Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Improve activity and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn. method and application of high-dispersion loading type nickel-based catalyst

InactiveCN1751789AImprove activity and stabilityStrong effectHydrogenCatalyst activation/preparationIonAcetylacetone

A high-dispersity carried Ni-base catalyst for reforming, oxidizing, or oxidizing-reforming methane in fluidized bed is prepared by direct dipping to make the Ni ions be carried by microspherical silica gel or alumina. Its advantages are high activity and high stability.

Owner:ZHEJIANG UNIV

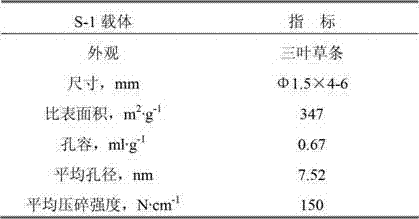

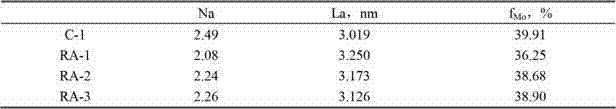

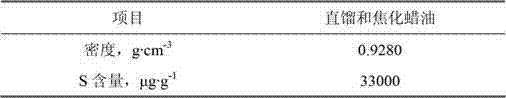

Hydro-fining catalyst roasted at low temperature and preparation method thereof

InactiveCN102784656AImprove activity and stabilityLow cost of preparationPhysical/chemical process catalystsRefining to eliminate hetero atomsOxideFluid catalytic cracking

The invention discloses a hydro-fining catalyst roasted at a low temperature and a preparation method thereof. The preparation method comprises the following steps of: taking aluminum hydroxide dry glue or modified aluminum hydroxide dry glue as a raw material to prepare a catalyst carrier, then impregnating metal active components in VIB and VIII groups and preparing the hydro-fining catalyst through drying and roasting. The content of an alumina carrier is 60-90 weight percent, the content of metallic oxide in the VIB group is 5-35 weight percent, and the content of metallic oxide in the VIII group is 1-10 weight percent. An activity phase of the catalyst has proper stacking layer number and film crystal length, the interaction between the carrier and metal is reduced, the better dispersion state of the active components can be kept, and the HDS (Hydro-desulfurization) ability of sulfide difficult to remove in an oil product is improved. The hydro-fining catalyst is particularly suitable for the hydro-desulfurization of naphtha, the hydro-fining of inferior diesel oil and the hydro-treatment of FCC (Fluid Catalytic Cracking) raw materials or hydro-cracking raw materials and other distillate oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

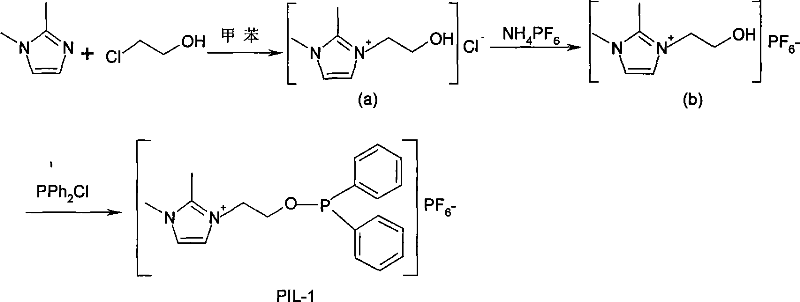

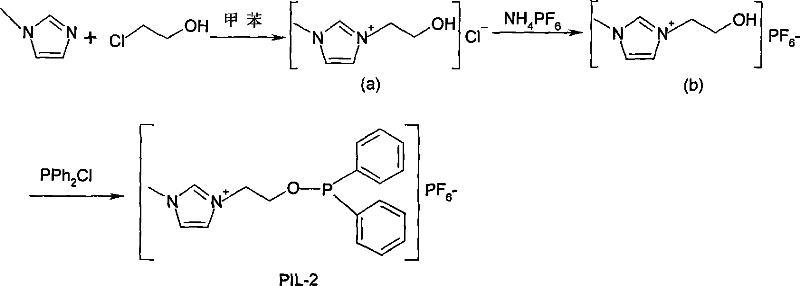

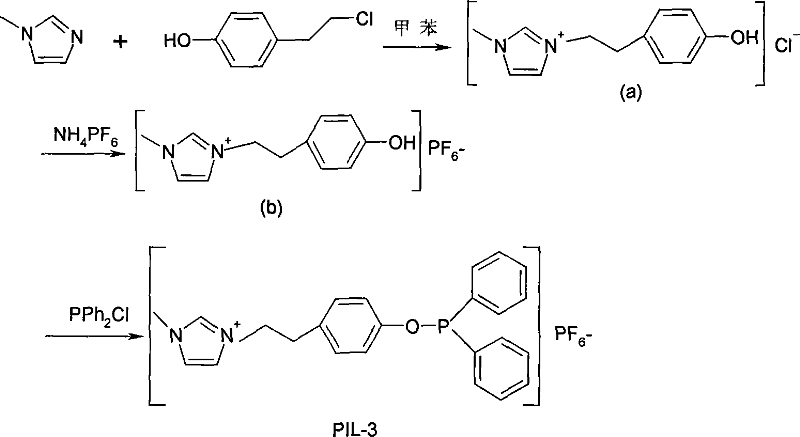

Multifunctional ion liquid system, preparation and application thereof

InactiveCN101037388AImprove activity and stabilityGood solubilityOrganic compound preparationGroup 5/15 element organic compoundsIonSolvent

The invention relates to a complex function ion liquid system, producing method and the application thereof belonging to new material and refinery chemical field. The complex function ion liquid system is composed of phosphine ligand functional ion liquid and alkali functional ion liquid, in which the phosphine ligand functional ion liquid is to link the traditional phosphine ligand to the typical ion liquid with an introducing position on the cation segment or the anion segment of the ion liquid. The cation ion and anion ion parts of the alkalescence functional ion liquid may have the alkaline group respectively or simultaneously. The provided complex function ion liquid can be applied in the coupling reaction of C-C / C-N. The advantages is that: complex function ion liquid system simultaneously plays a role of ligand, attaching acid agent and solvent and puts up an integrated cooperative catalytic effect; and it can be reused for several times and avoids using the poisonous, harmful and volatile organic solvent.

Owner:EAST CHINA NORMAL UNIVERSITY

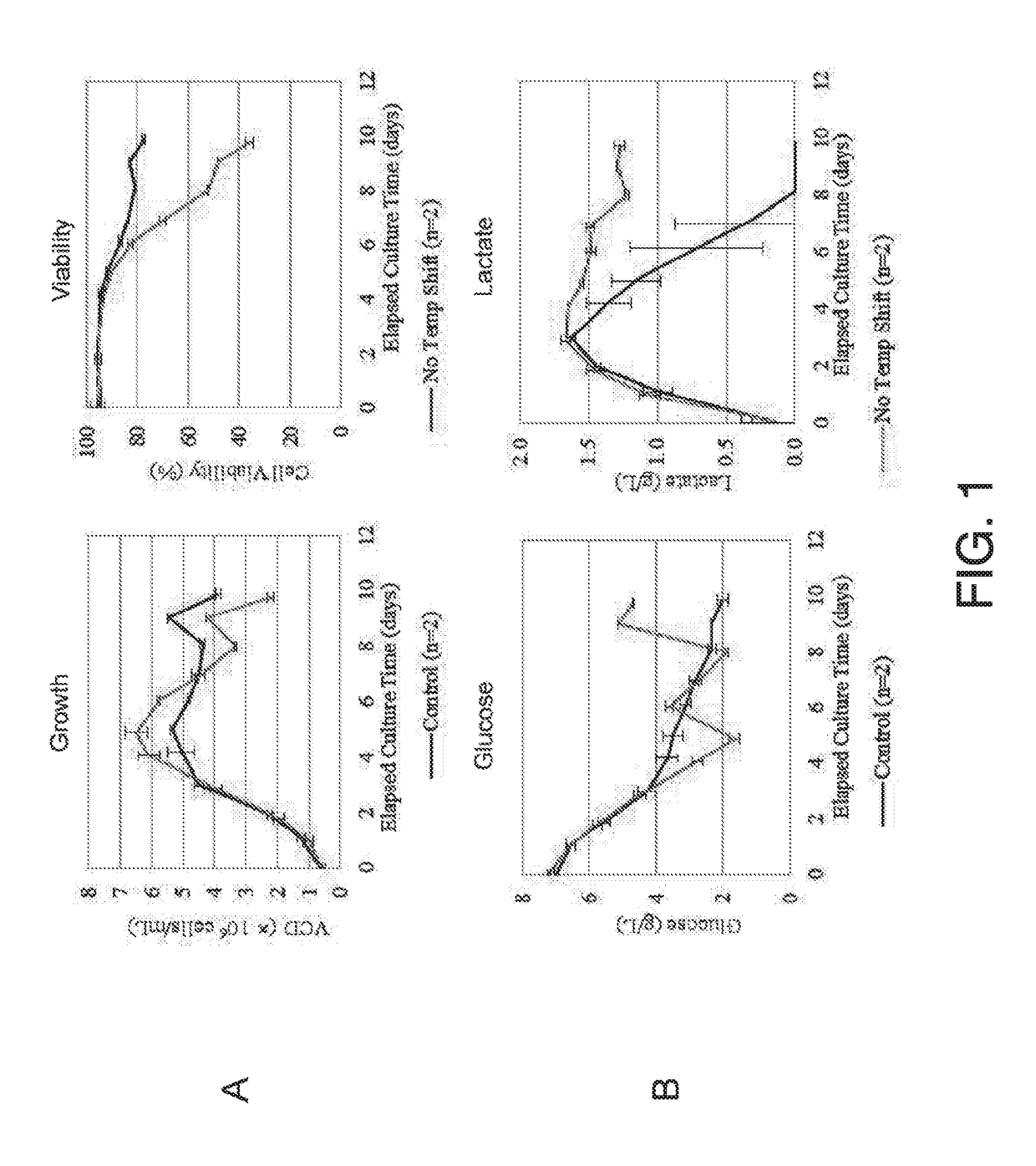

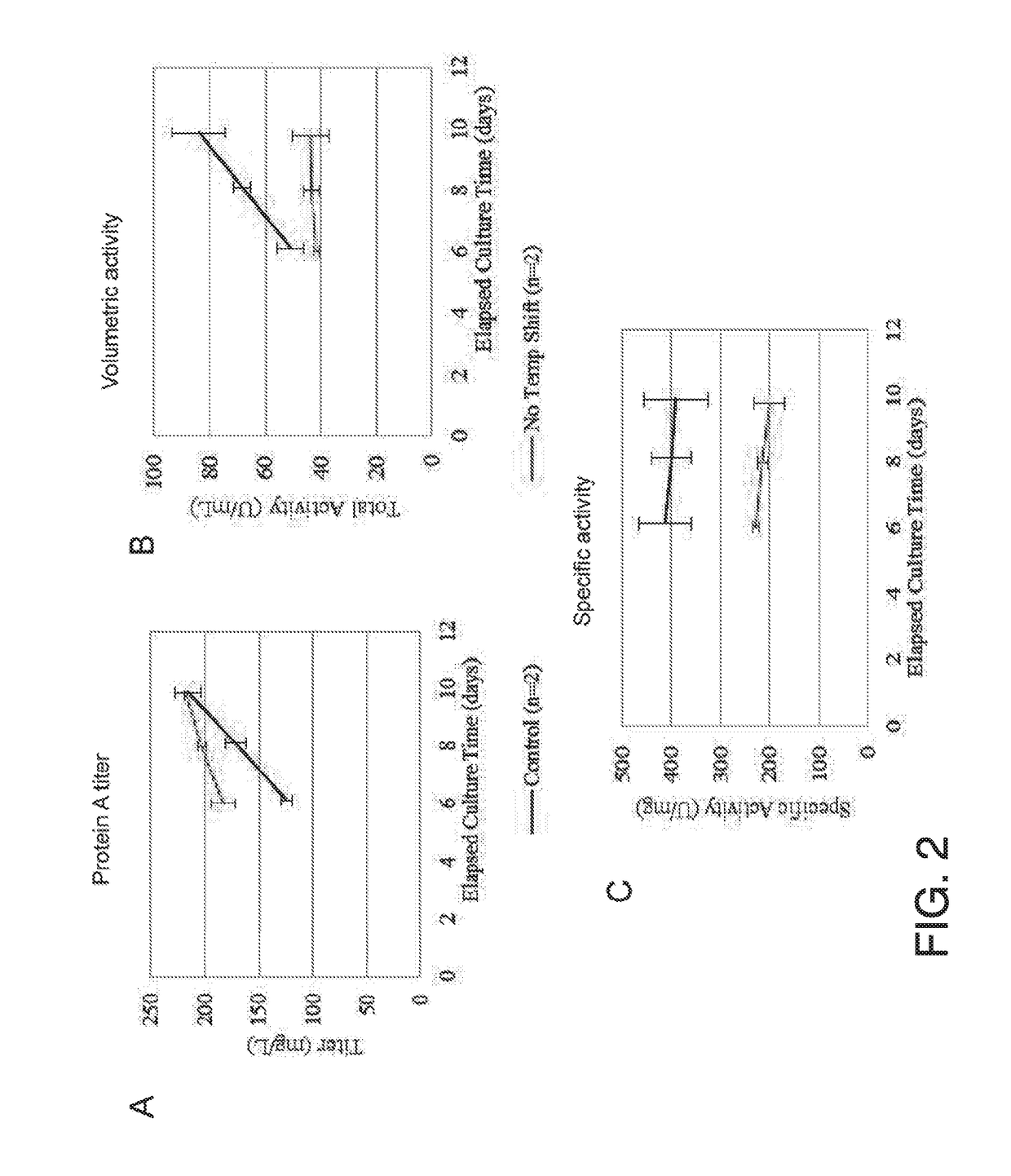

Manufacturing of alkaline phosphatases

ActiveUS20180230445A1Improve activity and stabilityImproves specific activityPeptide/protein ingredientsHydrolasesMicrobiologyZinc

A method for producing a recombinant polypeptide, comprising: (a) providing a 100 L to 25,000 L fed-batch bioreactor comprising (i) cells capable of expressing the recombinant polypeptide asfotase alfa (SEQ ID NO: 1), and (ii) a culture medium suitable for conducting such expression the culture medium comprising about 25 μM to about 300 μM zinc; (b) culturing the cells under conditions suitable to express the recombinant asfotase alfa wherein the pH of the culture medium is about 6.7 to about 7.1, and wherein zinc is added into said culture medium such that the zinc concentration in the culture medium is maintained at a concentration of about 25 μM to about 300 μM of zinc.

Owner:ALEXION PHARMA INC

Compositions and Processes for Reducing NOx Emissions During Fluid Catalytic Cracking

ActiveUS20090057199A1High activityImprove stabilityCatalytic crackingMolecular sieve catalystsParticulatesProcess conditions

Compositions for reduction of NOx generated during a catalytic cracking process, preferably, a fluid catalytic cracking process, are disclosed. The compositions comprise a fluid catalytic cracking catalyst composition, preferably containing a Y-type zeolite, and a NOx reducing zeolite having a pore size ranging from about 2 to about 7.2 Angstroms and a SiO2 to Al2O3 molar ratio of less than about 500 and being stabilized with a metal or metal ion selected from the group consisting of zinc, iron and mixtures thereof. Preferably, the NOx reducing zeolite particles are bound with an inorganic binder to form a particulate composition. In the alternative, the NOx reducing zeolite particles are incorporated into the cracking catalyst as an integral component of the catalyst. Compositions in accordance with the invention exhibit improved effectiveness for the reduction of NOx emissions released from the regenerator of a fluid catalytic cracking unit operating under FCC process conditions without a substantial change in conversion or yield of cracked products. Processes for the use of the compositions are also disclosed.

Owner:WR GRACE & CO CONN

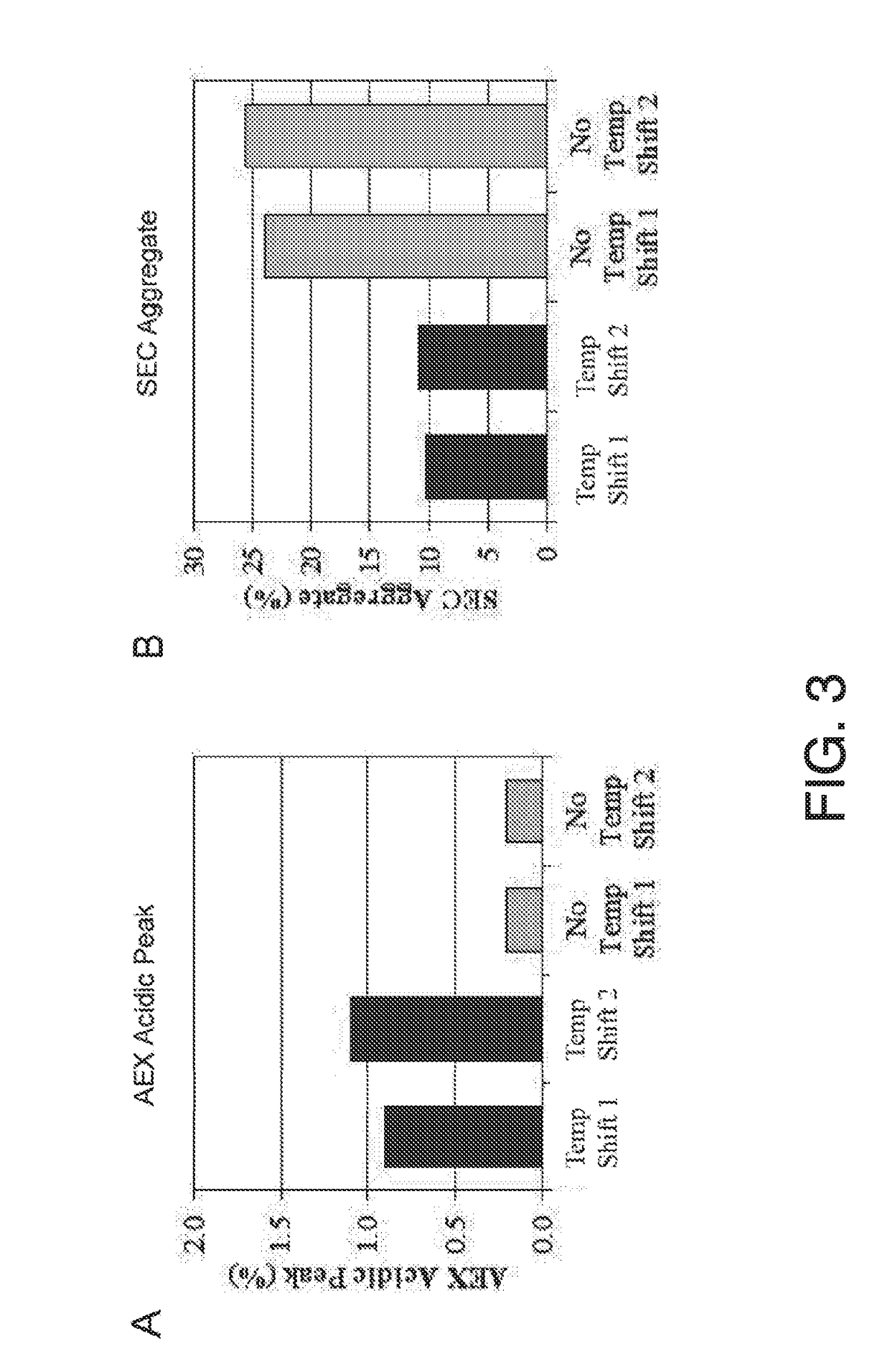

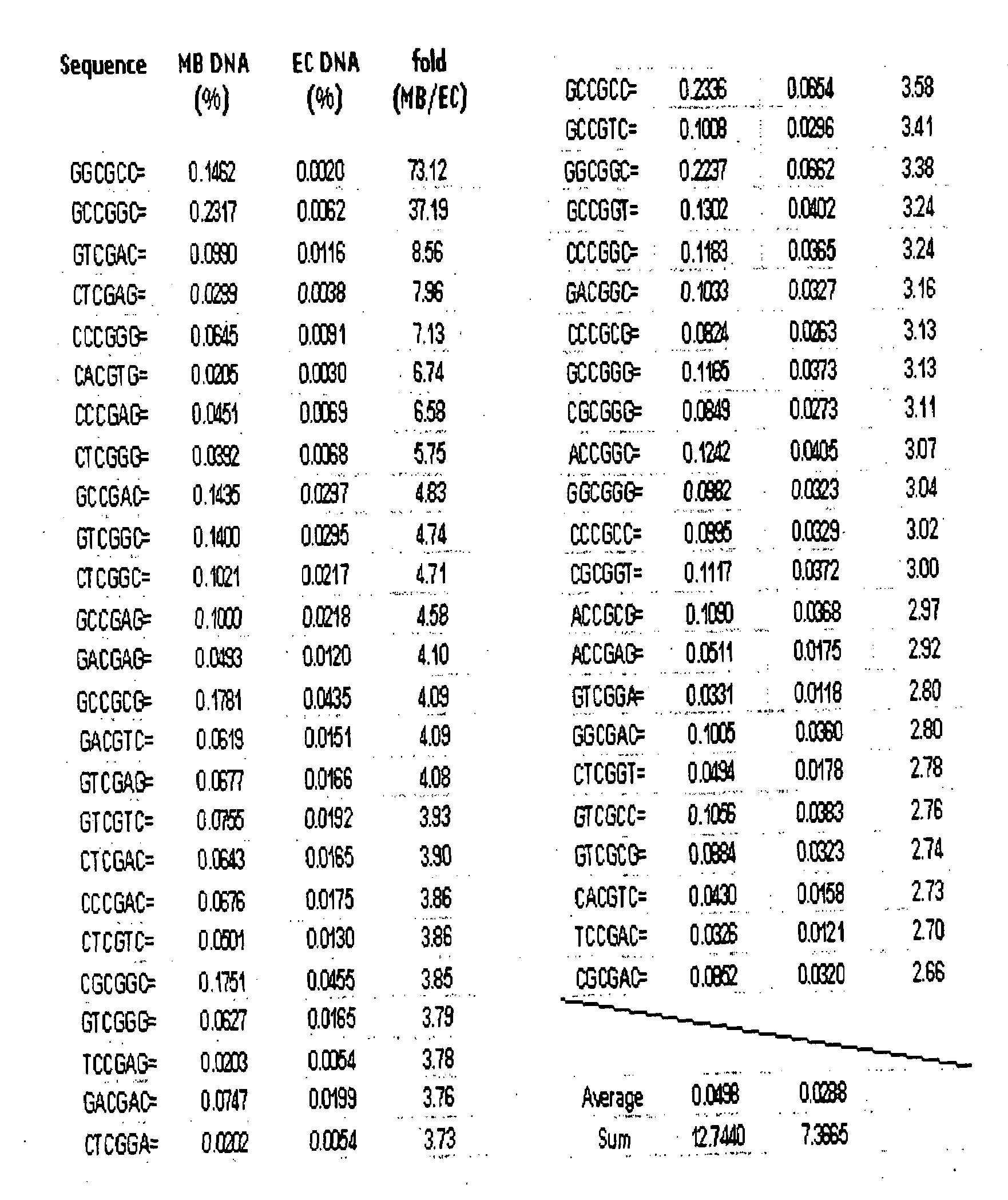

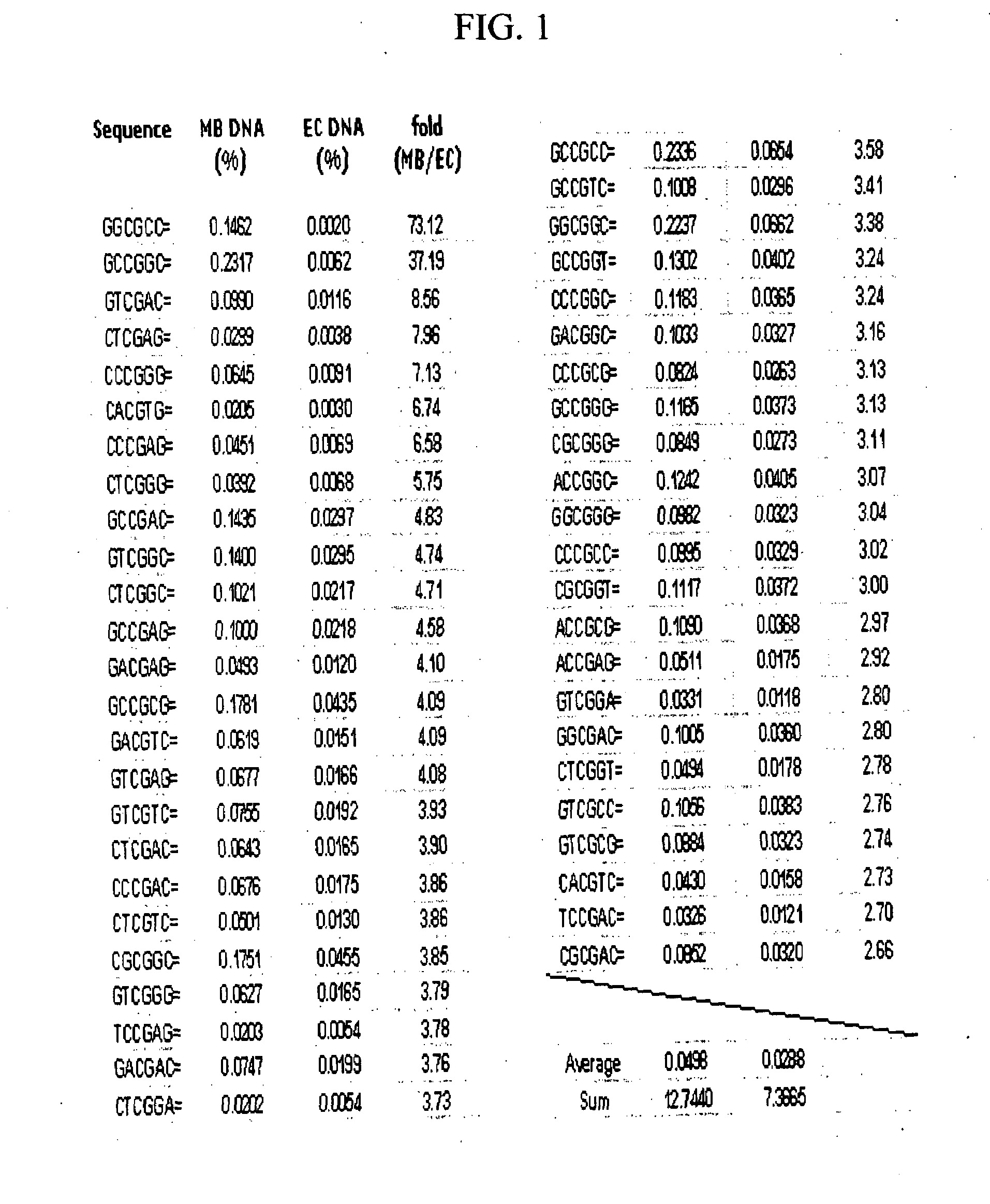

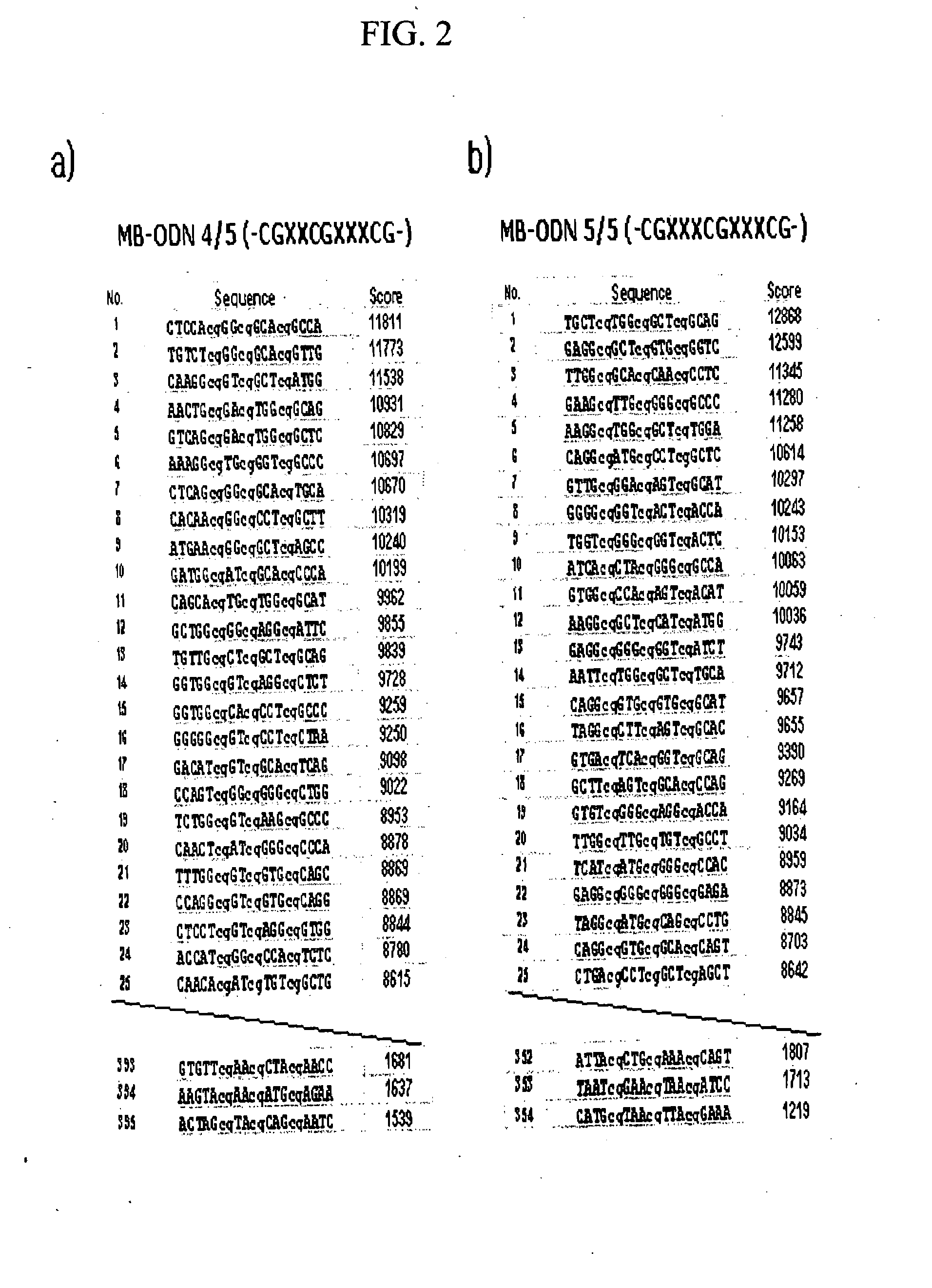

Oligonucleotides Derived From Mycobacterium for Stimulating Immune Function, Treating Immune-Related Diseases, Atopic Dermatitis and/or Protecting Normal Immune Cell

InactiveUS20080249291A1Reduce riskPromote decompositionSugar derivativesGenetic material ingredientsAtopic dermatitisOligonucleotide

Disclosed are oligonucleotides for manipulating an immune reaction. The oligonucleotides of the present invention may be useful to stimulate the immune function, to treat the immune-related diseases and the atopic dermatitis, or to protect the normal immune cells.

Owner:KWON HYUNG JOO +1

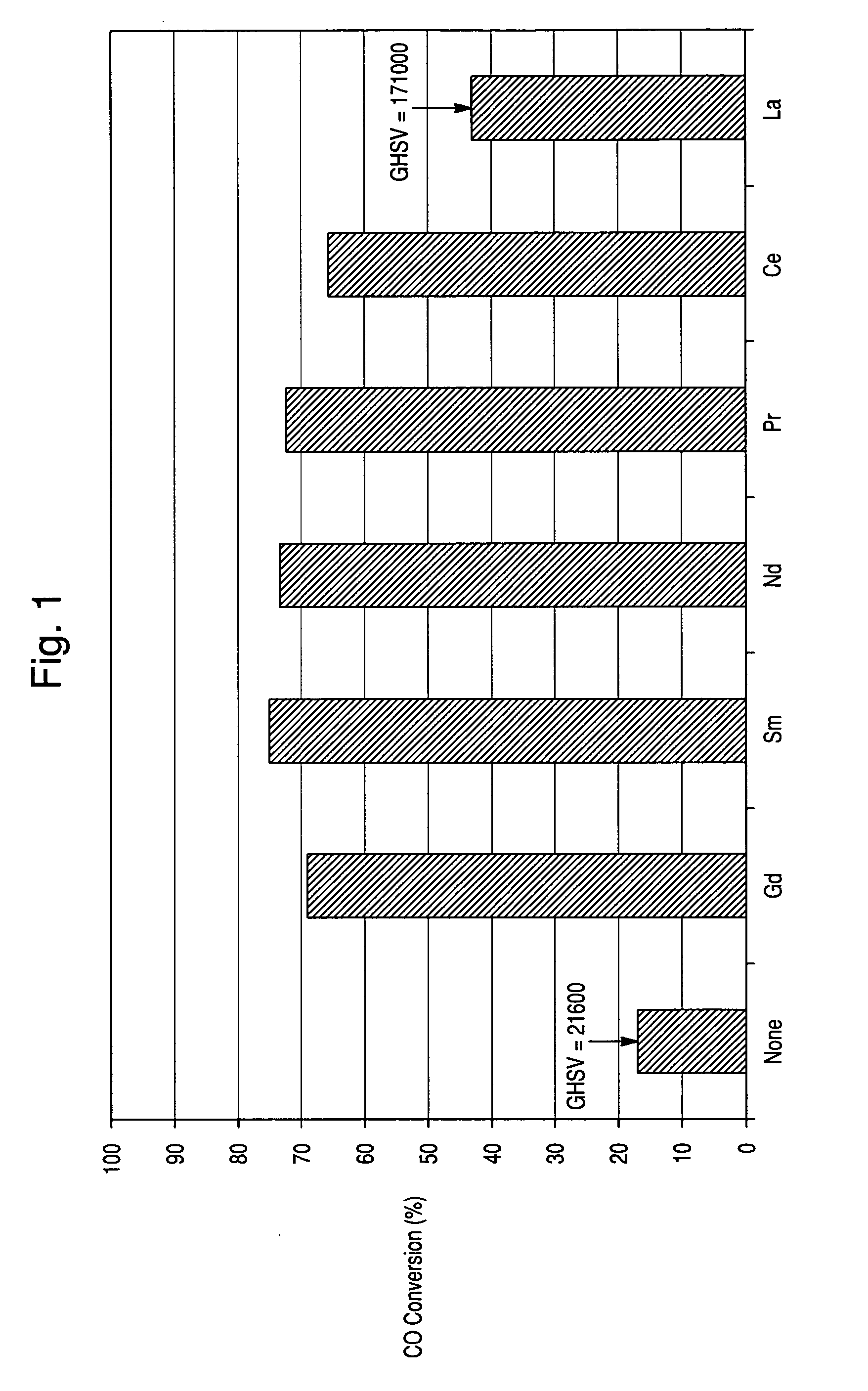

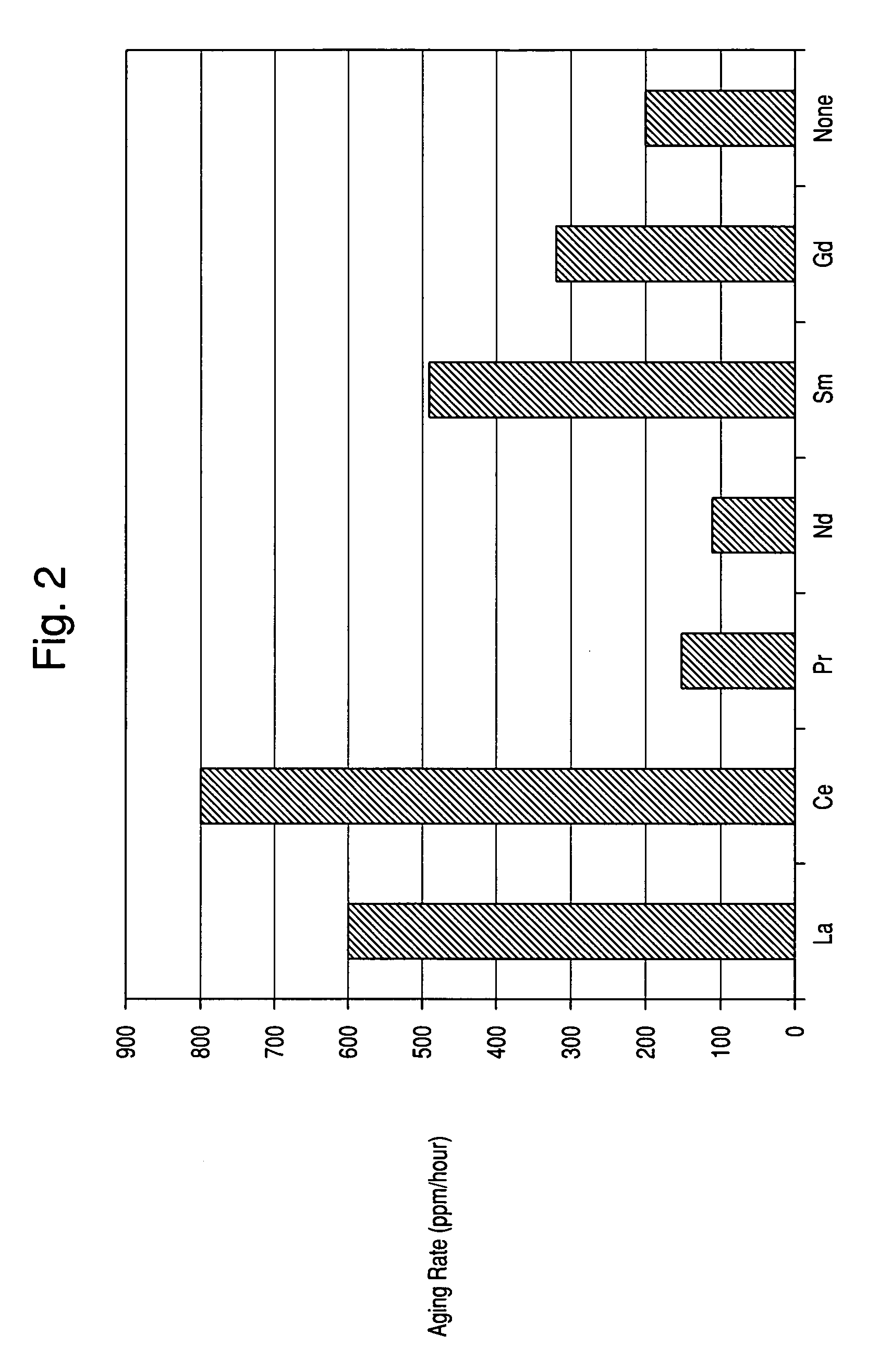

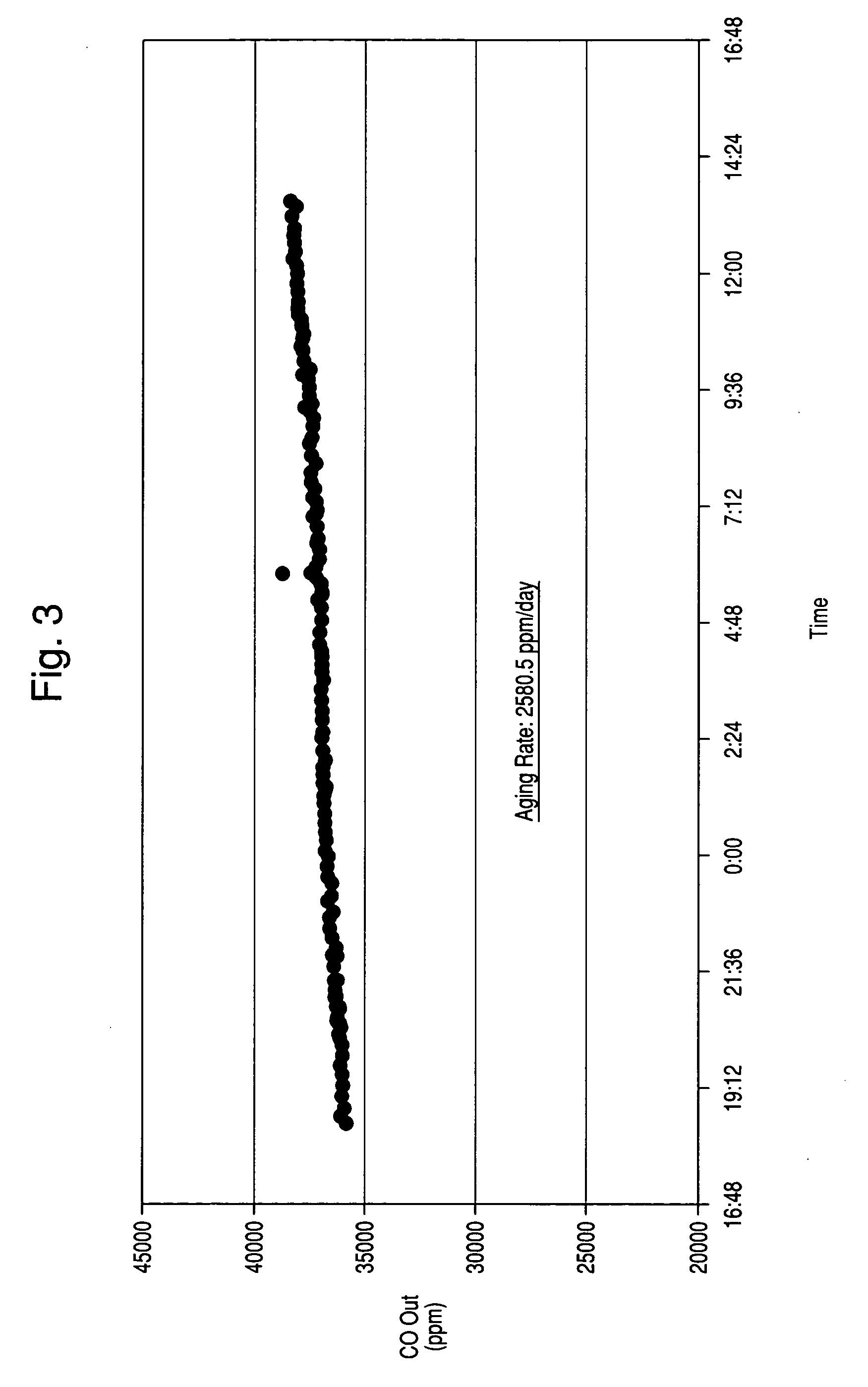

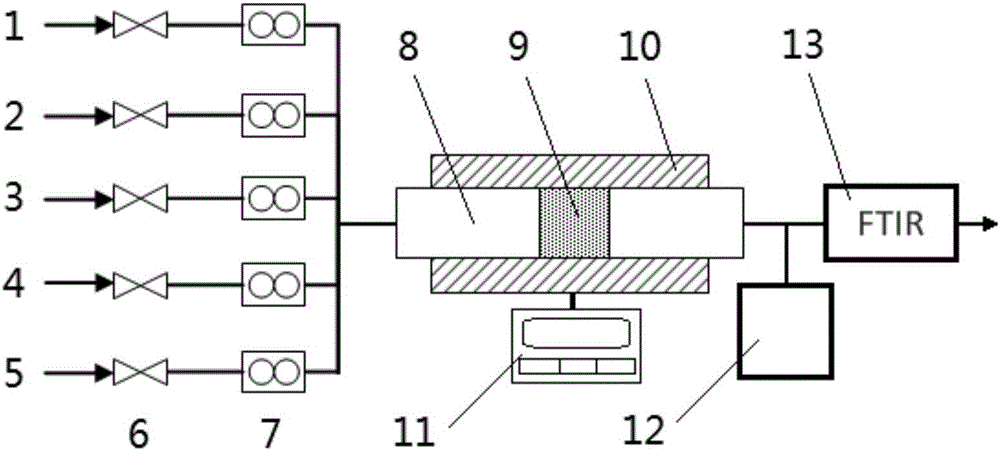

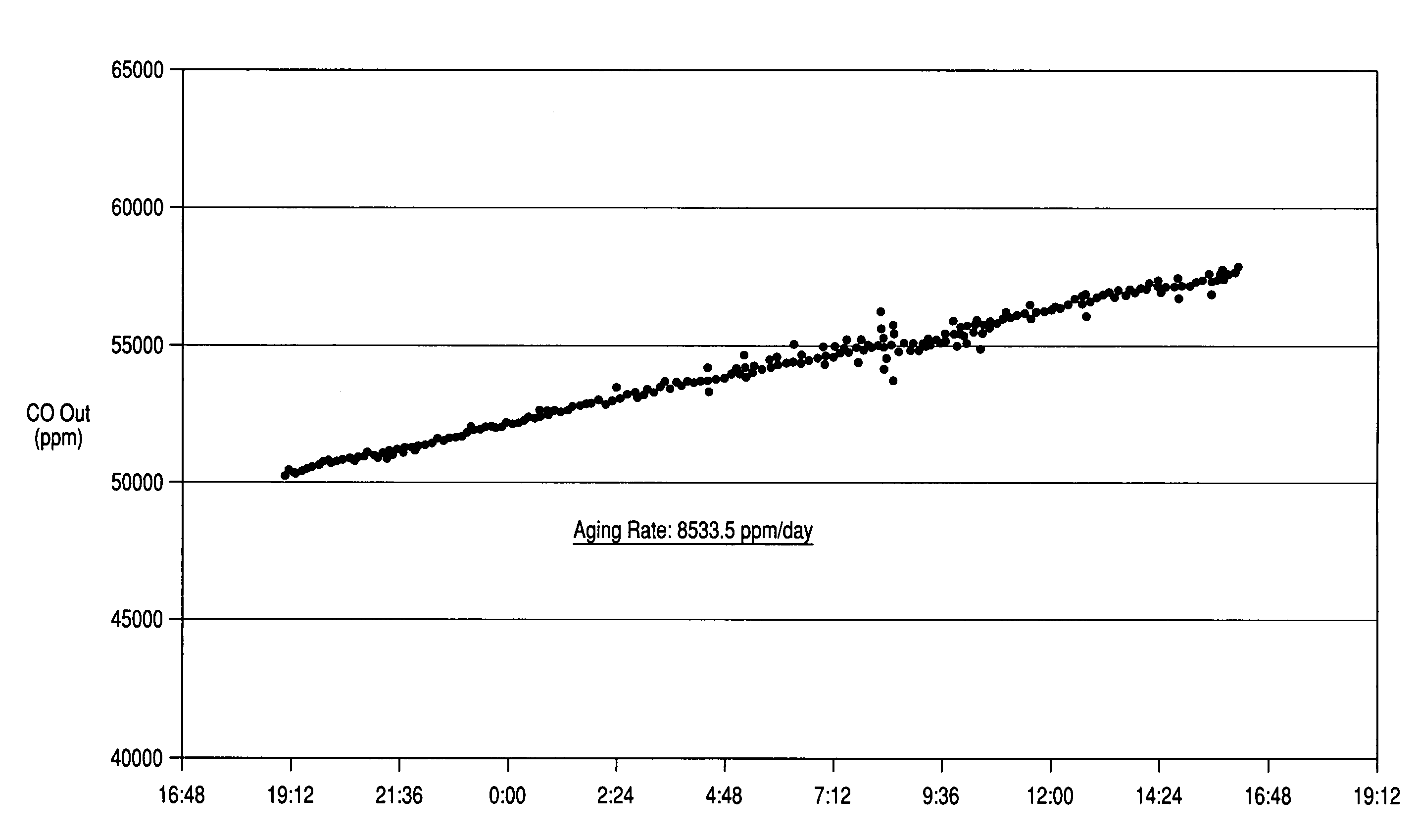

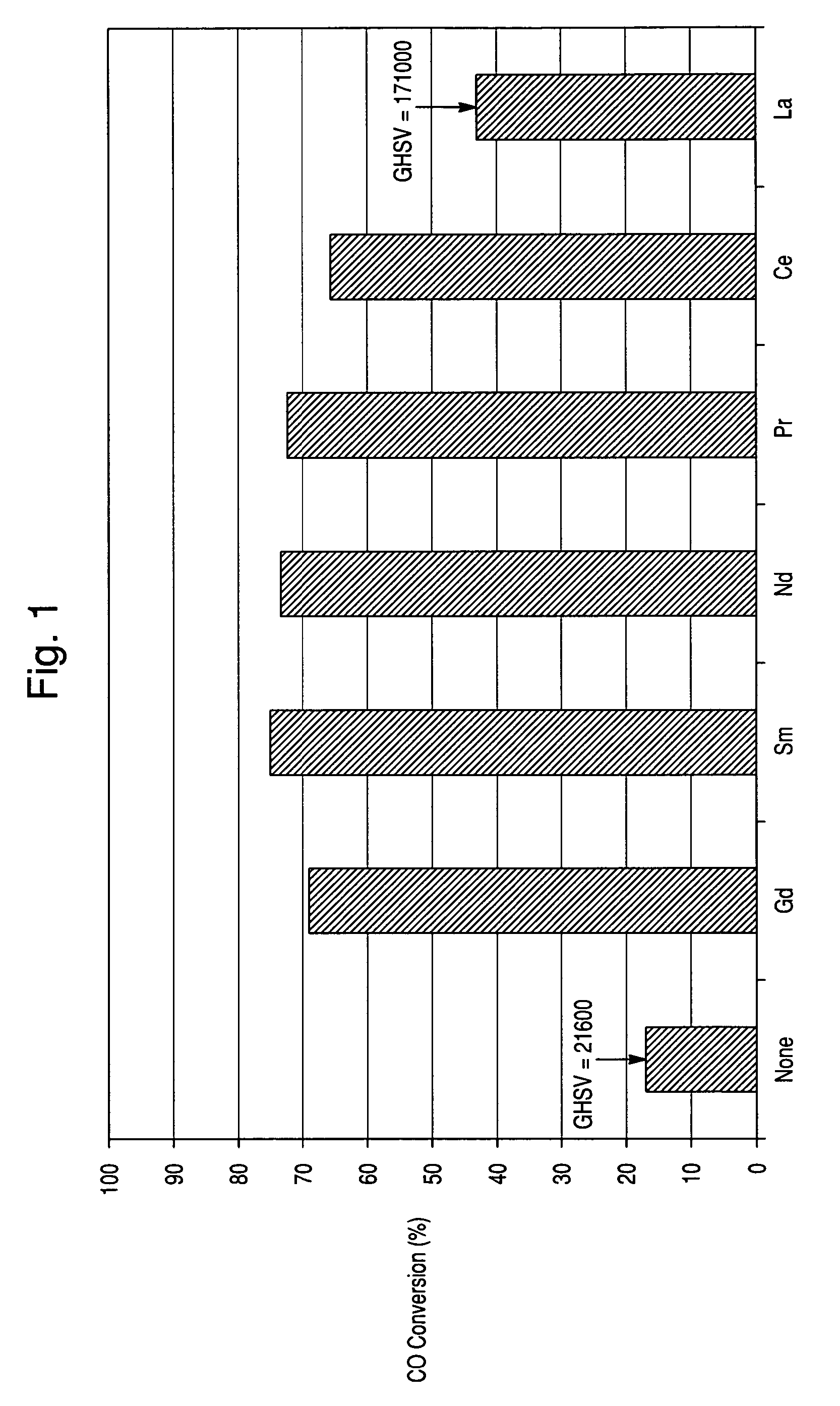

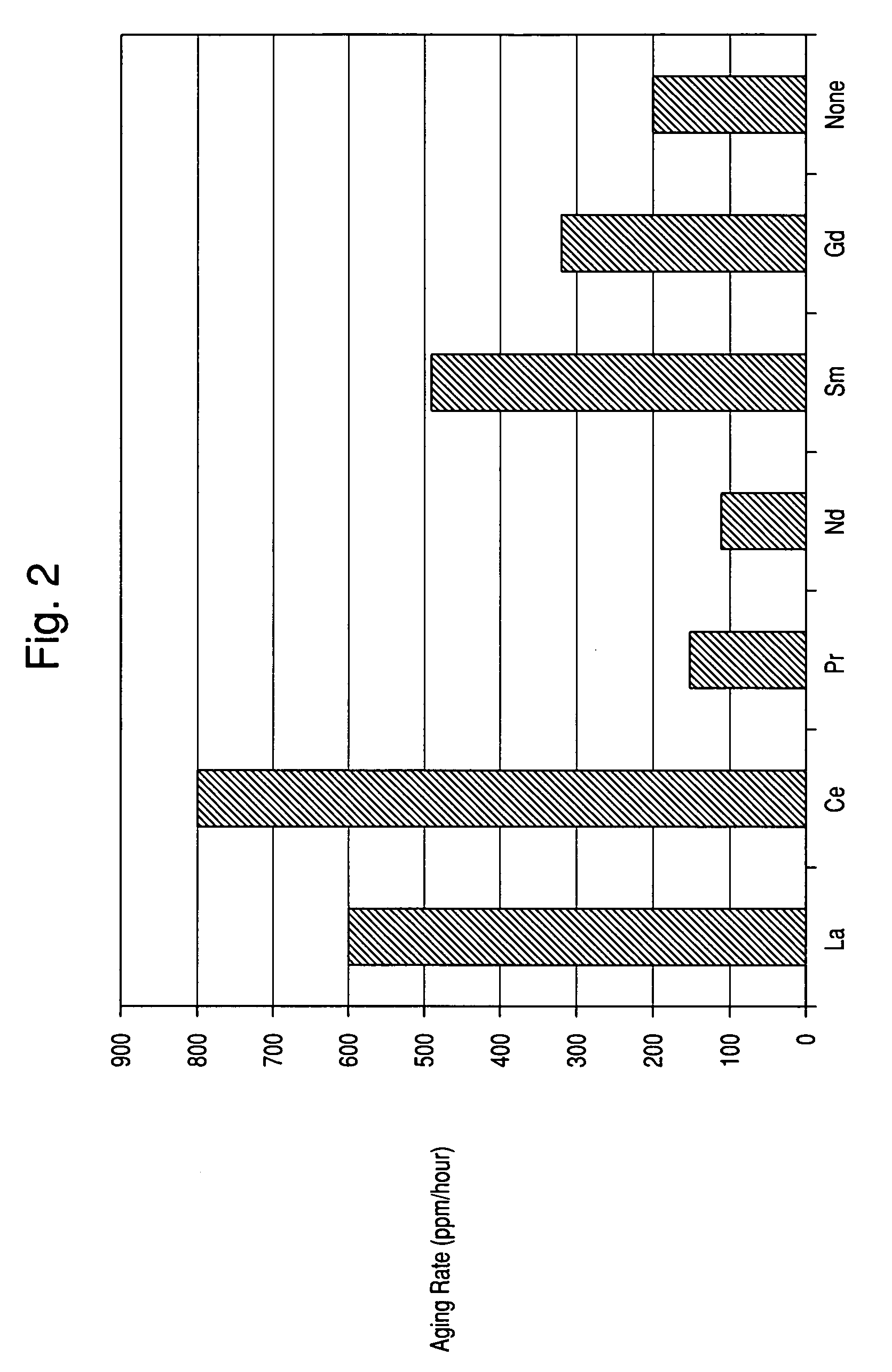

Precious metal water-gas shift catalyst with oxide support modified with rare earth elements

InactiveUS20060182679A1Improve activity and stabilityImprove stabilityHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementAluminium oxides

A water gas shift catalyst comprising a platinum group metal dispersed on an inorganic oxide support modified with a carbon-containing burn-out additive and a rare earth oxide. A water gas shift catalyst containing alumina, a platinum group metal, and oxides of Pr and Nd are also disclosed.

Owner:BASF CATALYSTS LLC

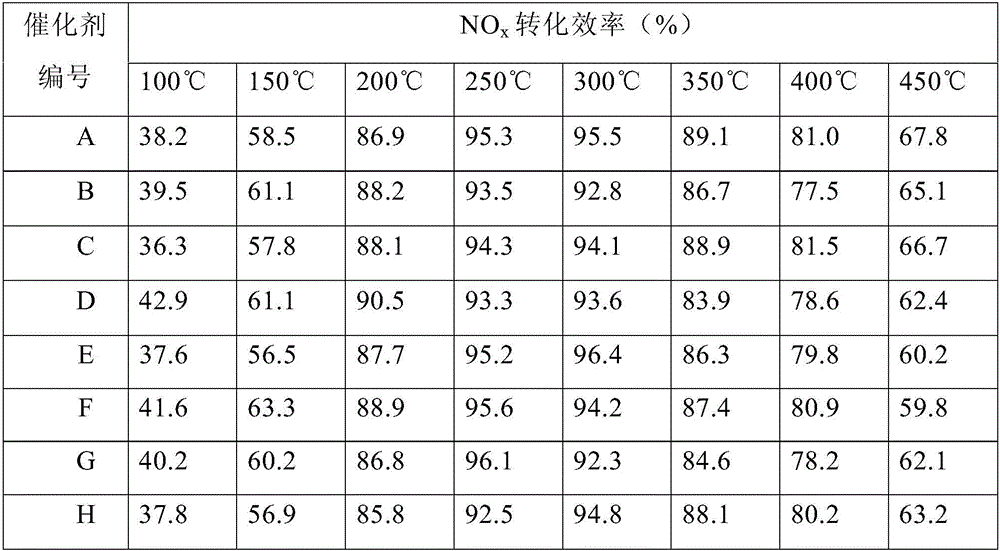

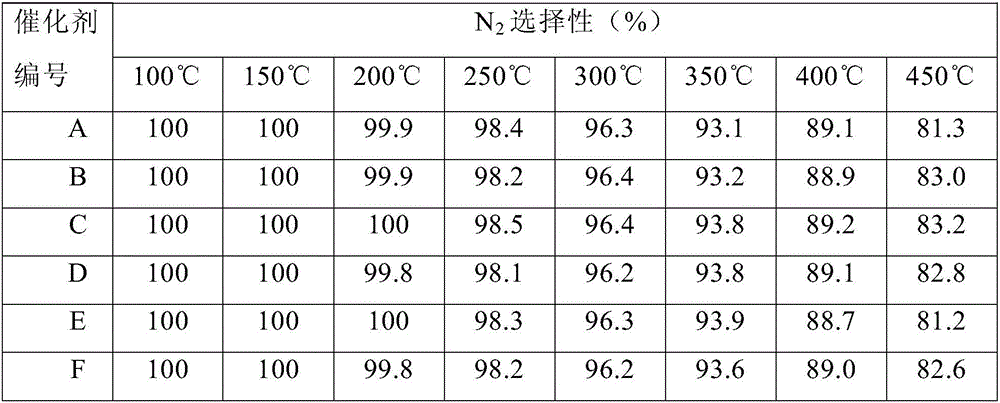

Catalyst for removing NOx of diesel engine and preparation method thereof

InactiveCN106000414AReduce NOxImprove activity and stabilityMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention discloses a catalyst for removing NOx of a diesel engine. The catalyst for removing the NOx of the diesel engine is characterized in that the catalyst is a multi-element metal oxide, and comprises TiO2 which serves as a carrier component, CeO2 and CuO which serve as main active ingredients, and WO3 which serves as a catalyst promoter component; the mass percentage of various components are respectively as follows: 55 to 65 percent of TiO2, 23 to 28 percent of CeO2, 3 to 5 percent of CuO, and 10 to 13 percent of WO3, and the sum of the mass percentage is 100 percent; the catalyst can be used in a catalysis process of NH3-SCR in a wide temperature window; the multi-element metal oxide catalyst provided by the invention has a relatively wide active temperature window, and particularly the removal efficiency of the NH3-SCR to NOx is improved under the working conditions of low exhaust temperature (100 to 250 DEG C) of the diesel engine, so that the purpose of greatly reducing the NOx in a wide exhaust temperature window of the diesel engine at 100 to 450 DEG C is achieved; therefore, the catalyst is particularly suitable for the traffic conditions of urban roads of China.

Owner:SHANGHAI JIAO TONG UNIV

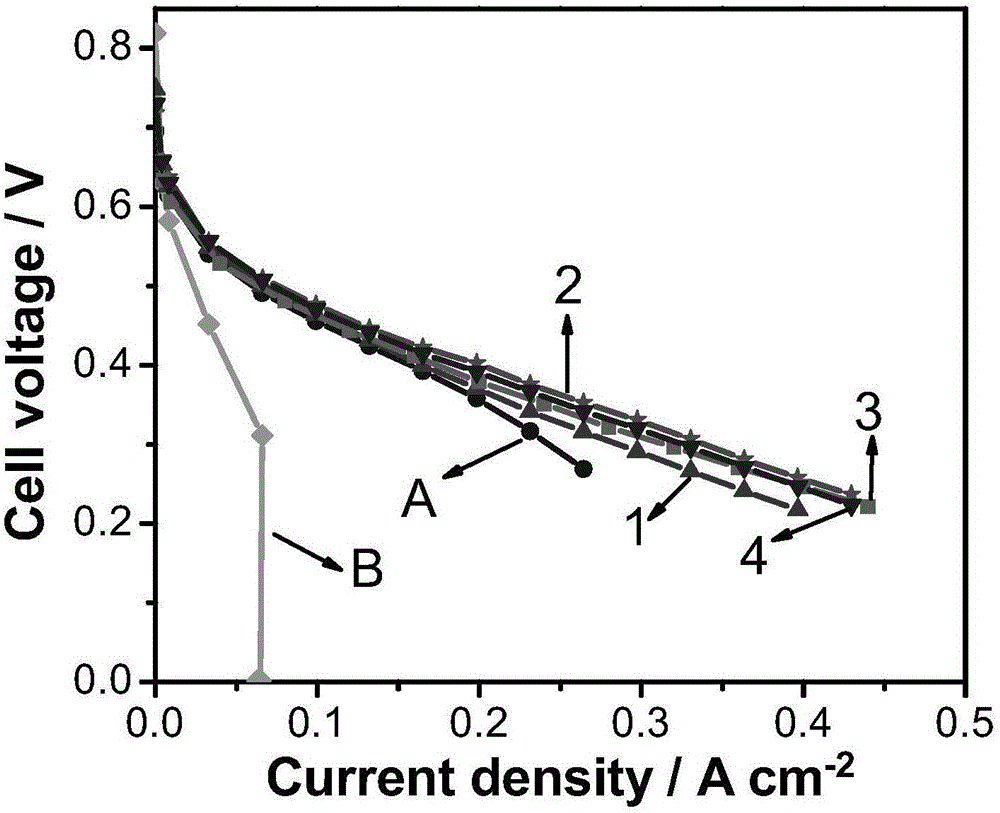

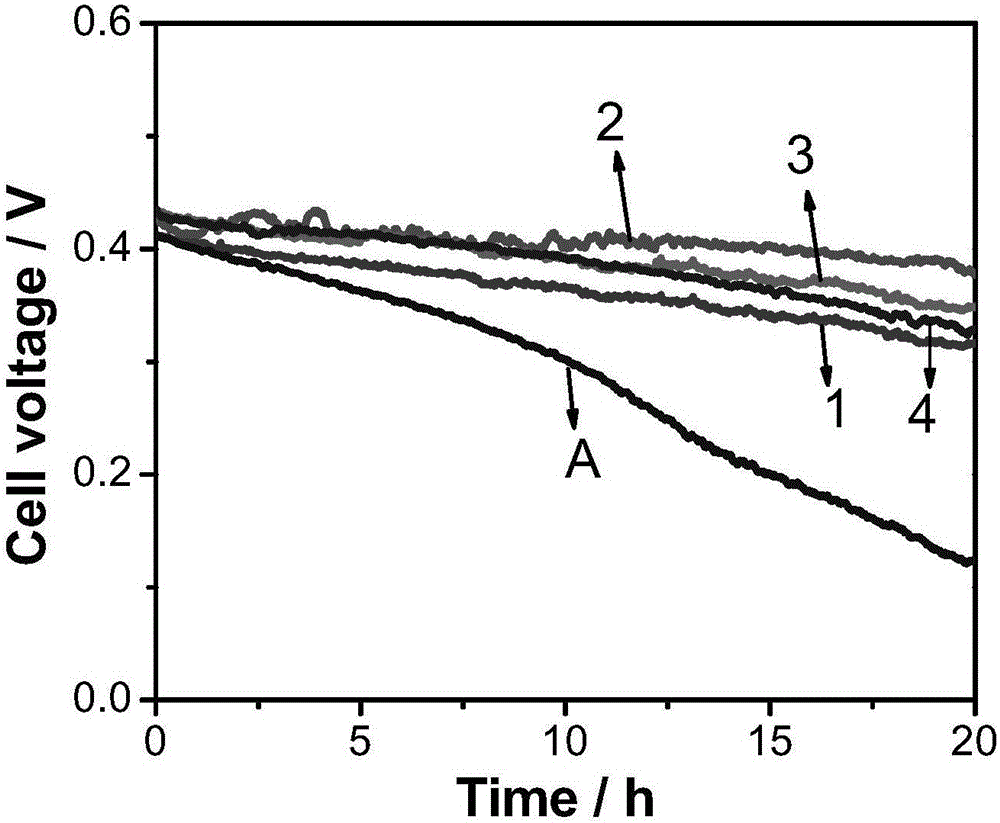

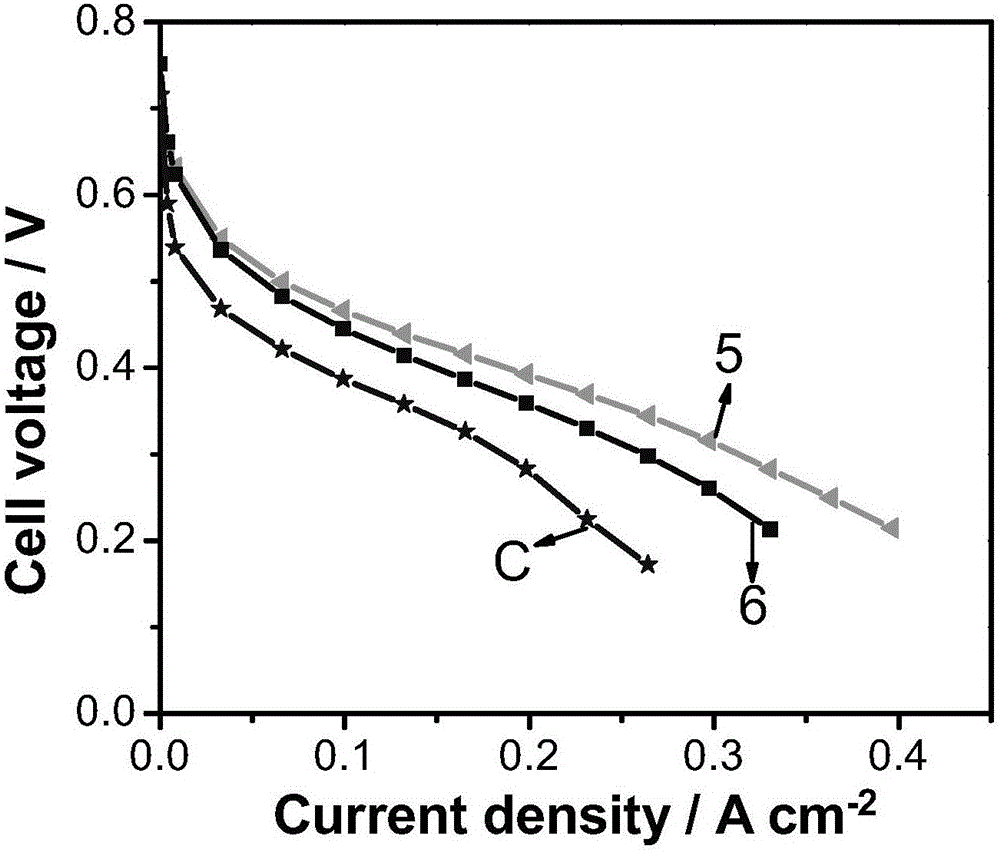

Method for preventing pore passages from being flooded with water in catalyst layer of fuel cell

InactiveCN105720274AImprove activity and stabilityPrevent floodingCell electrodesActive siteViscosity

The invention discloses a method for preventing pore passages from being flooded with water in the catalyst layer of a fuel cell, and relates to fuel cells. The method comprises the following steps of 1, selecting a hydrophobing agent which does not block the catalyst pore passages according to the pore passage structure of the catalyst and the pore sizes; and 2, adding the hydrophobing agent into the catalyst slurry, thus allowing the hydrophobing agent to uniformly cover the surfaces of the particles to establish a waterproof gas-permeable membrane in the catalyst layer of the fuel cell, and thereby achieving the effect of preventing the pore passages from being flooded with water in the catalyst layer of the fuel cell. By screening the molecular weights and viscosities of the hydrophobing agent, and covering the hydrophobing agent on the surfaces of the catalyst particles, the waterproof gas-permeable membrane is established; and the waterproof gas-permeable membrane can effectively prevent the catalyst micropores from absorbing water and can also be oxygen-permeable, thus active sites in the pore passages are prevented from being flooded with water to the utmost extent, and the activity and stability of the cell are improved. The method is particularly applicable to the three-way M / N / C catalyst based more on micropores, and meanwhile also can be applied to the pores more than 10nm.

Owner:XIAMEN UNIV

MnO2-RuO2/C catalyst for lithium-air battery and preparation method of MnO2-RuO2/C catalyst

ActiveCN103887528AImprove activity and stabilityReduce exposureMaterial nanotechnologyFuel and secondary cellsSide reactionLithium–air battery

The invention discloses a MnO2-RuO2 / C catalyst for a lithium-air battery and a preparation method of the MnO2-RuO2 / C catalyst. An active substance of the catalyst is MnO2-RuO2, a carrier of the catalyst is nanocarbon, and MnO2-RuO2 and nanocarbon comprise the following components by weight percent: 5-20 percent of MnO2, 25-55 percent of nanocarbon and the balance being RuO2. The nanocarbon is coated with nano MnO2-RuO2, and a great quantity of nano MnO2 and RuO2 particles are adsorbed by taking the nanocarbon as a carrier in the process of preparing the catalyst, so that the surface of the carrier is stably coated with MnO2 and RuO2, and the stability and the activity of the catalyst are improved. Meanwhile, because the nanocarbon is coated, the contact between the nanocarbon and Li2O2 is reduced, side reactions are reduced, and energy efficiency and cycle performance of the battery are improved.

Owner:CHENGDU DAAISI ELECTRONICS

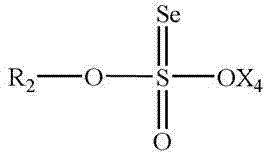

Chemical tinning liquid, preparation method thereof and chemical tinning method

ActiveCN104746057AImprove activity and stabilityGuaranteed long-term stabilityLiquid/solution decomposition chemical coatingDodecylsulfonic acidCompound (substance)

The invention provides a chemical tinning liquid and a preparation method thereof. The chemical tinning liquid contains tin salt, a complexing agent, a reducing agent and an accelerant, wherein the reducing agent is titanium dichloride; the accelerant contains sulfoacid accelerant; the sulfoacid accelerant is selected from at least one of A, B and C, wherein A is dedecylseleno sulfonate B is a mixture of dodecyl sulfonate and seleno sulfonate and C is a mixture of dodecyl sulfonate and seleno sulfate. The invention also provides a method for chemical tinning by using the chemical tinning liquid. According to the invention, the sulfoacid accelerant is added into the chemical tinning liquid using the titanium dichloride as the reducing agent, so that the activity and the stability of the chemical tinning liquid are effectively improved, the long-term stability of the tinning liquid is ensured and the compactness and the smoothness of a tin coating are improved.

Owner:BYD CO LTD

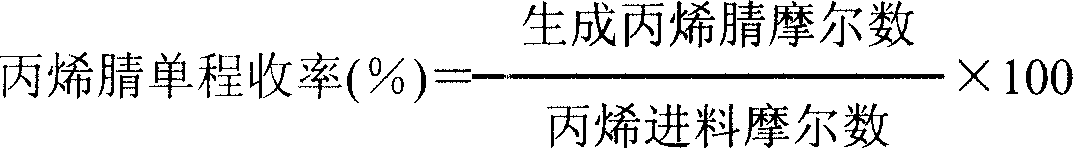

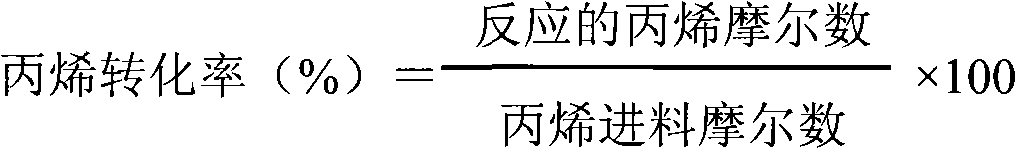

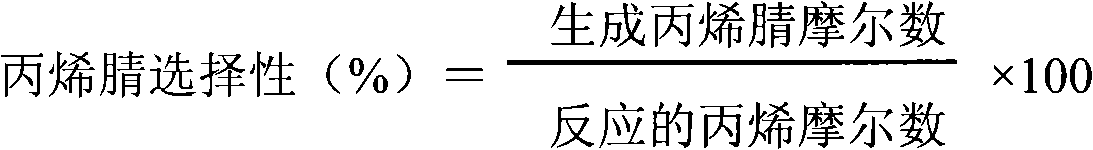

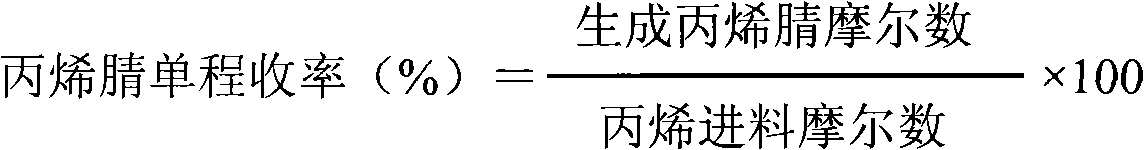

Fluid bed catalyst for acrylonitrile production

InactiveCN101147868AImprove activity and stabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedActive component

The present invention relates to a fluidized bed catalyst for producing acrylonitrile. It is characterized by that said catalyst uses silicone dioxide as carrier, and contains the following active components: A, B, C, K, Mg, Mn, I, Fe, Bi and Mo, in which A is at least one kind selected from Li, Na, Rb, Cs or Tl, B is at least one kind selected from La, Ce, Nd, Pr or Eu and C is at least one kind selected from Cr or W. Said catalyst can be used in industrial production of acrylonitrile under the condition of high reaction pressure and high propene load.

Owner:CHINA PETROLEUM & CHEM CORP +1

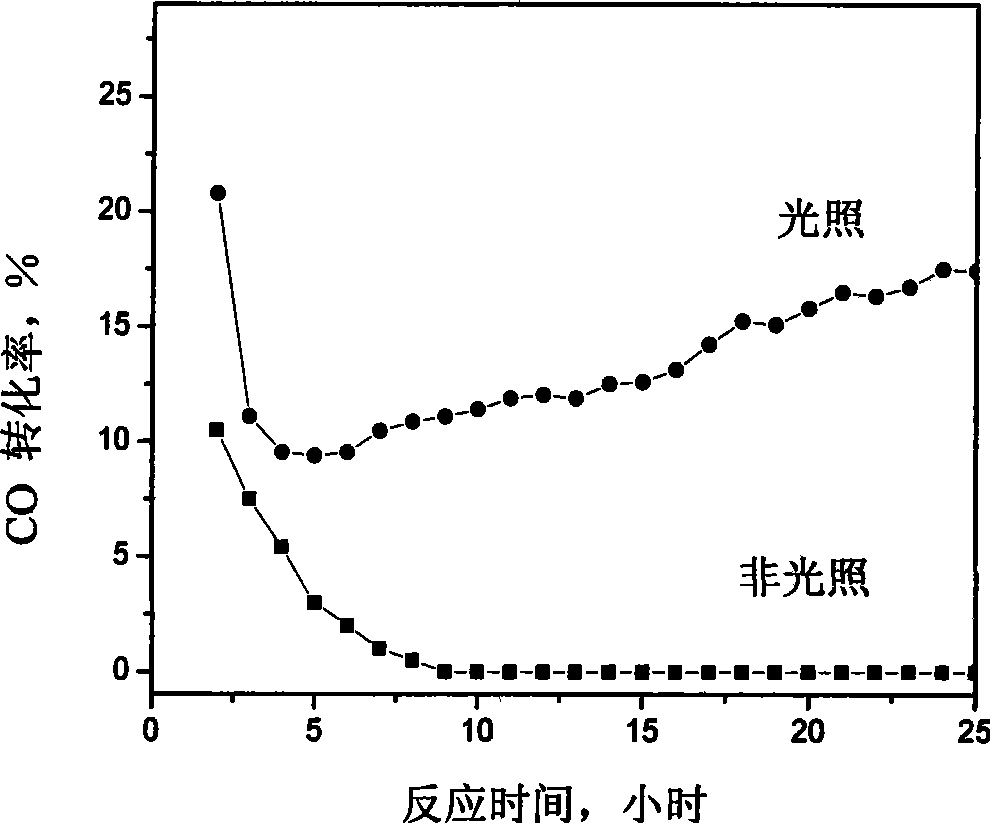

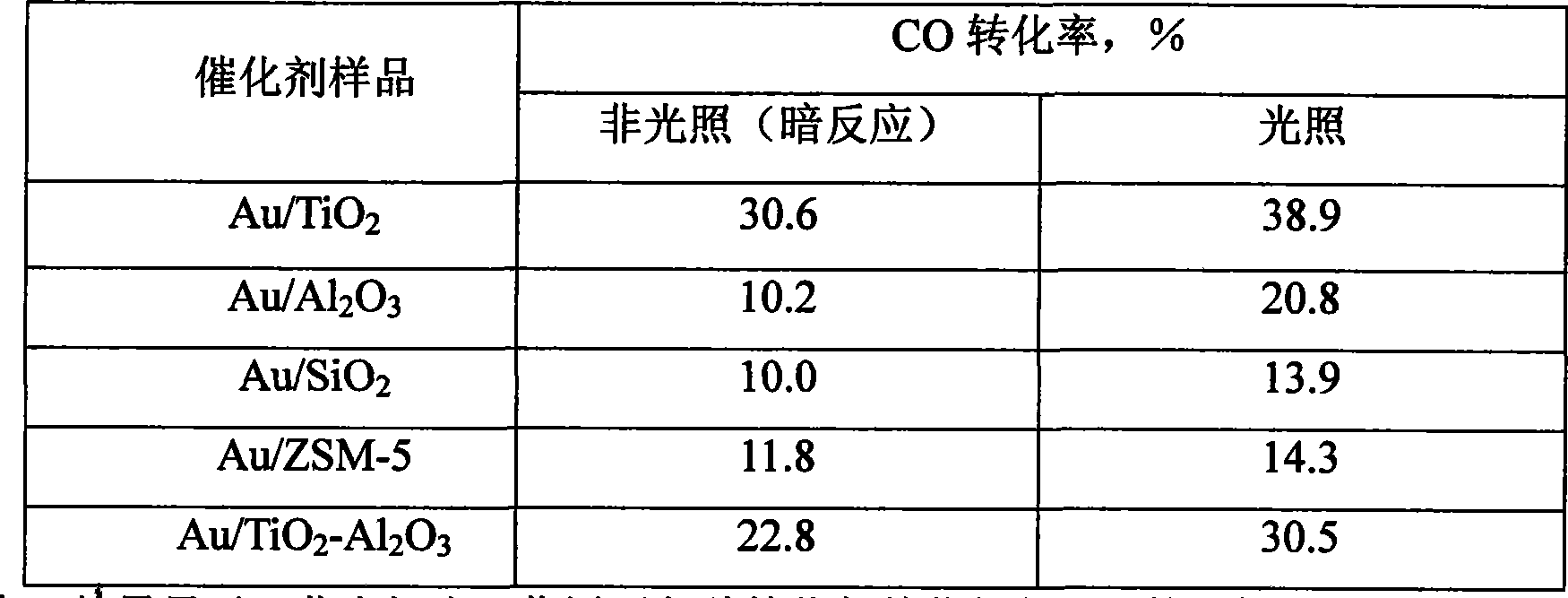

Technique for improving capability of removing CO with supported nano-Au catalyst normal temperature oxidization

InactiveCN101367040AImprove activity and stabilityExpand the scope of applicationMolecular sieve catalystsCell electrodesLight sourceSunlight

The invention provides a technology for improving the CO removing performance of a supported type nanometer Au catalyzer through oxidation at a room temperature. According to the technology, visible light acts on the surface of the supported type nanometer Au catalyst, and the performance of the catalyst for oxidizing CO is improved through the plasma resonance absorption of the surfaces of the nanometer Au particles. According to the invention, after the visible light is introduced onto the surface of the catalyst, the plasma resonance absorption is generated on the surfaces of the nanometer Au particles under the action of the visible light, and consequently the activity and stability of the Au catalyst for catalyzing and oxidizing CO are improved. Furthermore, the introduction of the light can also improve the temperature of the surface of the catalyst so as to improve the thermal catalytic activity of the catalyst. The technology has a simple and easy operation process. Natural light, sunlight and an artificial visible light source can be taken as the visible light source. The technology is suitable for a plurality of occasions for removing CO.

Owner:FUZHOU UNIVERSITY

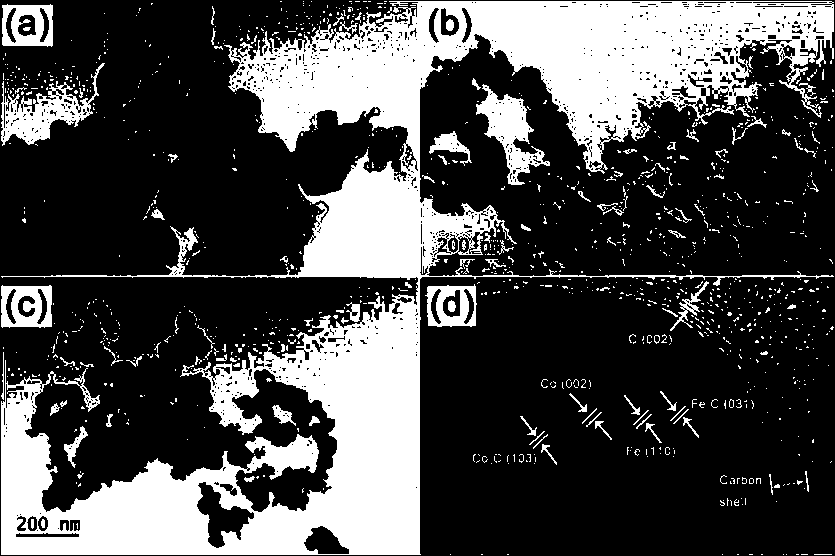

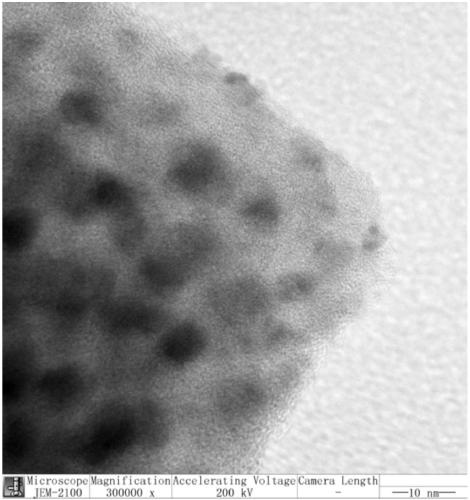

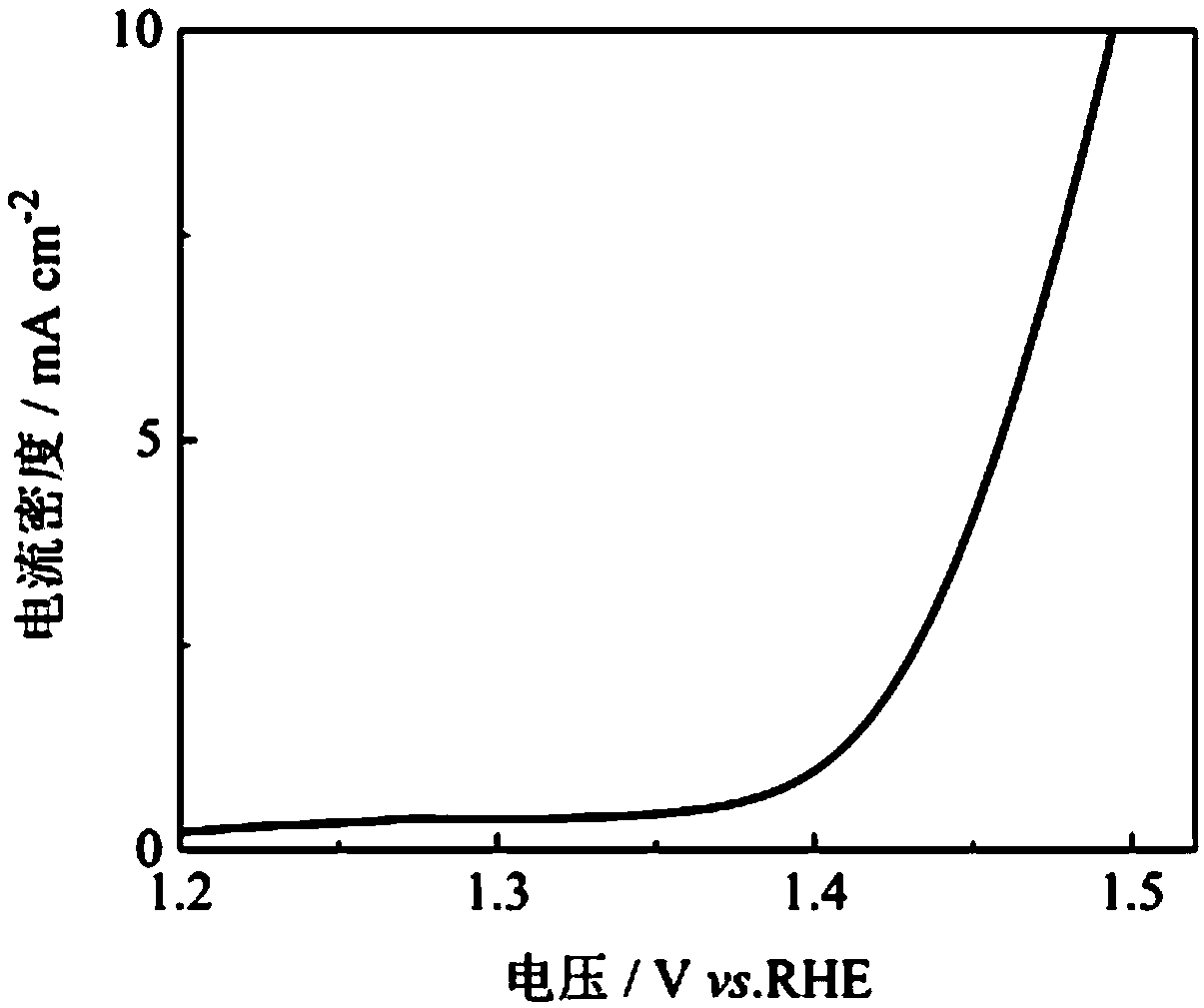

Water electrolysis hydrogen production catalyst and preparation method thereof

ActiveCN108315758AImprove activity and stabilityHigh activityElectrode shape/formsPotassium ferrocyanideCOBALTOUS NITRATE

The invention belongs to the technical field of water electrolysis hydrogen production and discloses a water electrolysis hydrogen production catalyst and a preparation method thereof. The catalyst has two structures, the first structure is a core-shell structure, the shell is a carbon shell, the carbon shell is doped with nitrogen, the core is a mixture of Fe, Co, Fe3C and Co3C, the second structure is a hollow carbon sphere structure and the carbon shell is doped with nitrogen. The preparation method comprises dissolving cobalt nitrate and sodium citrate in water to obtain a solution A, dissolving potassium ferrocyanide in water to obtain a solution B, fully mixing the solution A and the solution B under stirring, aging the mixture at the room temperature for at least 24h, then separating the precipitates, washing the precipitates with water and ethanol, carrying out drying to obtain a precursor, heating the precursor to 600-750 DEG C in an inert atmosphere, carrying out calcinationfor at least 1h, collecting the calcination product with the first structure, and immersing the calcination product with the first structure through an inorganic acid to obtain the product with the second structure. The catalyst has high activity and stability in water electrolysis hydrogen production.

Owner:ZHENGZHOU UNIV

Preparation method of graphene-multi-element metal positive electrode material

InactiveCN103811749AImprove activity and stabilityImprove electrical conductivity and cycle stabilityCell electrodesSecondary cellsCvd grapheneManganese oxide

The invention relates to a preparation method of a graphene-multi-element metal positive electrode material. The method comprises the following steps: (1) weighing lithium hydroxide, magnesium oxide, manganese oxide, aluminium hydroxide, cobaltous oxide and zirconia according to the molar weights of Li, Mg, Mn, Al, Co and Zr in the chemical formula of Li(1-x)MgxMn(1-y)AlyCo(1-z)ZrzO4, wherein x is equal to 0.2-0.25, y is equal to 0.1-0.3, and z is equal to 0.05-0.1, mechanically mixing, carrying out ball milling, and drying so as to obtain powder, crushing, and sintering so as to obtain the multi-element metal positive electrode material; (2) preparing powdery graphene; and (3) mixing the powdery graphene and a polyethylene glycol solution, ultrasonically dispersing the mixture into ethyl alcohol to form a conductive graphene dispersive liquid; mixing the multi-element metal positive electrode material with the conductive graphene dispersive liquid, carrying out ball milling, drying, and sintering so as to prepare the graphene-multi-element metal positive electrode material. According to the graphene-multi-element metal positive electrode material prepared by the invention, active substances are formed by utilizing the multi-element metal material, and the surface of the graphene-multi-element metal positive electrode material is coated with a graphene material prepared by a specific method, and the activity and the stability of the material are improved.

Owner:詹炳辉

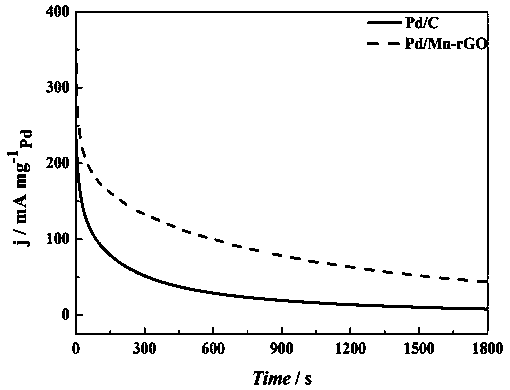

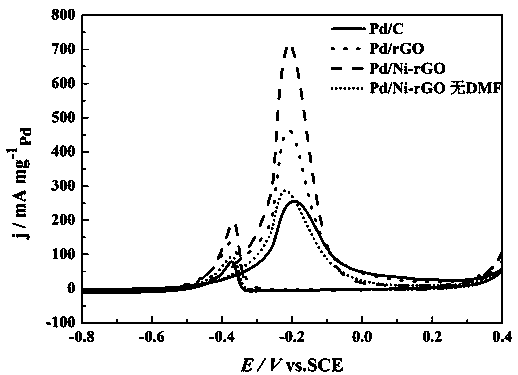

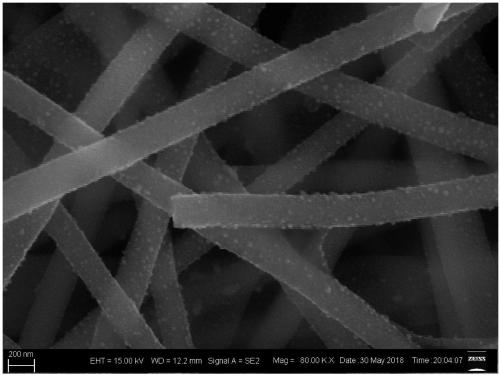

Nano-Pd/M-rGO composite catalyst and preparation method thereof

ActiveCN109433193AImprove activity and stabilityImprove catalytic performanceMaterial nanotechnologyCatalyst activation/preparationNano catalystFreeze dry

The invention relates to a nano-Pd / M-rGO composite catalyst and a preparation method thereof, and belongs to the technical field of nano-catalysts. The preparation method includes the steps: adding graphene oxide into N, N-dimethylformamide to ultrasonically strip mixture for 0.5-4 hours to obtain graphene oxide suspension liquid; uniformly mixing transition metal salt solution and the graphene oxide suspension liquid, performing reaction for 12-24 hours at the temperature of 160-200 DEG C in a stirred manner, cooling mixture to reach indoor temperature, filtering, washing and freeze-drying the mixture, and treating the mixture for 1-2 hours at the atmosphere temperature of 600-900 DEG C in Ar atmosphere to obtain an M-rGO composite material; uniformly mixing acetone, polyethylene glycol and Na2PdCl4 solution, and performing ultraviolet irradiation for 10-30 minutes to obtain a Pd nano-colloid; uniformly mixing the M-rGO composite material and the Pd nano-colloid to ultrasonically treat mixture for 10-15 minutes, continuing to stir the mixture for 3-5 hours, and filtering, washing and freeze-drying the mixture to obtain the nano-Pd / M-rGO composite catalyst. The Pd / M-rGO catalyst has the advantages of good dispersibility and stability and excellent catalytic activity.

Owner:KUNMING UNIV OF SCI & TECH

Chemical copper plating liquid as well as preparation method and chemical copper plating method thereof

ActiveCN104018140AImprove activity and stabilityLower reaction potentialLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention provides a chemical copper plating liquid and a preparation method thereof. The chemical copper plating liquid contains a copper salt, a complexing agent, a stabilizing agent, a reductant and a surfactant, and further contains imidazole quinolinic acid. The invention further provides a preparation method of the chemical copper plating liquid and a method for chemical plating by using the chemical copper plating liquid. Due to addition of the imidazole quinolinic acid in a normal chemical copper plating liquid, the activity and the stability of the chemical copper plating liquid provided by the invention are effectively improved, and the chemical copper plating liquid is particularly applicable to an LDS (Laser Direct Structuring) copper plating process and is fast in plating speed.

Owner:BYD CO LTD

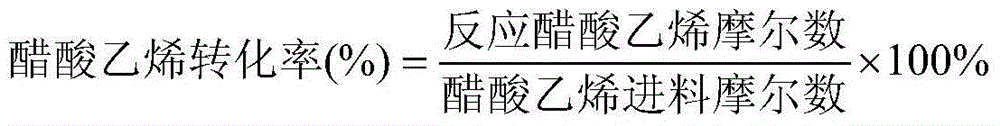

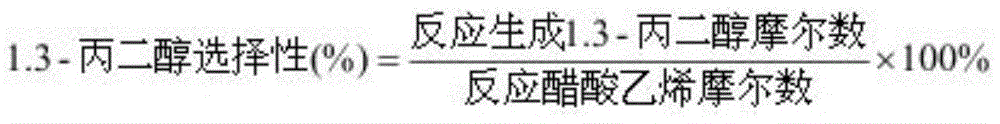

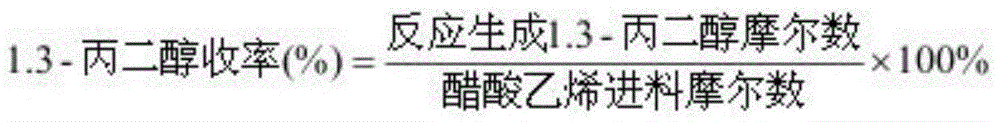

1,3-propanediol synthesis method

ActiveCN105585419AImprove activity and stabilityOrganic compound preparationCarboxylic acid esters preparationLow activityVinyl acetate

The invention relates to a 1,3-propanediol synthesis. The invention mainly aims at solving the problems of low activity and low selectivity of 1,3-propanediol catalyst in prior arts. The 1,3-propanediol synthesis method comprises the following steps: vinyl acetate is subjected to hydroformylation, such that 3-acetoxypropionaldehyde is obtained; 3-acetoxypropionaldehyde is hydrogenated, such that 3-acetoxypropanol is obtained; and 3-acetoxypropanol is is hydrolyzed, such that 1,3-propanediol is obtained. A hydroformylation catalyst adopts SiO2, Al2O3 or a mixture thereof as a carrier, and active components comprise rhodium, alkali metal and at least one metal element selected from IVA and IVB. With the above technical scheme, the technical problem is well solved. The method can be applied in 1,3-propanediol industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increasing activity and stability of microbial surface-displayed organophosphorus hydrolase

ActiveCN106867955AImprove activity and stabilityEasy to prepareChemical cell growth stimulationChemistryPhosphate

The invention relates to the fields of enzyme engineering and material science, and discloses a method for increasing activity and stability of microbial surface-displayed organophosphorus hydrolase. The method biomineralizes microbes displaying organophosphorus hydrolase on the surfaces to form a microbe-cobaltous phosphate hybrid material, and the material has higher activity and stability than microbial surface-displayed organophosphorus hydrolase before biomineralization. The method is simple, environment-friendly and effective.

Owner:QINGDAO AGRI UNIV

Catalyst for selective paraffin isomerization and preparation method and use thereof

ActiveUS20130248415A1High activityLow freezing pointMolecular sieve catalystsHydrocarbon oils refiningLiquid productAlkane

The present invention discloses a catalyst for paraffin isomerization, as well as a preparation method and use thereof. The catalyst comprises a TON molecular sieve modified by rare earth, an inorganic refractory oxide modified by zirconium oxide and a noble metal of group VIII. The weight ratio of the TON molecular sieve modified by rare earth to the inorganic refractory oxides modified by zirconium oxide is 10:90 to 90:10, and the content of the metal of group VIII is 0.1 to 10 wt % based on the metal. When used in the process of isomerization dewaxing of various raw materials containing paraffins, the catalyst can not only decrease the solidifying points of raw oil containing paraffins, but also increase the yield of liquid products. Particularly, when used in the process of isomerization dewaxing of lubricating oil distillates, the catalyst is advantageous in producing base oil for lubricating oil with a high a higher yield, a lower pour point (solidifying point) and a higher viscosity index.

Owner:CHINA PETROCHEMICAL CORP +1

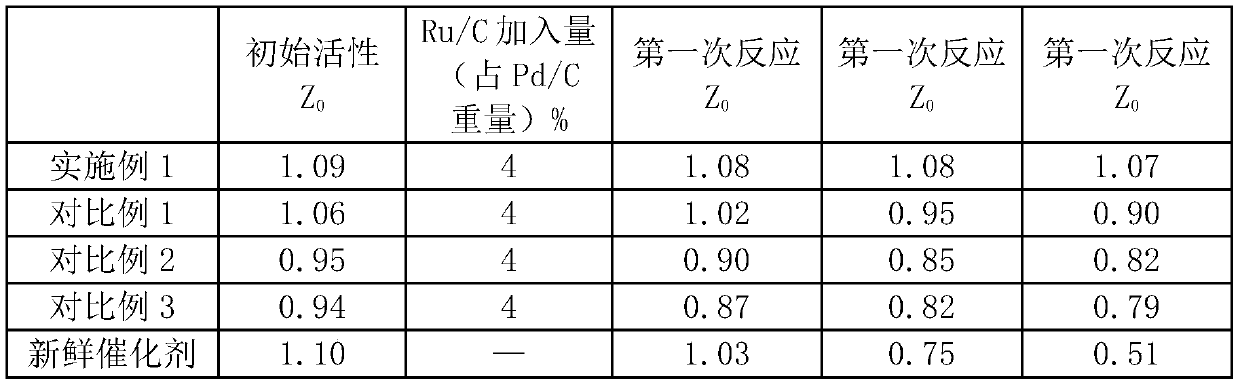

Benzoic acid hydrogenation continuous reaction device and method thereof

ActiveCN110961067AReduce manufacturing costImprove activity and stabilityProcess control/regulationCarboxylic preparation by ozone oxidationFormic acidCatalytic hydrogenation

The invention discloses a benzoic acid hydrogenation continuous reaction device and a method thereof. The method includes: under the action of a Pd / C catalyst and a Ru / C assistant, carrying out contact reaction on molten benzoic acid and hydrogen to generate cyclohexanecarboxylic acid, and after the reaction, depositing the mixed solution in a buffer tank to separate most of the Pd / C catalyst andthe Ru / C assistant from the mixed solution, and directly circulating the Pd / C catalyst and the Ru / C assistant back into the reaction tank for reuse; after the buffer tank is full, letting the mixed solution overflow from the top into a carbon rod filter for further separation, and circulating the separated turbid liquid containing the high-concentration Pd / C catalyst and Ru / C assistant back to a raw material tank system; and making the clear liquid of a carbon rod filter shell layer directly enter a next production procedure. The device does not discharge the catalyst and also has no need forfrequent adding of a fresh catalyst, so that the cost of the catalyst in the continuous preparation process can be saved, the processing cost of the benzoic acid hydrogenation reaction is lowered, thecatalytic hydrogenation activity of the Pd / C catalyst is improved, and the production capacity of the device is increased.

Owner:WUHAN YOUJI IND

Precious metal water-gas shift catalyst with oxide support modified with rare earth elements

InactiveUS7704486B2Improve activity and stabilityImprove stabilityHydrogenHeterogenous catalyst chemical elementsRare-earth elementBurning out

A water gas shift catalyst comprising a platinum group metal dispersed on an inorganic oxide support modified with a carbon-containing burn-out additive and a rare earth oxide. A water gas shift catalyst containing alumina, a platinum group metal, and oxides of Pr and Nd are also disclosed.

Owner:BASF CATALYSTS LLC

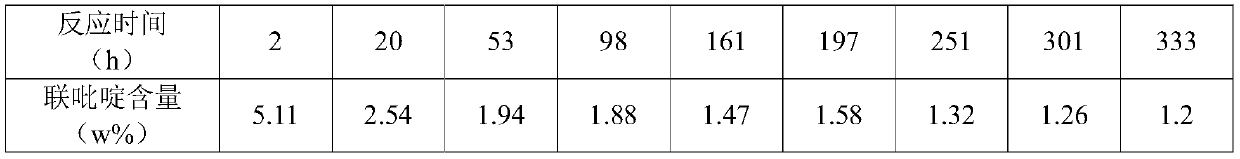

Catalyst for preparing 2,2'-bipyridine by pyridine coupling and preparation method and application thereof

PendingCN110801841AImprove activity and stabilityHigh activityOrganic chemistryCatalyst activation/preparationPoly ethyleneFixed bed

The invention provides a catalyst for preparing 2,2'-bipyridine by pyridine coupling and a preparation method and application thereof. The catalyst takes nickel as a main active component, and macroporous alumina modified by one or more of silica, oxalic acid, nitric acid, sulfuric acid and hydrochloric acid as a carrier, and adopts a conventional impregnation method to prepare the nickel / aluminacatalyst. During impregnation, L-arginine, cetyltrimethylammonium bromide (CTAB), polyvinylpyrrolidone (PVP) and the like are added to promote metal dispersion. The catalyst can be used to realize continuous reaction for preparing the 2,2'-bipyridine by pyridine coupling in a fixed bed reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Compositions and processes for reducing NOx emissions during fluid catalytic cracking

ActiveUS7918991B2Improve activity and stabilityAccelerate emissionsCatalytic crackingMolecular sieve catalystsParticulatesProcess conditions

Compositions for reduction of NOx generated during a catalytic cracking process, preferably, a fluid catalytic cracking process, are disclosed. The compositions comprise a fluid catalytic cracking catalyst composition, preferably containing a Y-type zeolite, and a NOx reducing zeolite having a pore size ranging from about 2 to about 7.2 Angstroms and a SiO2 to Al2O3 molar ratio of less than about 500 and being stabilized with a metal or metal ion selected from the group consisting of zinc, iron and mixtures thereof. Preferably, the NOx reducing zeolite particles are bound with an inorganic binder to form a particulate composition. In the alternative, the NOx reducing zeolite particles are incorporated into the cracking catalyst as an integral component of the catalyst. Compositions in accordance with the invention exhibit improved effectiveness for the reduction of NOx emissions released from the regenerator of a fluid catalytic cracking unit operating under FCC process conditions without a substantial change in conversion or yield of cracked products. Processes for the use of the compositions are also disclosed.

Owner:WR GRACE & CO CONN

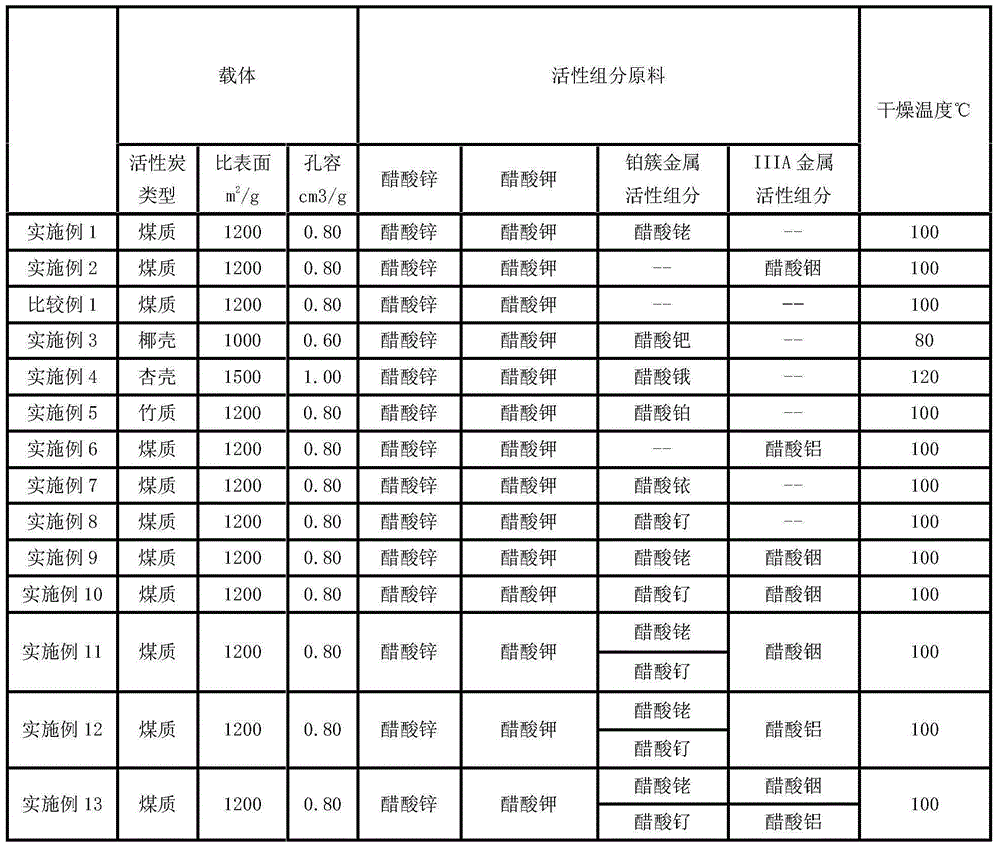

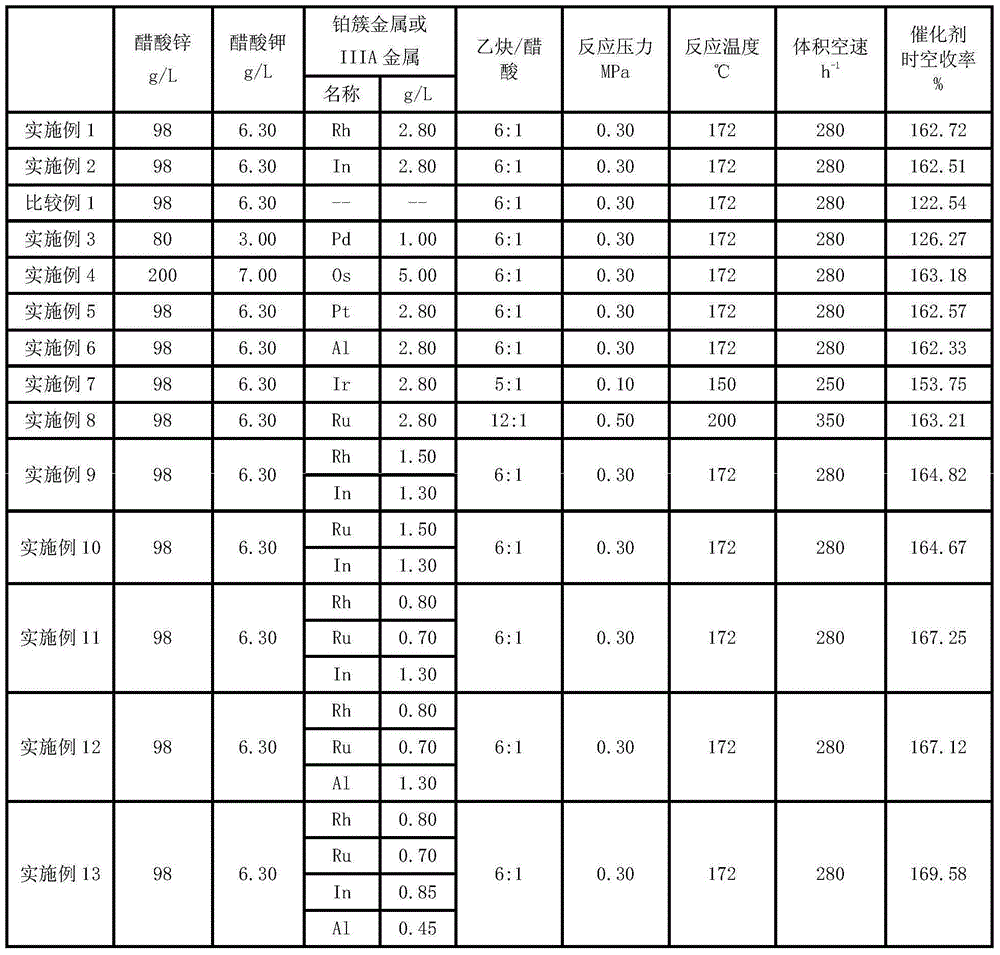

Catalyst for synthesizing vinyl acetate through acetylene method

ActiveCN106423157AImprove activity and stabilityHigh yieldOrganic compound preparationCarboxylic acid esters preparationZinc Acetate DihydrateActivated carbon

The present invention relates to a catalyst for synthesizing vinyl acetate through an acetylene method. A purpose of the present invention is to mainly solve the problem of not high activity of the catalyst of the acetylene gas phase method in the prior art. According to the present invention, the catalyst uses active carbon as a carrier, and active components comprise zinc acetate, potassium acetate and the compound of at least an element selected from a platinum group metal element and a IIIA metal element. With the technical scheme, the problem in the prior art is well solved. The catalyst of the present invention can be used for the industrial vinyl acetate production through the acetylene gas phase method.

Owner:CHINA PETROLEUM & CHEM CORP +1

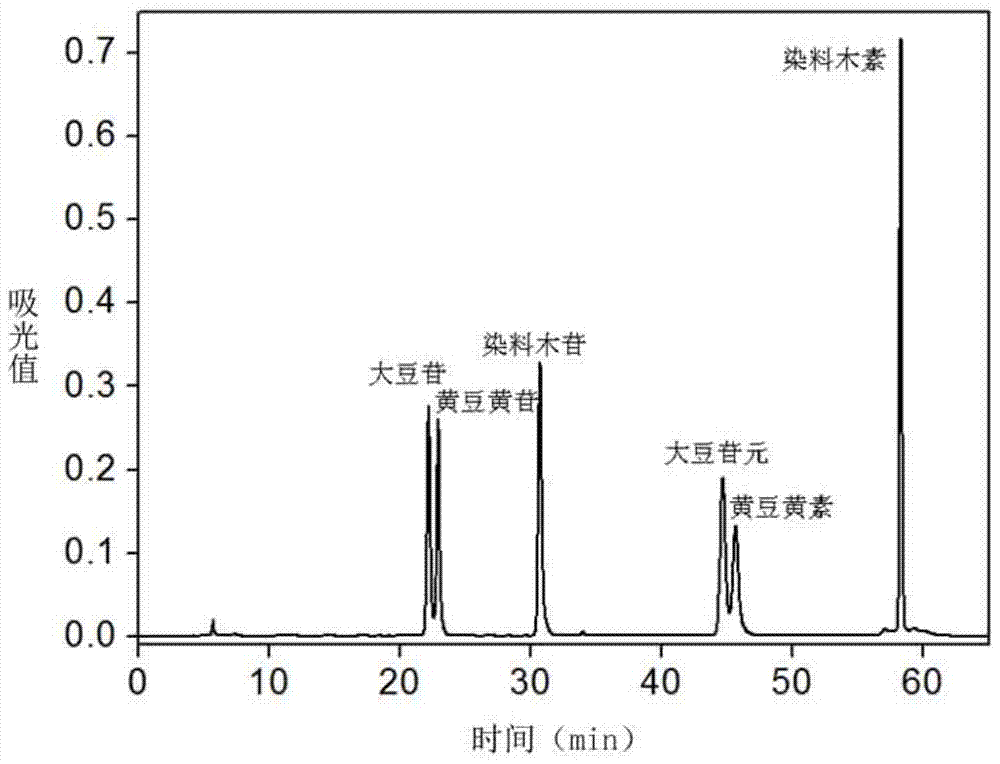

Method for preparing functional soybean protein by enzyme-assistant subcritical water method

ActiveCN104286370AAchieve strong binding and enrichmentImprove activity and stabilityProtein composition from vegetable seedsAlgluceraseChemistry

The invention discloses a method for preparing functional soybean protein by an enzyme-assistant subcritical water method The method comprises the following steps: 1)adding deionized water in high-temperature degreased soybean meal, adjusting pH value, adding beta-glucosidase or protease M for stirring and enzymatic hydrolysis; 2)adjusting the pH value of a soybean meal slurry through enzymatic hydrolysis and then performing subcritical water treatment; 3)cooling the obtained feed liquid, centrifuging and collecting an supernatant, adjusting the pH value to acidic, and standing; and 4) centrifuging the obtained protein slurry, depositing and redissolving in the deionized water, adjusting the pH value to neutrality, and freezing and cooling to obtain the aglycone isoflavone-rich functional soybean protein. The method has the advantage of high protein yield, is suitable for industrial production, and can reach the effect for enrichment of aglycone isoflavone, the product has good antioxidation performance, and can be used as a special-purpose protein ingredient for dairy product and vegetable protein beverage for menopause women.

Owner:SOUTH CHINA UNIV OF TECH

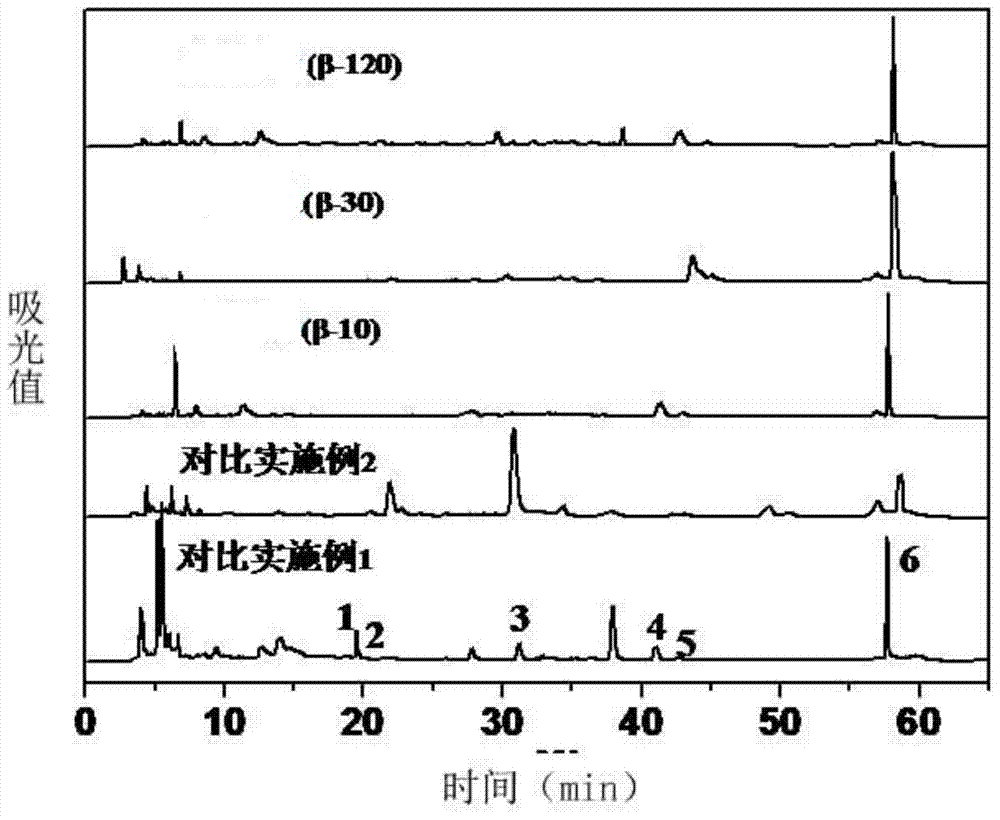

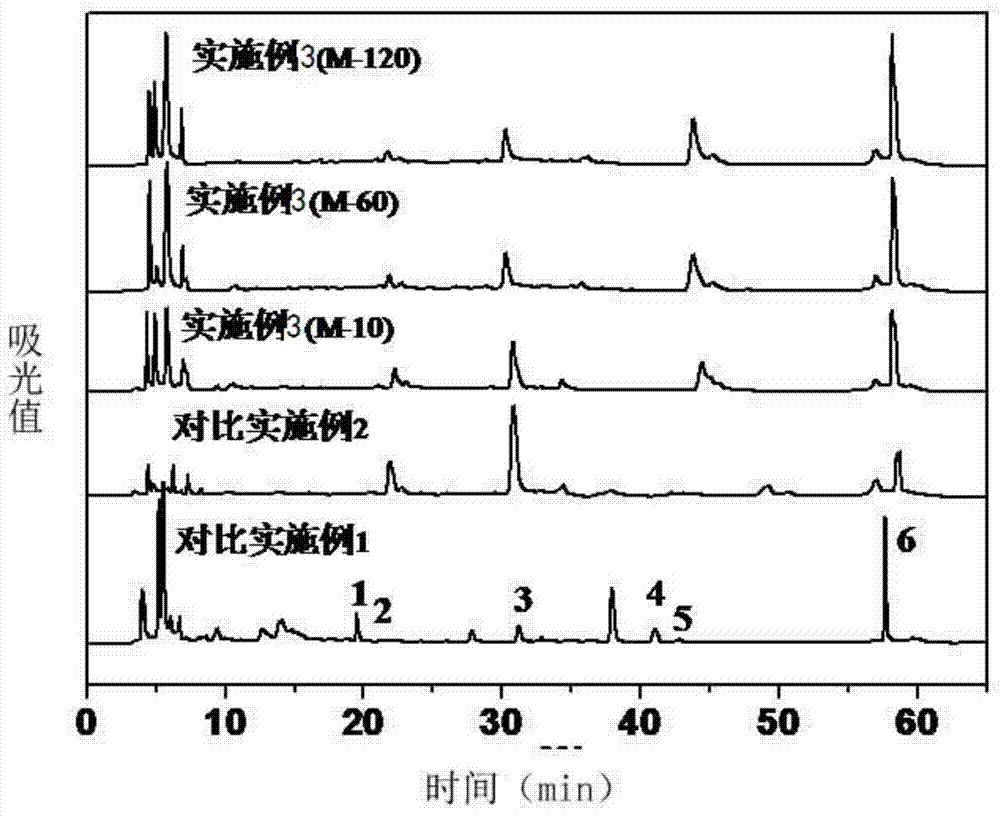

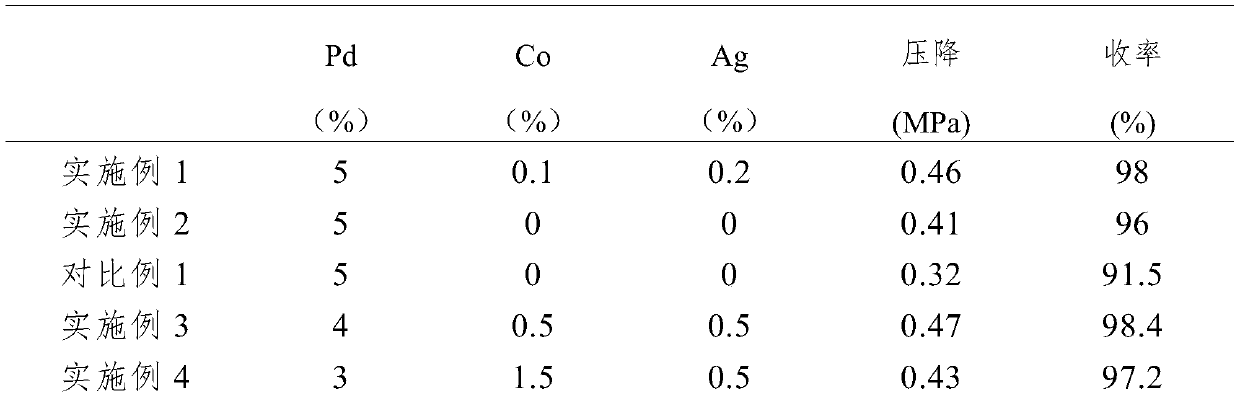

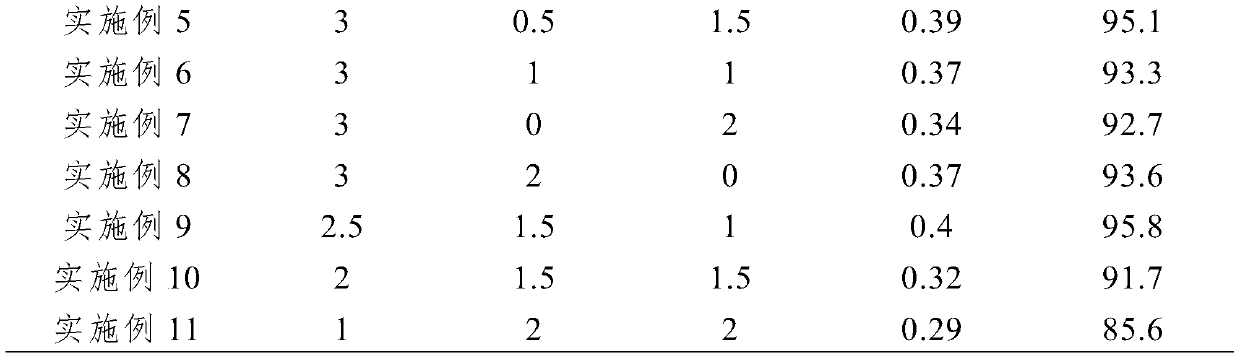

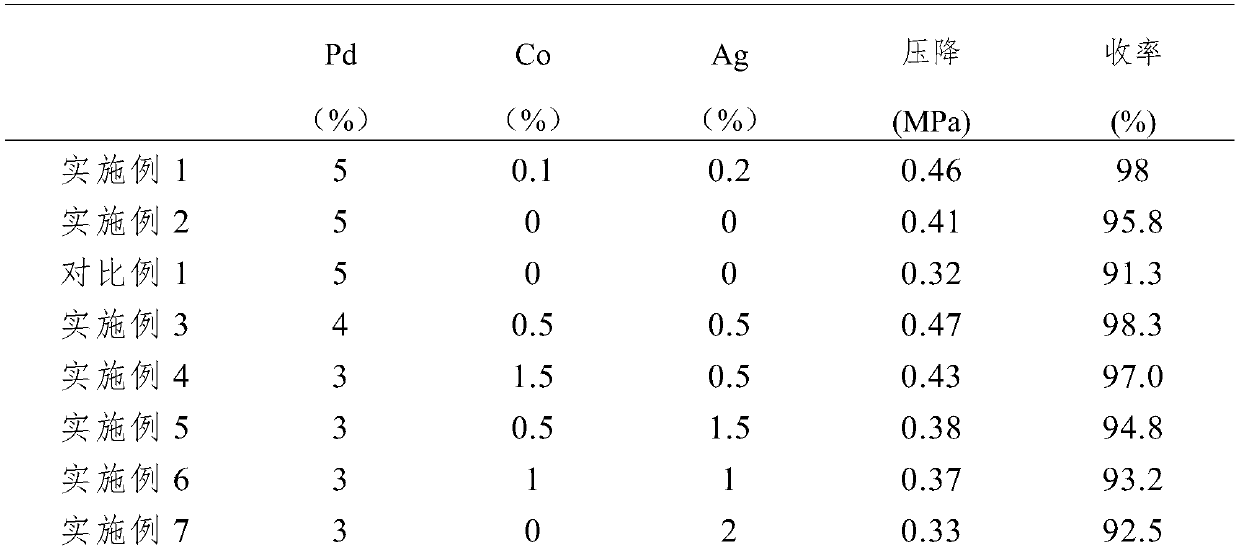

Method for preparing catalyst for nitro reduction and application

ActiveCN110694641AImprove activity and stabilityLow loadOrganic compound preparationChemical recyclingNitrobenzeneActivated carbon

The invention discloses a method for preparing a catalyst for nitro reduction. The method comprises the steps: (1) cooking activated charcoal in hydrochloric acid; (2) cooking the acid treated activated charcoal in an alkaline solution; (3) cooking the alkali treated activated charcoal in an oxidant solution, and carrying out pulping; (4) mixing a palladium chloride solution, a dispersant and oxidated activated charcoal pulp, carrying out stirring, and carrying out aging, so as to obtain a suspension; or mixing assistant metal with the oxidated activated charcoal pulp, carrying out stirring and pulping, then, mixing the palladium chloride solution, the dispersant and the assistant loaded activated charcoal pulp, carrying out stirring, and carrying out aging, so as to obtain the suspension;and (5) subjecting the suspension to reduction, thereby obtaining the catalyst for nitro reduction. In addition, the invention further provides an application of the catalyst prepared by adopting theabove-mentioned method in a hydrogenation reaction of o-nitroaniline. In a nitro reduction reaction of the o-nitroaniline, the catalyst shows superior performance, the pressure drop is 0.28MPa or more, and the yield is 85.2% or more.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst and preparation method thereof

ActiveCN109046426ASimple and effective preparation methodImprove activity and stabilityPhysical/chemical process catalystsElectrodesFiber matrixElectrospinning

The invention discloses a nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst and a preparation method thereof, and relates to a nickel cobalt based carbon fiber electrolytic water catalyst and a preparation method thereof. The invention aims at solving the problems of low electrolytic efficiency and poor stability of a used catalyst in the existing preparation of hydrogen. The catalyst is prepared from a carbon fiber matrix and nanoparticles, wherein the nanoparticles are loaded at the inner part and on the surface of the carbon fiber matrix. Thepreparation method comprises the following steps: weighing nickel nitrate, cobalt nitrate and a thioamide compound according to the molar ratio of all elements in molecular formulae NixCoyNz and NiaCobSxc, and then adding polyvinyl pyrrolidone to obtain a precursor solution; carrying out electrostatic spinning and finally carrying out high temperature sintering. The nitrogen and sulfur in situ co-doped nickel cobalt based carbon fiber electrolytic water catalyst material, disclosed by the invention, has the advantages of better catalyst activity and stability and double function catalysis of hydrogen precipitation and oxygen precipitation; the electrolytic efficiency reaches as high as 95 percent. The preparation method disclosed by the invention is suitable for preparing an electrolytic water catalyst.

Owner:HARBIN INST OF TECH

Fluid bed catalyst for acrylonitrile production

ActiveCN101306372AImprove activity and stabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedAtomic ratio

The invention relates to a fluidized bed catalyst which is used for producing acrylonitrile through propene ammoxidation, and mainly solves the problems of lower propene loading and lower reaction pressure in the prior art. The invention adopts a mixture which takes silicon dioxide as a carrier and has the chemical formula calculated in atomic ratio as follows: AaBbCcDdTeeNifMggFehBijMo12Ox, wherein, A is at least one of Li, Na, K, Rb and Cs; B is at least one of La, Ce, Nd and Eu; C is at least one of Cr, W and Mn; and D is at least one of Cu, Zn, Ag, Cd, Ca and S r or at least one in the B; thereby the technical proposal can better solve the problems. The catalyst can be applied to the industrial production of the acrylonitrile under higher reaction pressure and higher propene loading condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

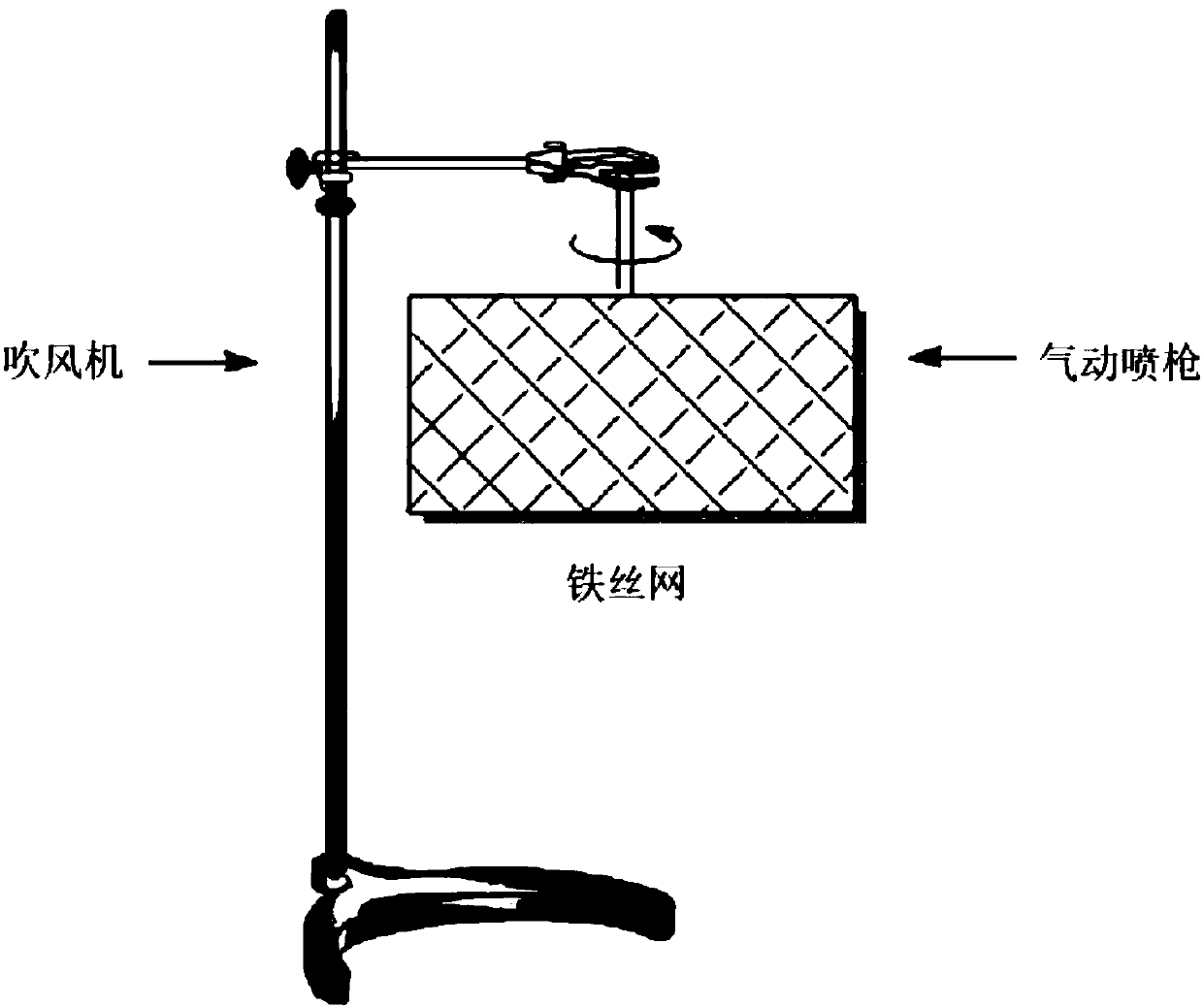

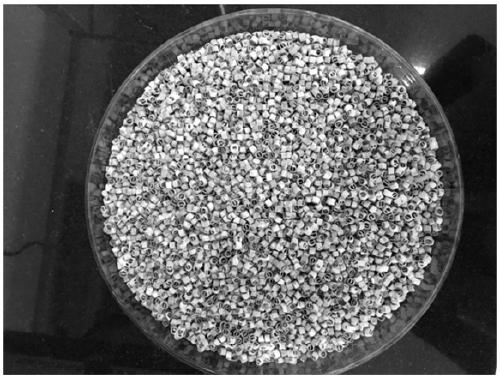

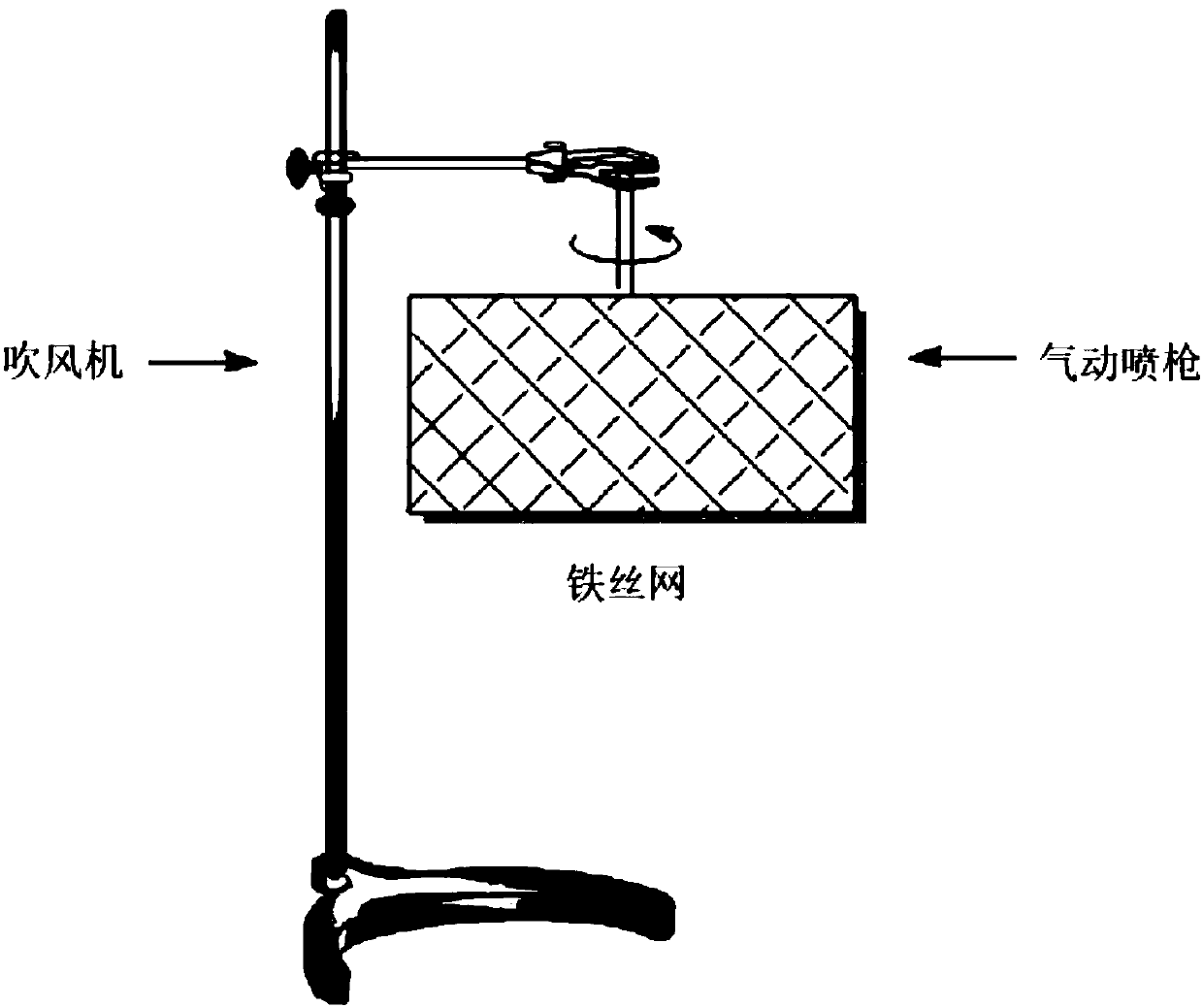

Enzyme-loaded filler and preparation method and application thereof

PendingCN109837271AImprove activity and stabilityEasy to preparePretreated surfacesFermentationEthyl acetateEthyl ester

The invention relates to an enzyme-loaded filler and a preparation method and application thereof. The preparation method of the enzyme-loaded filler lies in that enzyme-containing sol is sprayed to the surface of the filler, so that the enzyme-loaded filler is obtained. Compared with the enzymic activity and the stability of an enzyme-loaded filler prepared by an impregnation method, the enzymicactivity and the stability of the enzyme-loaded filler prepared by the preparation method disclosed by the invention are obviously improved; after the enzyme-loaded filler is stored at room temperature for 50 days, the enzymic activity loss is smaller than 5%, and the enzymic activity for catalyzing the rectification process of a transesterification reaction of ethyl acetate and n-butanol is 599-621U / g.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com