Water electrolysis hydrogen production catalyst and preparation method thereof

A technology of catalyst and electrolysis of water, which is applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problems of catalytic activity and stability reduction, and achieve the effect of high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

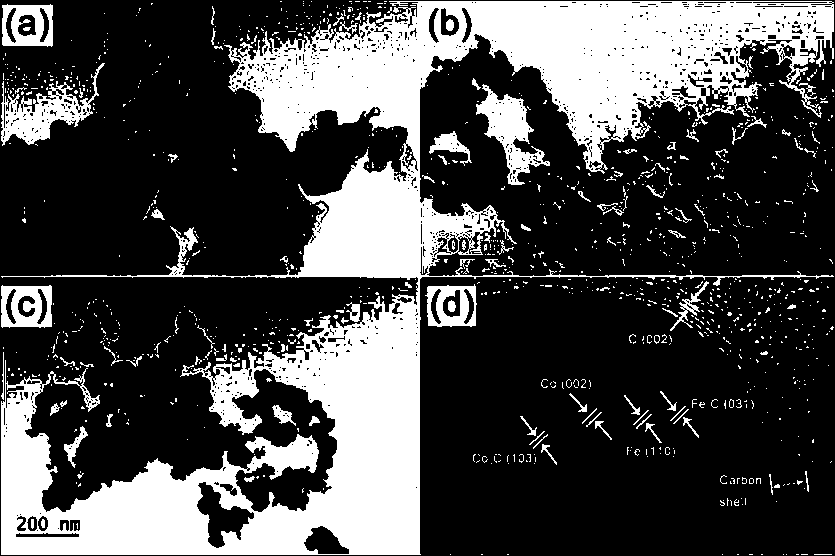

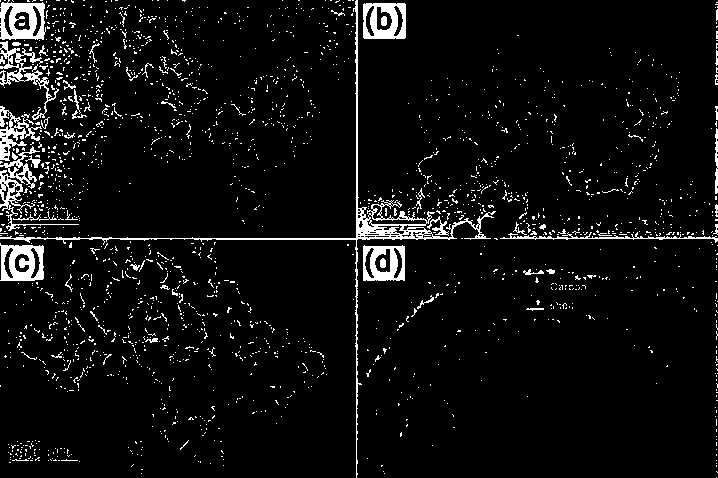

Image

Examples

Embodiment 1

[0029] A preparation method of a catalyst for hydrogen production by electrolysis of water, the steps are as follows:

[0030] (1) Dissolve 1.34 g of cobalt nitrate hexahydrate and 0.44 g of sodium citrate in 20 ml of deionized water to form solution A; dissolve 0.64 g of potassium ferrocyanide trihydrate in 20 ml of deionized water to form solution B;

[0031] (2) Fully mix solution A and solution B under magnetic stirring, then age at room temperature for 30 h, and then separate to obtain a precipitate, wash with water and ethanol respectively, and dry at 60 °C for 10 h to obtain a precursor , denoted as MOF;

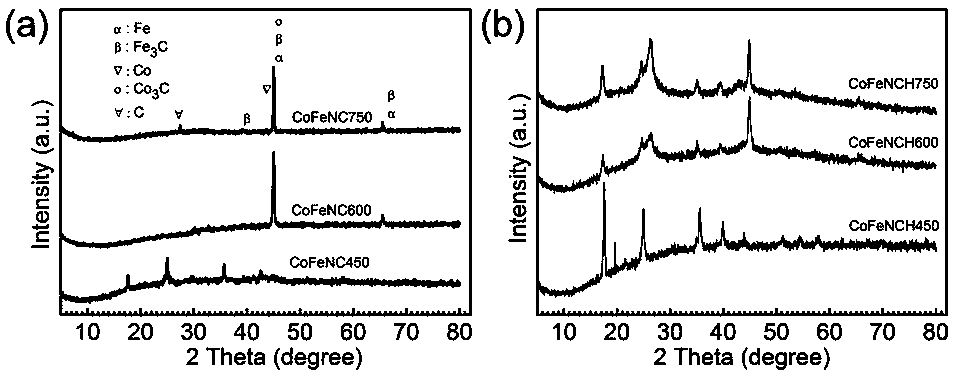

[0032] (3) The obtained precursor was calcined at a rate of 3 °C / min to 750 °C for 1 h in a nitrogen atmosphere in a tube furnace, and the flow rate of the atmosphere was controlled at 200 mL min −1 , to obtain catalyst 1, denoted as CoFeNC750; CoFeNC750 was acid-washed in 2 M hydrochloric acid for 4 days, and most of the metals in the carbon shell were washed away, ...

Embodiment 2

[0034] The difference from Example 1 is that: in step (3), the calcination temperature is 600°C to obtain catalyst 2, which is denoted as CoFeNC600; the catalyst 2' is further obtained by acid washing, which is denoted as CoFeNCH600; the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com