Catalyst for preparing 2,2'-bipyridine by pyridine coupling and preparation method and application thereof

A catalyst, bipyridine technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as catalyst failure and reaction yield decline, and achieve good stability, high activity, high Effects of activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

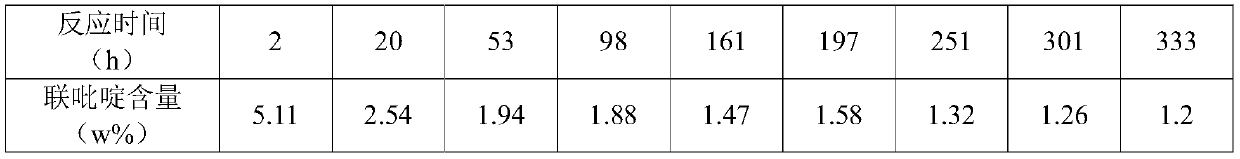

Examples

Embodiment 1

[0020] The spherical alumina carrier containing 3.0% silica is treated with one or more solutions of about 3% oxalic acid, nitric acid, sulfuric acid and hydrochloric acid at 80°C, then washed 1-2 times with water, and dried at 120°C. Calcined at 650°C for 3 hours to obtain a catalyst carrier;

[0021] According to the content of the active component nickel, nickel nitrate and polyvinylpyrrolidone were dissolved in water to form a solution. After vacuuming the modified alumina carrier, the impregnation solution was sucked into the carrier by conventional impregnation method, and then aged at 80 °C 2 hours, drying at 80°C for 6 hours, drying at 120°C for 12 hours, and calcination at 450°C for 3 hours; the calcined catalyst was reduced by passing hydrogen at 550°C for 5 hours.

[0022] Catalyst A prepared in this example contains 21% nickel, and 5% polyvinylpyrrolidone is added to the impregnation solution.

Embodiment 2

[0024] Catalyst B is prepared in the same manner as in Example 1, except that the nickel content of the catalyst is 25%, and 2% cetyltrimethylammonium bromide (CTAB) and 3% polyvinylpyrrolidone (PVP) are added in the impregnation solution. ).

Embodiment 3

[0026] Catalyst C was prepared in the same manner as in Example 1, except that the nickel content of the catalyst was 30%, and 5% polyvinylpyrrolidone (PVP) was added to the impregnation solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com