Silage Membrane Solutions

A technology of silage and multi-layer film, applied in the field of multi-layer film, can solve problems such as film rupture and equipment interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

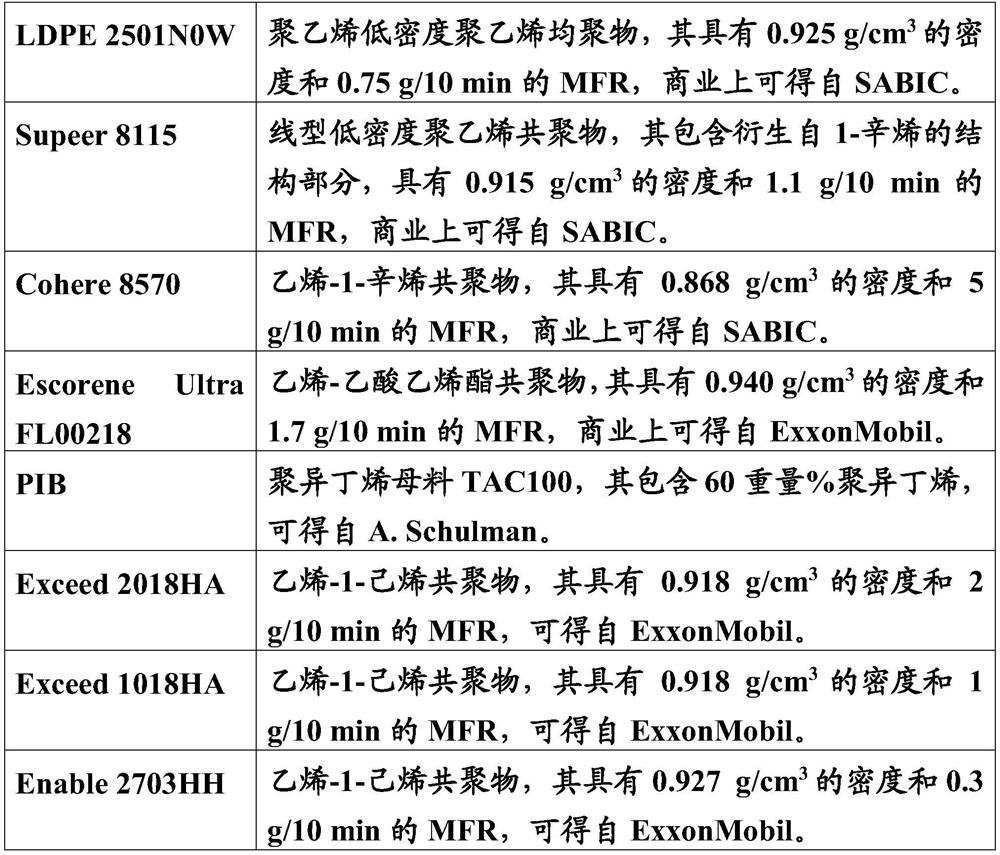

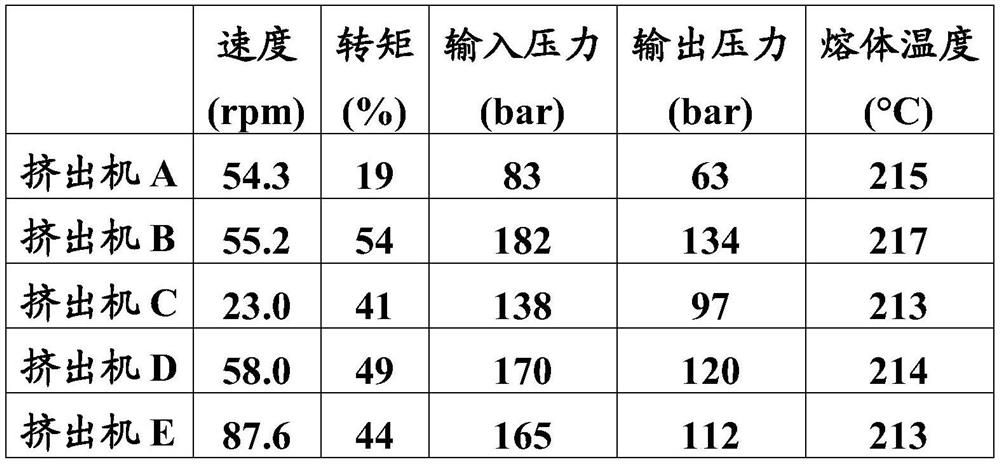

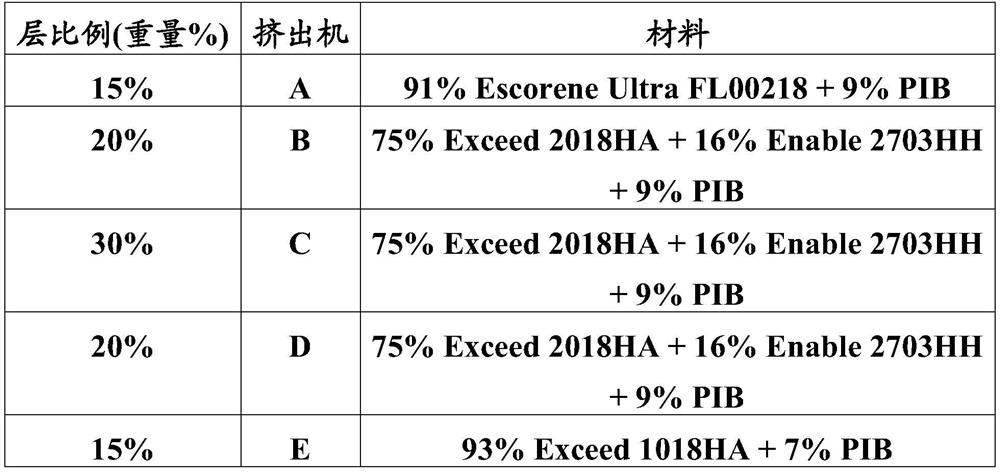

[0108] Example 1. Films according to the invention were produced on a 5-layer coextrusion blown film line as described below.

[0109] Line description and process settings:

[0110] Number of extruders 5 number of layers 5 thickness 25μm BUR (Blow-Up Ratio) 2.5 die Gap: 2.4mm; diameter 550mm double ring Dual flow air ring, non-contact type air cooling temperature 15℃ ring 52% of total power IBC 60% power Line speed 61m / min output 352kg / h

[0111] Extruder temperature distribution (°C):

[0112] Extruder A Extruder B Extruder C Extruder D Extruder E Area 1 40 40 40 40 40 Zone 2 210 210 210 210 210 Zone 3 210 210 210 210 210 Zone 4 210 210 210 210 210 Zone 5 - - 210 - - filter 1 210 210 210 210 210 filter 2 210 210 210 210 210 filter 3 210 210 210 210 210

[0113] Die temperature distribution (°...

Embodiment 2

[0119] Example 2 (comparative). Films according to the prior art were produced on a 5-layer coextrusion blown film line as described below.

[0120] Line description and process settings:

[0121] Number of extruders 5 number of layers 5 thickness 25μm BUR (Blow-Up Ratio) 2.4 die Gap: 2.4mm; diameter 400mm double ring Dual flow air ring, non-contact type air cooling temperature 15℃ ring 51% of total power IBC 46% power Line speed 55m / min output 240kg / h

[0122] Extruder temperature distribution (°C):

[0123] Extruder A Extruder B Extruder C Extruder D Extruder E Area 1 40 40 40 44 40 Zone 2 199 186 210 187 198 Zone 3 210 210 210 210 210 Zone 4 210 210 210 210 210 Zone 5 210 210 210 210 210 Area 6 210 210 210 210 210 Area 7 210 210 210 210 210 Area 8 - 210 - 210 -

[0124] Die temperature distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com