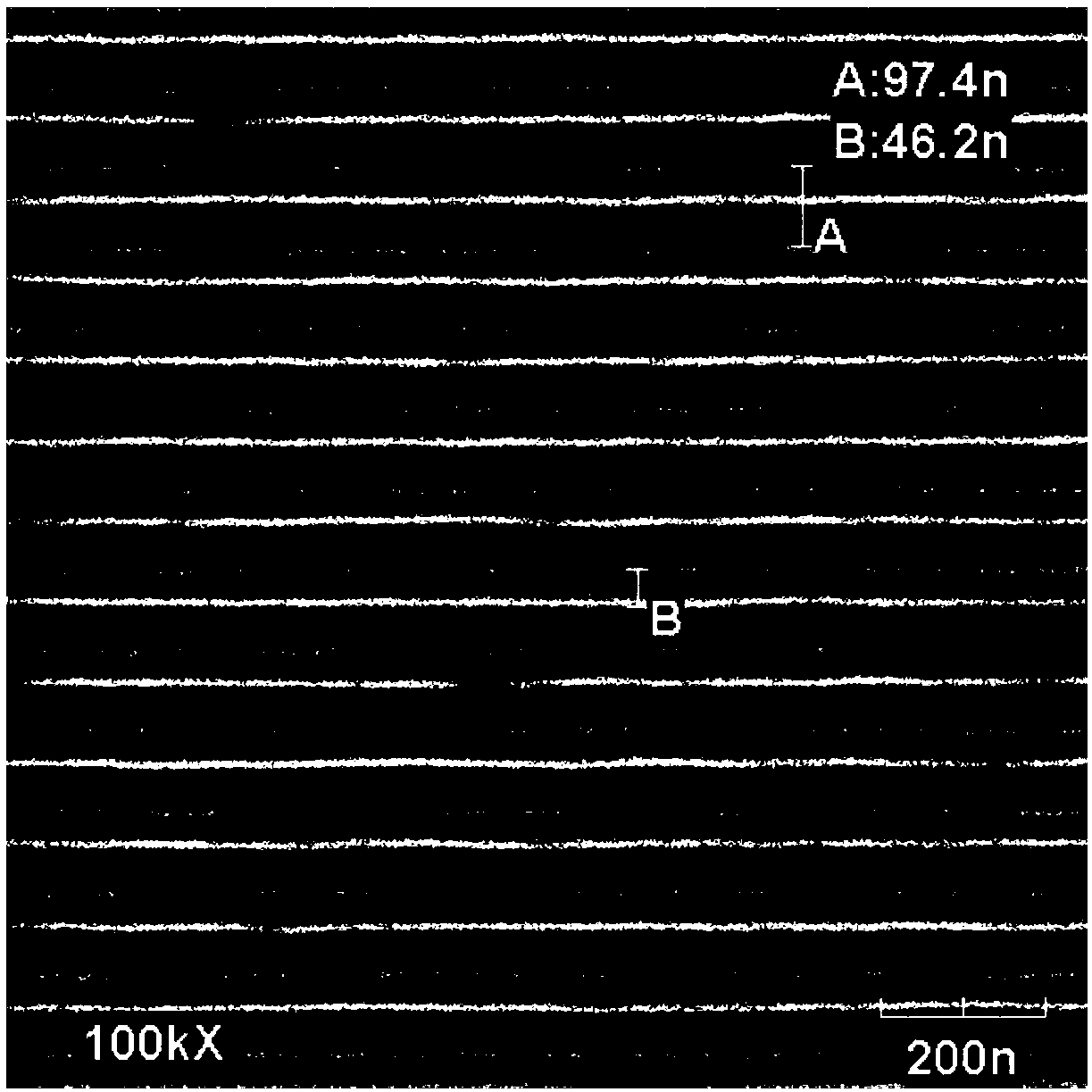

Image

Examples

Embodiment 1

[0040]

[0041] The structure of the polymer P-I-1a is shown in the above formula. The polymer is obtained by copolymerization of two monomers shown in the formulas M-1 and M-I-1. The synthesis of the copolymer is completed by the following steps:

[0042] Add: 4.16g (0.04mol) methyl fluoroacrylate, 10.57g (0.06mol) benzyl methacrylate Esters, 50mL tetrahydrofuran, nitrogen gas into the reaction system for 10 minutes under stirring, after the reaction was closed, the system was heated to 60°C, and after the temperature became constant, 5mL 2,2'-azo-2 was added through a constant pressure dropping funnel , 4-Dimethylvaleronitrile (1.54 g, 0.006 mol) in tetrahydrofuran solution, continued to stir and react at 60° C. for 24 hours. After the reaction, the polymer reaction solution was washed with n-hexane (3×200 mL), concentrated with a rotary evaporator, precipitated in methanol, filtered with suction, and dried in vacuum at 60° C. for 24 hours to obtain a white solid powder. ...

Embodiment 2

[0044]

[0045] The structure of the polymer P-II-1a is shown in the above formula. The polymer is obtained by copolymerization of two monomers shown in the formulas M-3 and M-II-3. The synthesis of the copolymer is completed by the following steps:

[0046] Add: 8.13g (0.05mol) n-butyl chloroacrylate, 8.41g (0.05mol) 2-isopropylene Base naphthalene, 50mL xylene, nitrogen gas into the reaction system for 10 minutes under stirring, after the closed reaction, heat the system to 80°C, after the temperature is constant, add 5mL 2,2'-azo - 2,4-Dimethylvaleronitrile (1.54 g, 0.006 mol) in xylene, after stirring for 15 hours at 60°C. After the reaction, the polymer reaction solution was washed with n-hexane (3×200 mL), concentrated with a rotary evaporator, precipitated in methanol, filtered with suction, and dried in vacuum at 60° C. for 24 hours to obtain a white solid powder. The ratio is 85%, the molecular weight Mw: 38000, and the molecular weight distribution is 1.52.

Embodiment 3~6

[0048] Polymers P-I-1b, P-I-1c, P-II-1b, and P-II-1c are prepared based on the polymerization methods of Example 1 and Example 2, respectively, by changing the reaction temperature and the amount of the initiator. The specific polymer Weight average molecular weight (Mw), number average molecular weight (Mn), and molecular weight distribution (Mw / Mn) are shown in the following table:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com