Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "High fuel value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

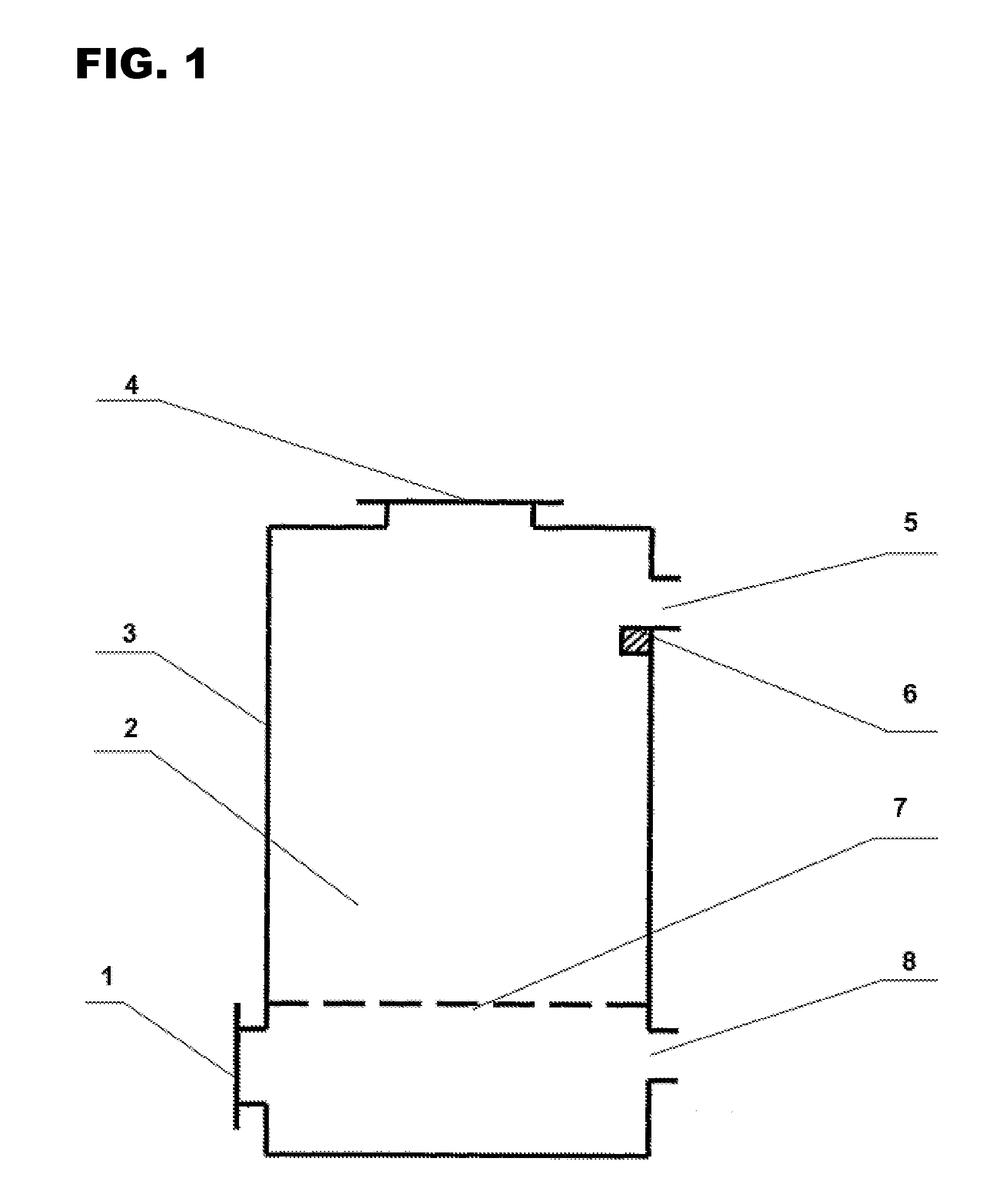

Conversion of municipal solid waste to high fuel value

InactiveUS7252691B2Increasing value of such fuelHigh fuel valueBiofuelsSolid fuelsEnvironmental engineeringUrban solid waste

A combustible pellet comprising municipal solid waste. The pellet has a water content of less than 10% by weight and a fuel value of at least 10,000 BTU. A process for the forming of a combustible pellet from municipal solid wastes, comprising the steps of removing solid hazardous waste from said municipal solid waste; subjecting the municipal solid waste so obtained to at least one step to separate recyclable products therefrom; and subjecting the resultant product to a shredding and a pulverizing step. A fluff with a water content of less than 10% by weight is obtained. The fluff is compacted to form a combustible pellet.

Owner:SENTINEL WASTE INT

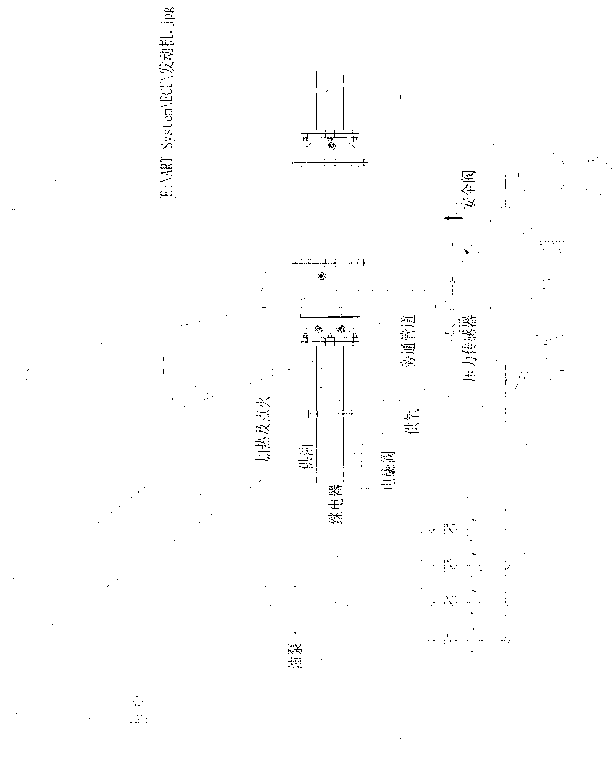

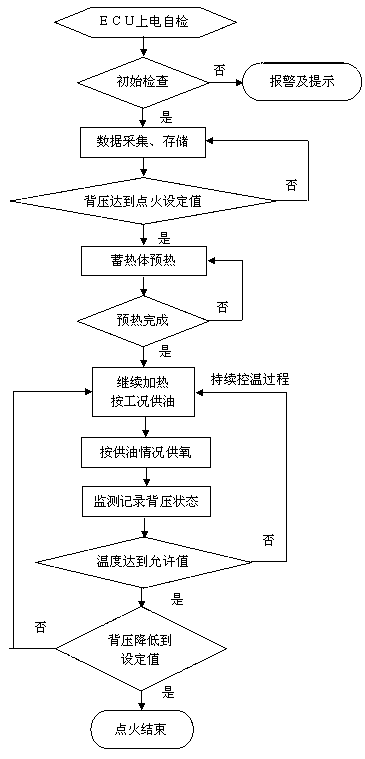

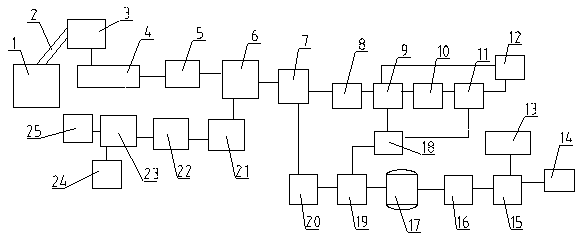

Control system and control method for temperature rising of diesel engine exhaust aftertreatment device

ActiveCN103277173ABurn fullyHigh fuel valueInternal combustion piston enginesExhaust apparatusControl systemFuel tank

The invention relates to a control system and a control method for temperature rising of a diesel engine exhaust aftertreatment device. A signal input end of an ECU is respectively connected with a diesel engine speed signal output end, a voltage multiplying signal output end of the diesel engine exhaust aftertreatment device, a temperature signal output end of a temperature rising device of the aftertreatment device, a signal output end of a pressure sensor of an air storage tank of an air compressor, and an oil tank oil quantity liquid level signal output end. A signal output end of the ECU is respectively connected with a switch signal control end of an oil supply pump, a switch signal control end of a multipath air valve, and a switch signal control end of a temperature rising controller. An outlet of an oil tank is communicated with an inlet of the oil supply pump through an oil conveying pipe, an outlet of the oil supply pump supplies oil to the temperature rising device of the aftertreatment device through an oil conveying pipe, air inlets of the multipath air valve are in parallel connection to be communicated and communicated with an outlet of the air storage tank of the air compressor, and air outlets of the multipath air valve are in parallel connection to be communicated to supply oxygen to the temperature rising device of the aftertreatment device.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

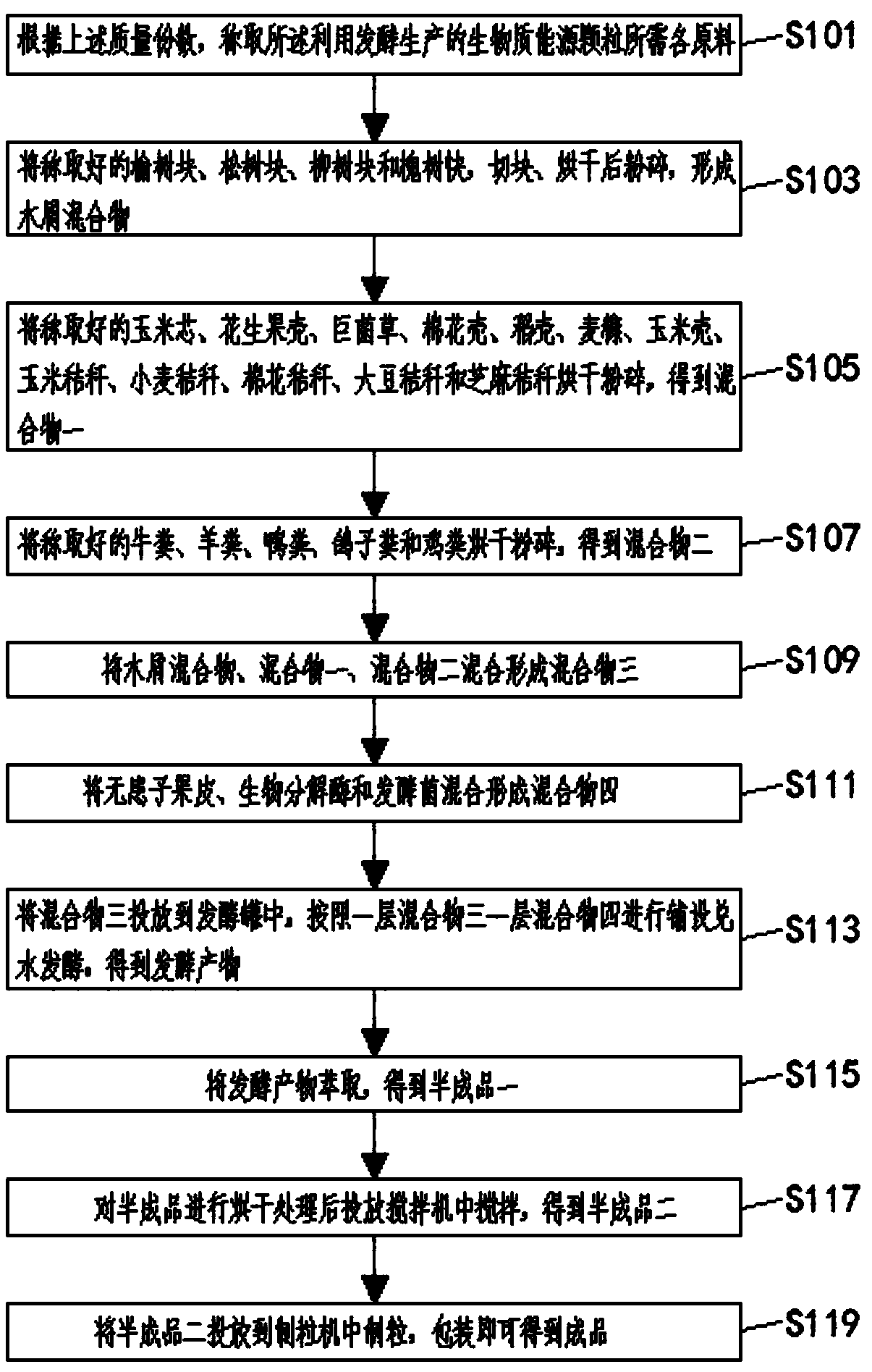

Biomass energy particles produced by means of fermentation and preparation method thereof

The invention discloses biomass energy particles produced by means of fermentation and a preparation method thereof. The biomass energy particles produced by means of fermentation are prepared from the following raw materials in parts by mass: 10-20 parts of sapindus mukurossi peel, 20-40 parts of corncobs, 2-10 parts of tar, 5-13 parts of wood vinegar, 20-40 parts of coal slime, 20-40 parts of peanut shells, 20-40 parts of pennisetum sinese, 15-25 parts of levant cotton exocarp, 15-25 parts of rice husk, 15-25 parts of wheat bran, 15-25 parts of corn husk, 15-25 parts of yellow mud, 70-110 parts of wood brick compound, 80-160 parts of agricultural straw, 18-33 parts of feces of livestock and poultry, 20-40 parts of biological clastic enzyme and 20-40 parts of fermentation bacteria. The biomass energy particles produced by means of fermentation and the preparation method thereof have the beneficial effects that biomass bricks can be subjected to sufficient burning; the cost is low, waste products are few, biomass energy can be fully used, and the biomass energy particles produced by means of fermentation have good economic benefits; a combustion value is high, generated smoke is little, harmful gas is little, pollution to the environment is reduced, meanwhile, the straw can be reused, the production cost of a manufacturer is reduced, and a product is high in heat value, good inshaping, and high in economic and social benefits.

Owner:梁丰

Advanced treatment process of biochemical tail water of percolate of city consumption residue

InactiveCN101289235AHigh desorption rateHigh fuel valueWater/sewage treatment by sorptionHigh concentrationEmission standard

The invention discloses an advanced treatment method for biochemical tail water of leachate of municipal household waste. Tail water mainly comes from biochemical effluent from a treatment device of the leachate of the municipal household waste or effluent of simply chemical-physical treated biochemical effluent. The steps of the method are as follows: at normal temperature and under the condition of 0.5 BV / h to10BV / h of flow, pretreated tail water is absorbed by a device filled with adsorbent resins with complex functions or macroporous resin to yield water, so as to be discharged by reaching the mark; the resin is desorbed and regenerated by sodium hydroxide solution, the flow of desorbing agent is 0.5BV / h to 3.0BV / h, desorbing liquid with high concentration is burnt or disposed by other safe disposal methods, and desorbing liquid with low concentration can be used for preparing the next batch of desorbing agent for circular application. The method of the invention can reduce the COD of the tail water to below 100mg / L from about 150mg / L to 500mg / L and can reduce the ion concentration of ammonia nitrogen, total nitrogen and heavy metal to be below first-grade state emission standard. The method of the invention has the advantages of simple technique and large treatment amount, which can make up the shortcomings of the existing treatment technology of leachate of municipal household waste.

Owner:NANJING UNIV

Method for preparing biomass fuel mainly from fresh chicken manure

ActiveCN106244278AWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsMicroorganismMushroom

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing a biomass fuel mainly from fresh chicken manure. The method comprises the following steps: 1) pretreating raw materials; 2) fermentation: mixing fresh chicken manure, mushroom sticks and calcined shell powder, inoculating deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes, and carrying out pile fermentation; 3) naturally drying the fermentation material; and 4) adding tea stems, and carrying out extrusion granulation. The fresh chicken manure is used as the main raw material, the waste mushroom sticks, calcined shell powder and tea stems are used as the auxiliary raw materials, the deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes are added, and the flammability and comprehensive combustion characteristics of the reinforcing material of the composite microbes are fully utilized, thereby preparing the biomass granular fuel which has the advantages of low ignition point, high combustion heat value and high combustion rate. The method can greatly consume chicken manure, and solves the problem of environmental pollution caused by chicken manure. The method provides direction for the recycling of the waste mushroom sticks, shells and tea stems.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

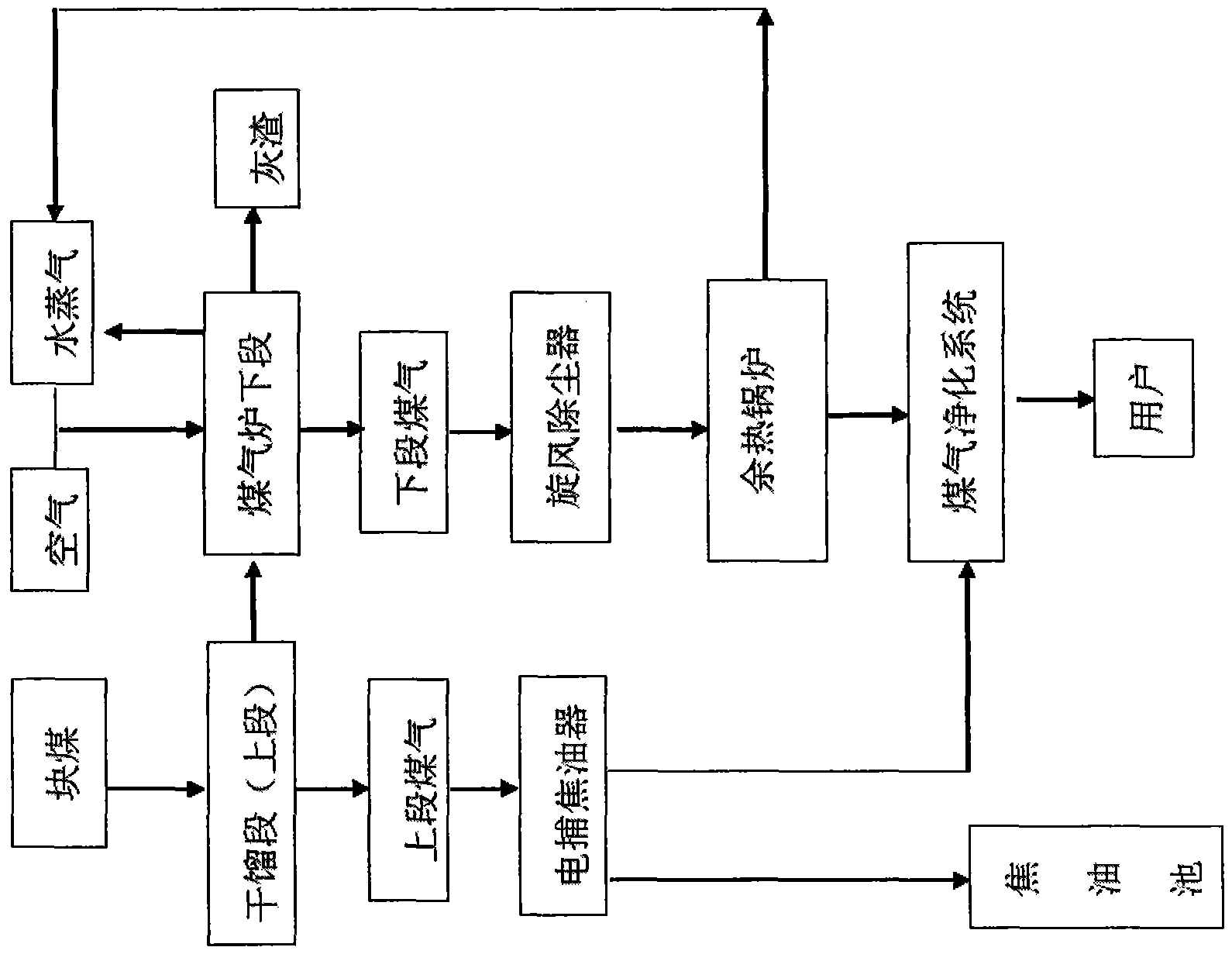

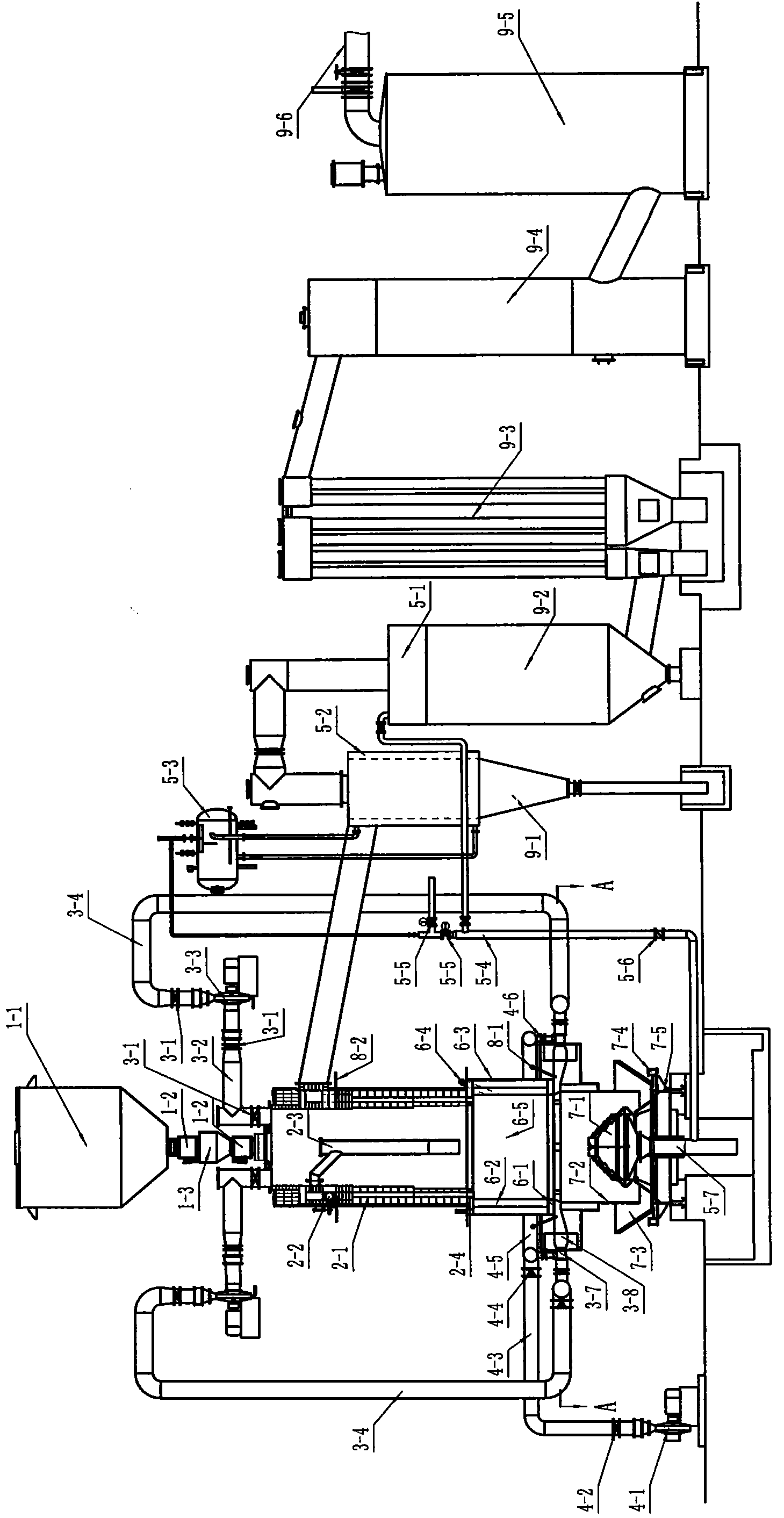

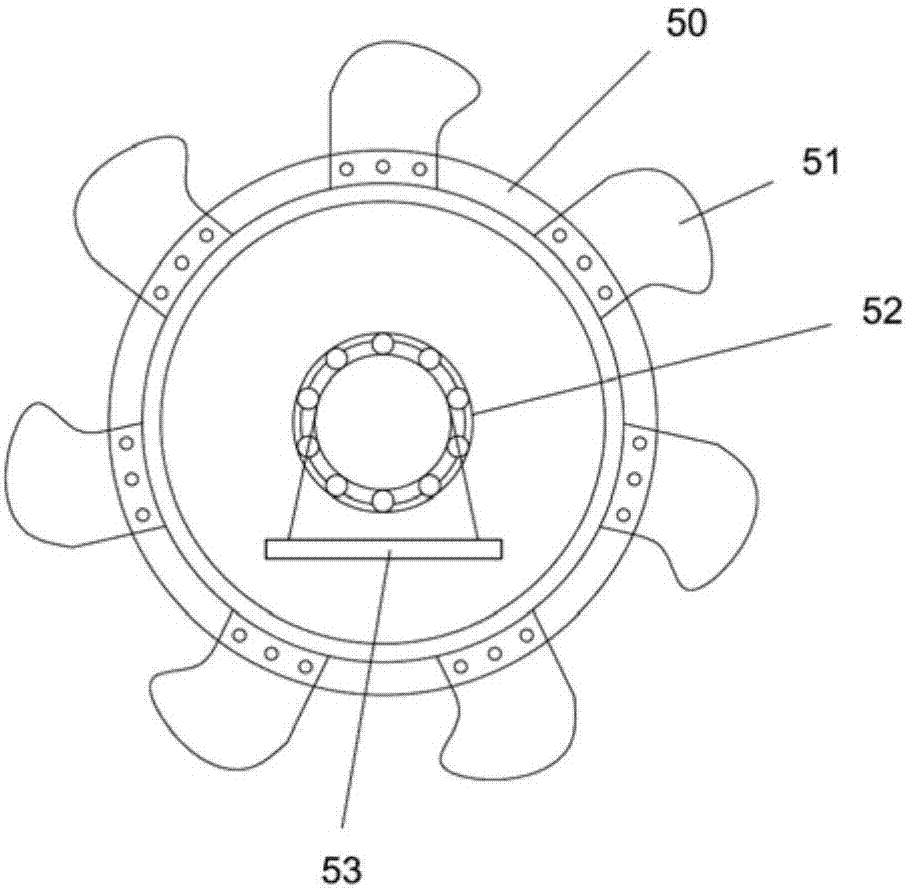

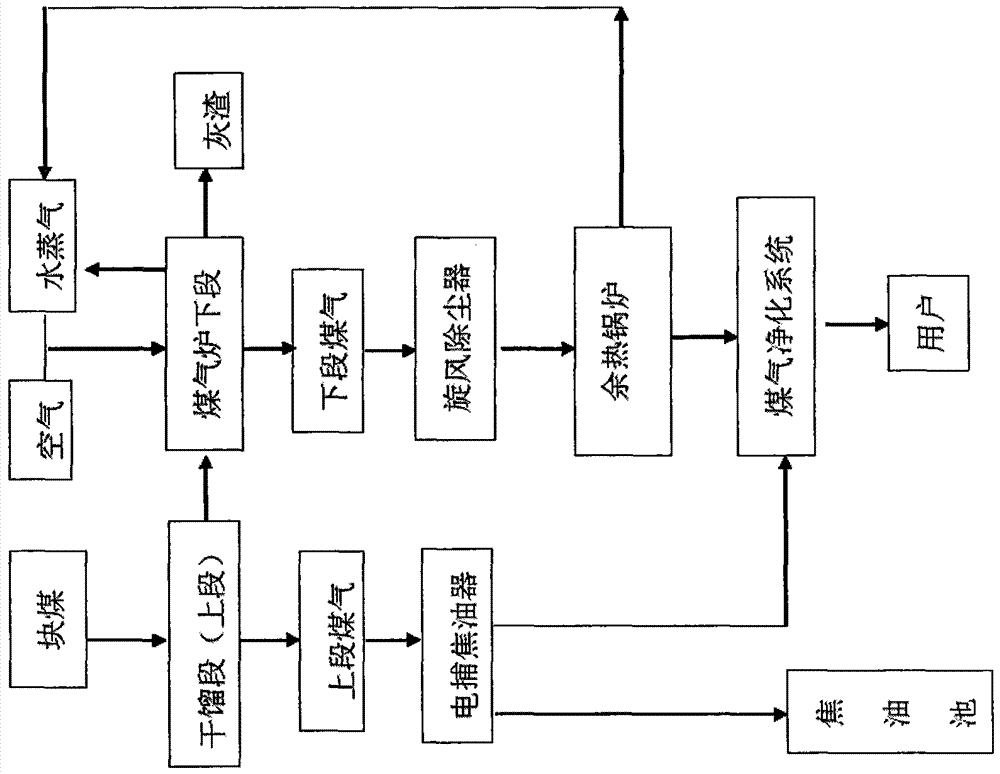

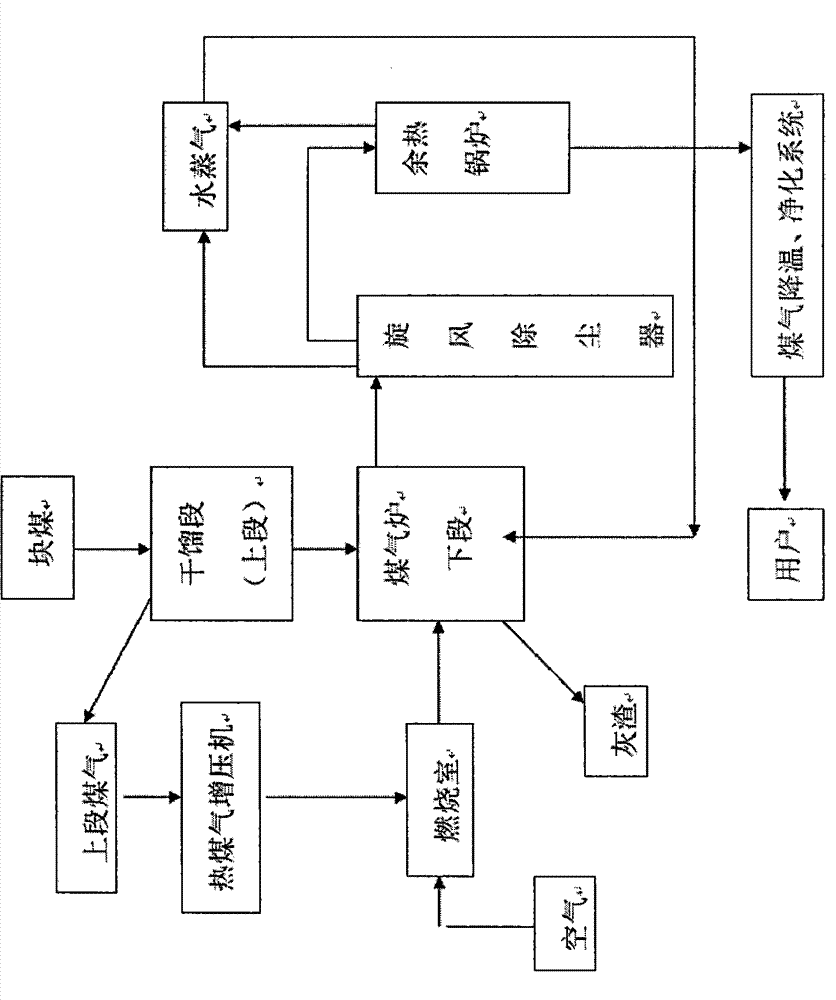

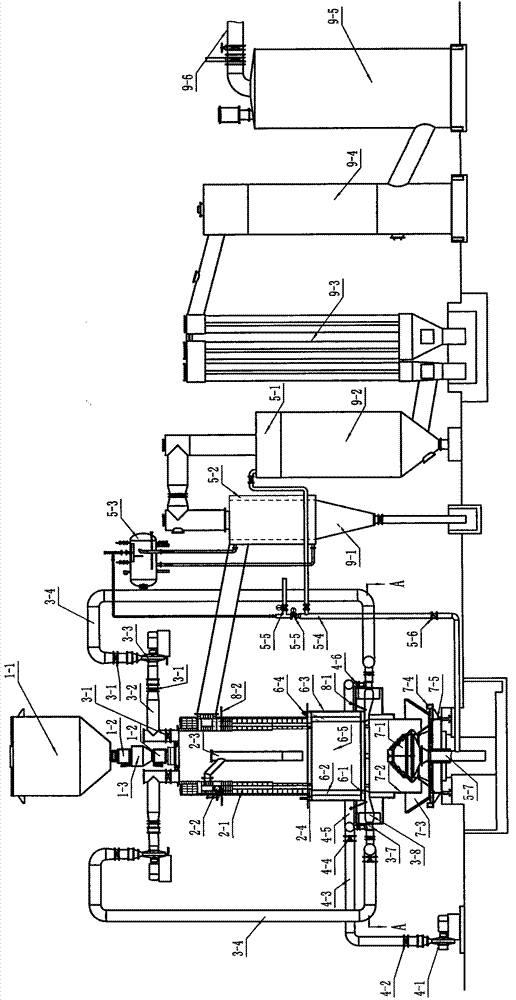

Counterflow burning type coal gasifier device and process thereof

ActiveCN103642530AImprove reliabilityReduce labor intensityChemical industryGasification with fuel pre-distillationThermal energyCombustion chamber

The invention specifically relates to a novel counterflow burning type coal gasifier device and a process thereof. The device is composed of following nine major systems: a coal charging system, a dry distillation system, a counterflow burning heating system, a combustion supporting air supply system, a steam supply system, a gas generation system, an ash removal system, an automatic temperature control system and a gas cooling purification system; the process comprises the following steps: 1) generating upper section gas containing dry distillation gas, tar gas, phenol organic matter gasses and water steam; 2) feeding the upper section gas into a combustion chamber for combustion through a hot gas supercharger; 3) introducing high temperature gas generated after combustion in the combustion chamber and containing water vapor and CO2 into the hearth at the lower section of the coal gasifier to contact with coke, and generating to generate lower section gas; 4) cooling and separating dust from the generated lower section gas and then transmitting the gas to the user end. The device and the process provided by the invention are free of discharge of pollutants such as tar and carbolisata aqua, and have the advantages of high heat utilization rate, energy conservation and environmental friendliness; the generated gas is high in cleanness and combustion value.

Owner:淄博硕丰环保设备有限公司

Wheat straw biomass particles and preparation method thereof

The invention relates to the technical field of biofuel, in particular to wheat straw biomass particles. The wheat straw biomass particles comprise 55-75 parts of wheat straw, 30-45 parts of rice husk, 25-32 parts of corn stalk, 15-18 parts of waterweeds, 22-40 parts of sawdust, 20-35 parts of desulfurized coal slag, 50-60 parts of Chinese herbal medicine dregs, 5-12 parts of gypsum, 0.8-5 parts of swelling agent, 10-30 parts of paraffin wax, and 8-20 parts of squalane powder. A preparation method is also provided and comprises the steps of drying, segmenting, pulverizing, mixing, stirring, press forming, drying, granulating and packaging. According to the invention, the desulfurized coal slag and sawdust are added to the raw materials, so that the burning value of the biomass particles are higher than that of conventional biomass particles; the gypsum is added, and the prepared biomass particles are high in molding rate and not easy to loose due to good consolidation property of the gypsum; and the swelling agent is added, so that the biomass particles are loosened and can be fully burned when burned.

Owner:亳州市创亿生物质燃料科技有限公司

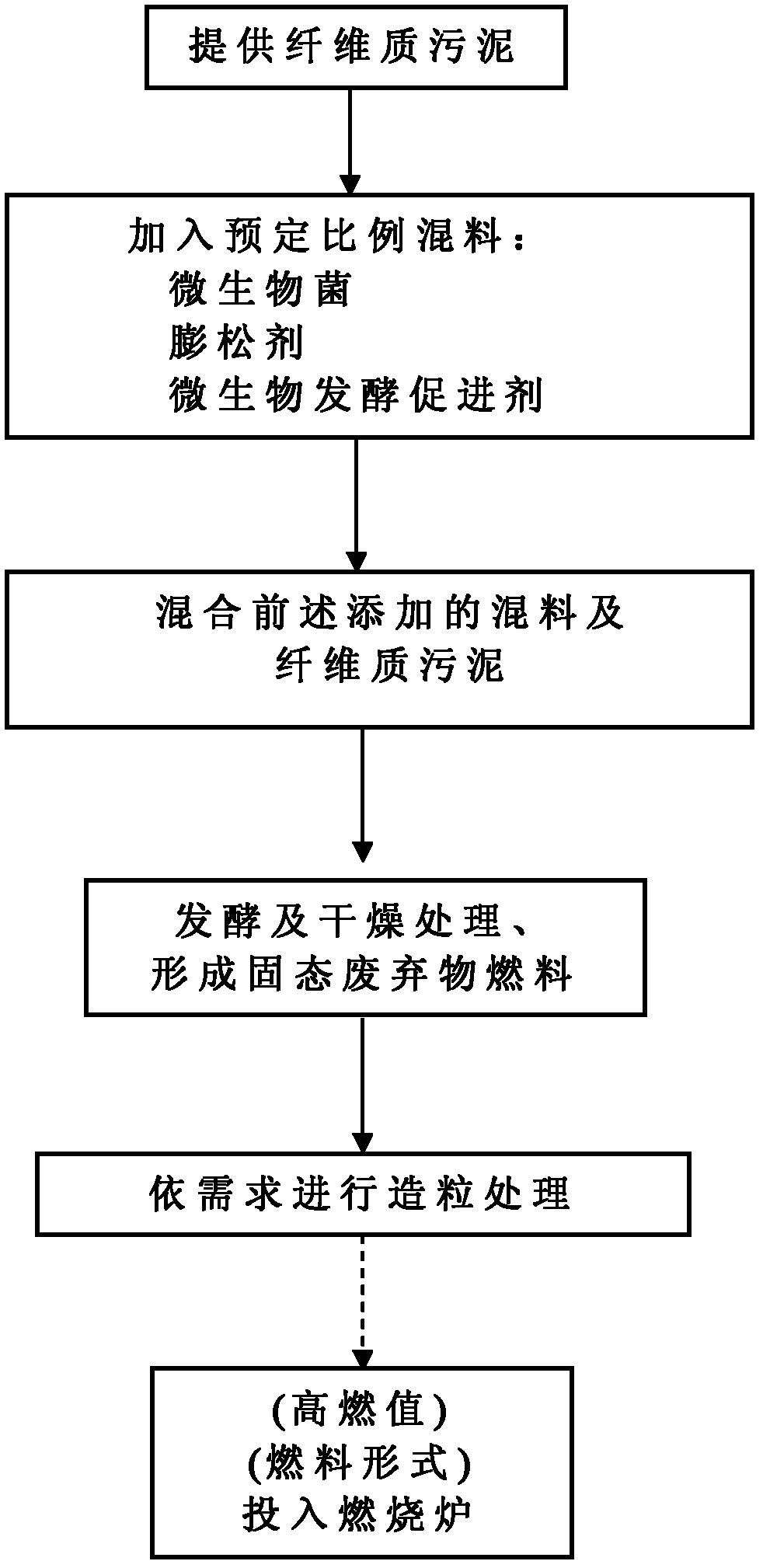

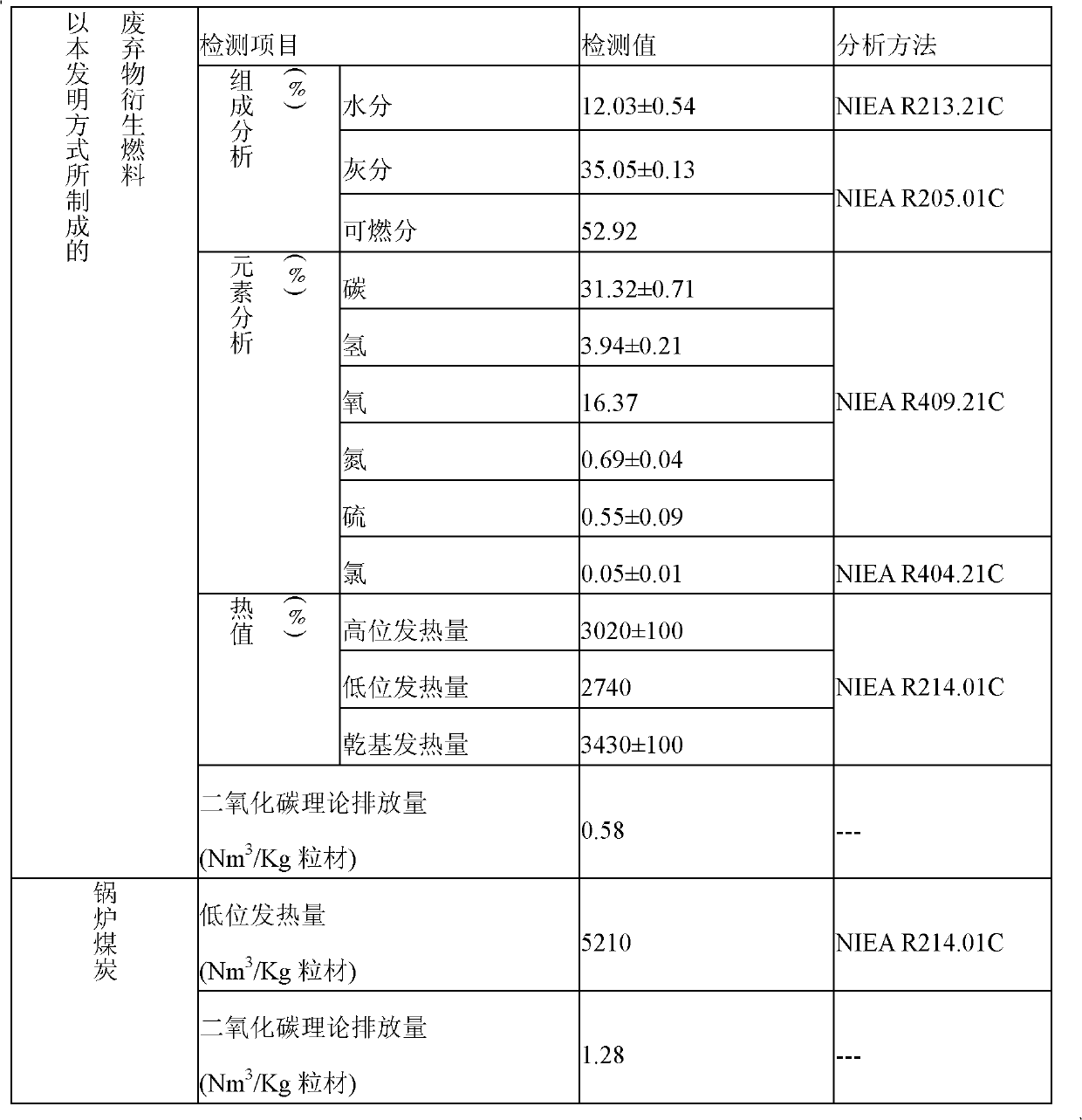

Preparation method of refuse derived fuel

A preparation method of a refuse derived fuel comprises the following steps of: providing fiber sludge, adding a mixed material containing microbial flora, a bulking agent and a microbial fermentation promoter which are mixed according to a predetermined proportion, uniformly mixing, and carrying out fermentation on the uniformly-mixed materials and fiber sludge for a period of time so as to form the solid refuse fuel.

Owner:MINGDA BIOTECH

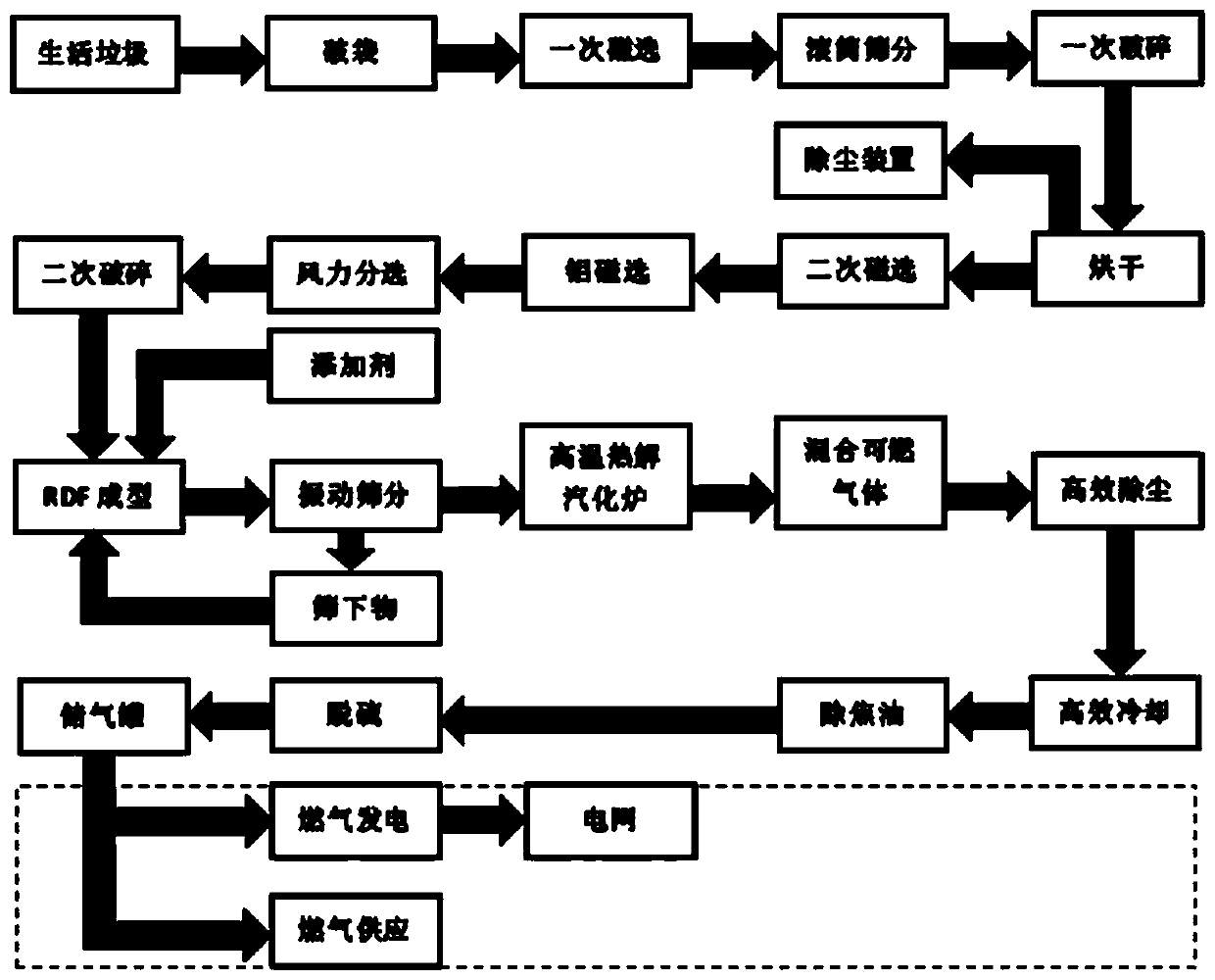

Process for making RDF from domestic garbage and high-temperature pyrolysis gasification treatment

InactiveCN110551550AWide range of industrial applicationsHigh economic valueBiofuelsSolid fuelsSustainable economyAir separation

The invention discloses a process for making RDF from domestic garbage and high-temperature pyrolysis gasification treatment. The process comprises the following procedures of domestic garbage, bag breaking, primary magnetic separation, drum screening, primary breaking, drying, secondary magnetic separation, aluminum magnetic separation, air separation, fine breaking, additives adding, stirring, RDF molding, cooling, screening, gasification, dust removal, cooling, oil removal and dechlorination and desulfurization. Metal, glass, high-value plastic, sand, stone, soil and the like in household waste are completely separated, and the effects of resource recycling and sustainable economic development are achieved.

Owner:浙江华环环境有限公司

Garbage refinement pretreatment system and method for garbage incineration power plant

InactiveCN109489043AHigh fuel valueRealize sortingMagnetic separationIncinerator apparatusPower stationMagnetic separator

The invention discloses a garbage refinement pretreatment system and a method for a garbage incineration power plant, comprising a garbage storage pool and a sorting system, wherein the sorting systemcomprises a bag breaking machine, an intelligent sorting platform, a crusher and an extruder; a slurry outlet of the extruder is sequentially connected with a slurry pool and an oil-water separator;a solid outlet of the extruder is connected with a bouncing sieving machine; an oversize product outlet of the bouncing sieving machine is sequentially connected with a first magnetic separator, a first sorting machine, a disc sieving machine and a second sorting machine; the combustible material outlet of the second sorting machine is connected with a combustible storage bin; a screen underflow outlet of the bouncing sieving machine is sequentially connected with a second magnetic separator and a star disc sieving machine, and the combustible material outlet of the star disc sieving machine is connected with the combustible material storage bin. The pretreatment technology adopted by this system has advanced principle, good sorting effect; the sorting combustible material has high heat value and high single-line treatment capacity; therefore the pretreatment technology is a more optimized, more suitable, more economical and more reliable garbage refinement pretreatment technology.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

Method for preparing derived fuel from domestic sludge through high-temperature pyrolysis and gasification

InactiveCN111575059AHigh fuel valueImprove anti-corrosionGasification processes detailsGranular/pulverulent flues gasificationSludgeDust control

The invention discloses a method for preparing derivative fuel from domestic sludge through high-temperature pyrolysis and gasification. The method comprises the following steps of: preparing the derivative fuel, namely, adding domestic sludge, biomass fuel and an additive in proportion, stirring and mixing the materials to prepare the derivative fuel; and preparing biogas by pyrolyzing the derivative fuel, namely cracking the derivative fuel in a high-temperature pyrolysis gasification furnace, and performing oil removal, dust removal, cooling, desulfurization and dechlorination on mixed biogas obtained in the pyrolysis gasification furnace to obtain clean gas fuel and regenerated building material solid particles. According to the method of the invention, the domestic sludge and biomassfuel are prepared into the derivative fuel, then the derivative fuel is cracked into the mixed biological gas fuel and solid particles, the mixed biological gas fuel can be used for combined heat andpower generation and industrial and civil gas fuel, the solid particles can be used as building material preparation raw materials; and therefore, the purposes of resource regeneration and thorough garbage treatment are achieved. The ecological benefit, environmental benefit, social benefit and economic benefit of the method are excellent.

Owner:浙江华环环境有限公司

Low-sulfur biomass rod fuel and preparation method thereof

The invention discloses a low-sulfur biomass rod fuel, which comprises the following raw materials: rice straw, wheat straw, Pennisetum giganteum, Pennisetum purpureum, Arund donax, corncob, coal, lanthanum oxide, copper nitrate, cobalt nitrate, fluororesin, polymethacrylate, p-xylylene, silicon resin, nitrocellulose, a silane coupling agent KH-570, a modified waterproof environment-friendly adhesive, an adhesive reinforcement material, modified reinforcing filler, methyl ethyl ketone peroxide and isocyanate. The invention also provides a preparation method of the low-sulfur biomass rod fuel. The biomass rod fuel prepared by the method provided by the invention has the advantages of high calorific value, good toughness, difficult breakage, and excellent environmental protection performance.

Owner:林佳鸿

Honeycomb briquette prepared by using fermented cow dung and preparation method thereof

The invention discloses a honeycomb briquette prepared by using fermented cow dung and a preparation method thereof. The honeycomb briquette comprises 20wt%-50wt% of maturely fermented cow dung and 50wt%-80wt% of pulverized coal. The preparation method of the honeycomb briquette comprises the following steps of (1) adding a certain amount of fermentative bacteria and rice hull powder to the cow dung so as to ferment the cow dung into the maturely fermented cow dung; and (2) fixing and forming, namely mixing the maturely fermented cow dung with the pulverized coal, crushing, stirring and mixing uniformly, selectively adding water during uniform mixing, and carrying out compression molding. The brand-new honeycomb briquette prepared by mixing the fermented cow dung and the pulverized coal, provided by the invention, is odorless and has high acceptability; smashed grasses or straws do not need to be additionally added to the honeycomb briquette, so that the cost is saved, and the honeycomb briquette is easy to form; and the preparation time of the honeycomb briquette is short, and the preparation process is simple, so that the honeycomb briquette is easy to popularize. The preparation method has the advantages that (1) the pollution problem of cattle farms can be greatly reduced; (2) the shortage of fuels can be solved; and (3) the utilization model of energy sources is explored.

Owner:SOUTHWEST UNIV

A method and plant of production of combustible gas using biomass

This invention involves a method and plant of production of combustible gas using biomass. This plant comprises a furnace body, a furnace cavity, gasifying agent inlet, combustible gas outlet (arranged on furnace cavity and higher than gasifying agent inlet), and a device that ignites biomass arranged at intersection between the horizontal plane where the combustible gas outlet is located and the internal wall of the furnace cavity. Method of operation: load biomass in the plant and ignite the upper part; gasifying agent will run through the material from bottom to top, gasifying the material and generating flue gas. This invention features outstanding advantages of stable gasifying reaction, safe and reliable operation, high fuel gas calorific value, low environmental pollution, and easy purification of combustible gas etc. This method can be used to produce combustible gas from not only biomass, but also solid organic gasifying raw materials such as household garbage and industrial refuse etc.

Owner:LIU WENZHEN

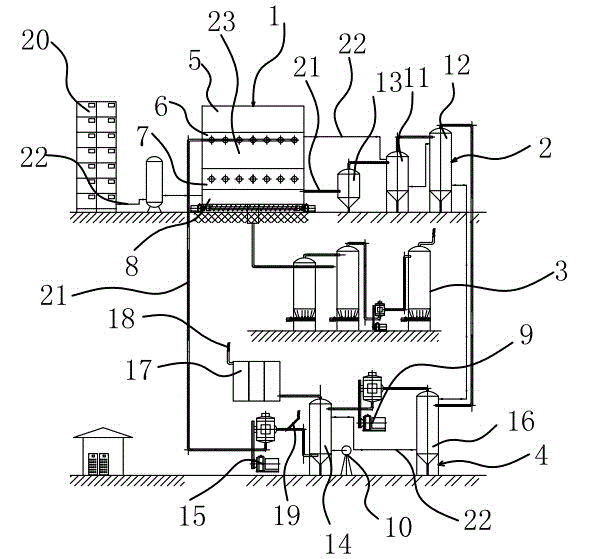

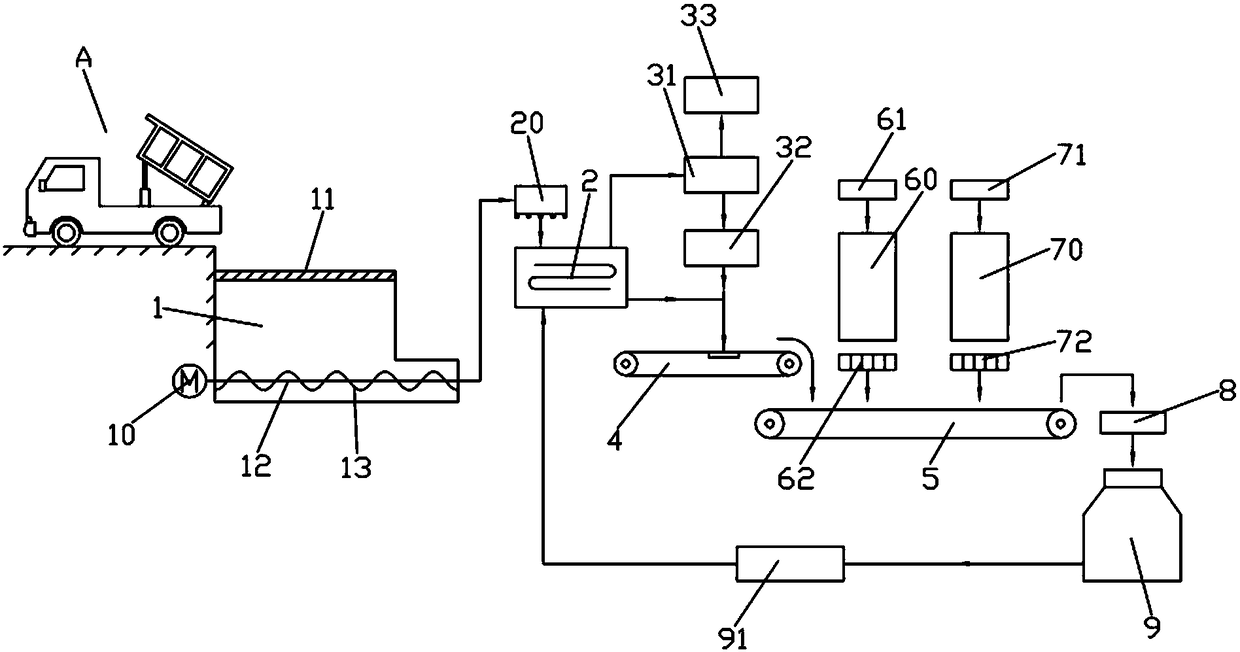

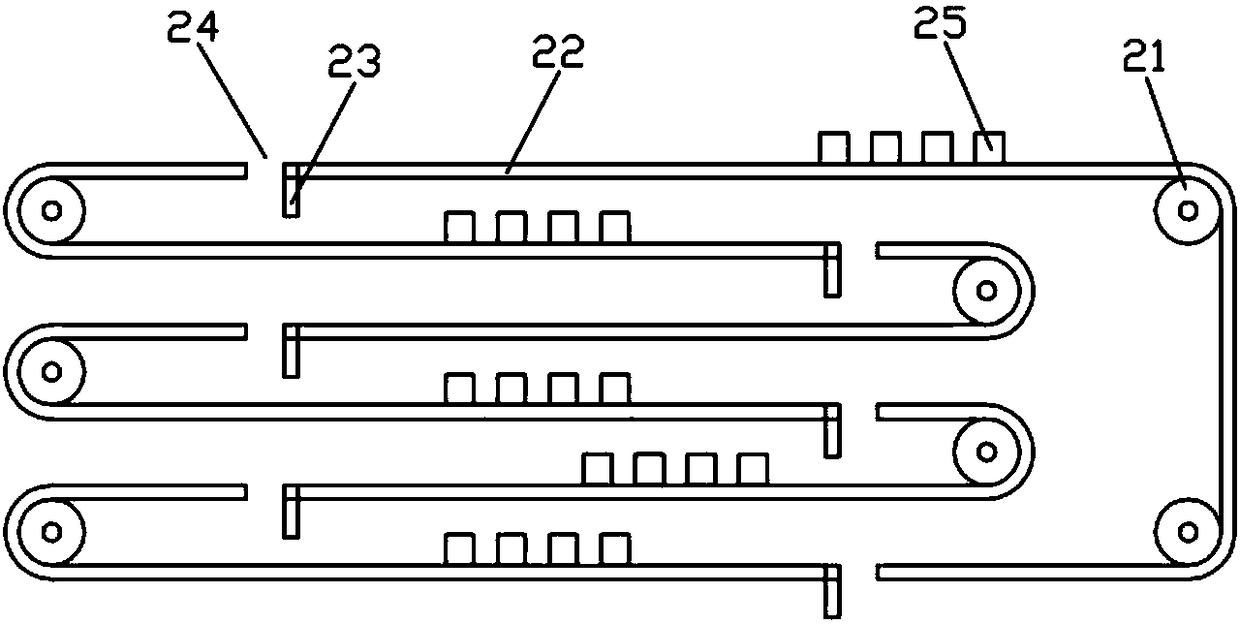

Garbage treatment complete equipment

ActiveCN105987384AAchieving self-powered dry combustionSave energyIncinerator apparatusTreatment completedCombustion system

The invention provides garbage treatment complete equipment, and belongs to the technical field of garbage treatment. The garbage treatment complete equipment solves the problem that the treating performance of existing garbage treatment complete equipment is poor. The garbage treatment complete equipment comprises a pyrolysis gasification burning system, a circulation water cooling heat exchange system and a smoke secondary burning system; the pyrolysis gasification burning system is connected with the circulation water cooling heat exchange system through a gas conveying pipe, and the circulation water cooling heat exchange system is connected with a heat source reusing system through a cooling water pipe; and a slag classifying system is connected with the pyrolysis gasification burning system through a material conveying pipe, one end of the smoke secondary burning system is connected with the circulation water cooling heat exchange system through a gas conveying pipe, and the other end of the smoke secondary burning system is connected with the pyrolysis gasification burning system through a gas conveying pipe. By means of the garbage treatment complete equipment, the garbage treatment performance can be improved.

Owner:深圳市鑫旭源环保有限公司

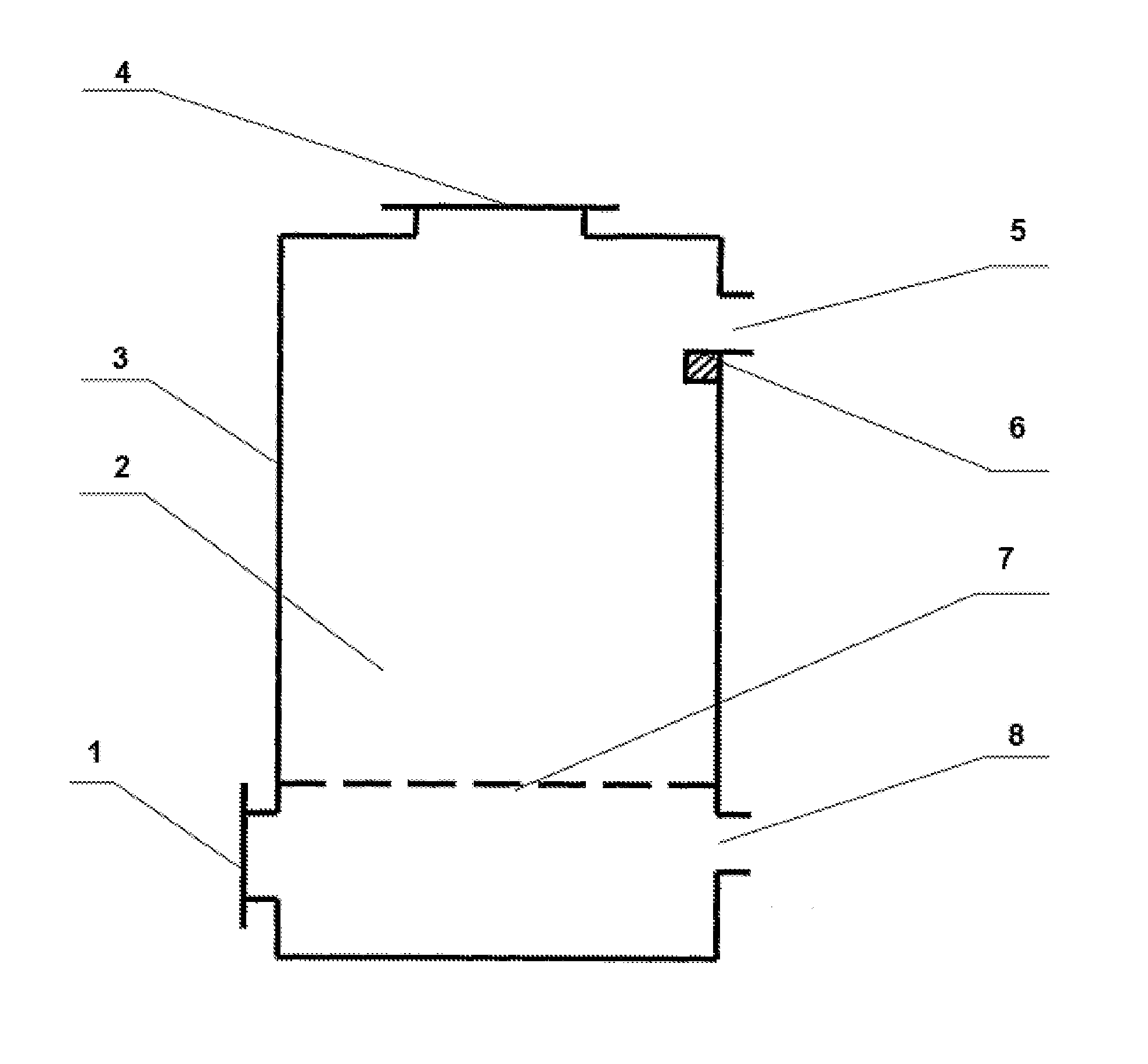

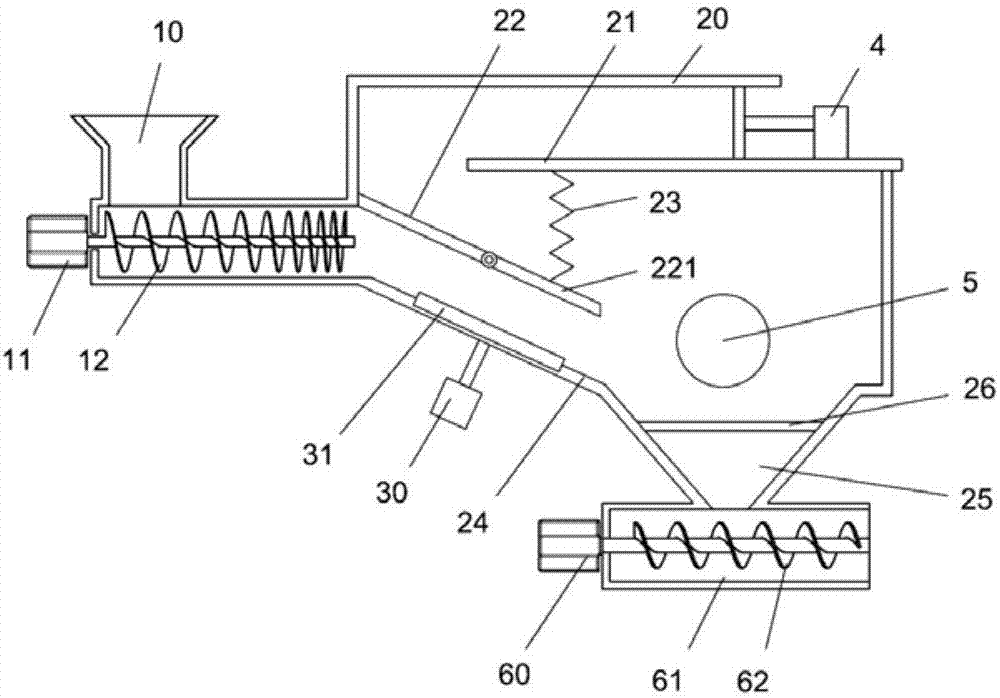

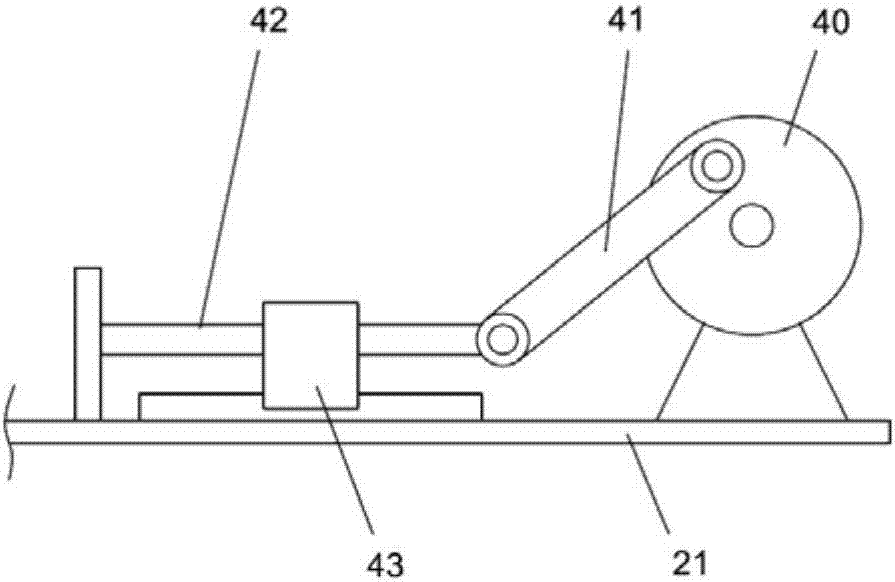

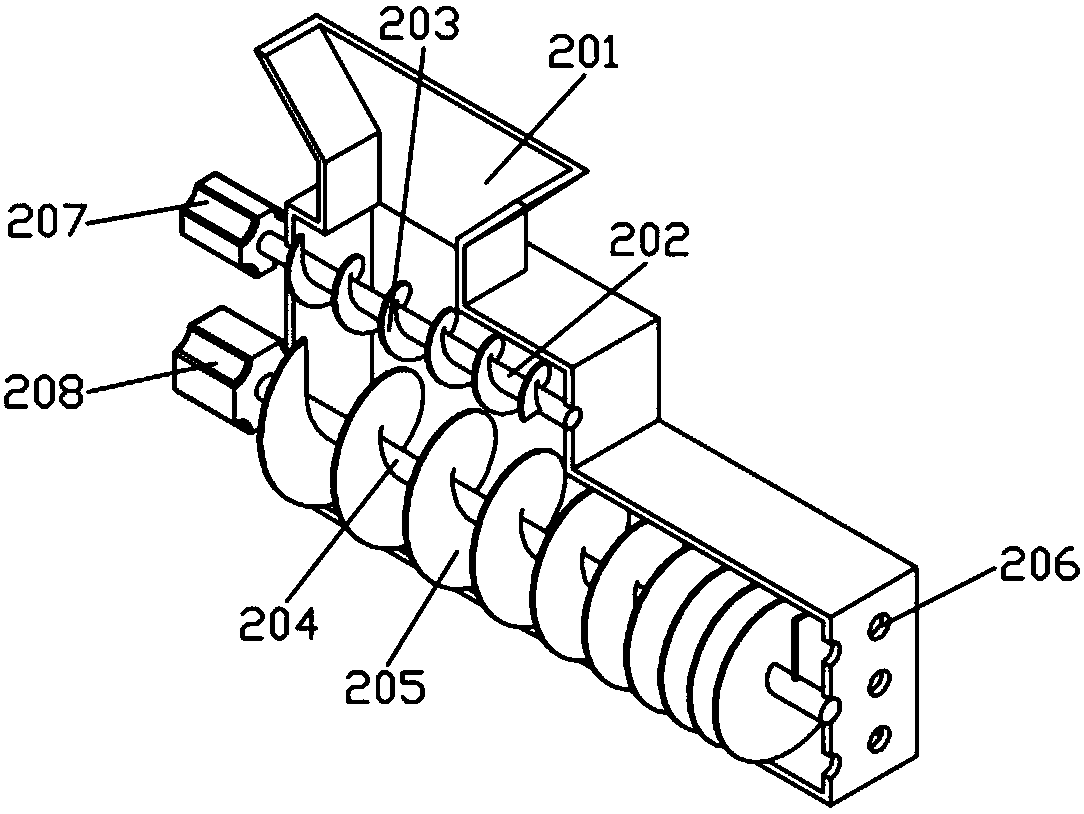

Production equipment for environmental-friendly solid fuels

InactiveCN107267245AHigh fuel valueSimple structureTransportation and packagingMixersSludgeVertical edge

The invention discloses production equipment for environmental-friendly solid fuels. The production equipment comprises a special-shaped mixing chamber, wherein the section of the special-shaped mixing chamber is of a special-shaped structure which comprises a lower short edge; a first vertical edge is connected to the right side of the lower short edge; an inclined edge is connected to the left side of the lower short edge; a first upper edge is connected to the upper part of the vertical edge; a second upper edge is also arranged at the upper part of the first upper edge; a second vertical edge is arranged at the left side of the second upper edge; the second vertical edge and the inclined edge are connected to form a sludge feeding opening; an inclined guide plate is arranged at the upper end of the sludge feeding opening and extends into the mixing chamber; the second upper edge and the first upper edge form a feeding channel for rice straws; the inclined guide plate and the inclined edge form a sludge feeding channel; and a discharging hopper is connected to the lower part of the mixing chamber. According to the production equipment disclosed by the invention, sludge and the rice straws are mixed, granulated and molded to form sludge regeneration solid fuels with higher fuel value; and the system has the advantages of simple structure, small occupied area and high production efficiency.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

Biomass particle fuel

InactiveCN106147915AImprove drynessHigh densityBiofuelsSolid fuelsLivestock manureNon-renewable resource

The invention discloses a biomass particle fuel. The biomass particle fuel is prepared from 10%-20% of bamboos, 50%-60% of xylon, 2%-6% of rice hull, 10%-15% of livestock manure, 8%-12% of grease, 6%-10% of coal gangue powder and 0.5-1% of calcium oxide. According to the biomass particle fuel, the bamboos, various kinds of xylon, the rice hull, the livestock manure, the waste grease, the coal gangue powder and calcium oxide are combined, the raw material source is wide, waste biomass is fully utilized, energy saving and environment friendliness are achieved, the heating value is large, non-renewable energy resources can be fully utilized, and emissions of carbon dioxide, sulfur dioxide and other harmful gas can be reduced. Meanwhile, the biomass particle fuel can fundamentally solve the problem that the utilization rate of rural waste is low, waste is turned into wealth, and environment friendliness and energy saving are achieved.

Owner:长沙振科新能源科技有限责任公司

Method for preparing biomass fuel by taking fresh cow dung as main raw material

ActiveCN106244279AWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsResource utilizationMushroom

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing a biomass fuel by taking fresh cow dung as a main raw material. The method particularly includes the steps: 1) raw material pretreatment; 2) fermentation: mixing the fresh cow dung, mushroom rods and calcined shell powder, inoculating nitrogen fixation-desulfurization compound microorganisms and performing composting fermentation; 3) naturally airing fermented materials; 4) adding tea stalks and performing extruding granulation. The fresh cow dung serves as the main raw material, the waste mushroom rods, the calcined shell powder and the tea stalks serve as auxiliary raw materials, the nitrogen fixation-desulfurization compound microorganisms are added, and the biomass granule fuel with a low ignition point, a large combustion heat value and a high combustion ratio is prepared by making full use of enhanced material flammability and comprehensive combustion characteristics of the compound microorganisms and the water-absorbing capacity and the heat production capacity of the calcined shell powder. The method can greatly reduce the cow dung, solve the problem of environmental pollution of the cow dung and provide direction for resource utilization of the waste mushroom rods, the shell powder and the tea stalks.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Anti-burning coal gasifier device and process

ActiveCN103642530BAvoid pollutionIncrease gasification rateChemical industryGasification with fuel pre-distillationThermal energyCombustion chamber

The invention specifically relates to a novel counterflow burning type coal gasifier device and a process thereof. The device is composed of following nine major systems: a coal charging system, a dry distillation system, a counterflow burning heating system, a combustion supporting air supply system, a steam supply system, a gas generation system, an ash removal system, an automatic temperature control system and a gas cooling purification system; the process comprises the following steps: 1) generating upper section gas containing dry distillation gas, tar gas, phenol organic matter gasses and water steam; 2) feeding the upper section gas into a combustion chamber for combustion through a hot gas supercharger; 3) introducing high temperature gas generated after combustion in the combustion chamber and containing water vapor and CO2 into the hearth at the lower section of the coal gasifier to contact with coke, and generating to generate lower section gas; 4) cooling and separating dust from the generated lower section gas and then transmitting the gas to the user end. The device and the process provided by the invention are free of discharge of pollutants such as tar and carbolisata aqua, and have the advantages of high heat utilization rate, energy conservation and environmental friendliness; the generated gas is high in cleanness and combustion value.

Owner:淄博硕丰环保设备有限公司

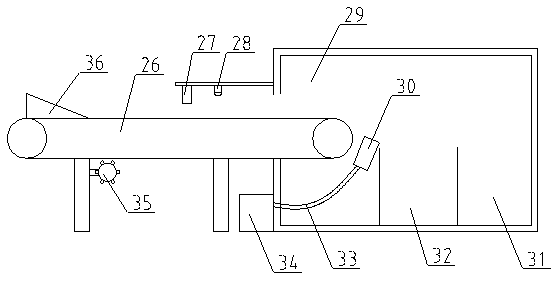

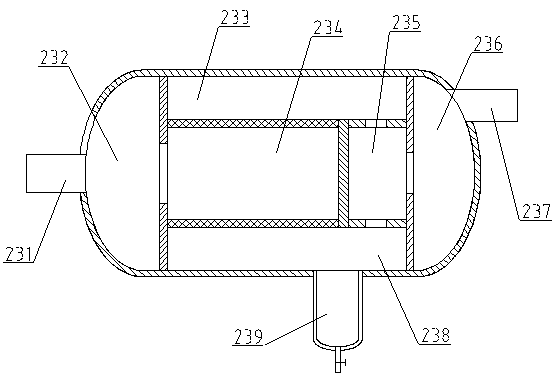

Dehydration process and equipment for biomass solid

InactiveCN102636006AReduce moisture contentHigh fuel valueDrying using combination processesSludge treatment by de-watering/drying/thickeningEnvironmental engineeringMoisture

The invention relates to a dehydration process and equipment for a biomass solid, and belongs to the technical field of biomass dehydration. The invention aims at provided with a dehydration process and the equipment which have the advantages that slight energy source is consumed, the cells in the biomass solid are ruptured, the moisture is dissolved out, the water ratio of the biomass solid is greatly reduced, and the burning value of the biomass solid is improved. The technical scheme adopted by the dehydration process for the biomass solid is as follows: the dehydration process is performed according to the following steps of: 1, fracturing the biomass solid; 2, filtering the biomass solid after fracture; 3, putting the biomass solid into a heating unit, heating, and then entering a pressure container to stay for 10 minutes, thus obtaining a biomass solid cracking liquid; 4, putting the biomass solid cracking liquid into a cooling unit and cooling; and 5, entering a water extractor and carrying out dehydration. The dehydration process and equipment provided by the invention are especially suitable for carrying out dehydration treatment on the biomass solid with higher water ratio.

Owner:太原正阳环境工程有限公司

Method for manufacturing bio-fuel from radix paeoniae alba extraction waste

InactiveCN106190396AReduced Humidity RequirementsIncrease production capacityBiofuelsSolid fuelsCombustionSulfur

The invention discloses a method for manufacturing bio-fuel from radix paeoniae alba extraction waste. The method includes steps of S1, drying radix paeoniae alba residues and then uniformly mixing the radix paeoniae alba residues and sawdust with one another to obtain mixtures; S2, pressing the mixtures to obtain bio-fuel lumps with the density of 0.8-1.2 kg / m<3>. The method for manufacturing the bio-fuel from the radix paeoniae alba extraction waste has the advantages that the bio-fuel manufactured by the aid of the method is easy to industrially produce and use, has high combustion values, is easy to clean and free of boiler corrosion and does not contain sulfur or phosphorus, and the costs can be reduced for enterprises.

Owner:NINGBO LIWAH PLANT EXTRACTION TECH

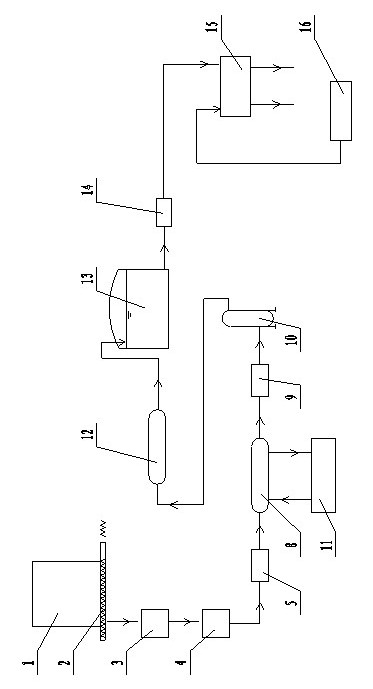

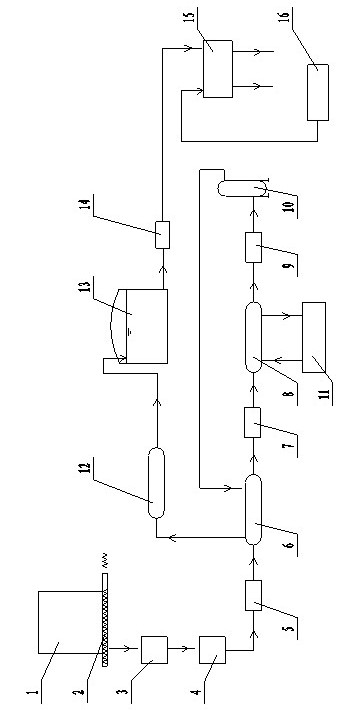

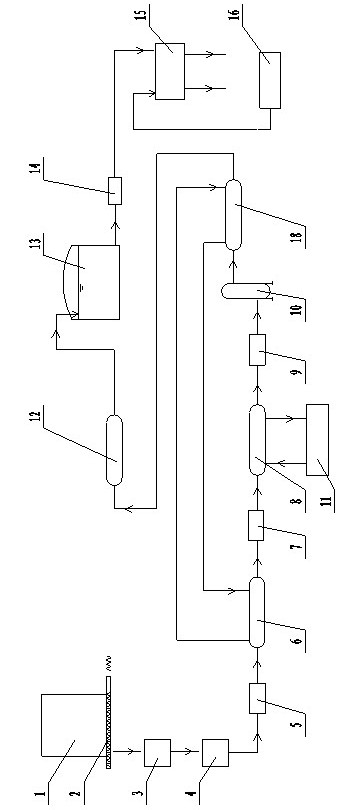

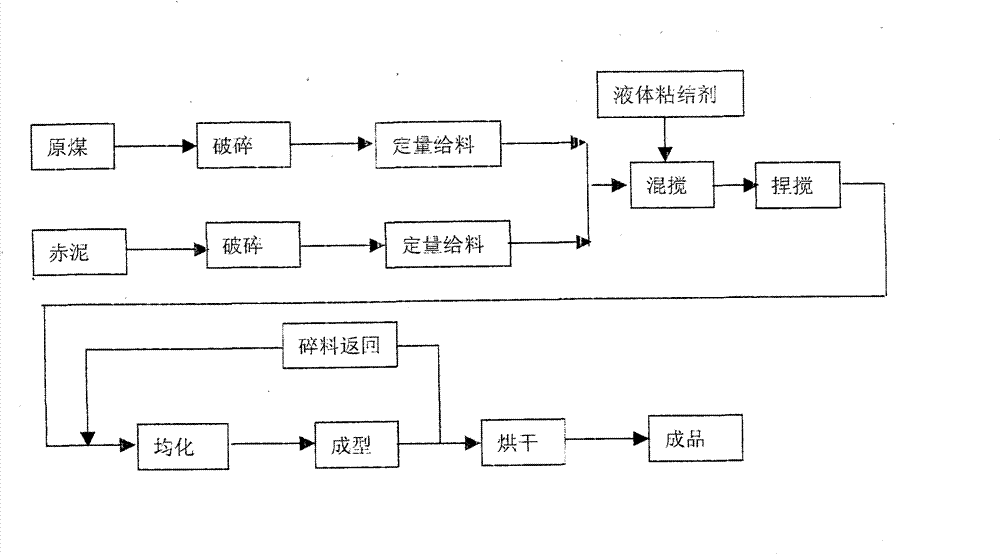

Water-soluble briquette adhesive and process applied to briquette production thereof

The invention discloses a water-soluble briquette adhesive and a process applied to briquette production thereof and relates to an adhesive for briquette for production industry and civilian use and application thereof. The water-soluble briquette adhesive is combined by organic water-soluble adhesive, inorganic water-soluble adhesive, water-soluble preservative, water-soluble combustion improverand water-soluble sulfur and fluorine removal agent, and the process flow for producing the briquette by utilizing the adhesive is as follows: A. raw material crushing; B. quantitative feeding; C. mixing and stirring; D. pinching and stirring; E. homogenizing; F. molding; and G. drying. The adhesive has little use amount in the briquette production, high adhesive strength, high content of fixed carbon and high fuel value, fire-leading is easy, the firepower is large, and soot smell is difficult to smell.

Owner:宋邦娟

Method for preparing biomass fuel with fresh chicken manure as main raw material

ActiveCN106244278BWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsMushroomFermentation

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Method for producing boiler fuel by utilizing papermaking black liquid

InactiveCN102154036AHigh fuel valueReduce pollutionLiquid carbonaceous fuelsCarboxylic acid salt preparationSodium acetateComponents of crude oil

The invention relates to a method for producing boiler fuel by utilizing papermaking black liquid, comprising two steps, namely extraction of lignin and preparation of boiler fuel, wherein the extraction of the lignin comprises the following steps of: firstly, adding glacial acetic acid into papermaking black liquid with the Baume concentration of 36-38'Be and stirring until the pH value becomes 7-8, then adding ammonia acetate and industrial alcohol sold on the market, stirring uniformly, then sealing 12 hours at normal temperature for depositing, carrying out azeotropic distillation on clear liquid for recovering all ethanol and most of water to obtain ammonia lignin paste, wherein the deposition is sodium acetate which is recovered as a byproduct after being washed with methanol; and the preparation of the boiler fuel comprises the following steps of: adding methanol and dioxane in the ammonia lignin paste, filtering after uniformly stirring to obtain basic fuel, and finally, and adding methanol to the basic fuel to produce the boiler fuel provided by the invention. Through the method provided by the invention, resource components in the black liquid are completely utilized, waste materials are changed into valuables, the pollution of the environment is remarkably lightened, the producing process is simple and convenient, and the produced boiler fuel has a high combustion value and lower cost.

Owner:杜良才 +2

Method of preparing biofuel by using radix paeoniae alba extraction wastes

InactiveCN106906020AHigh fuel value of finished productHigh fuel valueBiofuelsSolid fuelsWater contentSaw dust

The invention provides a method for making biofuel by utilizing the wastes extracted from Radix Paeoniae Alba. Take 500 kg of waste dregs after extraction from Radix Paeoniae Alba, a Chinese medicinal material, dry them to a water content of 40% to 50%, and add 1 / 3 to 1 / 3 of the residues of Radix Paeoniae Alba 2 / 3 times the sawdust, mix evenly; press the mixture into cuboids, the density is between 0.8 and 1.2, the cross-sectional diameter is between 3 and 5 cm, and the length is between 4 and 6 cm. The invention does not need cooling, the finished product has high fuel value, does not contain sulfur and phosphorus, and is environmentally safe.

Owner:NINGBO LIWAH PLANT EXTRACTION TECH

A system for making sludge into recycled solid fuel

The invention discloses a system for making sludge into regenerated solid fuel. The system comprises a sludge storage unit, a drying unit, weighing unit, a conveying unit, a granulating unit 8 and a combusting unit which are sequentially arranged. By means of the system, sludge is dried, and dried sludge, coal powder and rice straw are mixed and granulated to form sludge regenerated solid fuel high in combustion value. The system is simple in structure, small in occupied area and high in production efficiency.

Owner:PULIZI ENVIRONMENT TECH SUZHOU CO LTD

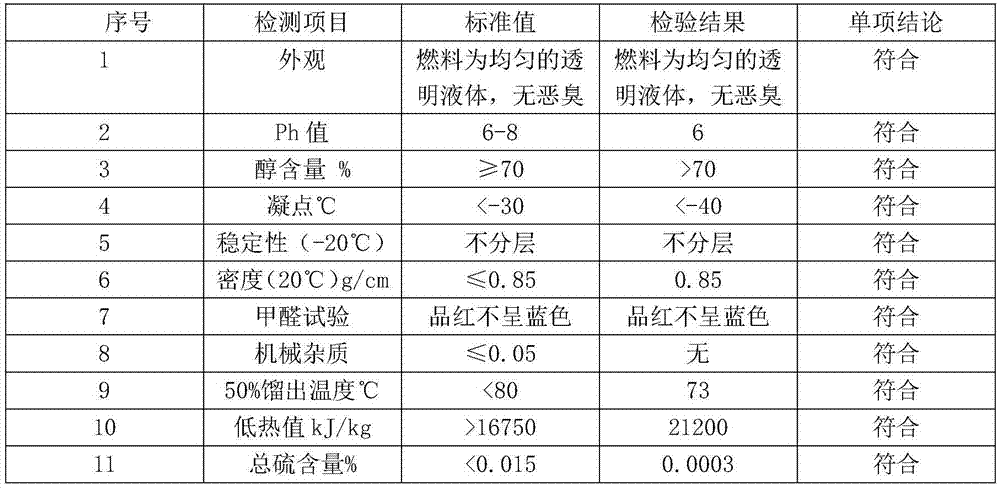

Alcohol base liquid fuel for alcohol base boilers and stoves and preparation method of fuel

An alcohol-based liquid fuel used in alcohol-based boilers and stoves, the formulation components of which include methanol, purified water, ferrocene, gentian violet, hydrogen peroxide, gasoline, and acetone. The beneficial effects are: tasteless, non-toxic, high combustion value, inflammable and non-explosive.

Owner:沈阳力生环保燃料有限公司

Honeycomb coal made from fermented cow dung and preparation method thereof

The invention discloses a honeycomb briquette prepared by using fermented cow dung and a preparation method thereof. The honeycomb briquette comprises 20wt%-50wt% of maturely fermented cow dung and 50wt%-80wt% of pulverized coal. The preparation method of the honeycomb briquette comprises the following steps of (1) adding a certain amount of fermentative bacteria and rice hull powder to the cow dung so as to ferment the cow dung into the maturely fermented cow dung; and (2) fixing and forming, namely mixing the maturely fermented cow dung with the pulverized coal, crushing, stirring and mixing uniformly, selectively adding water during uniform mixing, and carrying out compression molding. The brand-new honeycomb briquette prepared by mixing the fermented cow dung and the pulverized coal, provided by the invention, is odorless and has high acceptability; smashed grasses or straws do not need to be additionally added to the honeycomb briquette, so that the cost is saved, and the honeycomb briquette is easy to form; and the preparation time of the honeycomb briquette is short, and the preparation process is simple, so that the honeycomb briquette is easy to popularize. The preparation method has the advantages that (1) the pollution problem of cattle farms can be greatly reduced; (2) the shortage of fuels can be solved; and (3) the utilization model of energy sources is explored.

Owner:SOUTHWEST UNIV

Garbage treatment system and garbage treatment process

PendingCN114234196AQuick dehydration and dryingHigh purityCombination devicesElectrostatic separationProcess engineeringRefuse Disposals

The invention provides a garbage treatment system and a garbage treatment process. The garbage treatment system comprises a drying inner container, a gas conveying device and a driving device. The drying inner container is provided with a feeding port, a discharging port and a plurality of gas circulation holes, and a flow guide piece is installed on the inner wall of the drying inner container. The gas conveying device communicates with part of the gas circulation holes and is used for conveying high-temperature and high-speed gas into the drying inner container. The driving device comprises a frame body and a driver, the driver is arranged on the frame body, and the drying inner container is rotatably connected with the frame body; the driver is connected with the drying inner container and used for driving the drying inner container to rotate, so that garbage in the drying inner container moves from the feeding port to the discharging port under the action of the flow guiding piece. The device utilizes high-temperature and high-speed gas to quickly and effectively dry moisture in the garbage, the moisture content of the dried garbage is lower than 5%, follow-up treatment of the garbage is facilitated, energy consumption is low, cost is low, and the device is economical and environmentally friendly.

Owner:北京灵娲太昊环保科技研究院有限公司

New-energy high-definition clean methanol liquid fuel for vehicle

PendingCN114181744AImprove solubilityHigh fuel valueLiquid carbonaceous fuelsFuel additivesNew energyEngineering

The invention discloses a new energy high-definition clean methanol liquid fuel for vehicles, which comprises methanol and a core blender, and the core blender comprises the following raw materials: a cosolvent, an antiknock agent, a combustion improver, trithio acid, linoleic acid, carbonic acid, methyl iodide, n-butane, n-butyric acid, 4.5-5.5% of n-ethane, absolute ethyl alcohol, ethylene glycol, polyacrylamide, a corrosion inhibitor, an ether liquid and water. The methanol liquid fuel systematically solves the problems of adjustability, instant solubility, cold start, long-term storage stability of finished products, continuous synthesis of a production process and the like of methanol, and the comprehensive requirements of vehicle fuel can be met by blending the additive.

Owner:中弢能源有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com