Patterning methods for nanomaterials

A nanomaterial and patterning technology, applied in nanotechnology, printing, printing devices, etc., can solve the problems of difficulty in patterning methods, waste of raw materials, inability to accurately control the deposition amount of nanomaterials, etc., and achieve the effect of improving the quality of patterning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

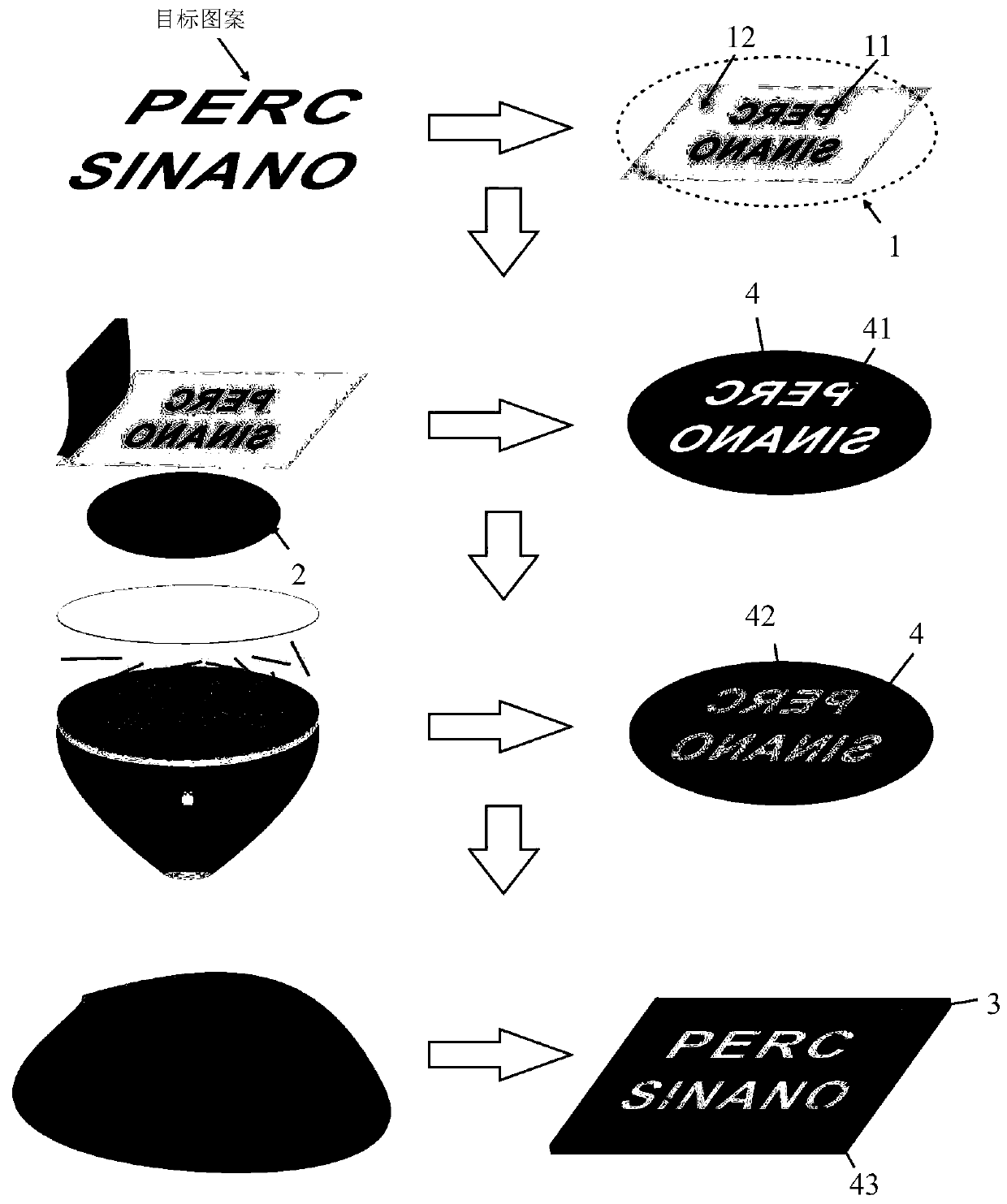

Method used

Image

Examples

Embodiment 1

[0037] Firstly, the pattern of the screen plate 1 is customized. In this embodiment, the target pattern is three simple geometric figures of triangle, circle and square. Then, on the surface of the filter membrane 2 covered with the screen plate 1, the polymer slurry is screen-printed, wherein the material of the filter membrane 2 is polytetrafluoroethylene, and the diameter of the filter membrane 2 is 50mm, and the micropores on the filter membrane 2 are The pore size is 0.2 μm, and the polymer slurry is polydimethylsiloxane (PDMS, 10:1). Heat and solidify rapidly at a temperature of 80° C. to obtain a patterned polymer paste layer 4 .

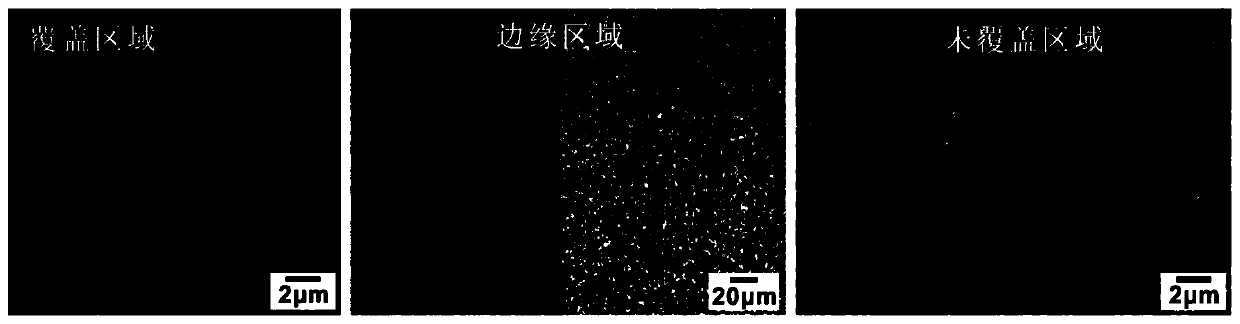

[0038] figure 2 Shown is the scanning electron microscope (SEM) image of different regions after screen printing PDMS on the surface of filter membrane 2. It can be seen that the PDMS uncovered area on filter membrane 2 maintains the original pore structure, and the boundary between the uncovered area and the covered area The edge area is ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that the filter membrane 2 is made of nylon, the nanomaterial is carbon nanotube (CNT), and the substrate 3 is polyethylene terephthalate (PET) film.

[0045] Image 6 Shown is the SEM image of the microelectrode made of CNT.

Embodiment 3

[0047] Embodiment 3 differs from Embodiment 1 in that the material of the filter membrane 2 is polyvinylidene fluoride, the diameter of the filter membrane 2 is 100 mm, the nanomaterial is graphene, and the substrate 3 is a silica gel film.

[0048] Figure 7 Shown is the SEM picture of the microelectrode made of graphene.

[0049] It can be understood that, in other embodiments, the filter membrane 2, the polymer slurry and the substrate 3 can be made of other materials, which are not limited here. Of course, other sheet-like two-dimensional materials or wire-like one-dimensional materials can also be used as nanomaterials. The graphene, carbon nanotubes, and silver nanowires given in this embodiment are only shown as examples and are not intended to be limiting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com