Method for preparing catalyst for nitro reduction and application

A catalyst and nitro technology, applied in the field of preparing catalysts for nitro reduction, can solve the problems of insufficient catalyst performance, low catalyst use efficiency, insufficient stability and activity, etc., to promote hydrogen dissociation and overflow, The effect of enhancing stability and activity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

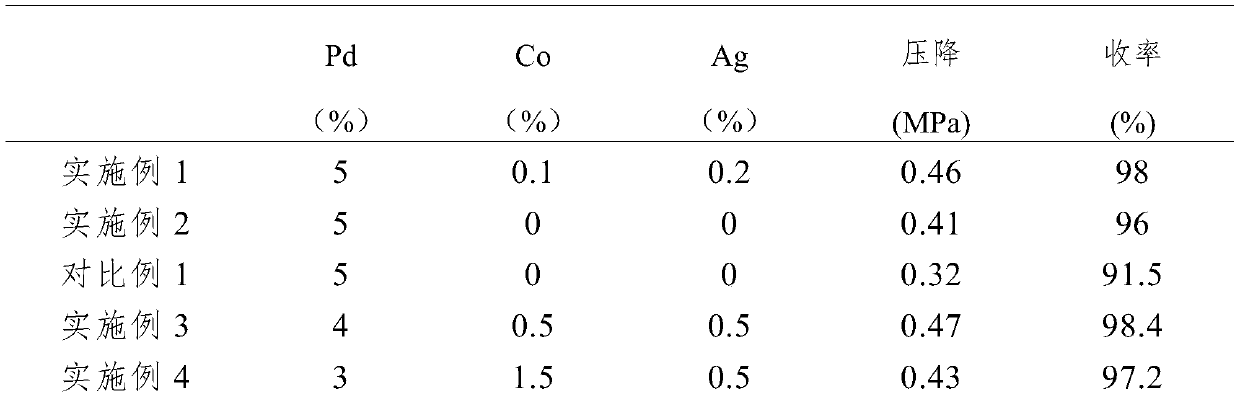

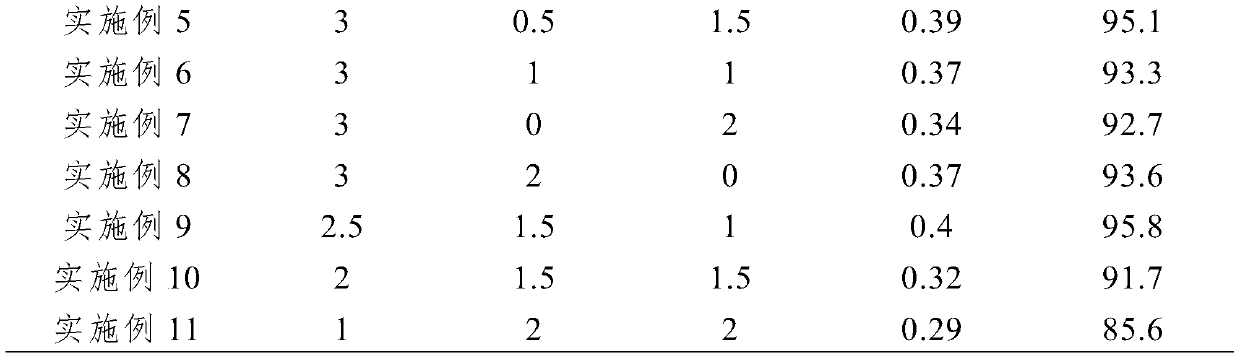

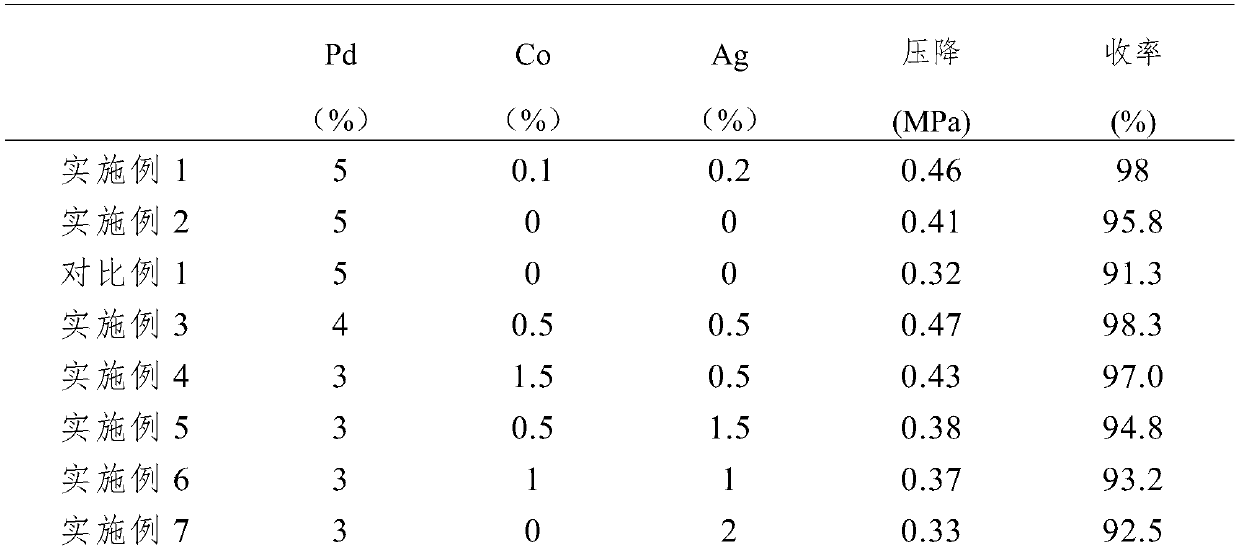

Examples

Embodiment 1

[0029] The method for preparing the catalyst for nitro reduction in this embodiment comprises the following steps:

[0030] Step 1. Place 100 g of activated carbon in 1000 g of hydrochloric acid solution with a mass concentration of 5%, carry out cooking treatment at 110° C. for 0.5 h, filter, wash the retentate with pure water until the pH is 6, and obtain acid-treated activated carbon;

[0031] Step 2, place the acid-treated activated carbon described in step 1 in 600 g of potassium hydroxide solution with a mass concentration of 15%, carry out cooking treatment at 80° C. for 0.5 h, filter, and wash the retentate with pure water until the pH is 8 , to obtain alkali-treated activated carbon;

[0032] Step 3, place the alkali-treated activated carbon described in step 2 in 1500 g of hydrogen peroxide with a mass concentration of 10%, carry out cooking treatment at 100° C. for 4 hours, filter, wash the retentate with pure water until the pH is 6, filter, and obtain the oxidized...

Embodiment 2

[0037] The method for preparing the catalyst for nitro reduction in this embodiment comprises the following steps:

[0038] Step 1. Place 100 g of activated carbon in 800 g of 5% hydrochloric acid solution, cook at 100° C. for 0.5 h, filter, wash the retentate with pure water until the pH is 6, and obtain acid-treated activated carbon;

[0039] Step 2, place the acid-treated activated carbon described in step 1 in 600 g of potassium hydroxide solution with a mass concentration of 20%, carry out cooking treatment at 80° C. for 1 h, filter, and wash the retentate with pure water until the pH is 8. Obtain alkali-treated activated carbon;

[0040] Step 3, place the alkali-treated activated carbon described in step 2 in 1500 g of hydrogen peroxide with a mass concentration of 10%, carry out cooking treatment at 100° C. for 3 h, filter, wash the retentate with pure water until the pH is 6, filter, and obtain the oxidized Activated carbon, the oxidized activated carbon is mixed with w...

Embodiment 3

[0049] The method for preparing the catalyst for nitro reduction in this embodiment comprises the following steps:

[0050] Step 1. Place 100 g of activated carbon in 600 g of hydrochloric acid solution with a mass concentration of 2%, carry out cooking treatment at 80° C. for 1 hour, filter, wash the retentate with pure water until the pH is 6, and obtain acid-treated activated carbon;

[0051] Step 2, place the acid-treated activated carbon described in step 1 in 500 g of a sodium hydroxide solution with a mass concentration of 15%, carry out cooking treatment at 70° C. for 2 h, filter, and wash the retentate with pure water until the pH is 8. Obtain alkali-treated activated carbon;

[0052] Step 3, place the alkali-treated activated carbon described in step 2 in 1000 g of nitric acid solution with a mass concentration of 5%, carry out cooking treatment at 110° C. for 2 h, filter, wash the retentate with pure water until the pH is 6, filter, and obtain the oxidized After ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com