Preparation method of piezoelectric ceramic transducer (PZT) thick film with micro structure

A lead zirconate titanate and microstructure technology is applied in the field of preparation of lead zirconate titanate PZT thick films with microstructures, which can solve the problems of surface roughness, difficulty in preparation and patterning, and high equipment cost, and achieves improved surface flatness and Density, overcoming difficult clean etching, high patterning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

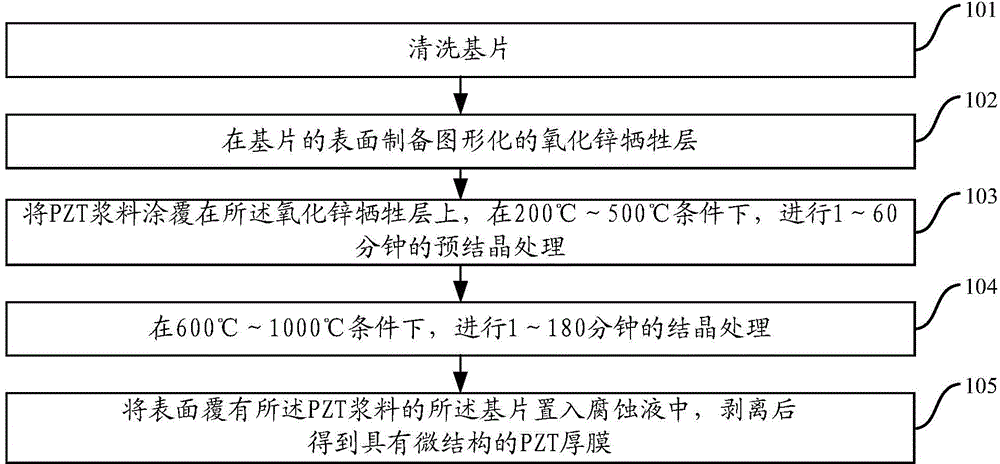

[0041] figure 1 It is a flow chart of the method for preparing a PZT thick film provided in Example 1 of the present invention. Figure 2-6 A schematic diagram of the preparation process for each step in the preparation process is provided. Below, according to figure 1 and combine Figure 2-Figure 6 , the preparation method of PZT thick film with microstructure is described in detail.

[0042] Such as figure 1 As shown, the preparation method specifically includes the following steps:

[0043] Step 101, cleaning the substrate.

[0044] Specifically, the substrate is put into an acid cleaning solution or an alkaline cleaning solution for cleaning, and then deionized water is used to rinse the substrate.

[0045] The substrate can be any one of silicon substrate, gallium nitride substrate, sapphire substrate, ruby substrate, quartz substrate, gallium arsenide substrate, silicon carbide substrate, germanium substrate, diamond substrate Substrate; or any one of the above-...

Embodiment 2

[0063] In this embodiment, the method provided in Example 1 is used to prepare a PZT thick film with a microstructure, and the preparation process of the PZT thick film is specifically as follows:

[0064] Add the PZT powder to the PZT colloid, and mix it into a slurry by ultrasonic dispersion; place the mixed slurry for 1 day, and then remove the coarse particles larger than 250nm after slurry precipitation; then remove the slurry after removing the coarse particles larger than 250nm Concentrating is carried out, and the concentrated slurry is left still for 5 days to form a PZT slurry containing fine powder.

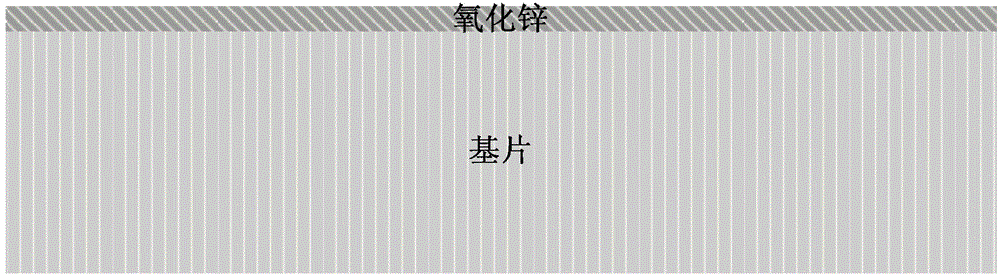

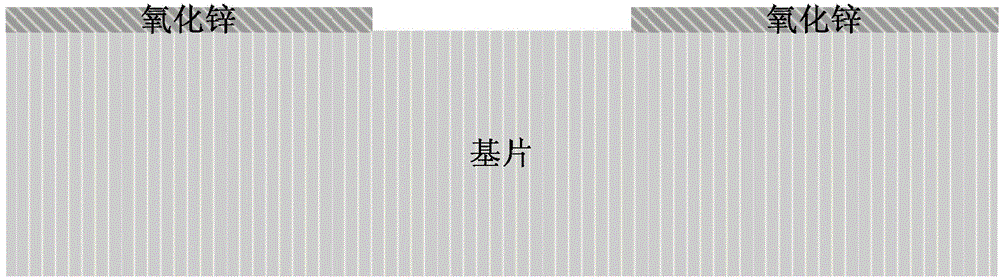

[0065] Prepare a 0.01μm zinc oxide sacrificial layer on the cleaned silicon substrate by radio frequency sputtering; apply a positive photoresist on the surface of the zinc oxide sacrificial layer, and use the negative plate of the PZT thick film pattern to be prepared for positive alignment Photoresist photolithography exposure and development; the silicon substrate a...

Embodiment 3

[0069] The embodiment of the present invention uses the method provided in Example 1 to prepare a PZT thick film with a microstructure, and the preparation process of the PZT thick film is specifically:

[0070] Add the PZT powder to the PZT colloid, and mix it into a slurry by ultrasonic dispersion; place the mixed slurry statically for 15 days, and then remove the coarse particles larger than 250nm after the slurry is precipitated; then remove the slurry after removing the coarse particles larger than 250nm Concentrating is carried out, and the concentrated slurry is left still for 20 days to form a PZT slurry containing fine powder.

[0071] Clean the potassium nitride substrate; prepare a zinc oxide sacrificial layer with a thickness of 0.01 μm on the potassium nitride substrate; repeat.

[0072] Using the prepared PZT slurry, a PZT wet film was prepared on a substrate with a patterned zinc oxide sacrificial layer through a coating process; at a temperature of 500 ° C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com