Enzyme-loaded filler and preparation method and application thereof

A spraying method and sol technology, applied in the field of enzyme catalysis, can solve the problems of insufficient activity and poor stability of enzyme-loaded fillers, and solve the problems of insufficient stability and poor activity of enzyme-loaded fillers, and achieve easy industrial application, activity and stability Enhanced performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

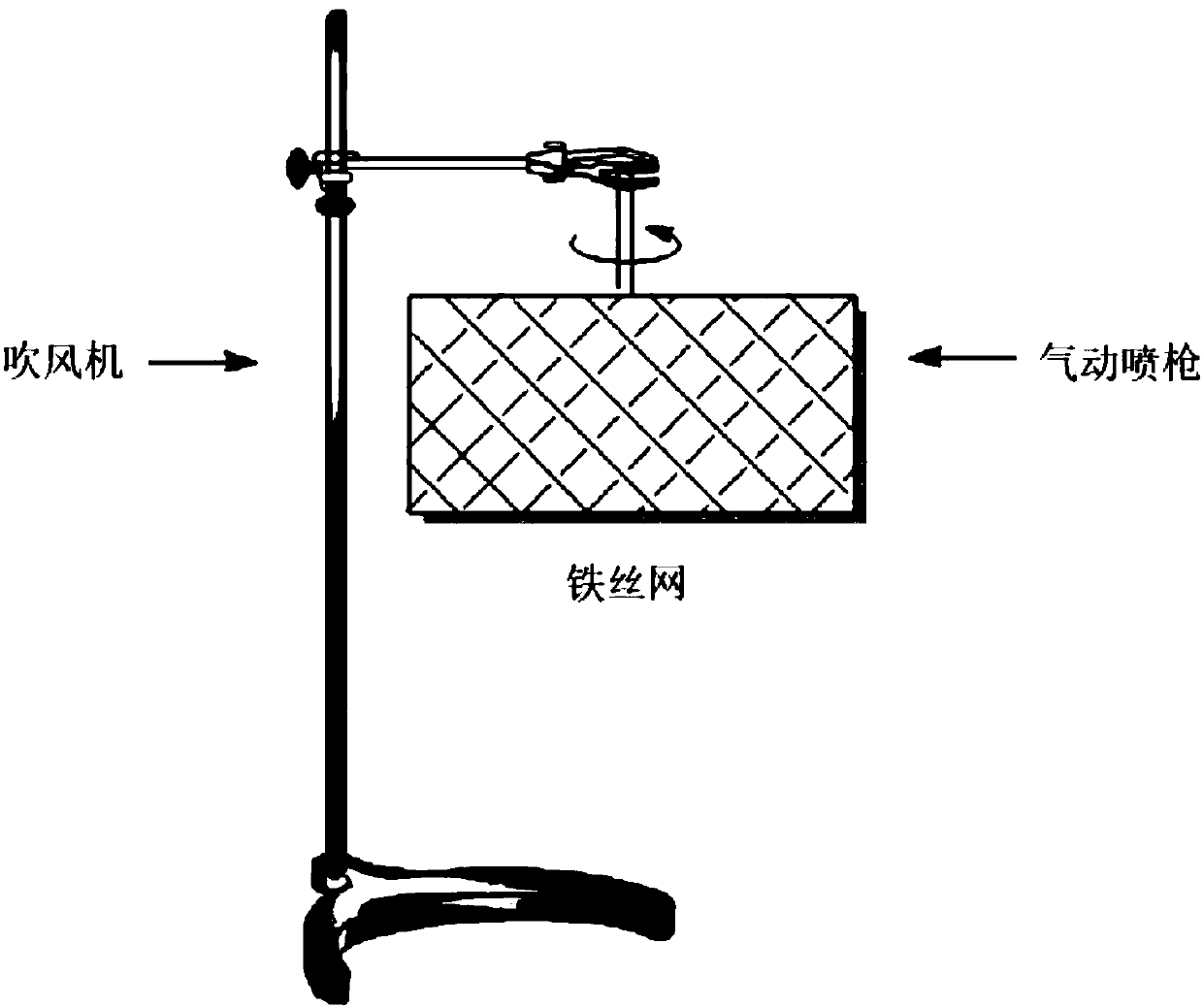

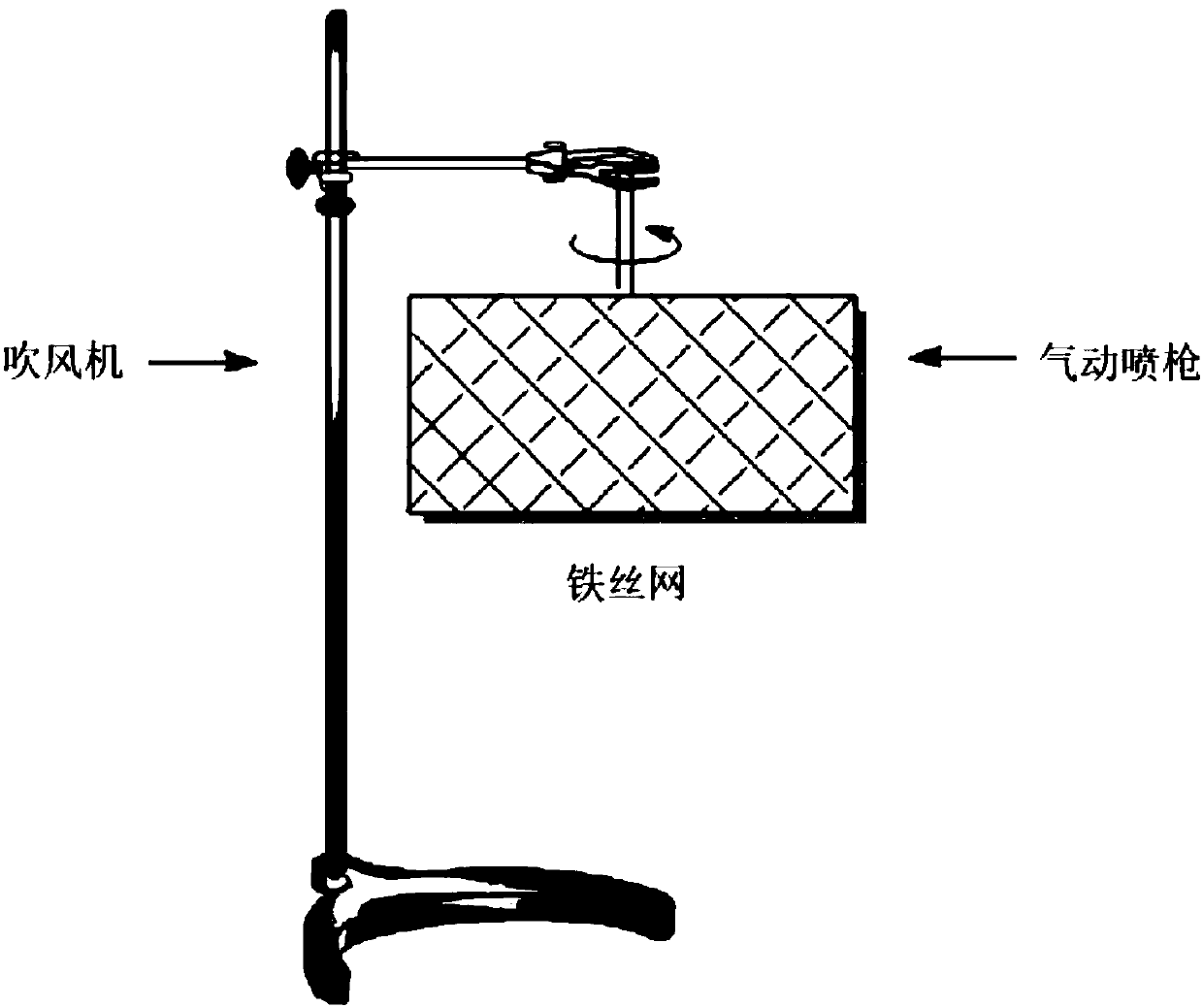

[0059] The schematic diagram of the preparation method of the enzyme-carrying filler of the present invention is as figure 1 Shown, as can be seen from the figure, the preparation method of described enzyme-carrying filler comprises the following steps:

[0060] (1) Fix the filler on the mechanical rotator with wire mesh, adjust the speed to make it rotate at a constant speed;

[0061] (2) Spray the enzyme-containing sol on the surface of the filler with a pneumatic spray gun on one side of the mechanical rotator, and dry it with a hair dryer on the other side to obtain the enzyme-loaded filler.

Embodiment 1

[0064] The preparation method of the enzyme-carrying filler of the present embodiment comprises the following steps:

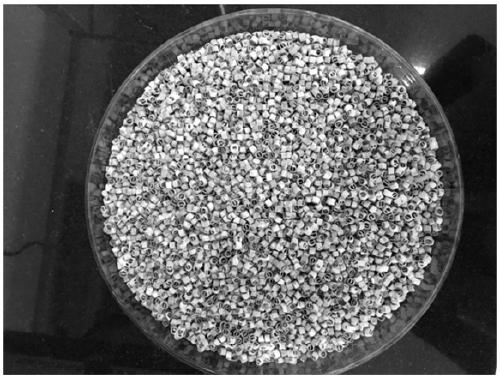

[0065] (1) Use wire mesh to fix the metal Θ ring packing on the mechanical rotator, adjust the rotating speed to make it rotate at a constant speed;

[0066] (2) Utilize a spray gun to spray the enzyme-containing sol on the filler surface, the spraying process adopts "zigzag" spraying, and in the process of the spraying, a hair dryer is used to dry the surface of the metal Θ ring filler to obtain the enzyme-containing filler, and the spraying The air pressure is 0.15MPa, the flow rate of the spraying is 1.82kg / h, and the distance between the spray gun and the filler surface during the spraying process is 15cm.

[0067] The specification of the metal Θ ring packing used in this embodiment is 3cm×3cm, and the following examples and comparative examples all adopt the metal Θ ring packing of this specification.

[0068] The preparation method of the enzyme sol of...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is that the air pressure of spraying is replaced by 0.2MPa, the flow rate of spraying is replaced by 2.05kg / h, the distance between the spray gun and the surface of the filler is replaced by 20cm, and other conditions are exactly the same as in embodiment 1 .

[0075] The enzyme-containing sol used in this example is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com