Method for preventing pore passages from being flooded with water in catalyst layer of fuel cell

A fuel cell and catalytic layer technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as voltage loss, blockage, and inability to effectively protect micropores, so as to improve activity and stability and prevent flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The molecular weight of dimethyl silicone oil is 9.4k; the viscosity is 200cp, which is used to prepare Fe / N / C ink;

[0019] Add simethicone (9.4kD, 200cp) to the cathode ink, and the ink composition is: Fe / N / C catalyst 25mg; simethicone (9.4kD, 200cp) 50mg; 5wt% nafion solution 0.55mL; solvent iso Propanol 1mL; place the cathode ink in an ice-water bath and ultrasonically disperse it evenly; prepare a gas diffusion electrode (GDS) by drop coating, and the final cathode catalyst loading is 5mgcm -2 ;

[0020] The preparation method of the anode gas diffusion electrode is similar to that of the cathode, and the ink composition is Pt-Ru / C (40wt%Ptand20wt%Ru, JohnsonMatthey)-20mg; 5wt% nafion solution 0.22mL; deionized water 0.2mL; isopropanol 0.4mL; The cathode ink was placed in an ice-water bath and ultrasonicated for 10 minutes; the gas diffusion electrode (GDS) was prepared by drop coating, and the final anode metal loading was 4mgcm -2 ;

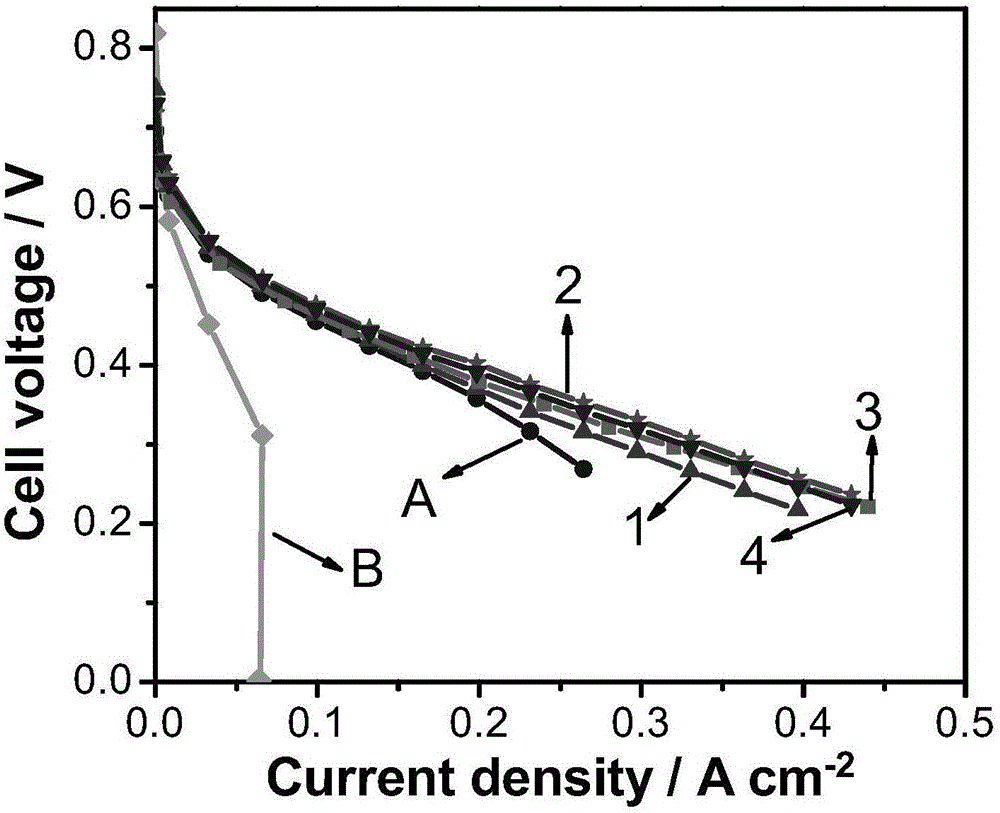

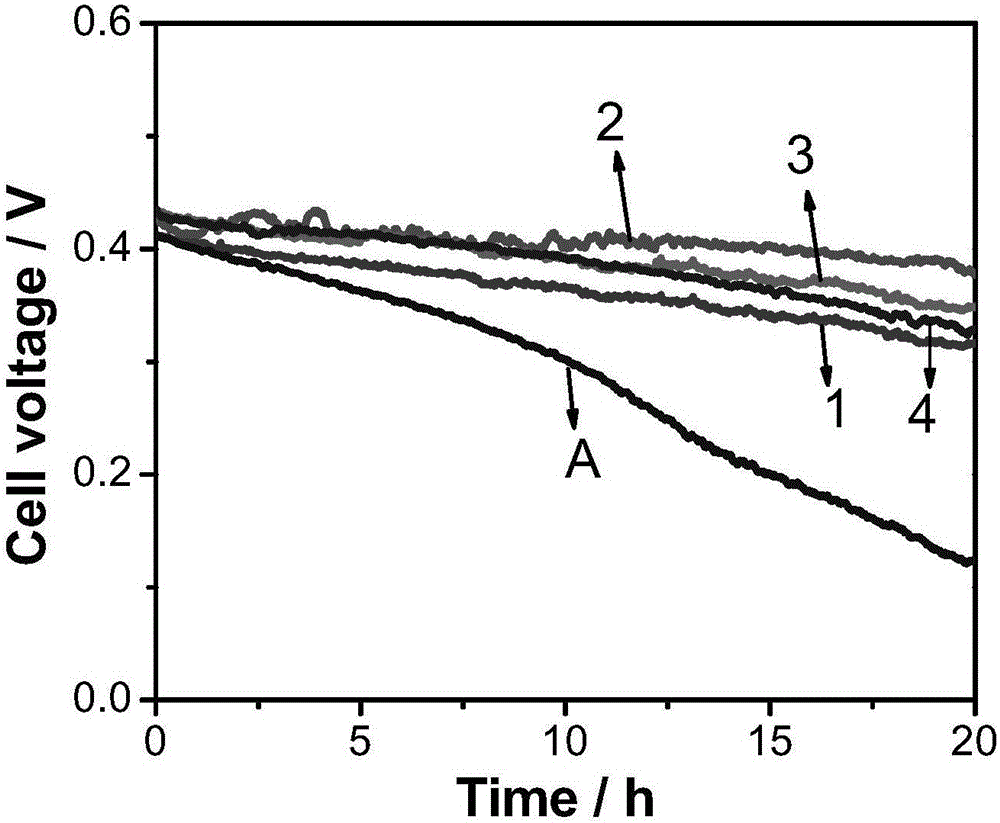

[0021] The prepared gas d...

Embodiment 2

[0023] The molecular weight of simethicone oil is 28k; the viscosity is 1000cp, which is used to prepare Fe / N / C ink;

[0024]Add simethicone (28kD, 1000cp) to the cathode ink, and the ink is composed of: Fe / N / C catalyst 25mg; simethicone (28kD, 1000cp) 50mg; 5wt% nafion solution 0.55mL; solvent isopropanol 1mL; place the cathode ink in an ice-water bath and ultrasonically disperse it evenly; prepare a gas diffusion electrode (GDS) by drop coating, and the final cathode catalyst loading is 5mgcm -2 ;

[0025] The preparation method of the anode gas diffusion electrode is similar to that of the cathode, and the ink composition is Pt-Ru / C (40wt%Ptand20wt%Ru, JohnsonMatthey)-20mg; 5wt% nafion solution 0.22mL; deionized water 0.2mL; isopropanol 0.4mL; The cathode ink was placed in an ice-water bath and ultrasonicated for 10 minutes; the gas diffusion electrode (GDS) was prepared by drop coating, and the final anode metal loading was 4mgcm -2 ;

[0026] The prepared gas diffusion...

Embodiment 3

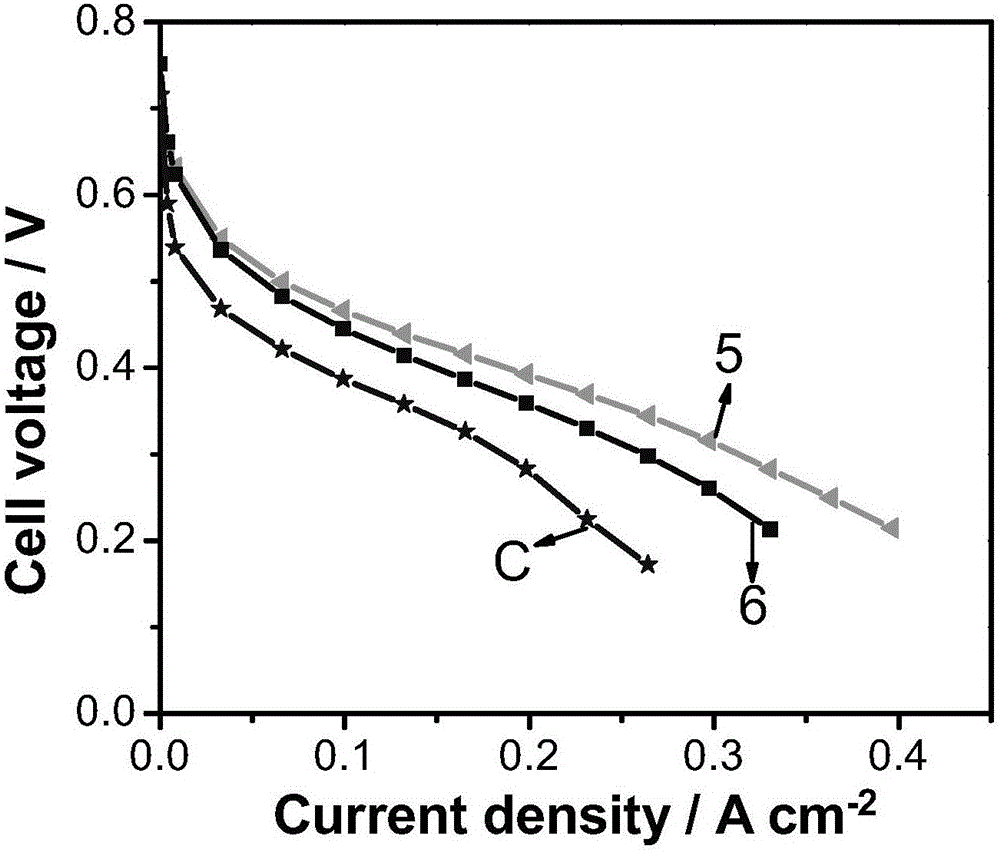

[0028] Select F modified silicone oil with a molecular weight of 30k and a viscosity of 1500cp for the preparation of Fe / N / C ink;

[0029] Add F modified silicone oil (30kD, 1500cp) to the cathode ink, and the ink is composed of: Fe / N / C catalyst 25mg; F modified silicone oil (30kD, 1500cp) 50mg; 5wt% nafion solution 0.55mL; solvent n-propanol 1mL; place the cathode ink in an ice-water bath and ultrasonically disperse it evenly; prepare a gas diffusion electrode (GDS) by drop coating, and the final cathode catalyst loading is 5mgcm -2 ;

[0030] The preparation method of the anode gas diffusion electrode is similar to that of the cathode, and the ink composition is Pt-Ru / C (40wt%Ptand20wt%Ru, JohnsonMatthey)-20mg; 5wt% nafion solution 0.22mL; deionized water 0.2mL; isopropanol 0.4mL; The cathode ink was placed in an ice-water bath and ultrasonicated for 10 minutes; the gas diffusion electrode (GDS) was prepared by drop coating, and the final anode metal loading was 4mgcm -2 ;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com