Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve adhesive properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite film and semiconductor light emitting device using the same

InactiveUS20110309398A1Improve adhesive propertiesExcellent light extracting efficiencyDecorative surface effectsLayered productsFluorescenceSemiconductor

The present invention relates to a composite film including a wavelength conversion layer and a diffusive reflection resin layer in a laminated state and being used in a semiconductor light emitting device, in which the wavelength conversion layer contains a phosphor material which absorbs a part or all of excitation light and is excited to emit visible light in a wavelength region longer than a wavelength of the excitation light, the diffusive reflection resin layer is selectively formed with patterning on one surface of the wavelength conversion layer, and a region on the one surface of the wavelength conversion layer where the diffusive reflection resin layer is not formed with patterning is a path of the excitation light which excites the phosphor material in the wavelength conversion layer.

Owner:NITTO DENKO CORP

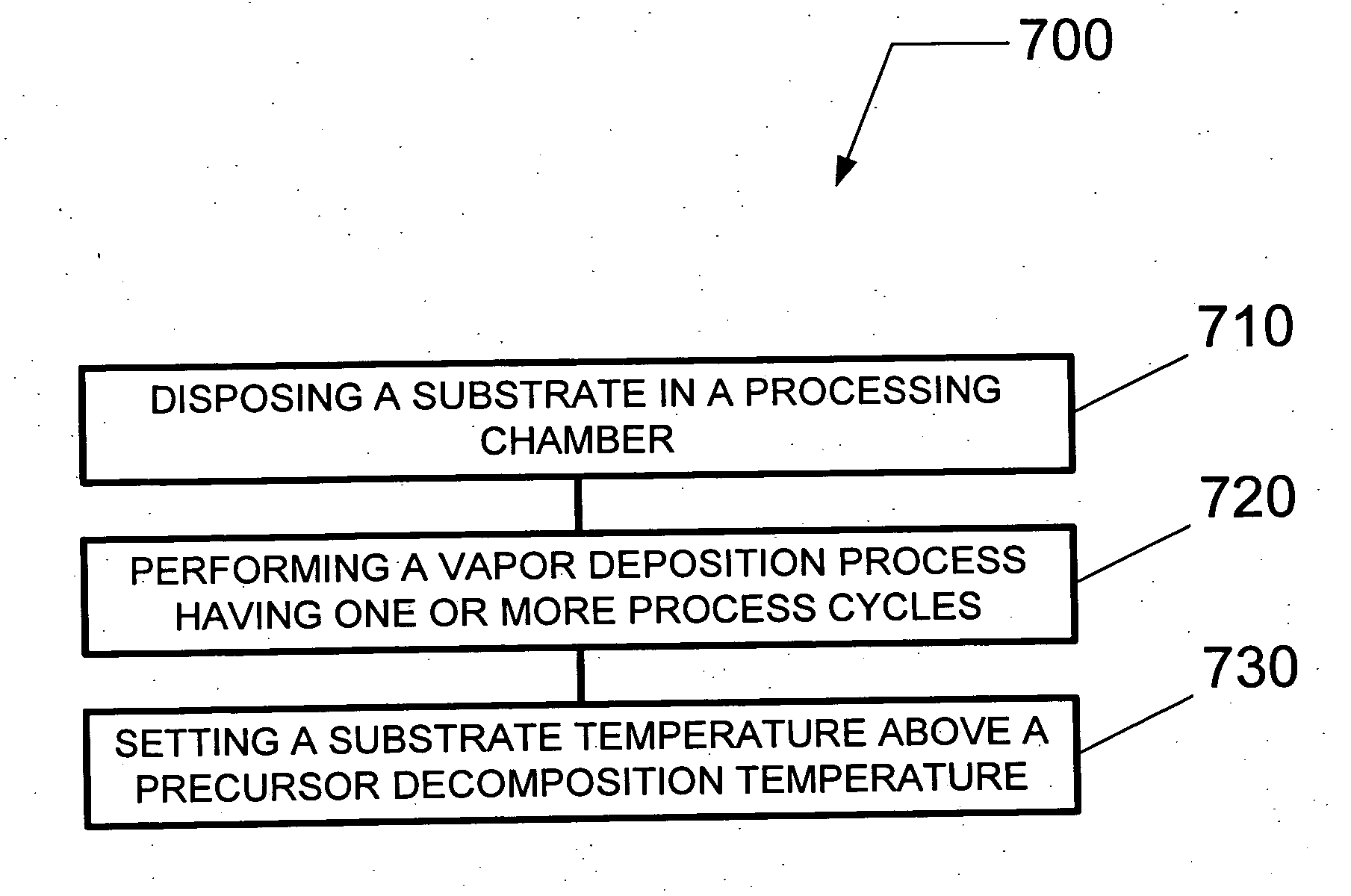

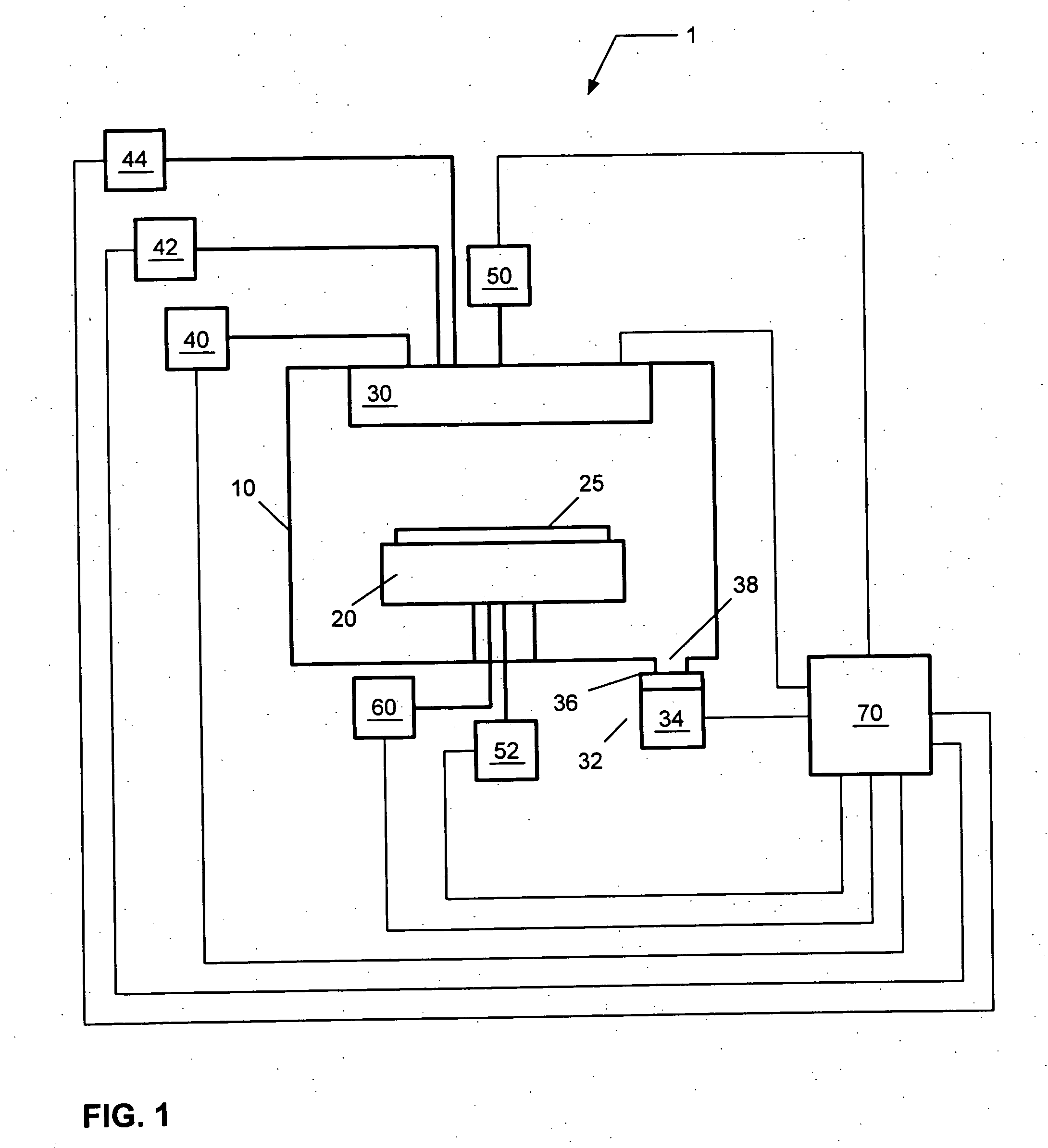

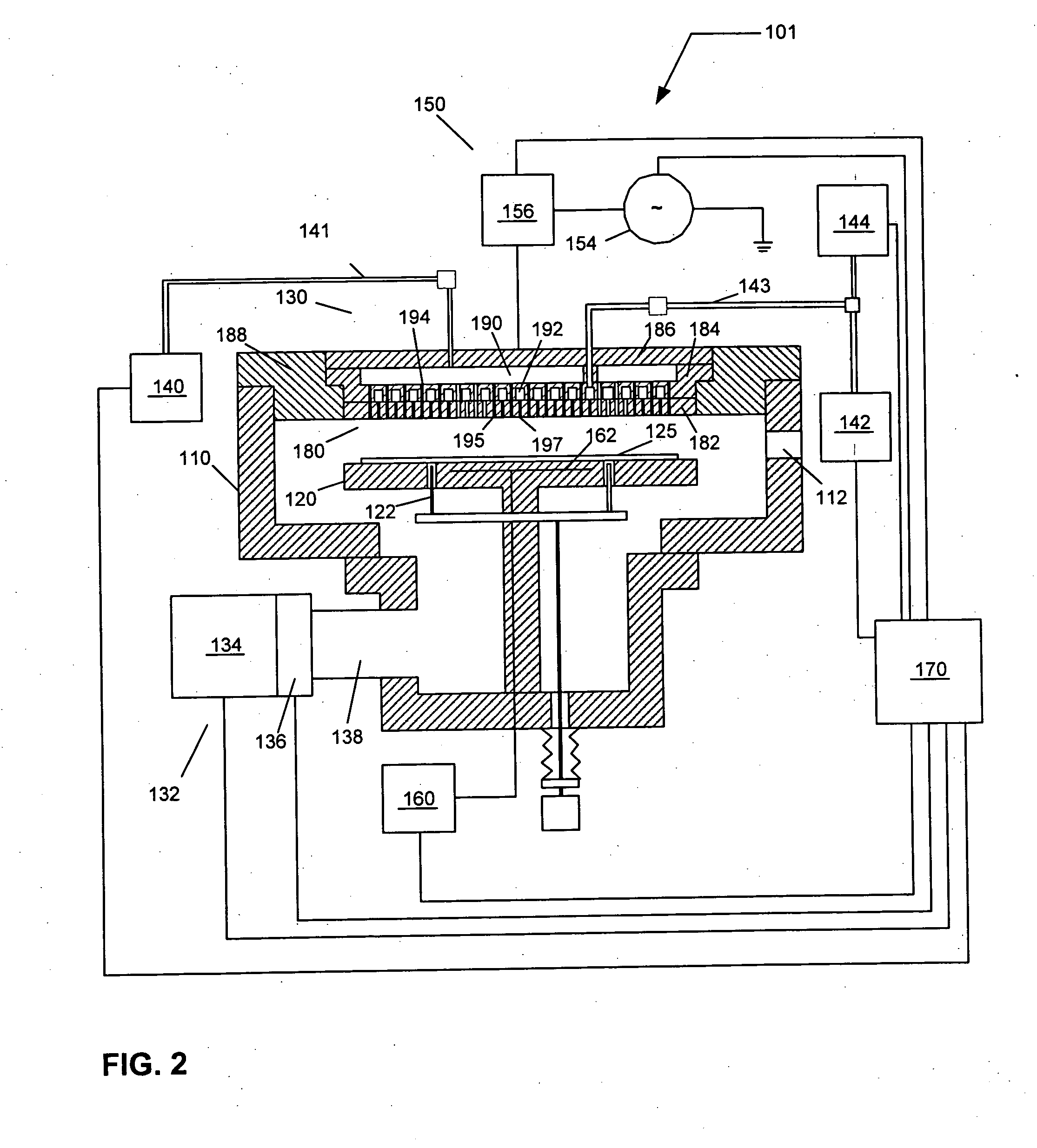

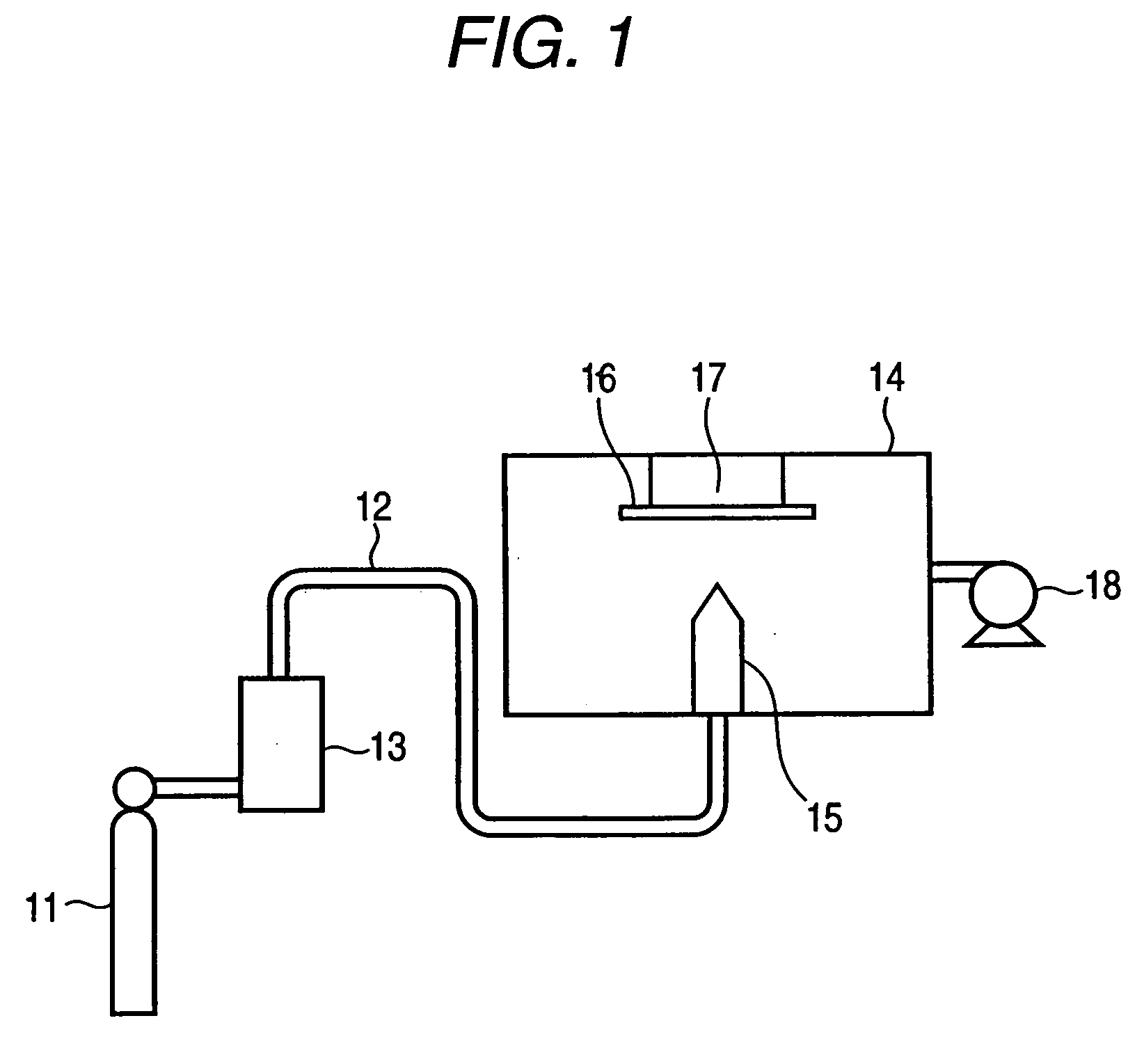

Method of forming a metal carbide or metal carbonitride film having improved adhesion

InactiveUS20070231487A1Improve adhesive propertiesImprove adhesionChemical vapor deposition coatingPlasma techniqueDecompositionDeposition process

A method for forming a metal carbide or metal carbonitride film on a substrate using a vapor deposition process. The method includes comprises introducing a first process material, such as a film precursor, to the substrate followed by introducing a second process material, such as a film reducing agent, to the substrate, whereby plasma can be formed during the introduction of the second process material in order to assist reduction of the first process material on the substrate. Additionally, the temperature of the substrate is elevated to a value approximately equal to or greater than the decomposition temperature of the first process material in order to improve adhesion properties for the metal carbide or metal carbonitride film.

Owner:TOKYO ELECTRON LTD

Strip, method for manufacturing the same, and method for manufacturing pneumatic tire

ActiveUS20130248085A1Step differenceImprove adhesive propertiesWithout separate inflatable insertsSynthetic resin layered productsChemistryComposite material

The present invention relates to a ribbon-shaped strip used for an inner liner and a method for manufacturing the strip. The strip is to be wound on an outer circumferential surface of a tire molding drum or a core body to form an inner liner. The strip has an inner layer disposed inwardly in a tire and an outer layer disposed outwardly in the tire. The inner layer and the outer layer are bonded to each other with their ends offset by 0.5 mm to 30 mm in a widthwise direction. At least one layer of the inner layer is formed of an elastomer composition containing a styrene-isobutylene-styrene block copolymer. At least one layer of the outer layer is formed of a thermoplastic elastomer composition.

Owner:SUMITOMO RUBBER IND LTD

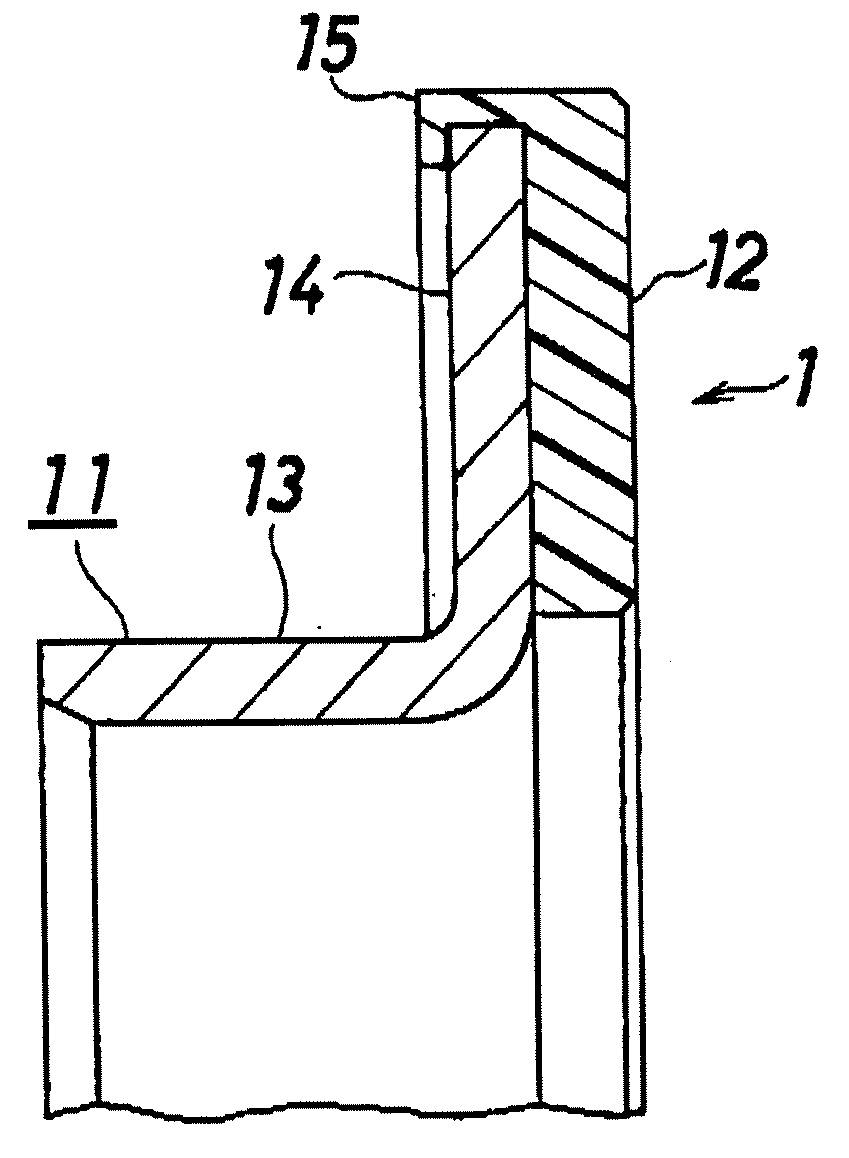

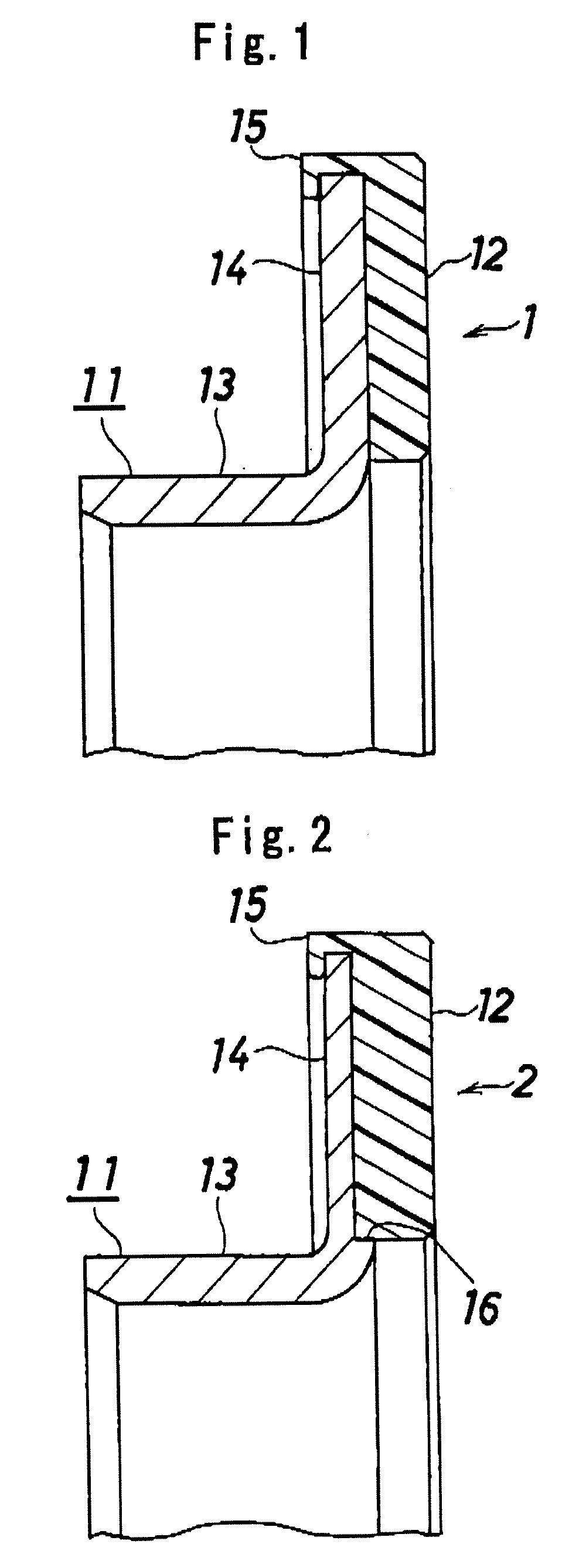

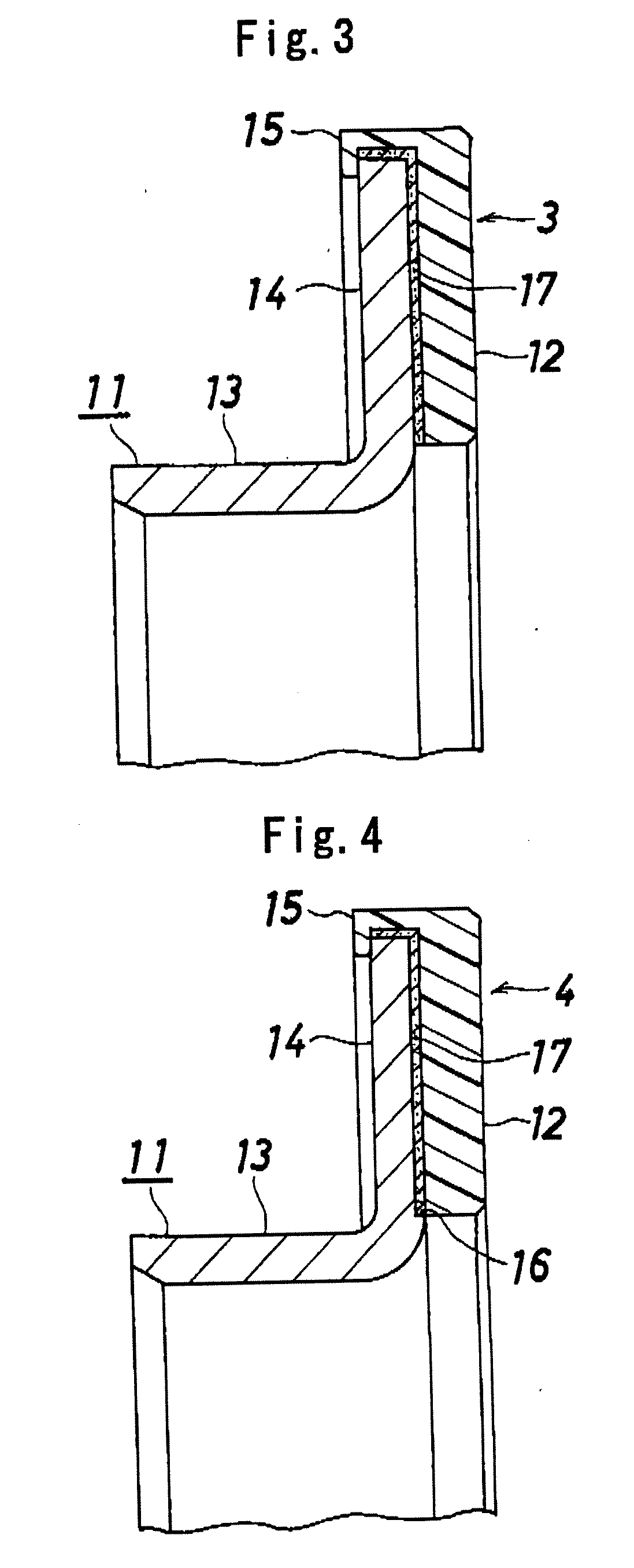

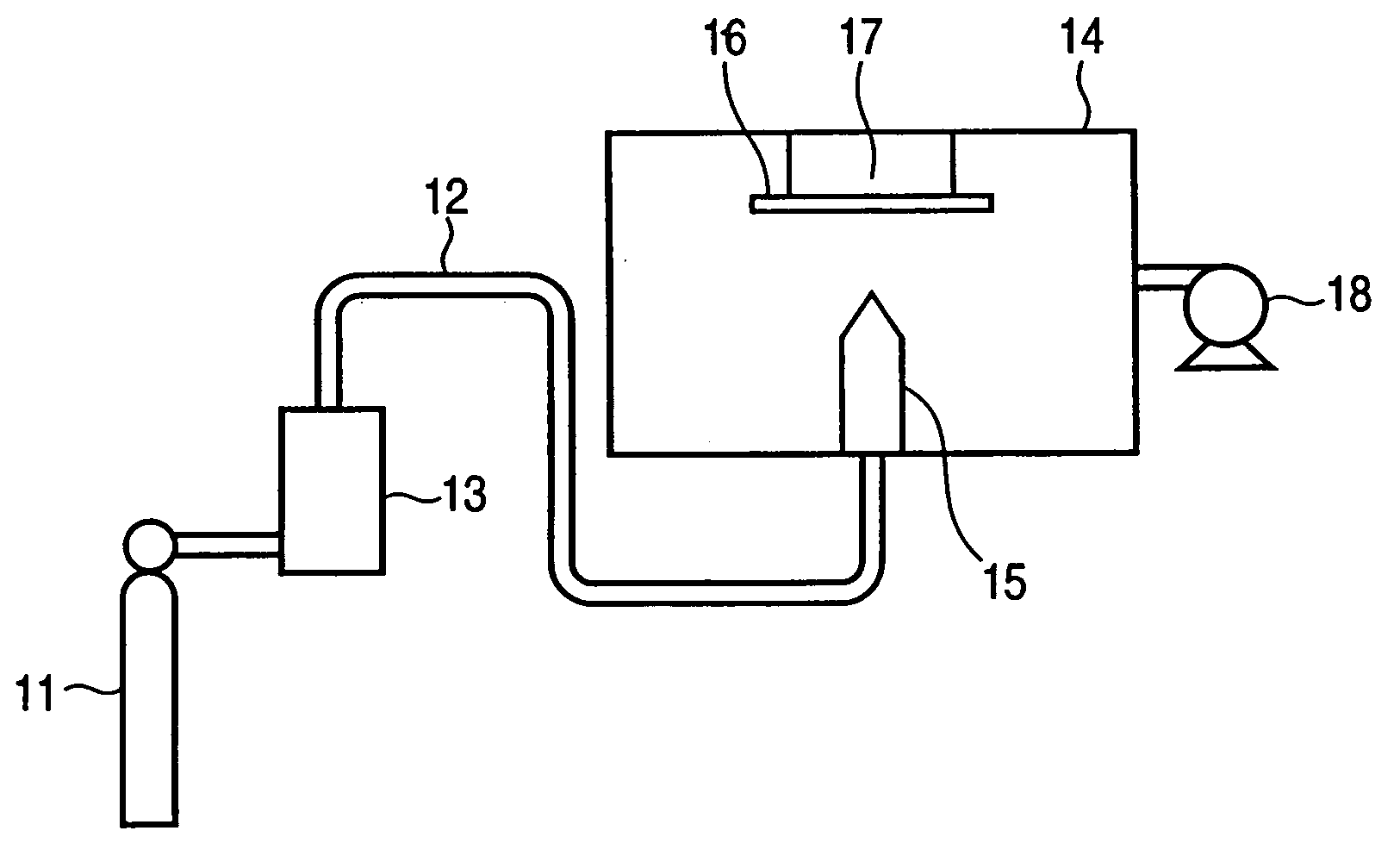

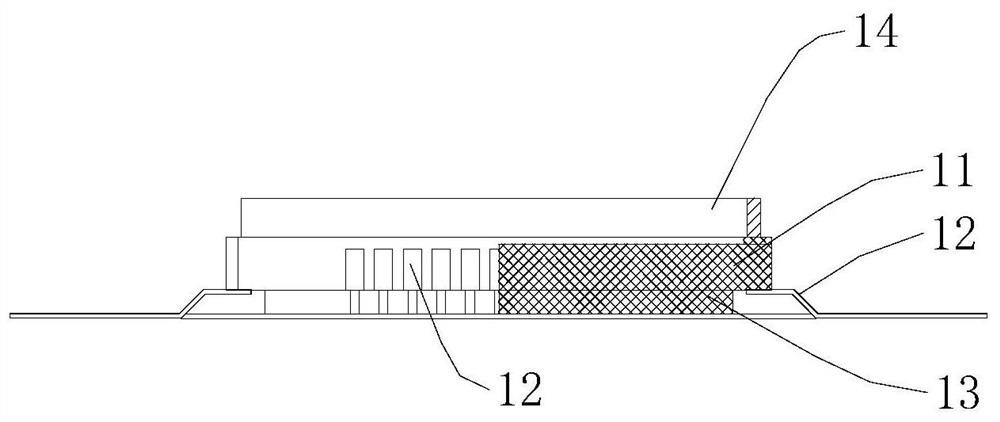

Magnetized pulsar ring

InactiveUS20070139035A1Improve adhesive propertiesHigh reliabilityEngine sealsDevices using electric/magnetic meansMagnetFlange

A magnetized body (12) is constituted by a resin bonded magnet, and is fixed to a support member (11) in accordance with an integral injection molding, in such a manner that a come-off preventing portion (15) engaging with an outer peripheral portion of a flange portion (14) is formed in an outer periphery of the magnetized body (12). An elastic layer (17) is interposed between the magnetized body (12) and the flange portion (14) A side surface of the flange portion (14) is provided with a concave portion (16) having a depth corresponding to a thickness of the elastic layer (17).

Owner:JTEKT CORP

Composite structure and production method thereof

ActiveUS20080274333A1Improve adhesive propertiesLayered productsPretreated surfacesComposite structureSubstrate surface

It is intended to provide a composite structure excellent in resistance characteristics such as plasma resistance. The composite structure includes a base material having a surface containing a ceramic polycrystal and a structure formed on the surface of the base material containing the ceramic polycrystal, wherein the structure contains a polycrystal containing a brittle material; a grain boundary layer having a glass layer does not substantially exist on a boundary face between crystals forming the polycrystal; a part of the polycrystal forms an anchor part embedded into the base material surface; and an average roughness (Ra) of an interface between the anchor part and the base material surface is 100 nm or less.

Owner:TOTO LTD

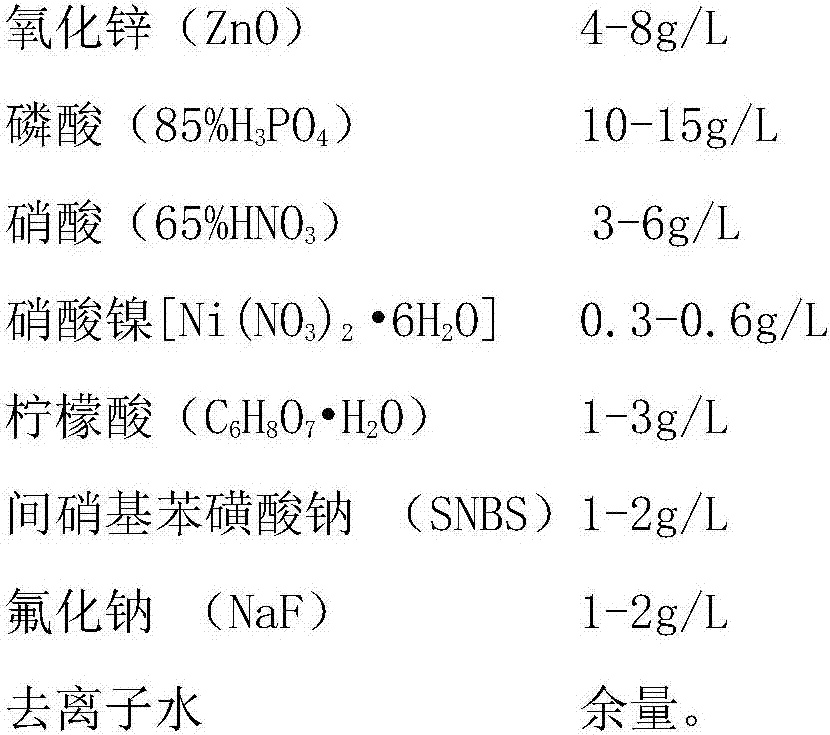

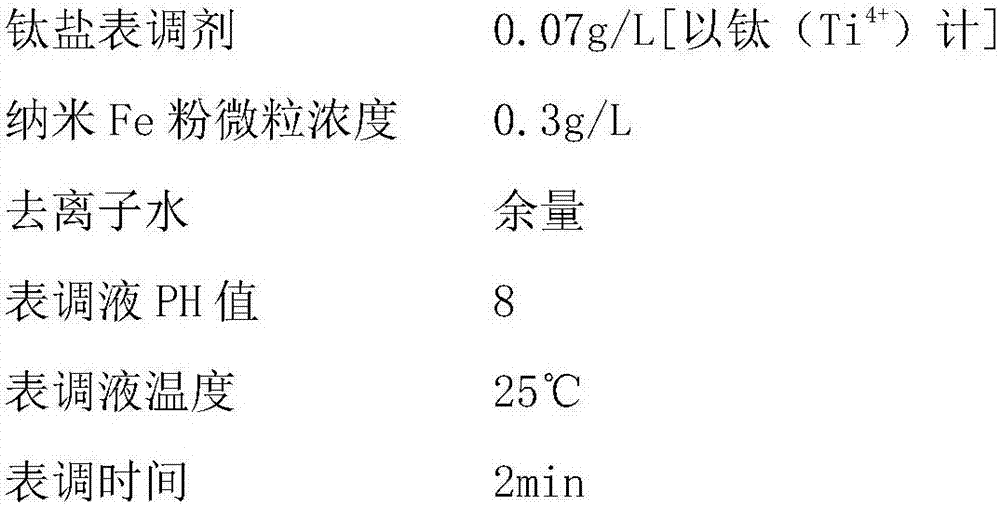

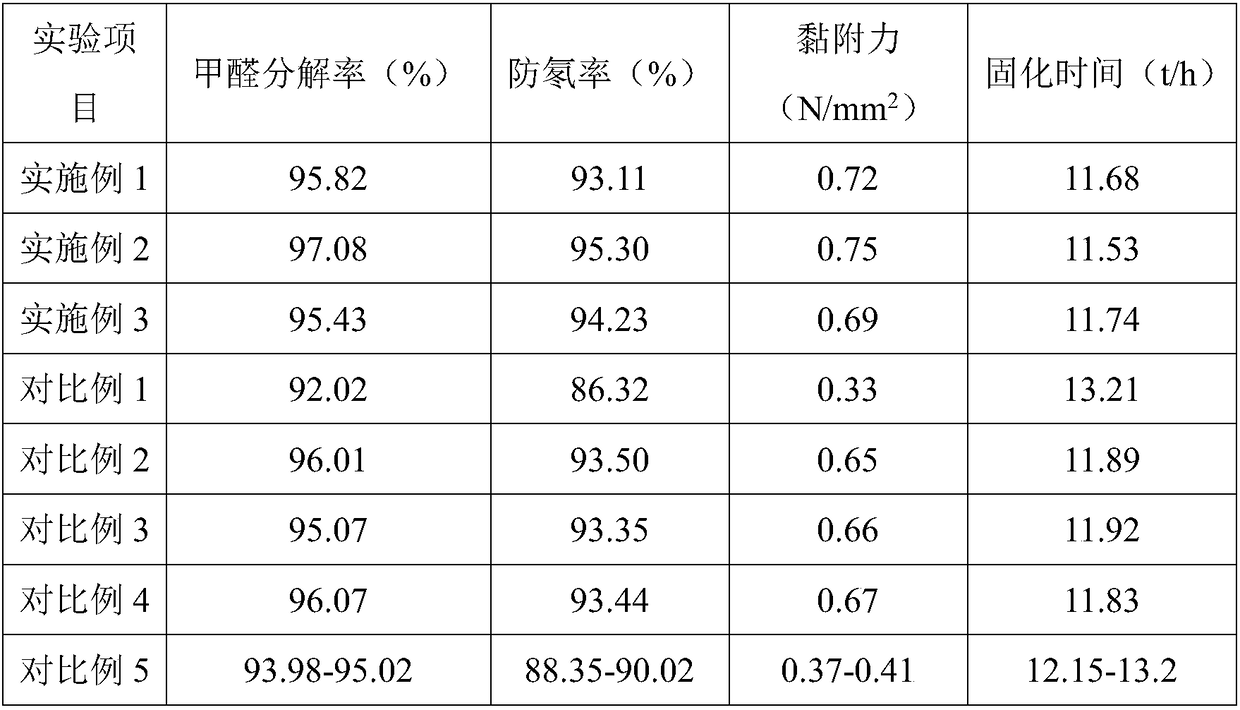

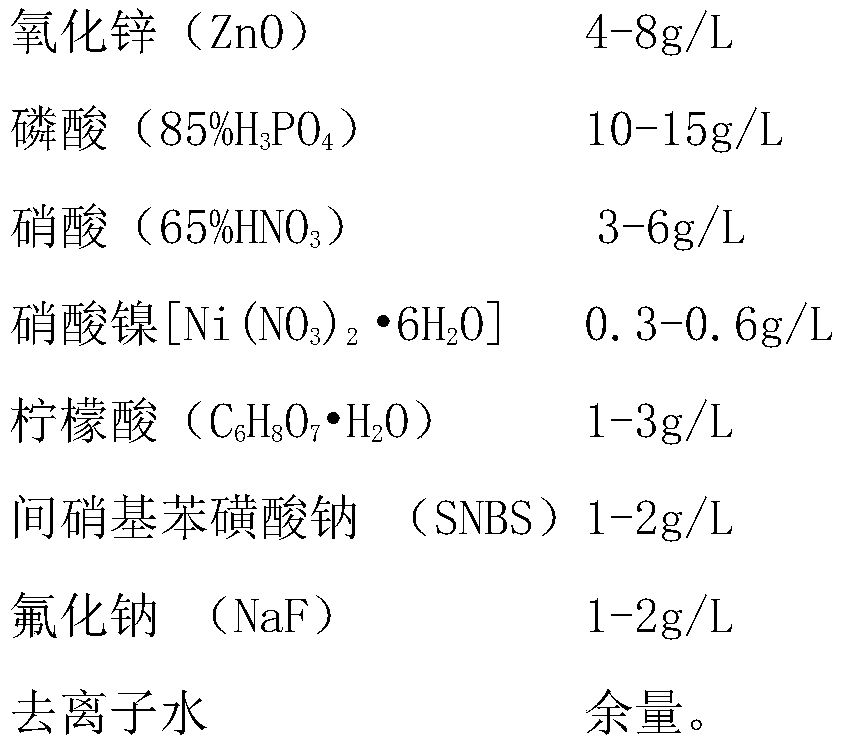

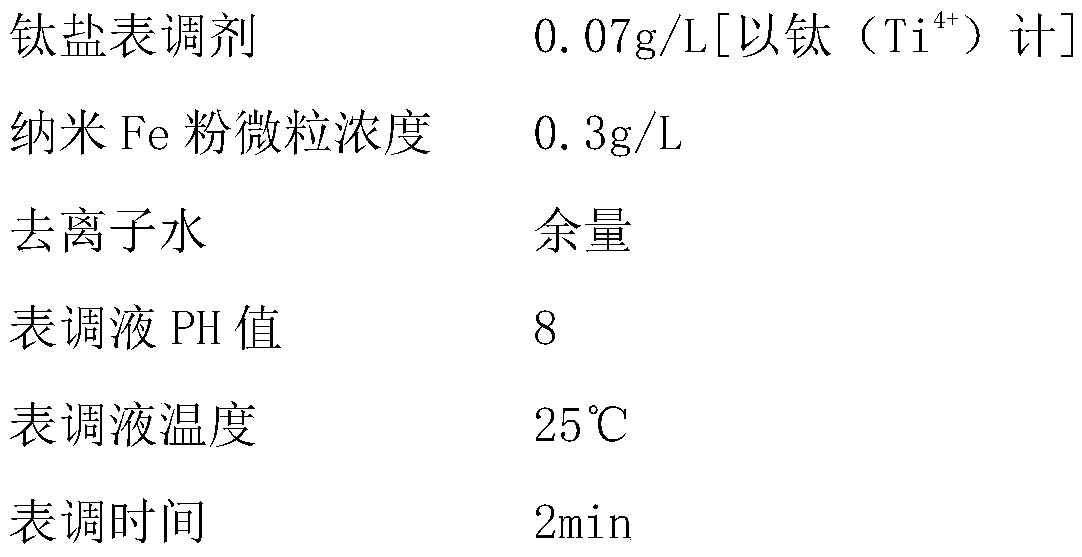

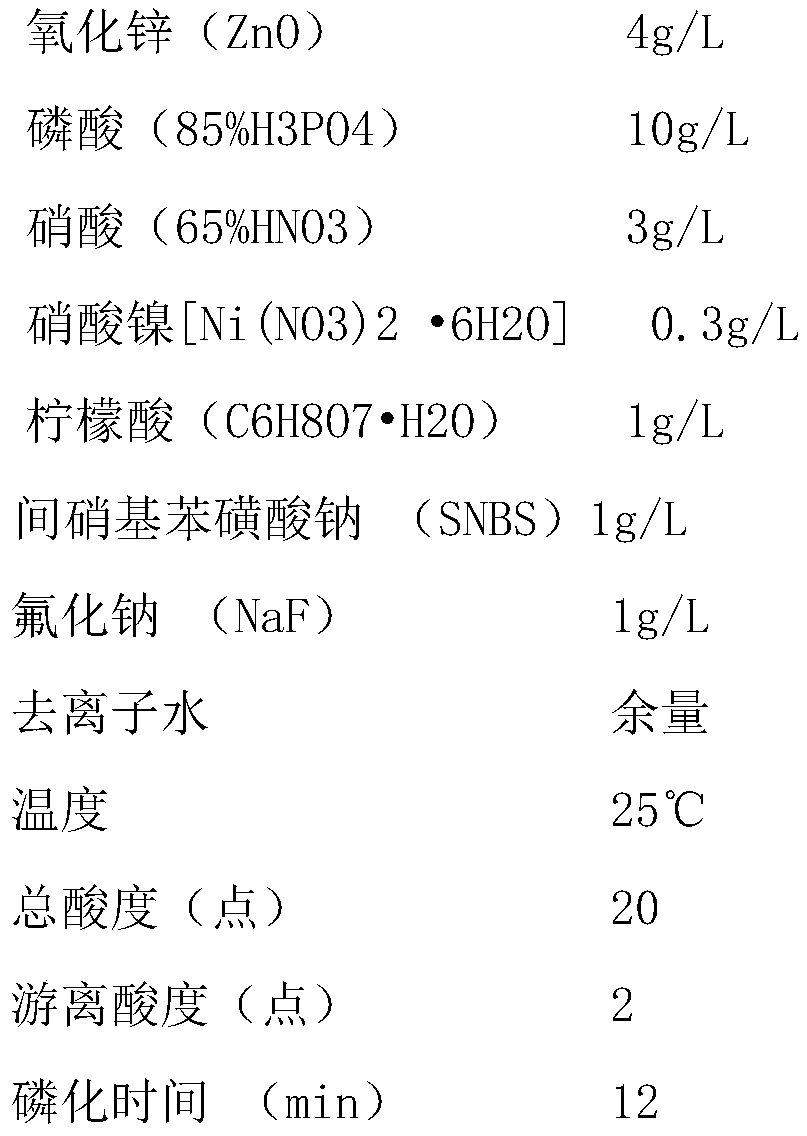

Method for improving corrosion resistance of sintered neodymium iron boron permanent magnet phosphating film

ActiveCN107164754AImprove corrosion resistanceExcellent adhesionMetallic material coating processesFiltrationTitanium

The invention discloses a method for improving corrosion resistance of a sintered neodymium iron boron permanent magnet phosphating film. The method comprises the steps that a machined and formed neodymium iron boron magnet is subjected to chamfering processing and is subjected to oil removing, acid pickling and water washing processing in sequence; in the stirring situation, the magnet is placed into surface conditioning liquid at the temperature of 20-30 DEG C for surface conditioning for 1-3 minutes, and the surface conditioning liquid is composed of a titanium salt surface conditioning agent, nanometer Fe powder particles and deionized water; and finally, the magnet is placed into a phosphating solution at the temperature of 20-40 DEG C for phosphating treatment for 10-20 minutes, and circulating filtration is performed. After the magnet is subjected to jointed surface conditioning by the titanium salt solution mixed with the nanometer Fe powder particles, the surface of the magnet is uniformly provided with a plurality of activated points and film forming factors, therefore the magnet can obtain the more uniform, more fine and more complete phosphating film in the phosphating reaction process, and thus corrosion resistance of the magnet is greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

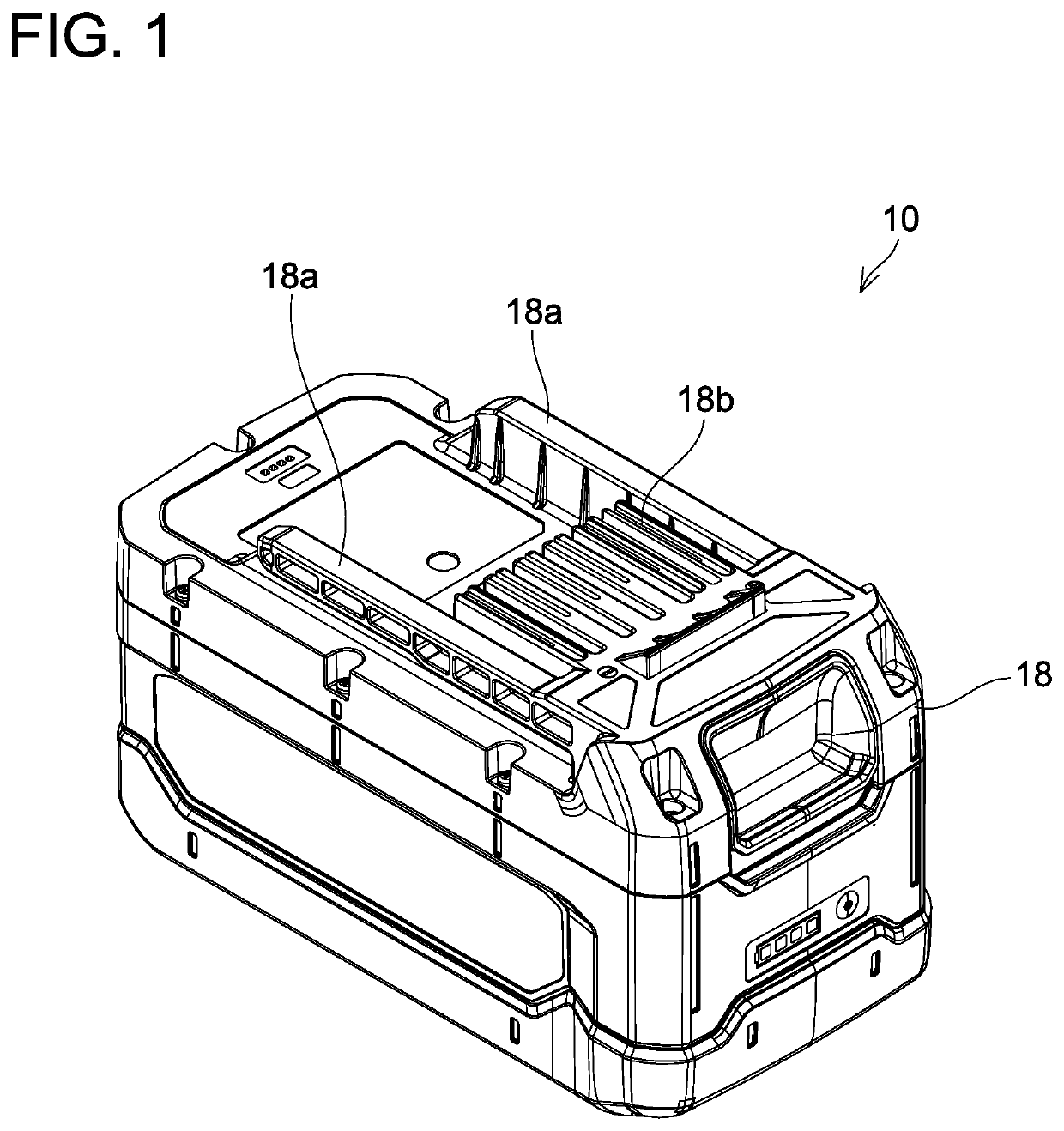

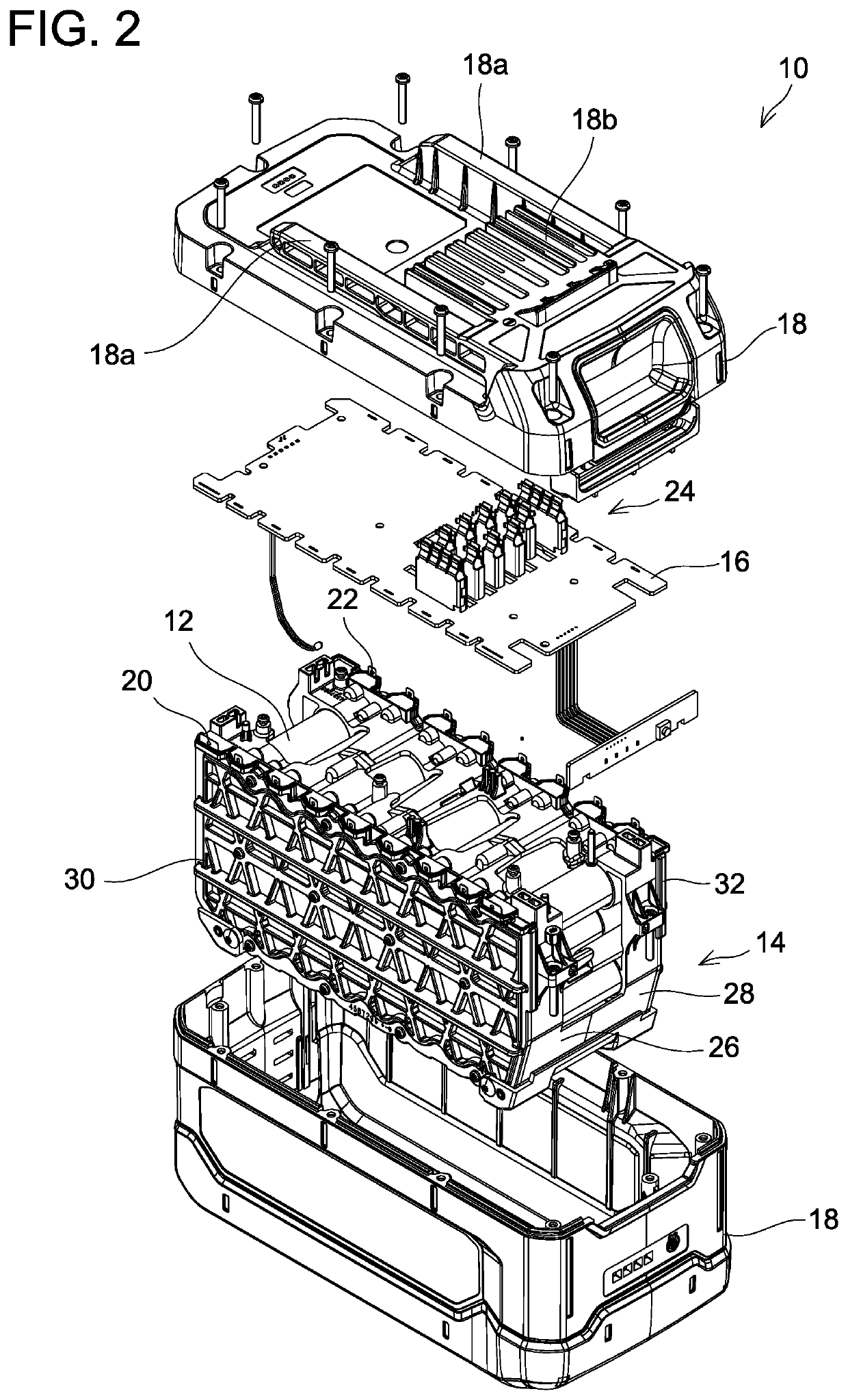

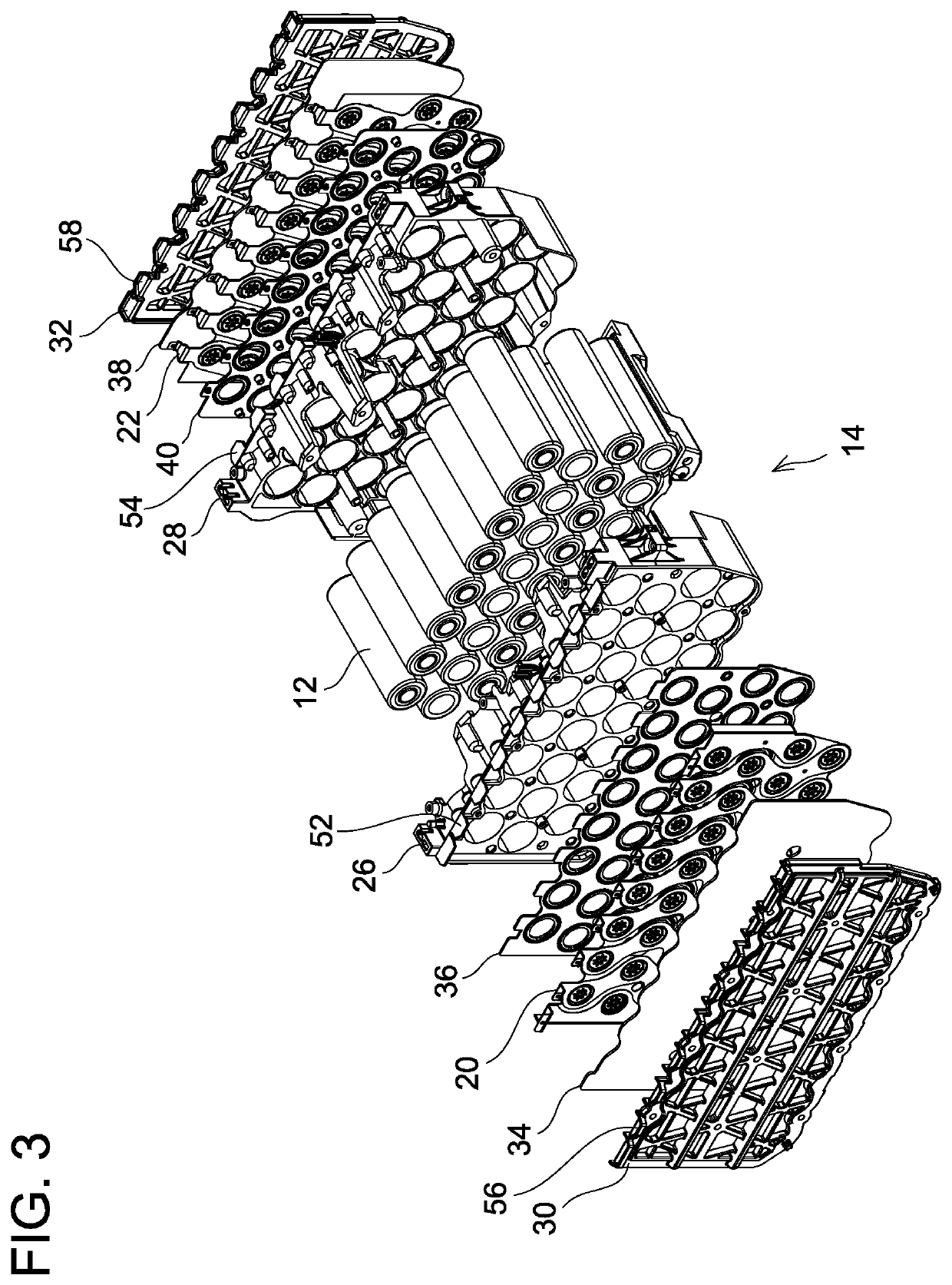

Battery pack

PendingUS20200321576A1Prevent adverse short circuitingImprove adhesive propertiesBatteries circuit arrangementsSmall-sized cells cases/jacketsEngineeringElectrical connection

A battery pack includes: a housing (18); one or more battery cells (12) housed inside the housing; one or more seat surfaces (52a, 54a, 56a, 58a) disposed inside the housing; a circuit board (16), which is housed inside the housing and is mounted on the seat surface(s); and one or more terminals (20b, 22b) electrically connected to the circuit board. One or more elastic sheets (60, 62) surround(s) the perimeter(s) of the terminal(s) and is (are) interposed between the circuit board and the seat surface(s).

Owner:MAKITA CORP +1

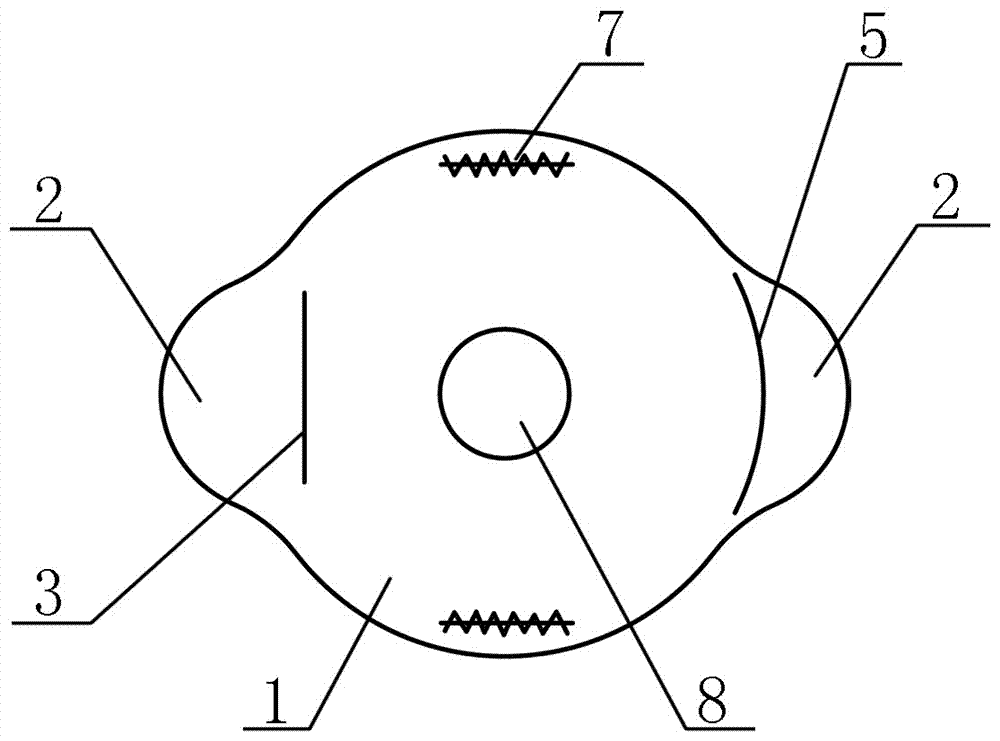

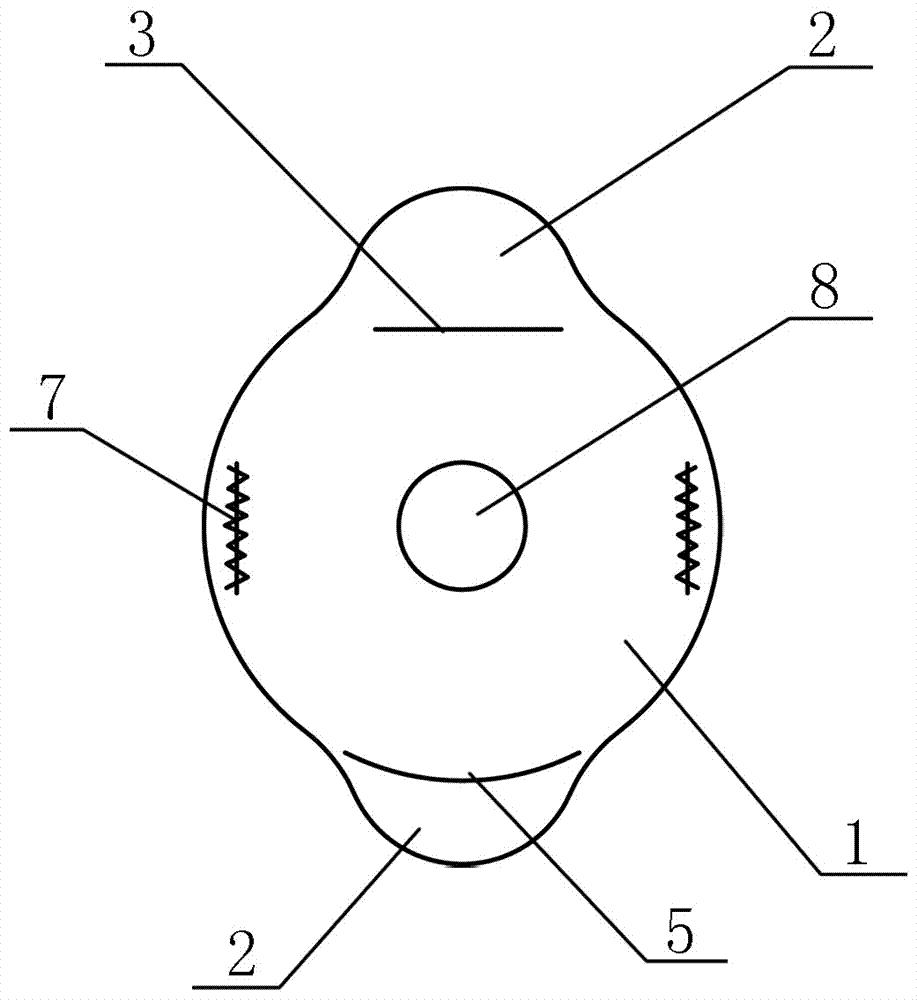

Multifunctional leakage-proof and spill-proof breast pad

The invention relates to the field of hygienic products, in particular to a multifunctional leakage-proof and spill-proof breast pad which comprises a breast pad body. Wings are arranged on the left side and the right side of the breast pad body, and leakage-proof components capable of preventing breast milk from laterally leaking are arranged on joints of the wings and the breast pad body. The multifunctional leakage-proof and spill-proof breast pad has the advantages that the wings are arranged on the left side and the right side of the breast pad body, the breast milk which laterally leaksfrom the multifunctional leakage-proof and spill-proof breast pad can be absorbed by the wings, and the problem of easiness in lateral leakage of spill-proof breast pads in the prior art can be solved; an adhesive layer further can be arranged on the outer surface of a bottom layer of the breast pad body, the area of the adhesive layer is larger than one third of the area of the bottom layer, theadhesive layer can be a rectangular or square or circular or elliptical adhesive layer, the area of the adhesive layer is enlarged, and accordingly adhesive effects can be improved.

Owner:GUANGZHOU JIANLANG MEDICAL TECH

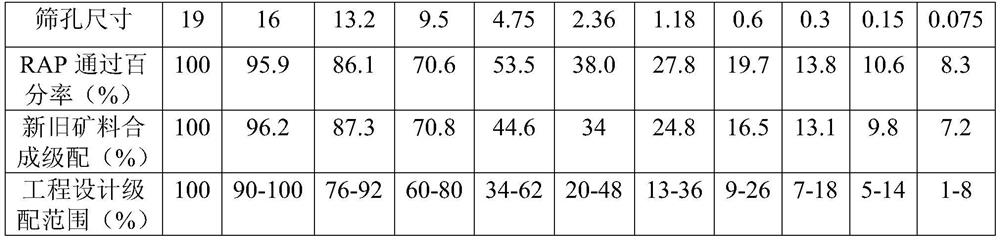

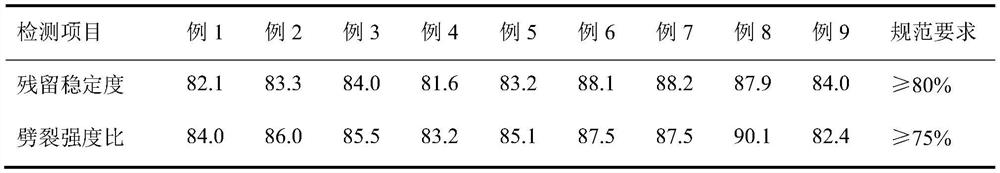

Warm mixing agent, regenerant and preparation method of warm-mixed recycled asphalt mixture

ActiveCN112358223AImprove adhesive propertiesHigh strengthSolid waste managementPolyamidePlasticizer

The invention provides a warm mixing agent, a regenerant and a preparation method of a warm-mixed recycled asphalt mixture. The warm mixing agent is prepared by mixing polyamide wax, chlorinated paraffin, resin, aromatic hydrocarbon and castor oil according to the mass part ratio of 20.1: 11.9: 8.2: 10.4: 3.1, and then melting and shearing for 10-12 minutes at the temperature of 120-130 DEG C; theregenerant is prepared by fully stirring and mixing illegal cooking oil, an anti-aging agent, waste rubber powder and a plasticizer at 70-80 DEG C and then cooling to normal temperature; according tothe preparation of the warm-mixed recycled asphalt mixture, the dosage of each component is determined according to tests, a certain amount of old RAP material is doped under the action of the warm mixing agent and the regenerant to prepare the new warm-mixed recycled asphalt mixture, and the prepared new warm-mixed recycled asphalt mixture has good advantages of fatigue resistance, stable strength and the like. According to the method, waste utilization is combined, material selection is optimized, regeneration of the old asphalt pavement is achieved, and meanwhile energy conservation, environmental protection and excellent performance are achieved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

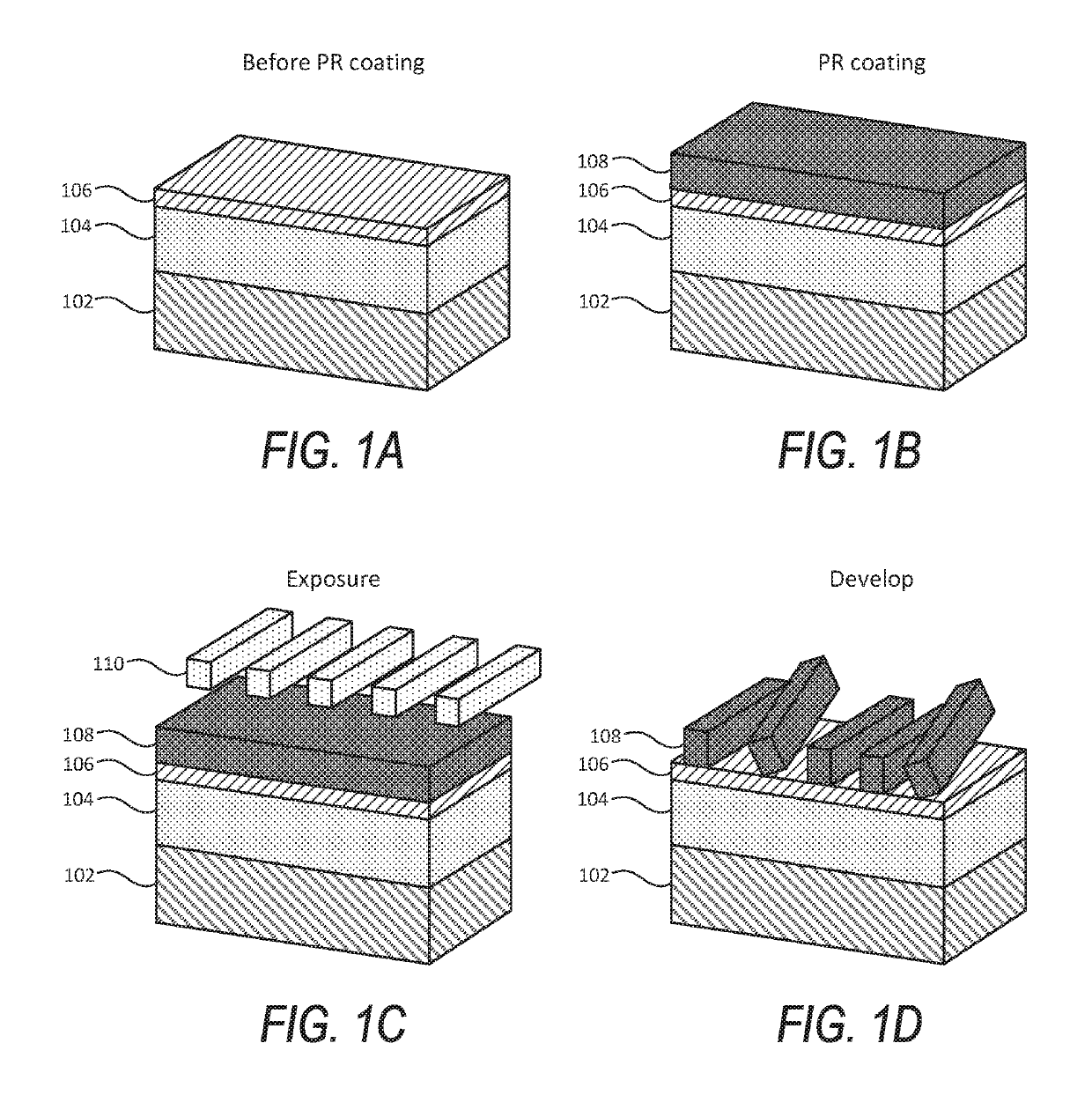

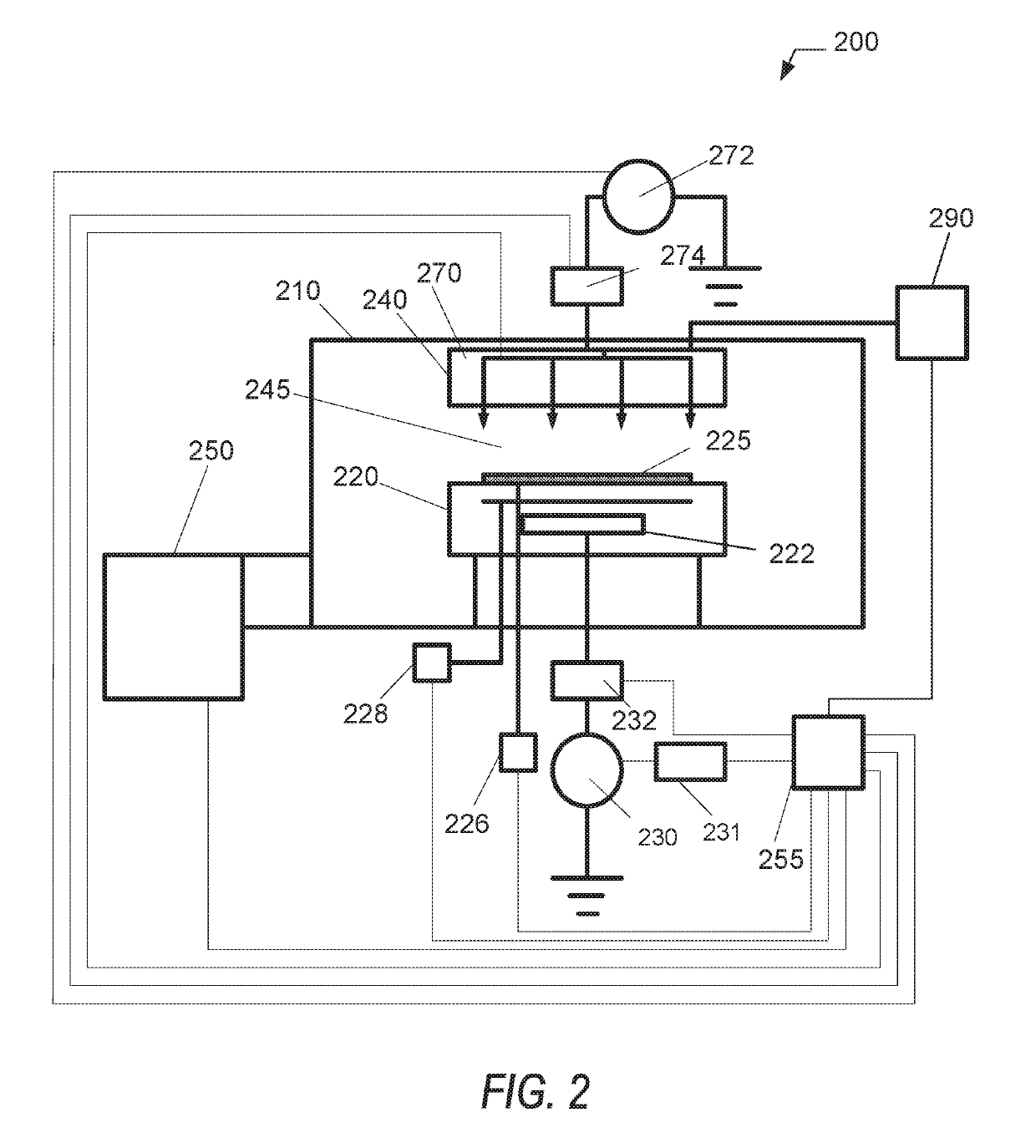

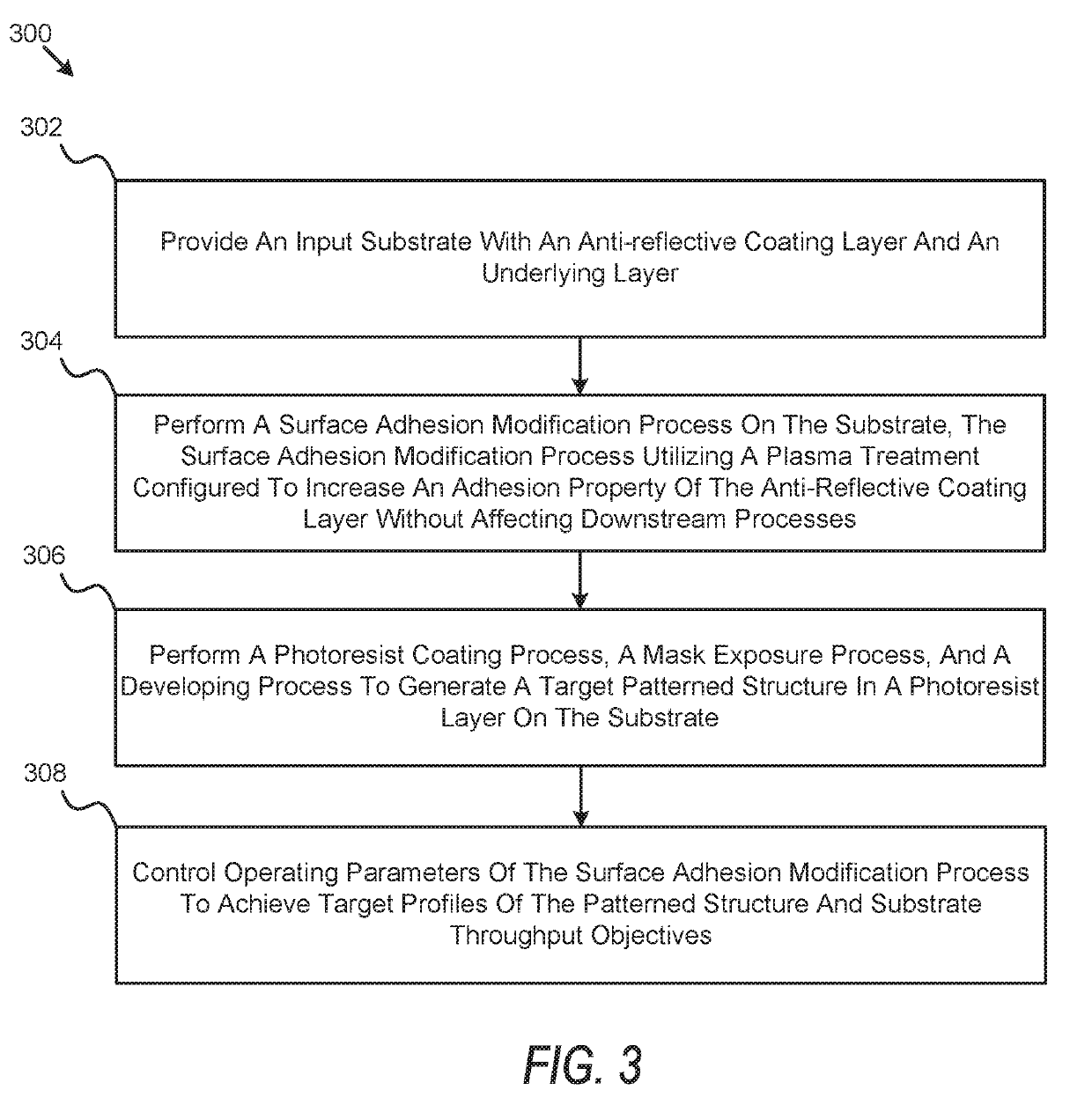

Plasma Treatment Method To Enhance Surface Adhesion For Lithography

ActiveUS20190187556A1Improve adhesive propertiesImprove adhesionSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusPhotoresistPlasma treatment

Embodiments of methods for patterning using enhancement of surface adhesion are presented. In an embodiment, a method for patterning using enhancement of surface adhesion may include providing an input substrate with an anti-reflective coating layer and an underlying layer. Such a method may also include performing a surface adhesion modification process on the substrate, the surface adhesion modification process utilizing a plasma treatment configured to increase an adhesion property of an anti-reflective coating layer without affecting downstream processes. In an embodiment, the method may also include performing a photoresist coating process, a mask exposure process, and a developing process to generate a target patterned structure in a photoresist layer on the substrate. In such embodiments, the method may include controlling operating parameters of the surface adhesion modification process to achieve target profiles of the patterned structure and substrate throughput objectives.

Owner:TOKYO ELECTRON LTD

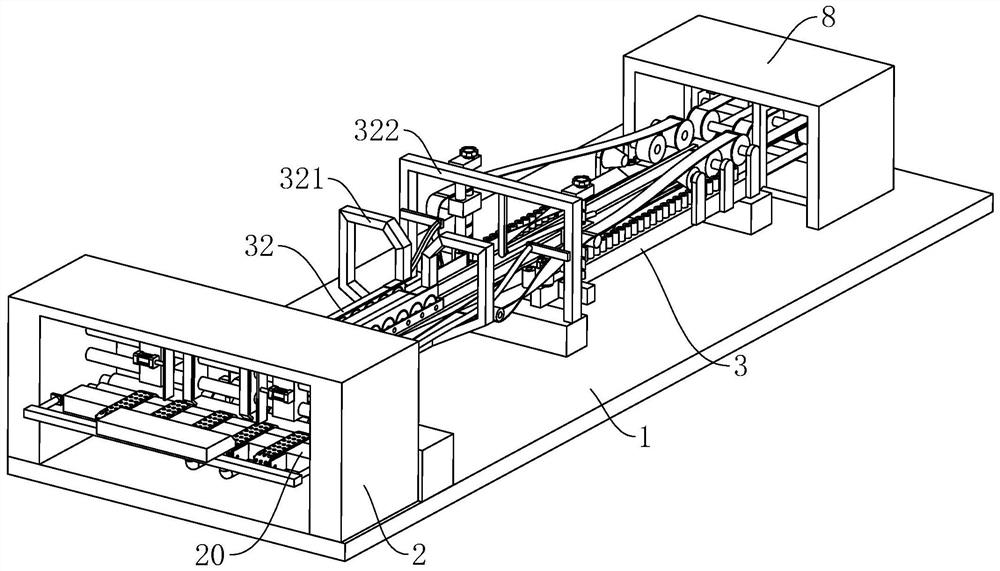

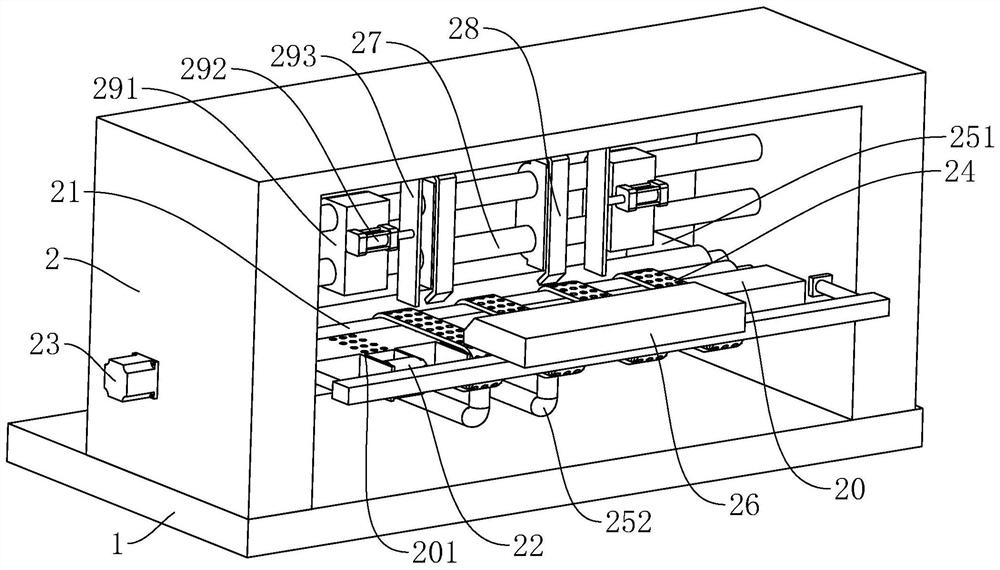

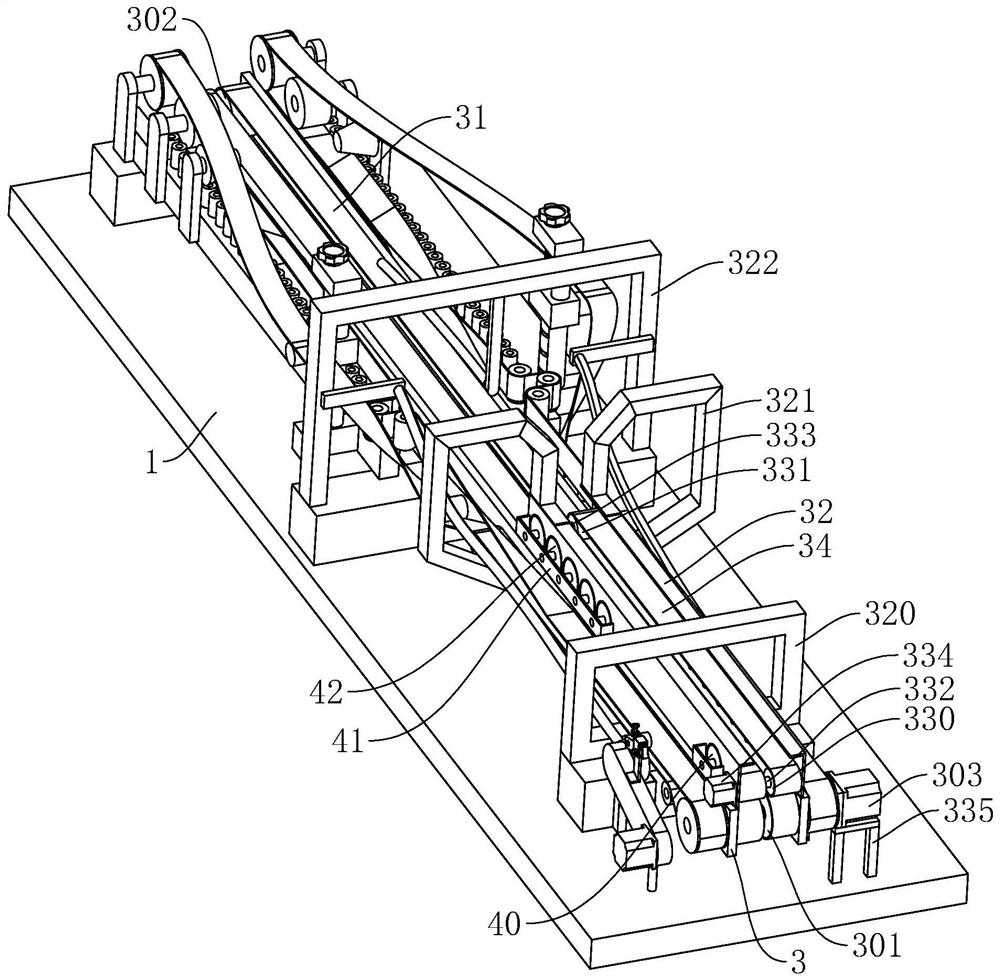

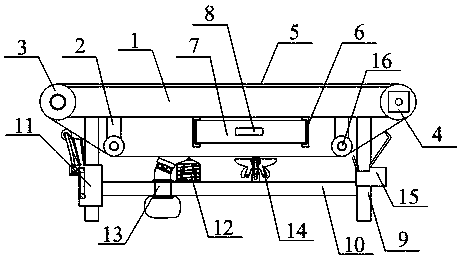

Automatic gluing machine with high gluing quality

InactiveCN112549645AImprove work efficiencyClose contactPaper-makingBox making operationsPaperboardCarton

The invention relates to an automatic gluing machine with high gluing quality, and relates to the field of carton production equipment. The automatic gluing machine comprises a machine frame, a feeding mechanism arranged on the machine frame and used for feeding paperboards, a conveying mechanism arranged on the machine frame and used for conveying the paperboards, a gluing mechanism arranged on the machine frame and used for gluing the paperboards on the conveying mechanism, a creasing mechanism arranged on the machine frame and used for creasing the paperboards on the conveying mechanism, anedge closing mechanism arranged on the machine frame and used for closing edges of the paperboards on the conveying mechanism, a folding mechanism arranged on the machine frame and used for folding the paperboards on the conveying mechanism, and a discharging mechanism for discharging the folded paperboards on the conveying mechanism, wherein gluing, creasing, edge closing and closing are performed in sequence. According to the automatic gluing machine, the feeding mechanism is used for feeding the paperboards, the conveying mechanism is used for conveying the paperboards, meanwhile, the gluing mechanism, the creasing mechanism, the edge closing mechanism and the folding mechanism can be used for gluing, creasing-folding, edge closing and folding the paperboards in sequence, the discharging mechanism is used for discharging the folded paperboards, and automatic processing of cartons is completed, so that the working efficiency is improved.

Owner:佛山市蓢森环保包装技术有限公司

Building adhesive preparation method

InactiveCN105623557AImprove adhesive propertiesHigh bonding strengthAmide/imide polymer adhesivesUnsaturated alcohol polymer adhesivesWeather resistancePolyvinyl alcohol

The present invention discloses a building adhesive preparation method, which comprises: adding prepared a polyvinyl alcohol glue into a stirring tank, stirring at a temperature of about 80 DEG C, adding an acrylamide glue into the tank, stirring for 2 min, carrying out a shut-off reaction for 30 min, stirring, adding pure water, adding a polyacrylamide glue, stirring for 2-3 min, carrying out a shut-off reaction for 20 min, adding water, and stirring for 10 min so as to obtain the product. According to the present invention, the adhesive prepared through the method has characteristics of good performance, high bond strength, easy operation, no toxicity, no odor, fire resistance, and weather resistance.

Owner:HARBIN TAOYI ADVERTISING DECORATION ENG

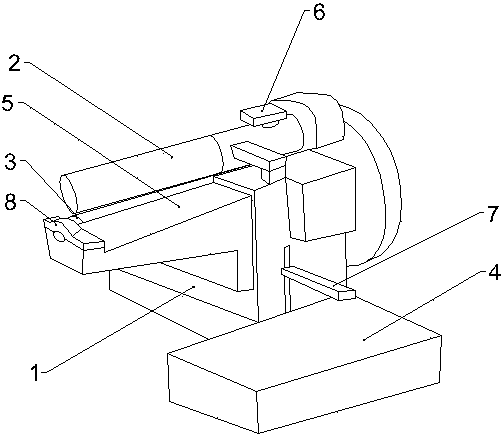

Gluing device for folded edges of cartons

ActiveCN104249482AImprove adhesive propertiesSimple structurePaper-makingBox making operationsPaperboardCarton

The invention provides a gluing device for folded edges of cartons. The gluing device for the folded edges of the cartons comprises a seat, a gluing roll, a transmission roll and a paper pressing table, wherein the front side of the top of the seat extends to form a gluing platform; one end of the gluing roll is hinged to the top of the seat; the gluing roll is driven by a motor to rotate; the other end of the gluing roll extends to a position above the gluing platform; the transmission roll is assembled on one side of the gluing platform, is parallel to the gluing roll and is positioned right below the gluing roll; a paperboard gluing channel is formed between the transmission roll and the gluing roll; a glue box is arranged at one end of the gluing roll; the paper pressing table is arranged on one side of the seat in the direction of the rotating discharging end of the transmission roll; and the seat is provided with a lifting paper pressing plate matched with the paper pressing table. According to the scheme, the gluing device for the folded edges of the cartons is simple in structure, convenient to operate, low in labor intensity and high in gluing effect.

Owner:香河燕通纸业有限公司

Antibacterial modified back paint

ActiveCN105131794ASolve hardness defectsSolve the problem of flexibilityAntifouling/underwater paintsPaints with biocidesNon toxicityPliability

The invention discloses an antibacterial modified back paint, and belongs to the field of paints. The antibacterial modified back paint comprises 10-30 parts of polyester resin, 6-20 parts of a solvent, 0.1-1 part of a dispersant, 0.1-1 part of an anti-settling agent, 10-35 parts of rutile titanium dioxide, 2-10 parts of precipitated barium sulfate, 15-40 parts of an epoxy solution, 5-20 parts of semi-etherified amino resin, 1-5 parts of urea-formaldehyde resin, 1-5 parts of an adhesion promoter, 0.1-1.5 parts of an acid catalyst, 20-30 parts of common bluebeard herb, 10-20 parts of Japanese ardisia and 15-30 parts of Herb of Hairystalk Loosestrife. A paint film produced by using the antibacterial modified back paint has a hardness reaching 4-5H, good flexibility, T bending of 2-3T, and back flush of 9J. Extract products of common bluebeard herb, Japanese ardisia and Herb of Hairystalk Loosestrife can inhibit or kill most bacteria or viruses as antibacterial components, and have the advantages of good antibacterial effect and non-toxicity.

Owner:山东富海材料科技有限公司

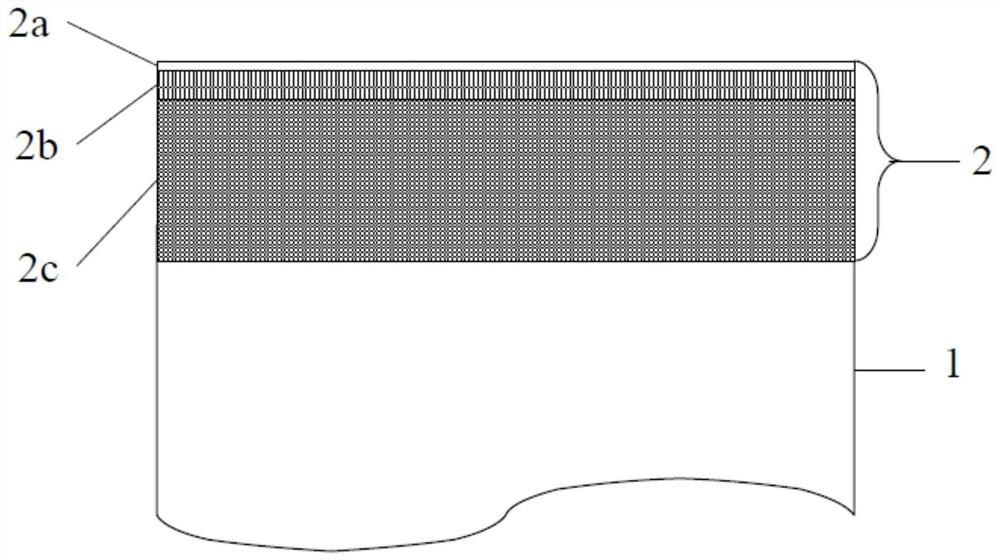

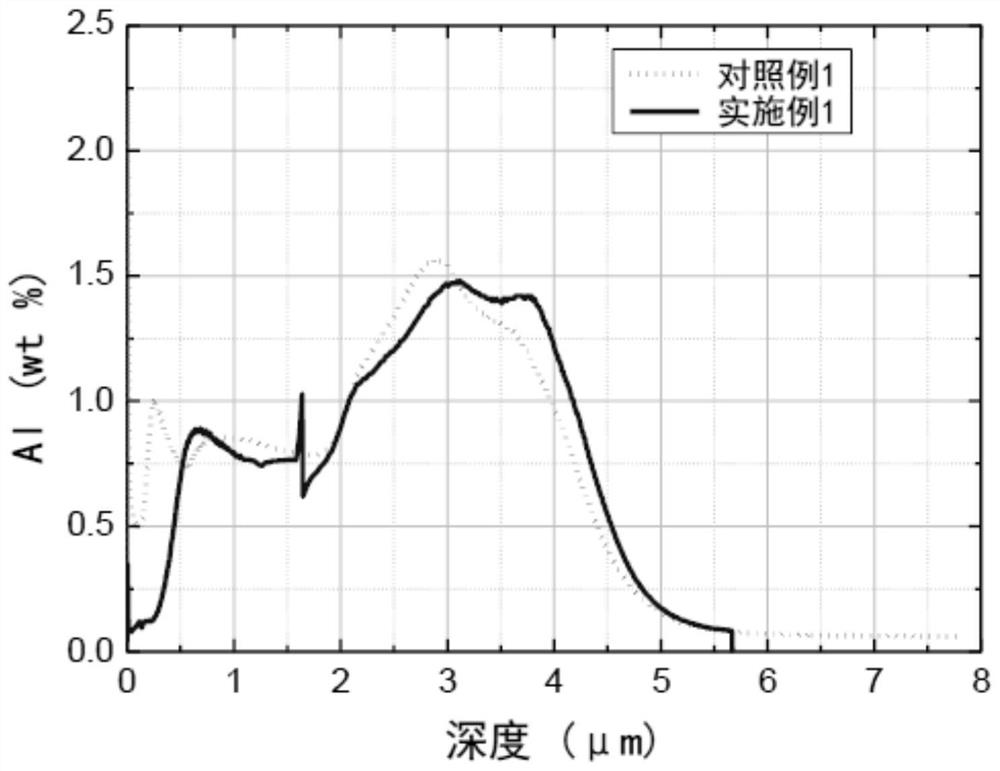

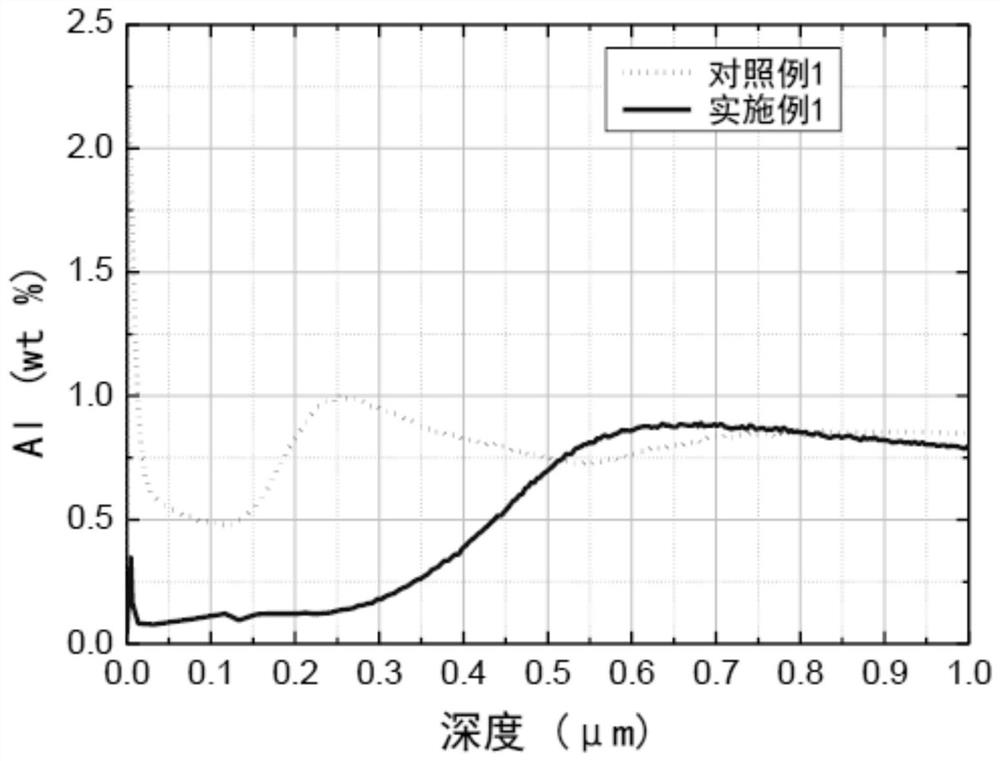

Zinc-aluminum-magnesium coated steel plate with excellent adhesive performance and manufacturing method thereof

ActiveCN113122790AImprove adhesive propertiesImprove corrosion resistanceHot-dipping/immersion processesAlkaline activationMagnesium

The invention discloses a zinc-aluminum-magnesium coated steel plate with excellent adhesive performance. The zinc-aluminum-magnesium coated steel plate with excellent adhesive performance comprises a steel plate and a zinc-aluminum-magnesium coating; the zinc-aluminum-magnesium coating sequentially comprises a surface layer, a secondary surface layer and a mother layer from outside to inside; the surface layer is provided with oxides of Al and Mg; the secondary surface layer is provided with a Zn / MgZn<2> binary eutectic phase and a Zn / Al / MgZn<2> ternary eutectic phase; and the mother layer adjacent to the steel plate; wherein the contents of Al and Mg elements of the surface layer are respectively not higher than 1.5 times of the contents of Al and Mg elements of the mother layer, and the contents of Al and Mg elements of the secondary surface layer are respectively not higher than 0.5 times of the contents of Al and Mg elements of the mother layer. In addition, the invention also discloses a manufacturing method of the zinc-aluminum-magnesium coated steel plate, which comprises the following steps: (1) steel plate pre-treating; (2) hot dipping; (3) cooling after plating: cooling to 40-200 DEG C, and carrying out the following step (4); and (4) coating surface treatment: carrying out alkaline activation treatment on the coating surface by adopting an alkaline aqueous solution.

Owner:BAOSHAN IRON & STEEL CO LTD

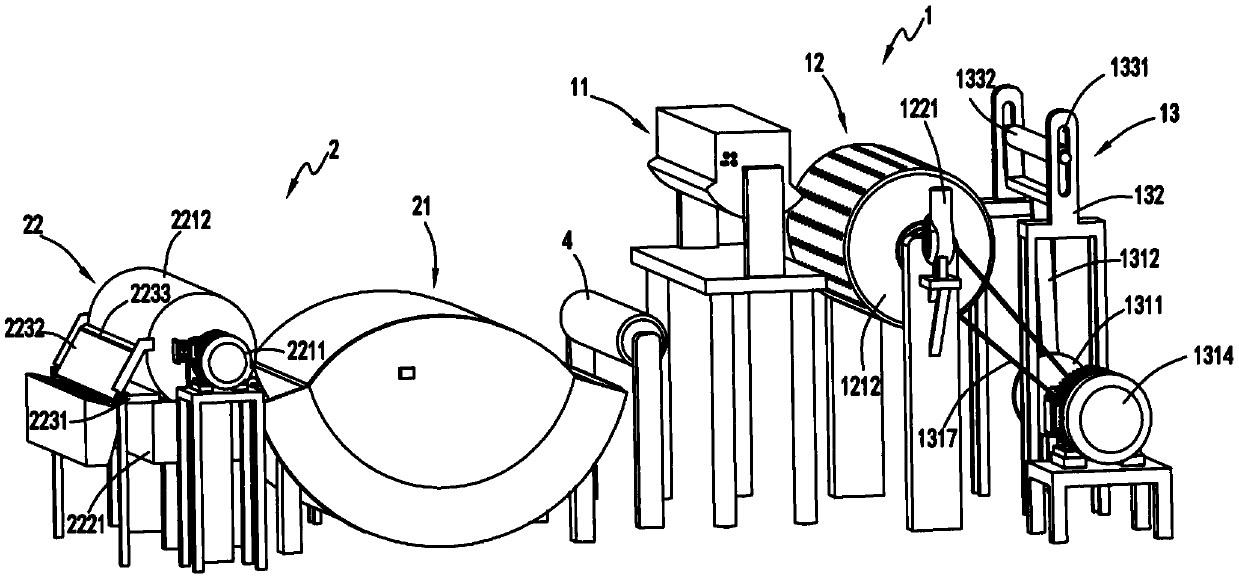

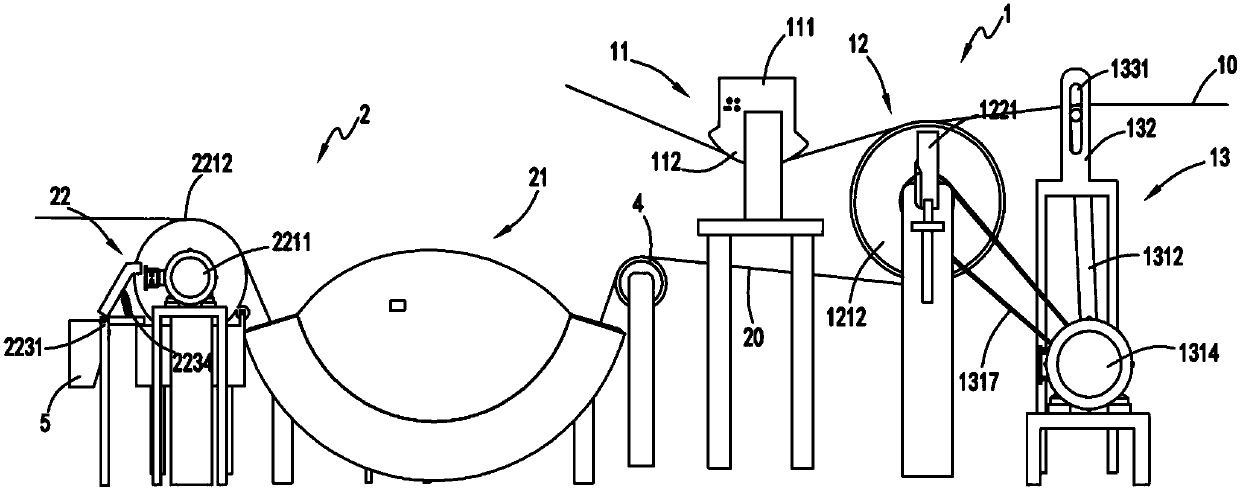

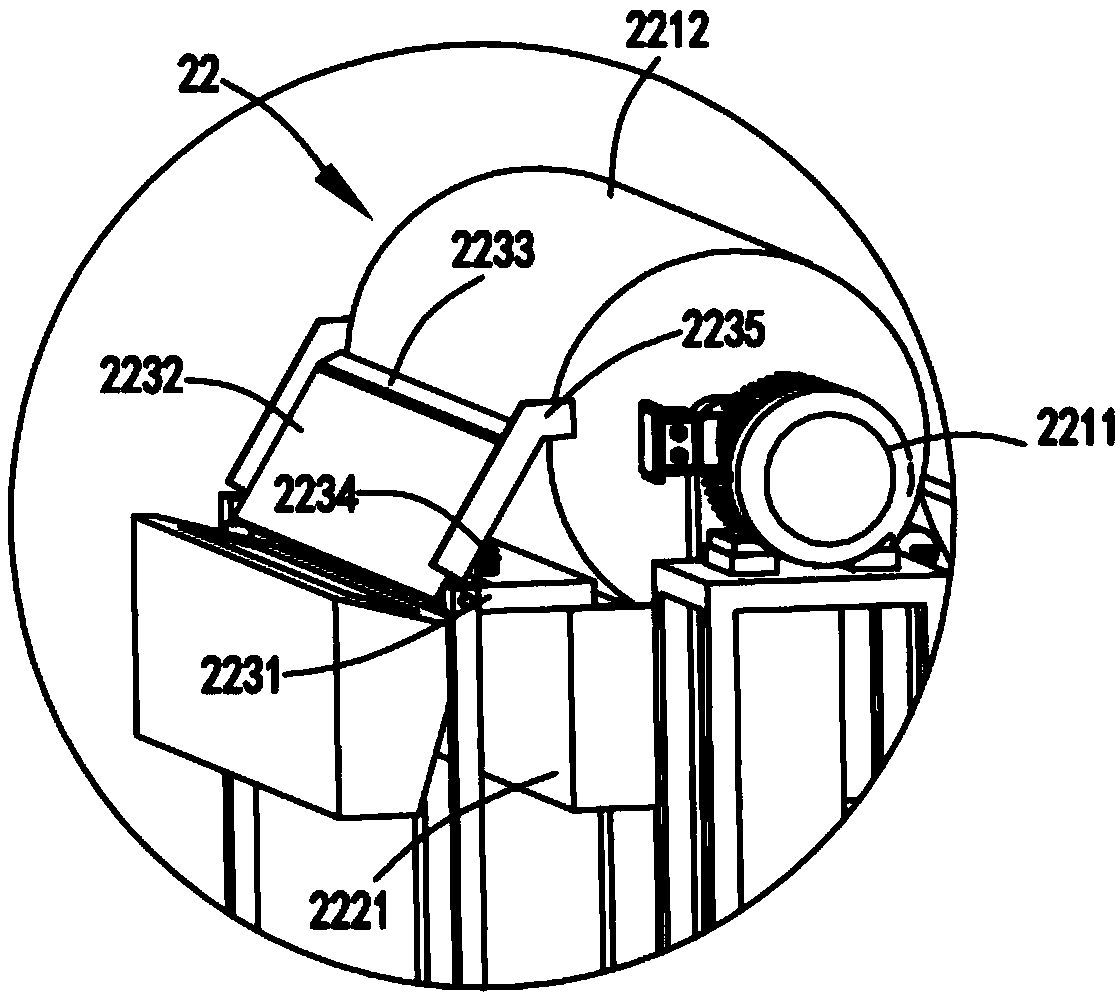

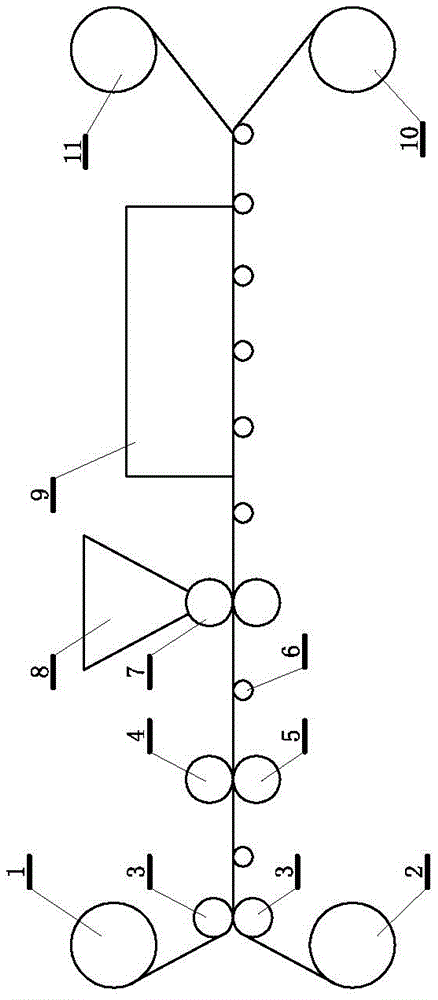

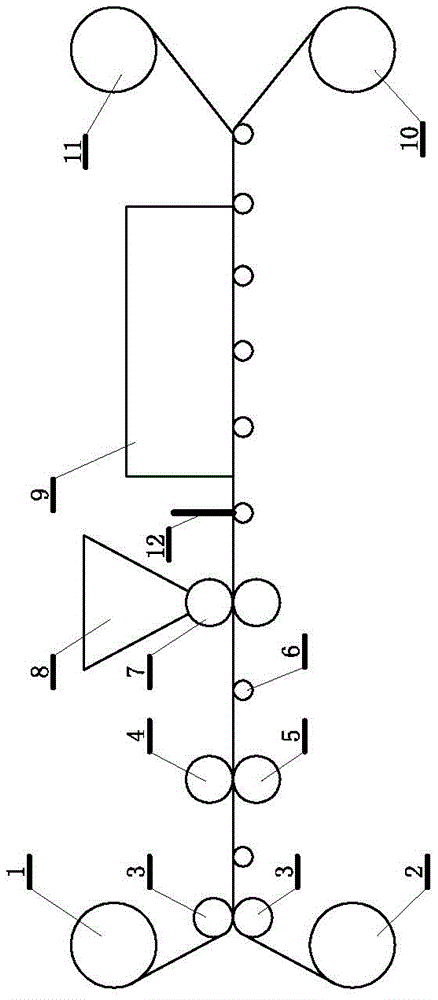

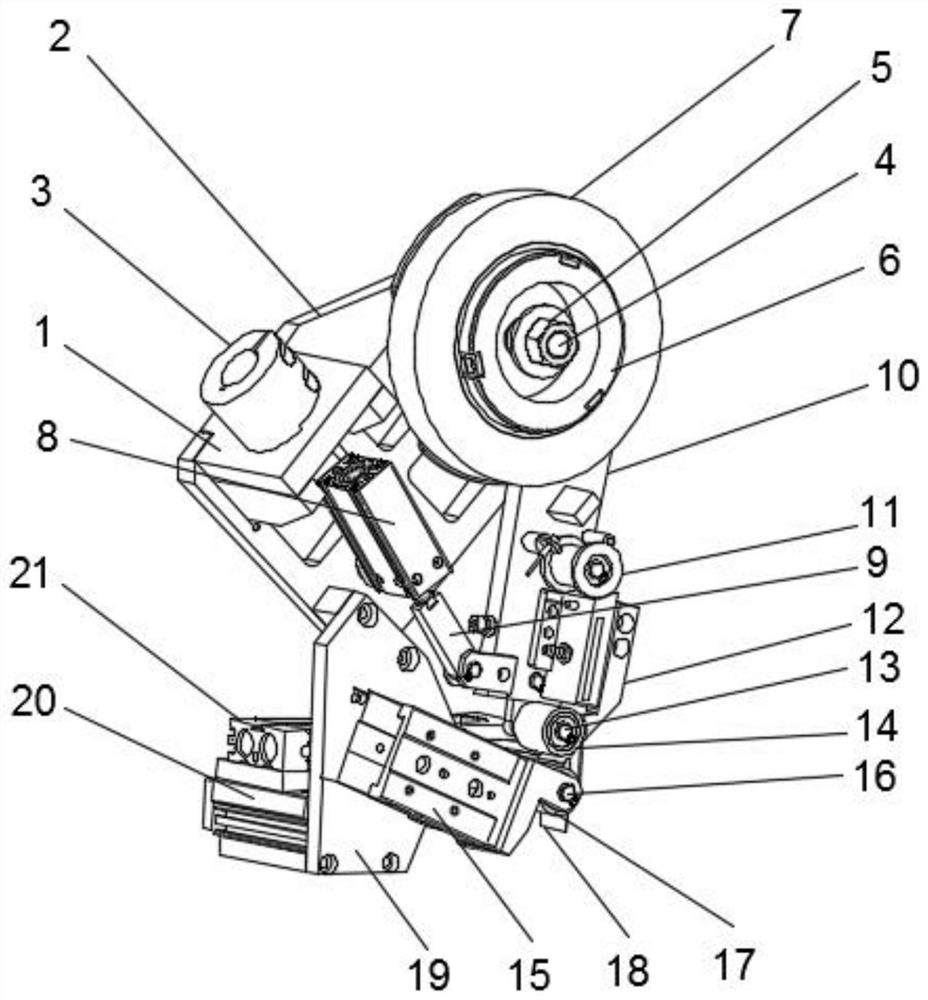

A high-efficiency processing equipment for unidirectional fabric isolation film for non-weft fabric production

ActiveCN107186919BAvoid problems that cannot be exploited againIncrease profitLamination ancillary operationsPlastic recyclingEngineeringMechanical engineering

The invention relates to an efficient processing device for a one-way cloth isolation film for production of weft-free cloth. The efficient processing device comprises a cloth film separating part and a glue removing part; the cloth film separating part is used for performing cloth and film separation on cloth with a film, the cloth film separating part comprises a heating mechanism for heating the cloth with a film to soften glue, a film separating mechanism for adsorbing the film and driving the film to rotate therewith to change a conveying direction and a cloth separating mechanism for pulling the cloth along a direction opposite to the conveying direction of the film; the glue removing part is arranged on the rear end of the cloth film separating part and used for removing residual glue on the film, and the glue removing part comprises a glue softening mechanism for heating the film to soften the glue on the surface and a glue removing mechanism for removing the softened glue from the film. The efficient processing device overcomes the problem that the film cannot be reused caused by a fact that the film is torn off by manual film tearing and the glue residual on the film after the film tearing cannot be cleaned.

Owner:湖州蓝澳无纬布有限公司

A kind of PU film direct gluing method

ActiveCN103878102BOvercome the deficiency of too low viscosityAvoid scratchesPretreated surfacesCoatingsEngineering

The invention discloses a direct gluing method for a PU film. The method comprises the steps that a PET film is attached to the one face of the PU film by oppositely pressing rubber rollers, a conveyer belt conveys the PU film coated with the PET film to a gluing rubber roller for gluing the other face of the PU film, and then the conveyer belt conveys the glued PU film to a drying oven for solidifying the glue; after the PU film with the solidified glue is output from the drying oven, a PET film wind-up roll peels off the PET film attached to the PU film, and a wind-up barrel rolls up the glued PU film. The direct gluing method for the PU film overcomes the defect that a PU film produced based on the existing technology is low in glueyness. Due to the fact that a layer of tensile protective film is arranged on the bottom face of the PU film in a compound mode during direct gluing, the PU film is directly glued and the problem that the PU film is scratched and is easily stretched during direct gluing is solved at the same time. Surface gluing uniformity and adhesiveness of the PU film are ensured.

Owner:北京美好生活家居用品有限公司

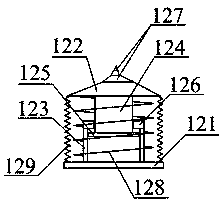

A glue removal and cleaning equipment for producing sanitary napkins

ActiveCN108706312BPlay the role of initial humidificationImprove adhesive propertiesCleaningSanitary towelsWater storage tankAdhesive

The invention provides adhesive cleaning equipment for producing sanitary towels. The adhesive cleaning equipment for producing sanitary towels comprises a transfer table, auxiliary brackets, transferrollers, a driving motor, a conveyor belt, U-shaped frames, a tool storage bucket, a handle, supporting legs, a fixed transverse plate, a belt surface circular humidifying rack structure, a bufferingand guiding belt surface adhesive removing rack structure, an adhesive fragment collecting storage rack structure, a secondary adhesive removing grinding rack structure, a belt surface dust fragmentscraping rack structure and auxiliary guide rollers, wherein the auxiliary brackets are longitudinally welded to four corners of the lower middle part of the transfer table, separately; and the transfer rollers are coupled to the left and right sides of the transfer table. By arranging a water guide pipe, a micro self sucking pump, a sponge guide roller and a water suction pipe, a water liquid ina water storage tank is sucked conveniently to humidify the conveyor belt preliminarily, so that an effect that an adhesive scraping blade scrapes an adhesive on the conveyor belt can be achieved; andby arranging a rubber scraping strip and a liquid guide frame, residual liquids on the conveyor belt are scraped conveniently, so that the residual liquids are prevented from splashing outward.

Owner:DADDY BABY

Silage Membrane Solutions

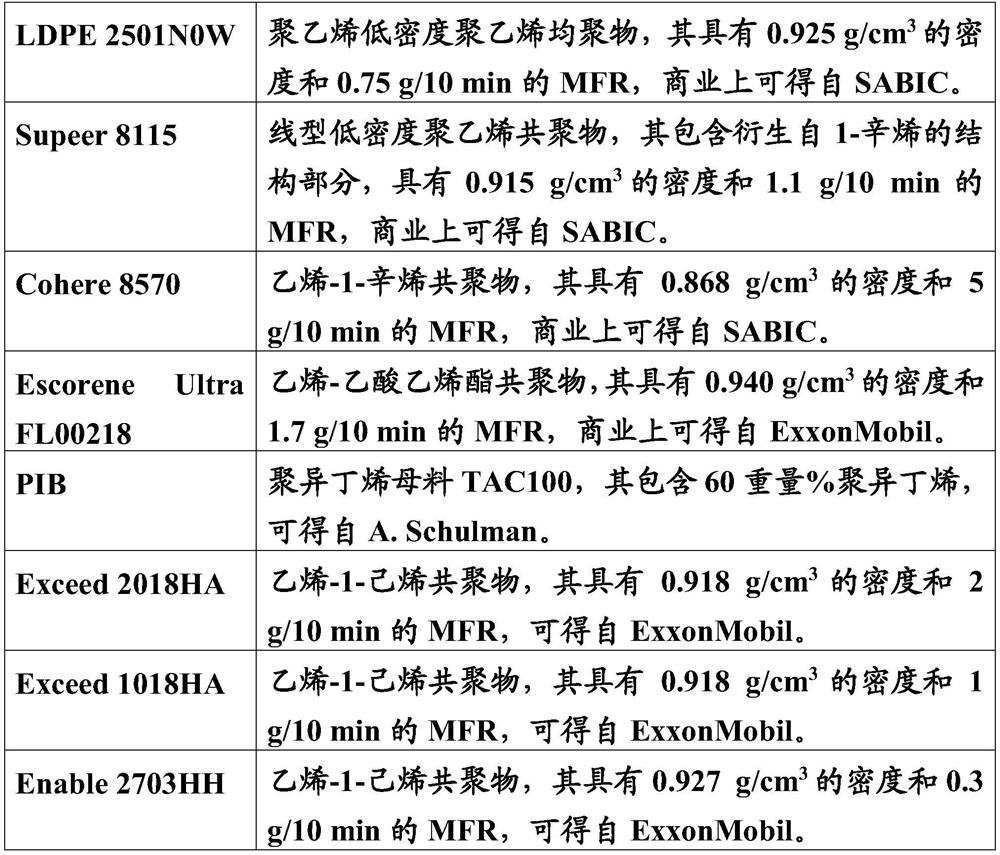

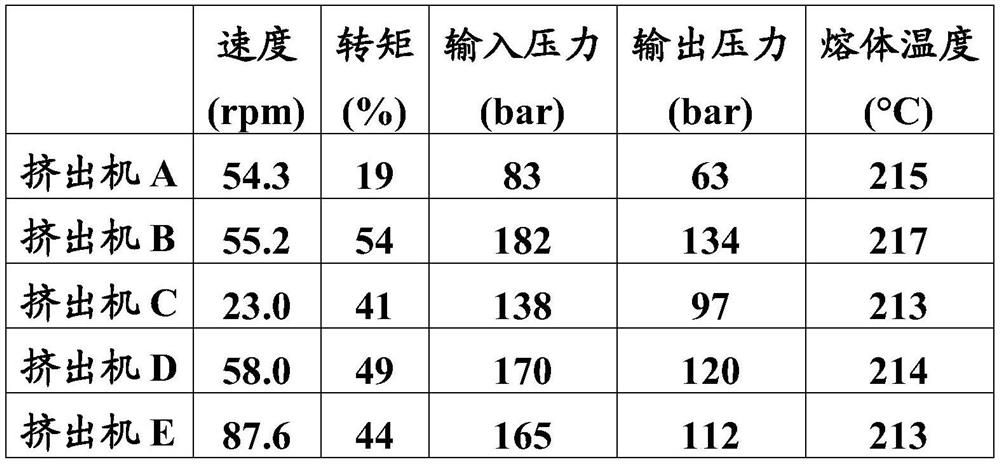

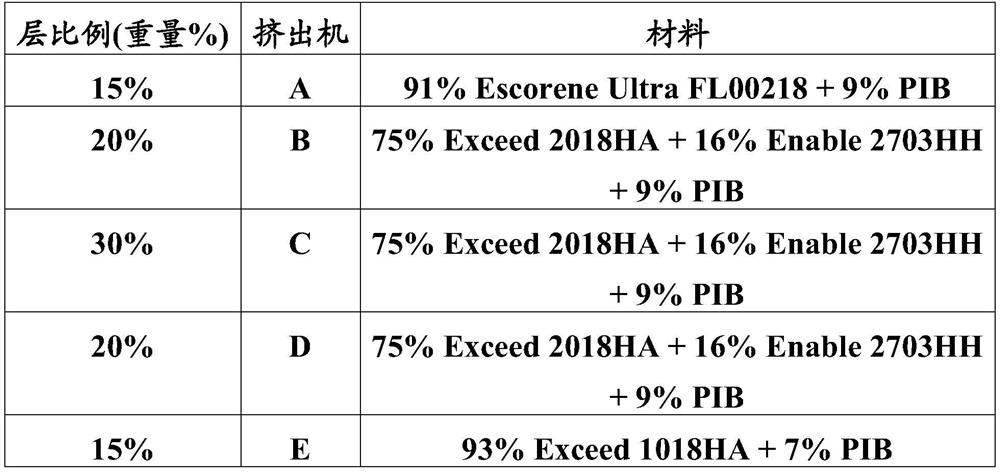

ActiveCN110914056BImprove adhesive propertiesPromote migrationAgricultural articlesSynthetic resin layered productsMultilayer membranePolymer science

The present invention relates to a multilayer film comprising at least three layers, two outer layers and a core layer, wherein: the core layer contains 1-octene and has a value between >0.910 g / cm 3 with 0.925g / cm 3 An ethylene copolymer of a density between, wherein the additional first outer layer comprises a density between >0.915 g / cm 3 with 0.930g / cm 3 An ethylene homopolymer of a density between, wherein the additional second outer layer comprises the optional first ethylene copolymer and has a density between 0.850 g / cm 3 with <0.890g / cm 3 between the density of the second ethylene copolymer. Such films exhibit improved adhesion properties and additionally provide benefits in, inter alia, reduced migration of components from the film during storage and use at elevated temperatures.

Owner:SABIC GLOBAL TECH BV

Gluing device for carton production line and working method thereof

ActiveCN112009022BImprove adhesive propertiesSolve the problem of poor glue effectBio-packagingPaper-makingCartonViscose

The invention discloses a gluing device for a carton production line, which can effectively improve the effect of gluing in carton production and processing through the coordinated use of a turntable, a first transfer column, a second transfer column and a third transfer column; The glue body is socketed on the turntable, and the turntable rotates on the first connecting column to stretch one end of the adhesive tape on the glue body, so that the glue body drives the turntable to rotate; through the set limit plate, vertical plate, The combined use of the pasting board, the cutting knife, the first driving block and the second driving block can improve the separation effect of the adhesive tape after gluing the carton. The invention also discloses a working method of the gluing device used in the carton production line; Various aspects disclosed in the invention can solve the problem of poor glue effect during carton production and processing, and the problem that cartons are not easy to separate after gluing.

Owner:界首市鑫华装璜彩印有限公司

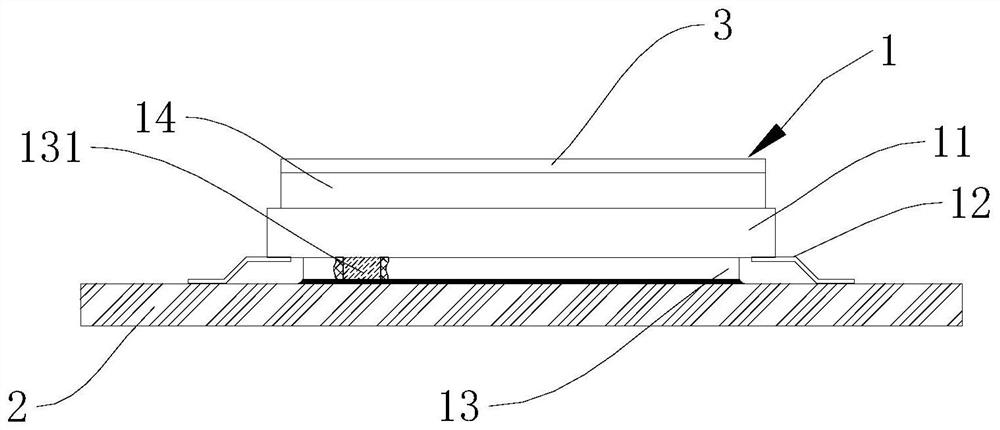

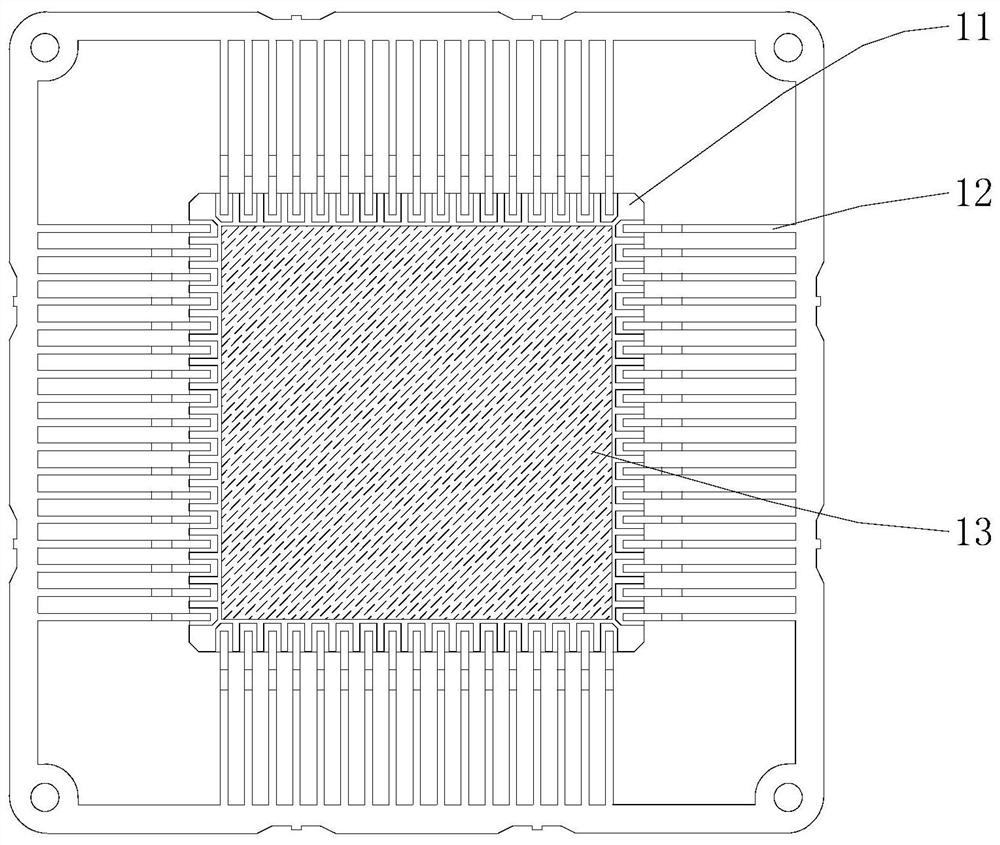

Ceramic four-side flat packaging shell and ceramic four-side flat packaging device

ActiveCN113345842AReduce stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesMaterials scienceComposite material

The invention provides a ceramic four-side flat packaging shell and a ceramic four-side flat packaging device. The ceramic four-side flat packaging shell comprises a ceramic shell body and a plurality of leads, the ceramic shell body is used for bearing a chip, the leads are led out from the bottom of the ceramic shell body to the periphery, the bottom of the ceramic shell body is further provided with a boss extending downwards, and the height difference between the bottom plane of the boss and the lowest point of each lead is 0-0.15 mm. The height difference between the bottom plane of the boss and the lowest point of the lead is 0-0.15 mm, and the gap between an existing packaging shell and a PCB is about 0.50-1.0 mm, so that the gap between the ceramic four-side flat packaging shell and the PCB is reduced, the thickness of an adhesive layer for reinforcement is reduced, the board-level reinforcement is reliable, the stress of the lead can be effectively reduced, the lead is prevented from being deformed or damaged, and high reliability of a mounted device is ensured.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Anti-radon and anti-formaldehyde coating

InactiveCN108084809AOptimal decomposition rateImprove performancePolyurea/polyurethane coatingsEpoxy resin coatingsMicrosphereAlkylphenol

The invention discloses anti-radon and anti-formaldehyde coating. The coating comprises bisphenol A type epoxy resin, an ethylene-vinyl acetate copolymer emulsion, nanometer glass hollow microspheres,nanosilicon dioxide, wollastonite powder, kaolin, sodium carboxymethylcellulose, an organic titanate coupling agent, a barium oxide complex, ethoxylated alkylphenol ammonium sulfate, nanometer silverparticles, polyurethane resin, sodium lignin sulfonate, malic acid, bamboo coal powder, anise oil, propylene glycol butyl ether and water. The coating is prepared through material preparing, modifying, purifying, material compounding and other steps. The coating is simple in preparing process, and the coating has anti-radon and anti-formaldehyde performance and meanwhile has high adhesiveness andrapid curing performance.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

Method for manufacturing rubber sheet

InactiveCN104589773AExtended service lifeAvoid crackingSynthetic resin layered productsLaminationPolymer scienceRoom temperature

The invention discloses a method for manufacturing a rubber sheet and relates to the field of manufacturing of rubber. The preparation of the rubber sheet is completed by seven steps, namely, plastifying, mixing, molding, processing, coating, gluing and drying, wherein in the preparation of the rubber sheet, the plastifying is firstly performed to improve the plasticity of the rubber so that rubber can be well mixed together with other substances in the subsequent steps; acetonitrile rubber is added to increase the ductility of the rubber; in the molding step, under a vacuum environment, the rubber is cooled and dried for 24 hours at 25 DEG C, bubbles in mixed rubber can be stripped under vacuum condition, the rubber is slowly cooled at room temperature so that cracks are hardly caused during the drying of colloid and the rubber is more compact; the phenomenon that the middle part is easily worn compared to the both end parts although the effectiveness of chloroprene rubber is better is mainly considered, two polyurethane films are adopted and added so as to prolong the service life of the rubber sheet.

Owner:GUANGXI UNIV

A method of improving the corrosion resistance of phosphating film of sintered NdFeB permanent magnet

ActiveCN107164754BImprove corrosion resistanceExcellent adhesionMetallic material coating processesFiltrationTitanium

The invention discloses a method for improving corrosion resistance of a sintered neodymium iron boron permanent magnet phosphating film. The method comprises the steps that a machined and formed neodymium iron boron magnet is subjected to chamfering processing and is subjected to oil removing, acid pickling and water washing processing in sequence; in the stirring situation, the magnet is placed into surface conditioning liquid at the temperature of 20-30 DEG C for surface conditioning for 1-3 minutes, and the surface conditioning liquid is composed of a titanium salt surface conditioning agent, nanometer Fe powder particles and deionized water; and finally, the magnet is placed into a phosphating solution at the temperature of 20-40 DEG C for phosphating treatment for 10-20 minutes, and circulating filtration is performed. After the magnet is subjected to jointed surface conditioning by the titanium salt solution mixed with the nanometer Fe powder particles, the surface of the magnet is uniformly provided with a plurality of activated points and film forming factors, therefore the magnet can obtain the more uniform, more fine and more complete phosphating film in the phosphating reaction process, and thus corrosion resistance of the magnet is greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

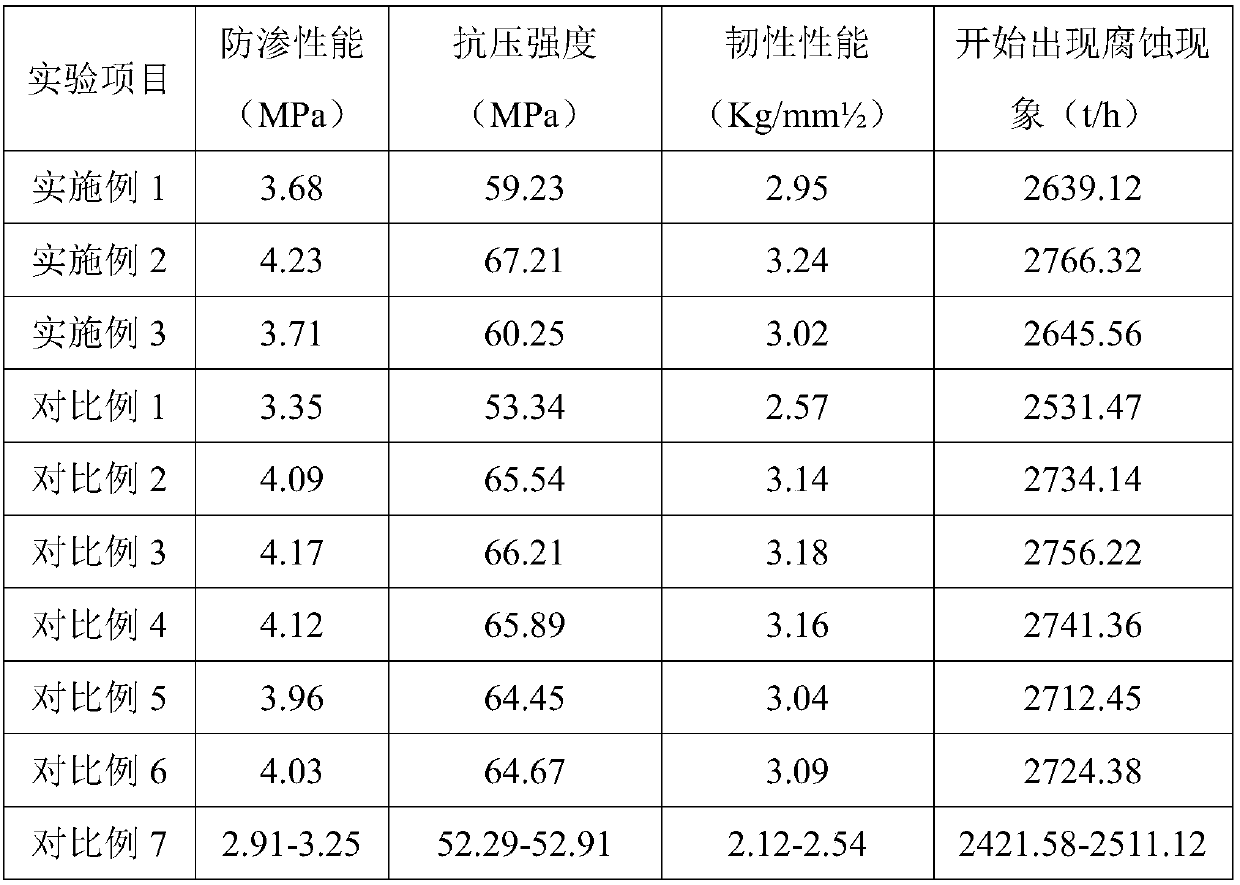

Multi-functional concrete additive and preparation method and concrete thereof

The invention discloses a multi-functional concrete additive and a preparation method and a concrete thereof. The multi-functional concrete additive comprises the following raw materials: polyacrylamide, sodium alginate, 3-aminopropyl trialkoxysilane, silicate, sulfuric acid, water, carbodiimide, polysulfone resin, cis1,4-polybutadiene rubber, 4-dimethylaminopyridine, poly[(2-oxiranyl group)-1,2-cyclohexanediol]2-ethyl-2-(hydroxymethyl)-1,3-propylene glycol ether. The multi-functional concrete additive is prepared by the steps of material modification, mixing and drying. The concrete preparedby the multi-functional concrete additive can obviously increase anti-compression performance, antiseepage performance, toughness performance and corrosion resisting performance, and can avoid phenomena of cracking and collapse of engineering.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

A method of manufacturing a rubber diaphragm

ActiveCN103538323BExtended service lifeSticky play wellLaminationLamination apparatusRoom temperatureNeoprene

The invention discloses a manufacturing method of rubber diaphragm, and relates to the rubber manufacturing field. The rubber diaphragm can be manufactured by plasticating, mixing, molding, processing, gelatinizing, gluing and drying. In the manufacturing course of the rubber diaphragm, plasticating can be carried out firstly to improve the plasticity of rubber, so that in the following steps, the rubber can be mixed well with other materials; the malleability is improved by adding acetonitrile rubber; in the step of molding, the rubber is cooled and dried for 24 hours in vacuum environment at 25 DEG C; bubbles in the mixed rubber can be removed in vacuum environment; the rubber mass is less susceptible to cracks in dry conditions due to slow cooling in room temperature and is more compact; polyurethane films are adopted because of relatively good effect of neoprene, the middle part of the rubber diaphragm is more susceptible to wearing than the two ends and the service time of the rubber diaphragm is prolonged by adding two pieces of polyurethane films.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

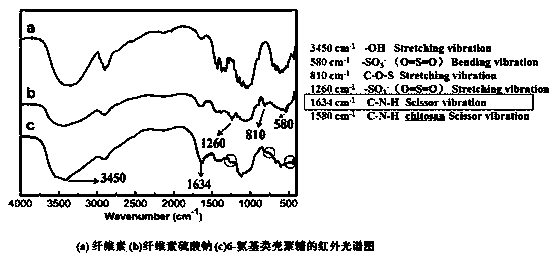

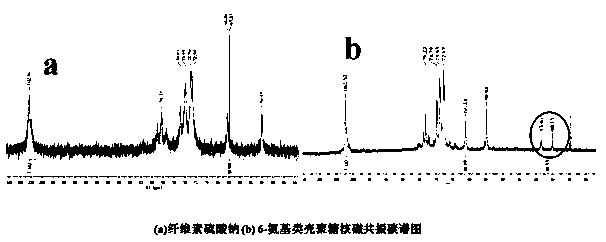

Synthesis and Application of Pseudochitosan and Its Derivatives

The invention relates to synthesis and application of pseudo-chitosan and derivatives of the pseudo-chitosan. A novel production technology is proposed which cellulose or hemicellulose sulfuric acid monoester salt is used as raw material, under the presence of a catalyst carboxylate, ammonia substitution is conducted to synthesize a series of pseudo-chitosan products, and a technical breakthroughis made that pseudo-chitosan type products of 6-aminocellulose or 6-animohemicellulose and a mixture of the 6-aminocellulose and the 6-animohemicellulose are synthesized with the higher transformationrate and substitution degree in an aqueous solution in short time. According to the novel technology, by-products are less, the purity is high, and separation and purification are easy; by means of the technical breakthrough, a high-substitution degree pseudo-chitosan product or mixture obtained through simple and clean production is more feasible in the aspects such as economy, technologies andthe product quality, and the synthesized product 6-aminocellulose crude product or pure product can be applied in the wide fields such as glue, water-retaining agents, controlled release fertilizers and liquid leaf fertilizers.

Owner:XIAMEN UNIV +1

A kind of manufacture method of flame retardant rubber

ActiveCN103538348BExtended service lifeSticky play wellSynthetic resin layered productsLaminationPolymer scienceCrazing

The invention discloses a production method of a flame retardant rubber and relates to the rubber production field. The flame retardant rubber is produced through plastifying, mixing, molding, treating, gumming, gluing and drying; in the production of the flame retardant rubber, plastifying is carried out at first to improve the plasticity of rubber; as a result, the rubber can be well mixed with other substances in the consequent steps; acetonitrile rubber is added to improve the ductility of the rubber; in the molding step, drying by cooling is performed for 24 h under the conditions of a vacuum environment and 25 DEG C; under the vacuum condition, bubbles in the mixed rubber can be removed; slow cooling at the room temperature is not easy to cause cracks of the rubber while the rubber is dried, and consequently, the rubber is more compact; the adoption of a polyurethane film mainly takes good effect of chloroprene rubber into account; however, the middle part of the polyurethane film is easier to consume as compared with the two end parts; therefore, two polyurethane films are added to prolong the service life of the flame retardant rubber.

Owner:江苏湘园化工有限公司

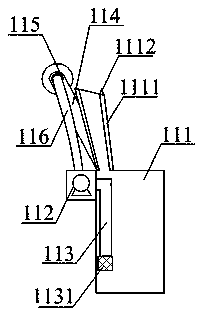

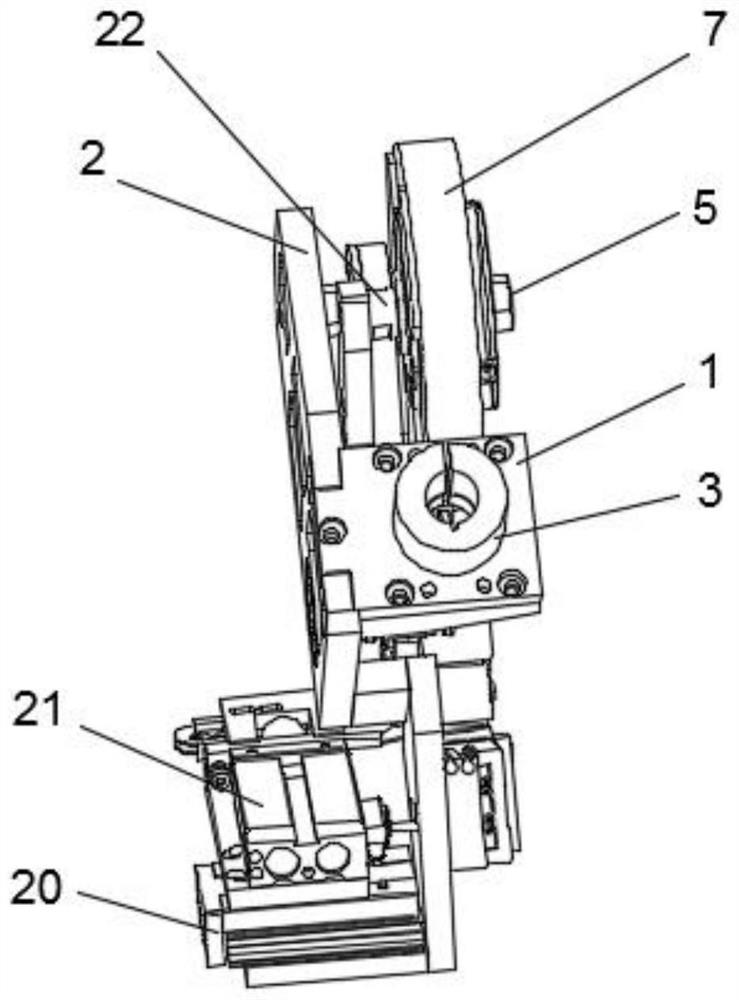

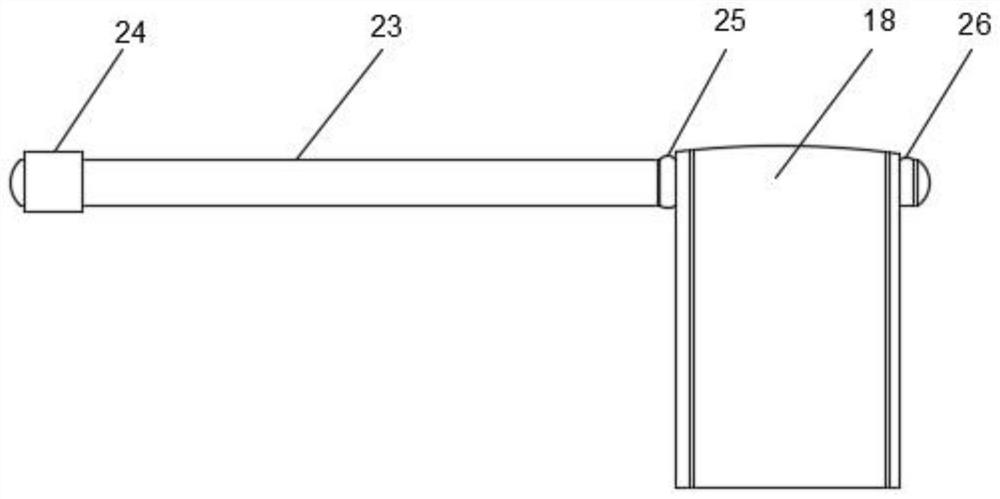

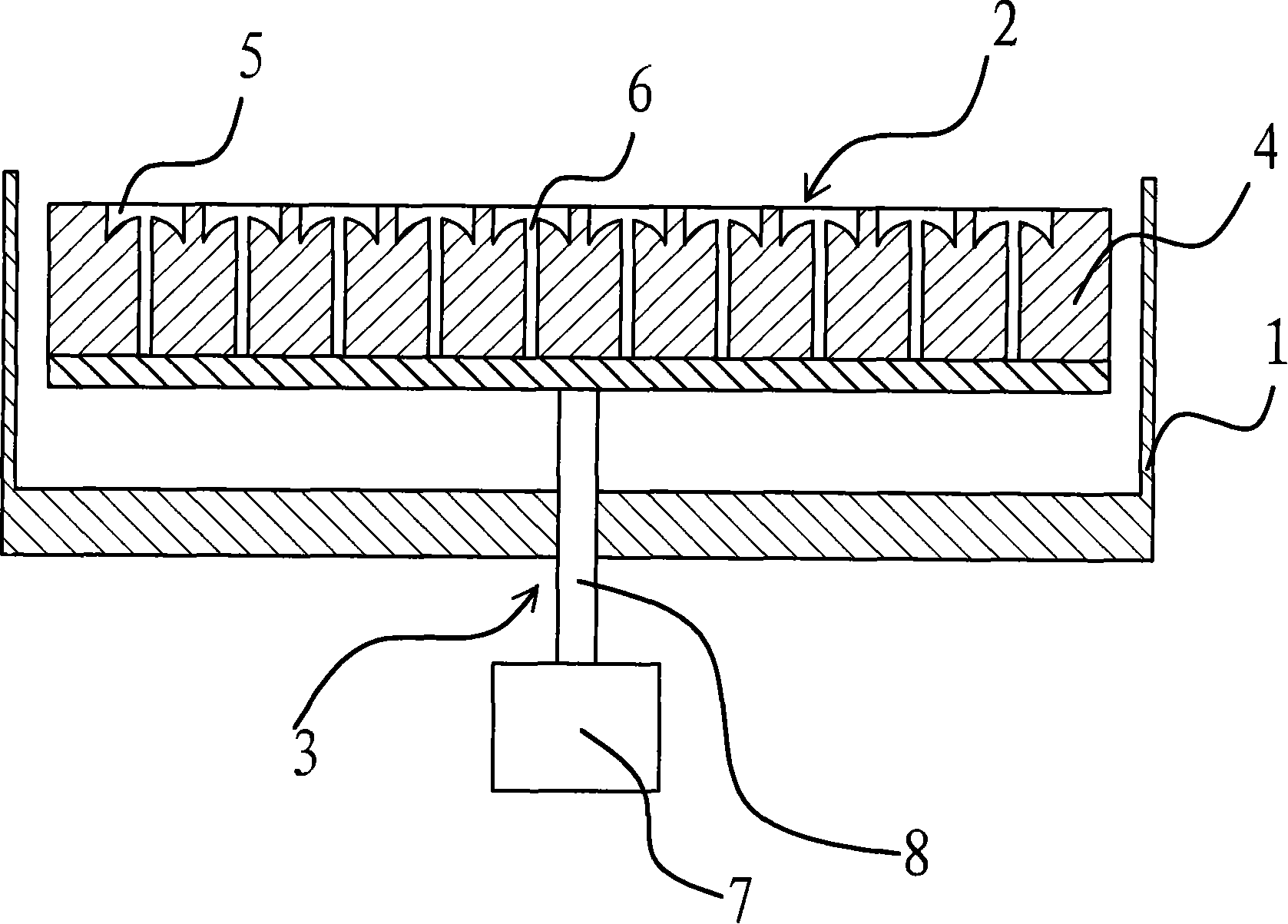

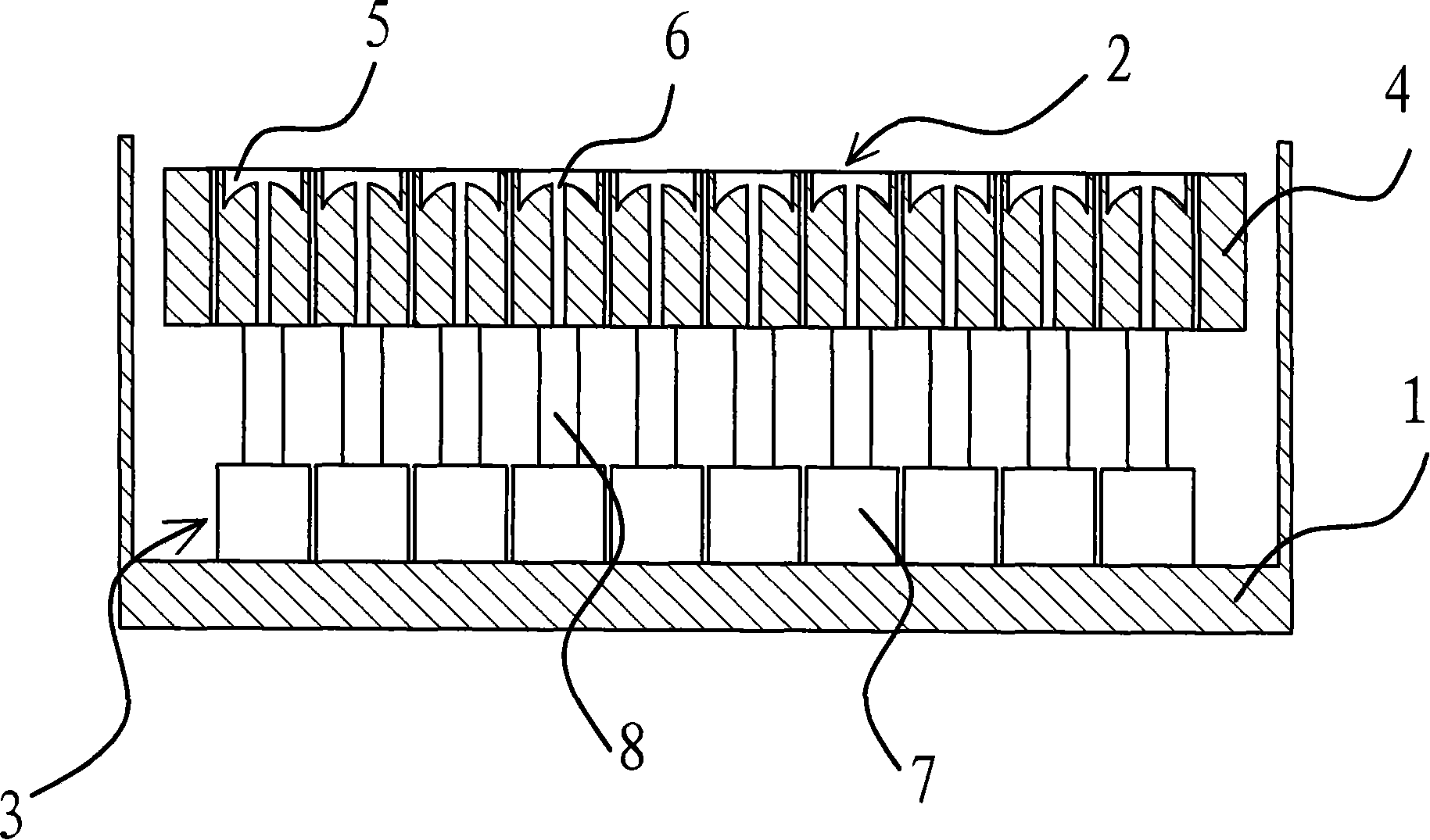

Transfusion device automatic assembling and rubber coating device

InactiveCN101249484BGlue volume controllableImprove adhesive propertiesLiquid surface applicatorsCoatingsAdhesiveAgricultural engineering

The invention provides a coating device of transfusion apparatus automatic assembling machine, which belongs to the field of mechanical technique. The coating device of transfusion apparatus automatic assembling machine overcomes the disadvantages in the prior art such as complex structure, high equipment cost and troublesome routine maintenance. The coating device of transfusion apparatus automatic assembling machine is disposed between a turntable and a charging device; and comprises an adhesive tank, and a coating mechanism disposed in the adhesive tank, moveably connected in a vertical direction to a lift control mechanism, wherein the coating mechanism comprises a coating plate connected to the lift control mechanism and an upper adhesive cup disposed on the coating plate; and the bottom of the upper adhesive cup is in upward arc-shape, and a through hole communicated to the adhesive tank is opened in the bottom center of the upper adhesive cup. The inventive coating device of transfusion apparatus automatic assembling machine can control adhesive amount with good adhering effect and low cost.

Owner:王兴章

A kind of antibacterial modified back paint

ActiveCN105131794BSolve hardness defectsSolve the problem of flexibilityAntifouling/underwater paintsPaints with biocidesPliabilitySolvent

The invention discloses an antibacterial modified back paint, which belongs to the field of paints. The present invention consists of the following components: 10-30 parts of polyester resin, 6-20 parts of solvent, 0.1-1 part of dispersant, 0.1-1 part of anti-sedimentation agent, 10-35 parts of rutile titanium dioxide, 2 parts of precipitated barium sulfate ‑10 parts, 15‑40 parts of epoxy solution, 5‑20 parts of hemimethylated amino resin, 1‑5 parts of urea-formaldehyde resin, 1‑5 parts of adhesion promoter, 0.1‑1.5 parts of acid catalyst, 20 parts of blue vanilla 30 parts, 10-20 parts of flat wood, 15-30 parts of fragrant herbs. The paint film produced by the antibacterial modified back paint of the present invention has a hardness of 4-5H, good flexibility, a T-bend of 2-3T, good adhesiveness and a recoil of 9J. The extracts of orchid vanilla, flat wood and Chinese herbal medicine are used as antibacterial components, which can inhibit or kill most bacteria or viruses, and have good antibacterial effect and are non-toxic.

Owner:山东富海材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com