Biomass energy particles produced by means of fermentation and preparation method thereof

A biomass energy and particle technology, which is applied in the fields of biofuel, waste fuel, solid fuel, etc., can solve the problems of unsatisfactory effect and discharge of harmful components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

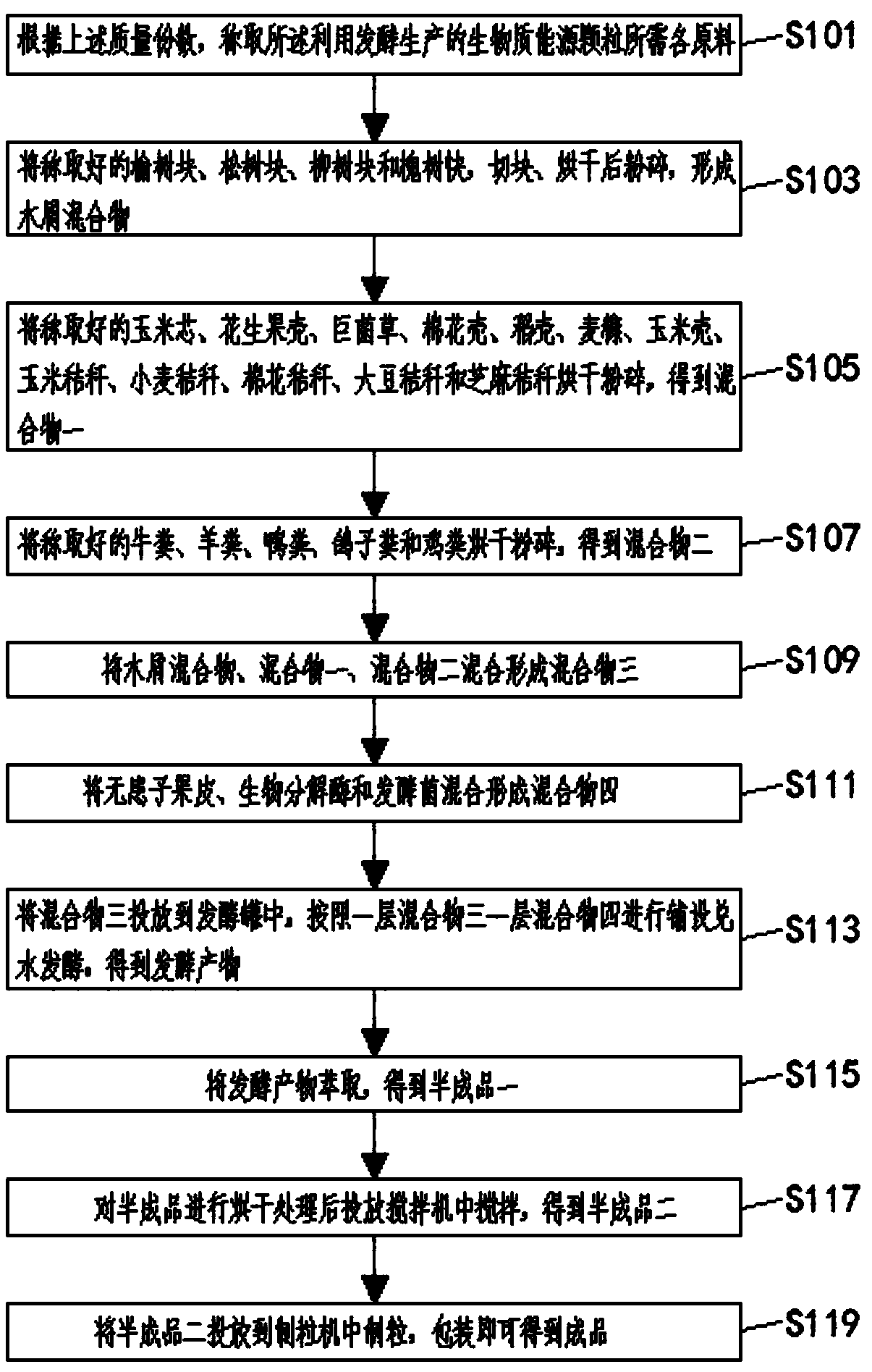

Method used

Image

Examples

Embodiment 1

[0070] A biomass energy granule produced by fermentation, the biomass energy granule produced by fermentation is made of the following raw materials in parts by mass:

[0071] Sapindus peel 10g, corn cob 20g, tar 2g, wood vinegar 5g, coal slime 20g, peanut husk 20g, giant fungus grass 20g, cotton husk 15g, rice husk 15g, wheat bran 15g, corn husk 15g, yellow mud 15g, 70g of wood block composition, 80g of agricultural straw, 18g of poultry manure, 20g of biodegradation enzyme, 20g of fermentation bacteria.

[0072] Wherein, the wood block composition includes the following raw material components: 20g of elm block, 20g of pine block, 15g of willow block and 15g of pagoda tree.

[0073] The agricultural straw includes the following raw material components: 20g of corn straw, 20g of wheat straw, 10g of cotton straw, 10g of soybean straw and 20g of sesame straw.

[0074] The poultry manure includes the following raw material components: 2g of cow manure, 5g of sheep manure, 3g of...

Embodiment 2

[0087] A biomass energy granule produced by fermentation, the biomass energy granule produced by fermentation is made of the following raw materials in parts by mass:

[0088] Sapindus peel 15g, corn cob 30g, tar 6g, wood vinegar 9g, coal slime 30g, peanut husk 30g, giant fungus grass 30g, cotton husk 20g, rice husk 20g, wheat bran 20g, corn husk 20g, yellow mud 20g, 90g of wood block composition, 120g of agricultural straw, 25g of poultry manure, 30g of biodegradation enzyme, 30g of fermentation bacteria.

[0089] Wherein, the wood block composition includes the following raw material components: 25g of elm block, 25g of pine block, 20g of willow block and 20g of pagoda tree.

[0090] The agricultural straw includes the following raw material components: 30g of corn straw, 30g of wheat straw, 15g of cotton straw, 15g of soybean straw and 30g of sesame straw.

[0091] The poultry manure includes the following raw material components: 5g of cow manure, 7g of sheep manure, 4g o...

Embodiment 3

[0104] A biomass energy granule produced by fermentation, the biomass energy granule produced by fermentation is made of the following raw materials in parts by mass:

[0105] Sapindus peel 20g, corn cob 40g, tar 10g, wood vinegar 13g, coal slime 40g, peanut husk 40g, giant fungus grass 40g, cotton husk 25g, rice husk 25g, wheat bran 25g, corn husk 40g, yellow mud 25g, wood block composition 110g, agricultural straw 160g, poultry manure 33g, biodegradation enzyme 40g, fermentation bacteria 40g.

[0106] Wherein, the wood block composition includes the following raw material components: 30g of elm block, 30g of pine block, 25g of willow block and 25g of pagoda tree.

[0107] The agricultural straw includes the following raw material components: 40g of corn straw, 40g of wheat straw, 20g of cotton straw, 20g of soybean straw and 40g of sesame straw.

[0108] The poultry manure includes the following raw material components: 7g of cow manure, 9g of sheep manure, 5g of duck manur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com