Preparation method of patterned metal layer

A patterning, metal layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unclean metal removal, increased peeling difficulty, and inability to achieve peeling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

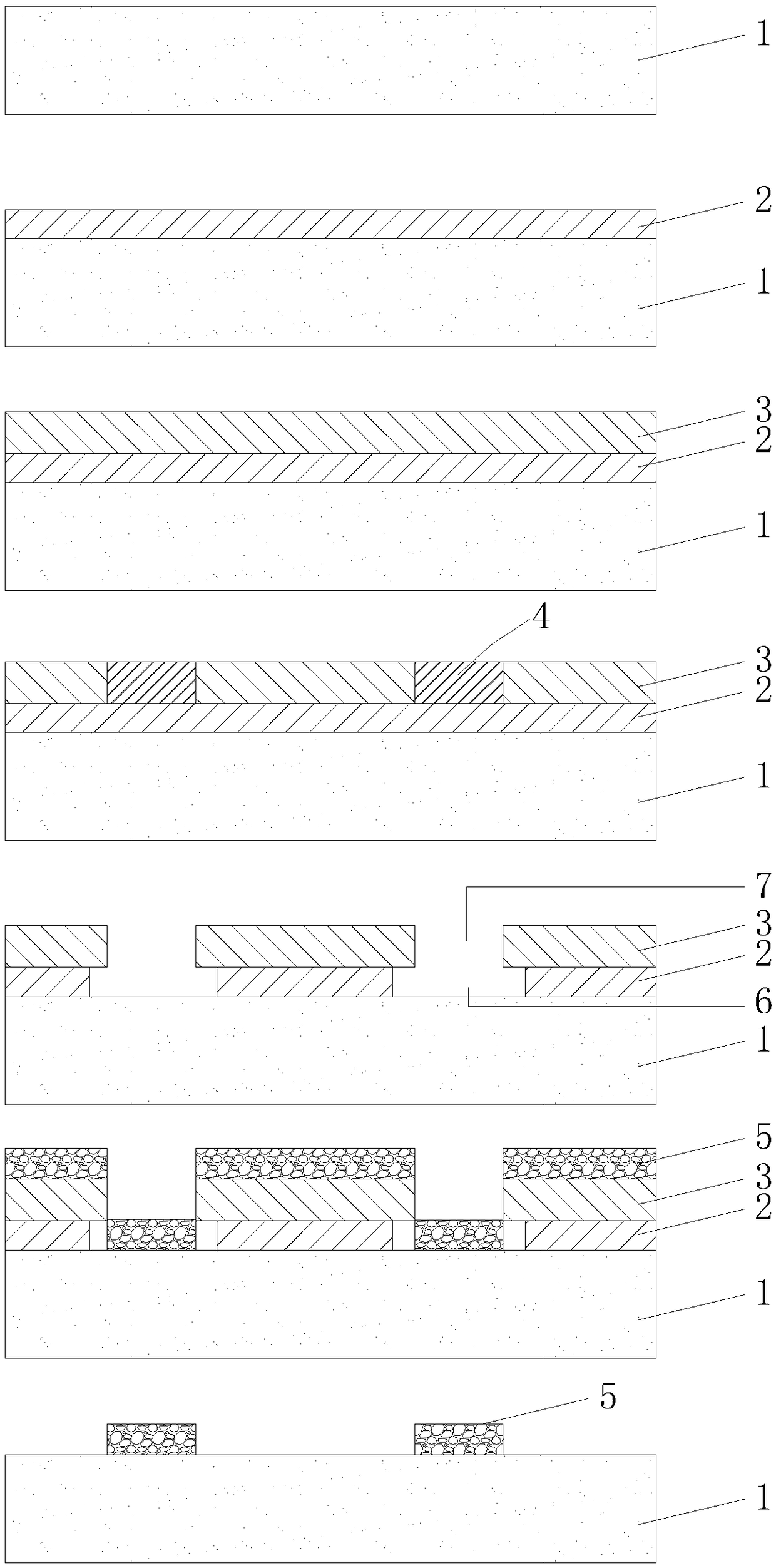

[0017] The preparation method of the graphic metal layer provided by the present invention will be further described below.

[0018] The invention provides a method for preparing a patterned metal layer, the preparation method comprising:

[0019] Provide a base, and sequentially form primer and photoresist on the base;

[0020] exposing the substrate with the primer and the photoresist and placing it in a developing solution for simultaneous patterning, wherein in the developing solution, the dissolution rate of the primer is greater than that of the exposed photoresist ;

[0021] Depositing a metal layer on the substrate with patterned primer and photoresist;

[0022] peeling off the underlayer glue and the photoresist to obtain a patterned metal layer.

[0023] The material of the bottom layer glue is LOR glue, and the photoresist is positive photoresist. Described LOR glue is a kind of non-photosensitive water-soluble macromolecule polymer, and chemical change can not ...

Embodiment 1

[0038] refer to figure 2 The process flow chart, using silicon wafers as the substrate 1, first clean the silicon wafers with RCA standard cleaning solution and dry them: when cleaning, first wash the silicon wafers in a volume ratio of 4:1 2 SO 4 with H 2 o 2 Wash in 5 min, rinse in deionized water after cleaning, and then put in NH with a volume ratio of 1:1:5 4 OH / H 2 o 2 Wash in a solution of deionized water for 5 minutes, rinse in deionized water after cleaning, and then put in HCl / H with a volume ratio of 1:1:4 2 o 2 Wash in a solution of deionized water for 5 minutes, rinse in deionized water after cleaning, then put in HF with a concentration of 2% for 30 seconds, and rinse in deionized water after cleaning. After cleaning, the silicon wafers were put into a spin dryer and dried at a speed of 2000r / min for 5min.

[0039] Use LOR-5B photoresist as the primer 2 and spread it evenly on the silicon wafer twice, with a thickness of 0.7 μm each time and a total thic...

Embodiment 2

[0049] refer to figure 2 The process flow chart, using silicon wafers as the substrate 1, first clean the silicon wafers with RCA standard cleaning solution and dry them: when cleaning, first wash the silicon wafers in a volume ratio of 4:1 2 SO 4 with H 2 o 2 Wash in 5 min, rinse in deionized water after cleaning, and then put in NH with a volume ratio of 1:1:5 4 OH / H 2 o 2 Wash in a solution of deionized water for 5 minutes, rinse in deionized water after cleaning, and then put in HCl / H with a volume ratio of 1:1:4 2 o 2 Wash in a solution of deionized water for 5 minutes, rinse in deionized water after cleaning, then put in HF with a concentration of 2% for 30 seconds, and rinse in deionized water after cleaning. After cleaning, the silicon wafers were put into a spin dryer and dried at a speed of 2000r / min for 5min.

[0050] Use LOR-5B photoresist as the primer 2 and spread it evenly on the silicon wafer twice, with a thickness of 0.5 μm each time and a total thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com