Warm mixing agent, regenerant and preparation method of warm-mixed recycled asphalt mixture

A technology of reclaimed asphalt and reclaiming agent, applied in the preparation of reclaiming agent and warm mix reclaimed asphalt mixture, and the field of warm mix agent, can solve the problems of poor performance, crack resistance and fatigue resistance of warm mix reclaimed asphalt mixture. , to solve the effect of poor fatigue resistance, improve strength and improve adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

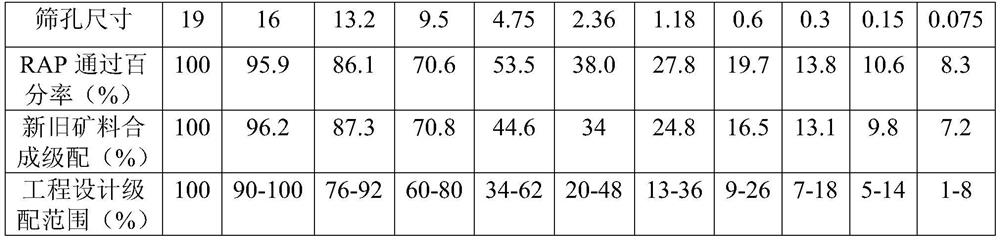

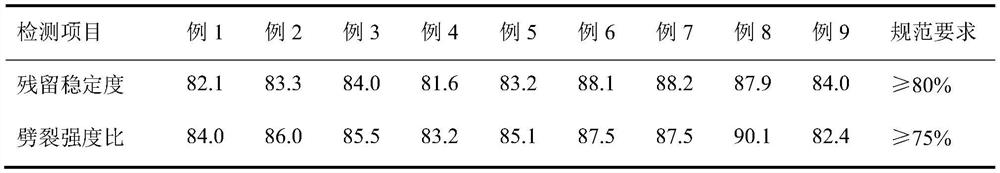

Examples

Embodiment 1

[0036] Preparation of warm mixing agent: After mixing polyamide wax, chlorinated paraffin, resin, aromatic hydrocarbon and castor oil according to the mass ratio of 20.1:11.9:8.2:10.4:3.1, melt shearing at 120-130°C for 10 ~12min to make. The amount of warm mix agent is expressed as a percentage of the total amount of old and new asphalt.

[0037] Preparation of regenerant: It is made from waste oil, waste rubber powder, anti-aging agent, and plasticizer under the condition of 70-80°C and then cooled to room temperature; among them, 3 parts of waste oil and 1.1 parts of waste rubber powder , 0.12 parts of anti-aging agent, 0.11 parts of plasticizer. The amount of regenerant is expressed as a percentage of the old asphalt mass.

[0038] Preparation of warm-mix regeneration compound agent: Weigh warm-mix agent and regeneration agent, mix the two, and melt and shear at 110°C to 120°C for 5-7 minutes to make warm-mix regeneration compound agent. In this example, warm-mix agent a...

Embodiment 2

[0050] Raw material and gradation are equal to embodiment 1, and difference is as follows:

[0051] (1) Rejuvenator: It is made of waste oil, waste rubber powder, anti-aging agent, and plasticizer under the condition of 70-80°C after fully stirring and mixing, and then cooled to room temperature; among them, 4 parts of waste oil, 1.2 parts of waste rubber powder parts, 0.13 parts of anti-aging agent, and 0.1 part of plasticizer.

[0052] (2) The mixing ratio of new mineral powder is 5%, of which 3% is replaced by mica powder with close gradation, and the other 2% is also made of new mineral powder with limestone powder.

[0053] (3) The consumption of warm mix agent and regeneration agent, this example is respectively 3.1% of new and old asphalt total amount and 7.7% of old asphalt quality; Warm mix regeneration compound agent: the mass ratio of this routine warm mix agent and regeneration agent is 1 :1.15.

Embodiment 3

[0055] Raw material and gradation are equal to embodiment 1, and difference is as follows:

[0056] (1) Rejuvenator: It is made of waste oil, waste rubber powder, anti-aging agent, and plasticizer under the condition of 70-80 ° C and fully stirred and mixed, and then cooled to room temperature; among them, 5 parts of waste oil, 1.3 parts of waste rubber powder part, 0.14 part of antiaging agent, and 0.09 part of plasticizer.

[0057] (2) 5% of the new mineral powder is all replaced by mica powder with close gradation.

[0058] (3) The consumption of warm mix agent and regeneration agent, this example is respectively 3.1% of new and old asphalt total amount and 7.6% of old asphalt quality; Warm mix regeneration compound agent: the mass ratio of this routine warm mix agent and regeneration agent is 1 :1.13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com