Small form factor camera module with mechanical iris and shutter

A camera, small-scale technology, applied in the direction of camera, camera body, shutter, etc., can solve the problems of complex structure, slow response speed, gear unit friction and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 is the same.

[0078] Therefore, the operation of Embodiment 2 is the same as that of Embodiment 1.

[0079] Figure 9 Various shapes of shutter slits are shown, among which the uppermost one is the shutter slit 27 in Embodiment 1, and the lower ones are shutter slits 34, 35 and 36 in Embodiments 3, 4 and 5, respectively.

[0080] First, for the shutter slit 27 in Embodiment 1, the ratio of the movement of the shutter actuator 26 to the horizontal movement of the aperture portion 24 in order to open and close the optical path is 1:1.

[0081] Furthermore, for the shutter slit 34 in Embodiment 3, the ratio of the movement of the shutter actuator 26 to the horizontal movement of the aperture portion 24 in order to open and close the optical path is 1:2.

Embodiment 4

[0082] The shutter slit 35 in Embodiment 4 is made convex, whereby the horizontal movement of the aperture portion 24 for opening and closing the optical path gradually decreases as the movement of the shutter actuator 26 increases.

[0083] Contrary to Embodiment 4, the shutter slit 36 in Embodiment 5 is made concave, whereby the horizontal movement of the aperture portion 24 for opening and closing the optical path gradually increases as the movement of the shutter actuator 26 increases.

[0084] In addition, the shutter slit 27 may be formed in a combination of a linear shape and a circular shape.

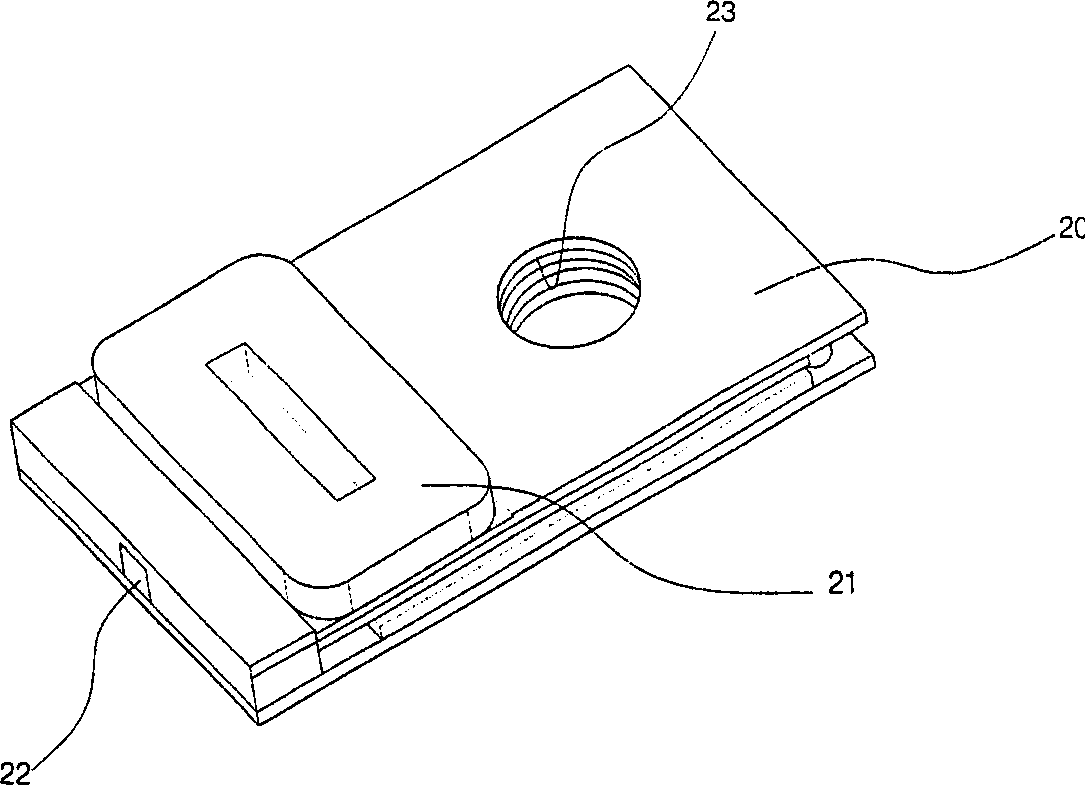

[0085] Figure 10 is a perspective view of a light quantity adjusting device according to Embodiment 6 of the present invention, Figure 11 is a bottom view of the bottom plate 28 according to Embodiment 6 of the present invention, Figure 12 is an exploded perspective view of a light adjusting device according to Embodiment 6 of the present invention.

[0086] Similar to E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com