Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "High firing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

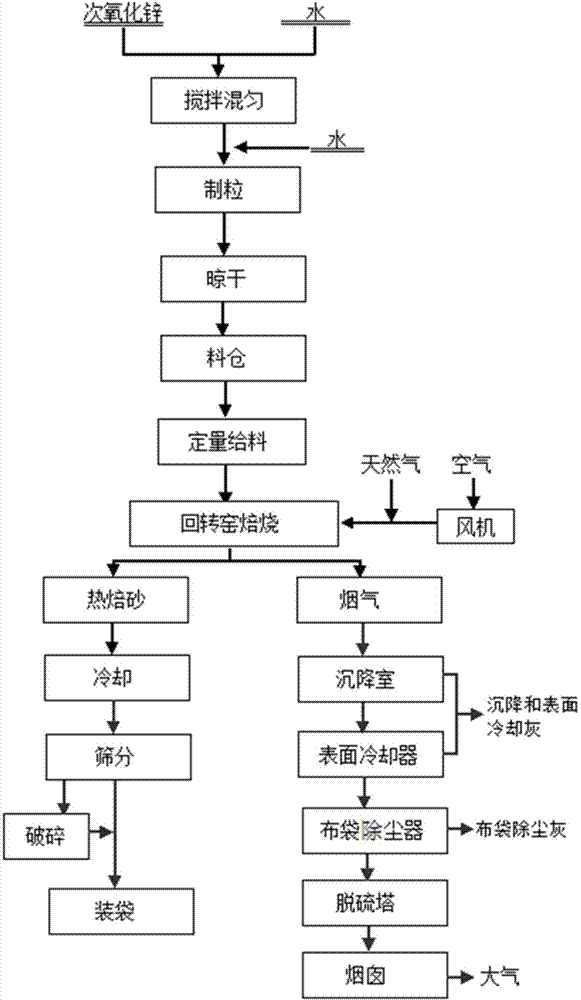

Method for removing fluorine, chlorine and valuable metals in secondary zinc oxide

ActiveCN104773751ASolve the problem of subsequent processingImprove efficiencyZinc oxides/hydroxidesIndiumHigh energy

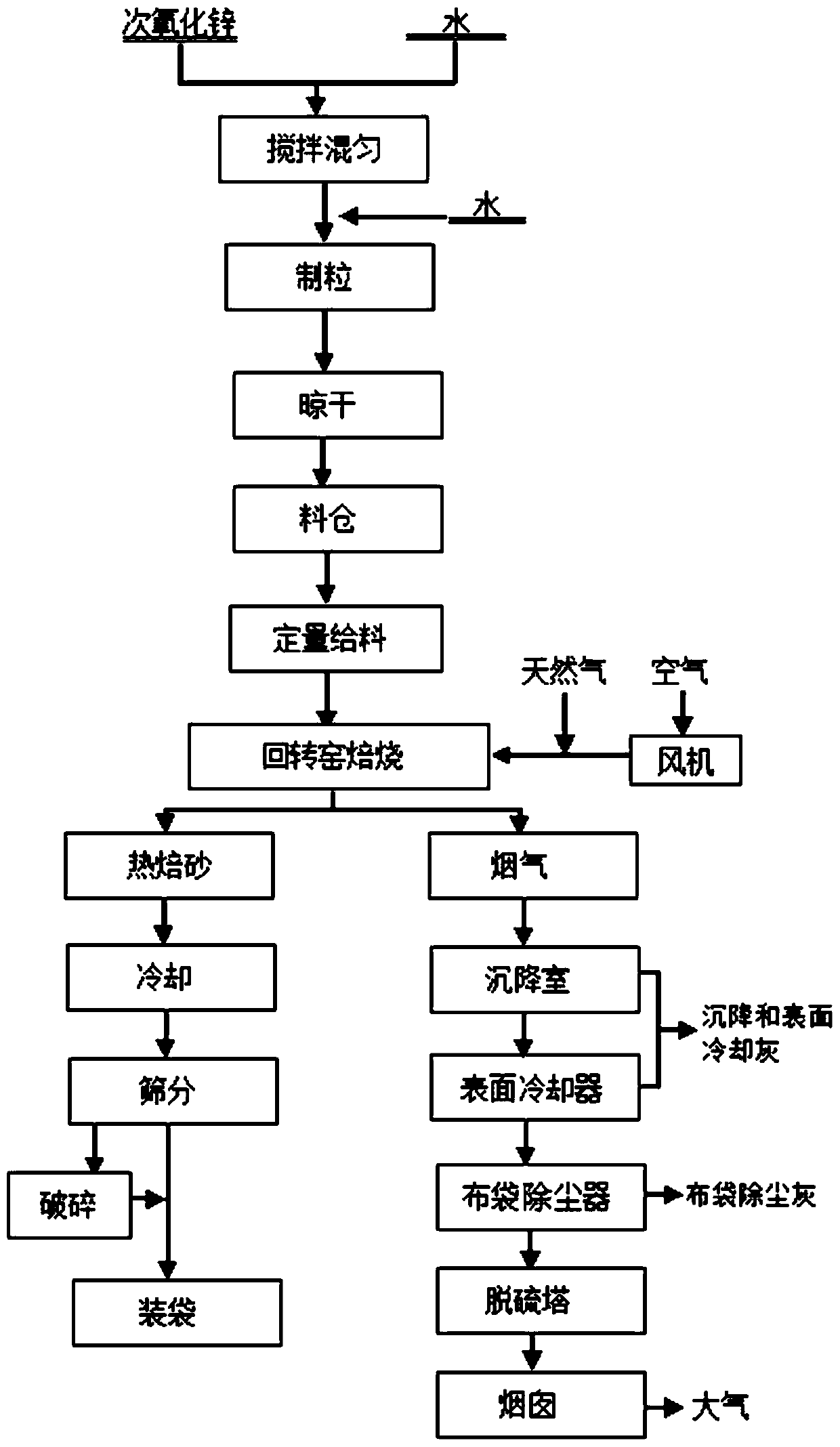

The invention provides a method for removing fluorine, chlorine and valuable metals in secondary zinc oxide, which solves the problems of low removal rate, high energy consumption, low environment friendliness and low economical efficiency in the prior art. According to the method, high-fluoride / chloride secondary zinc oxide used as a raw material is granulated, aired and subjected to rotary kiln roasting, flue gas is settled and subjected to dust collection, the roasted product is subjected to indirect water cooling, and a mixed air heating process is adopted by using natural gas as a heat source, thereby removing the fluorine, chlorine, lead and indium and implementing reenrichment of indium, lead and other valuable metals. The roasting process is utilized to remove most of fluorine, chlorine, lead and indium; the lead and indium are enriched in the roasted dust, thereby solving the problem of later processing of the high-fluoride / chloride secondary zinc oxide; and the method has the advantages of fewer required technical processes, high efficiency, smooth procedure, high degree of mechanization and the like, and greatly enhances the environmental and economic benefits.

Owner:QUZHOU YESHENG METAL MATERIAL CO LTD

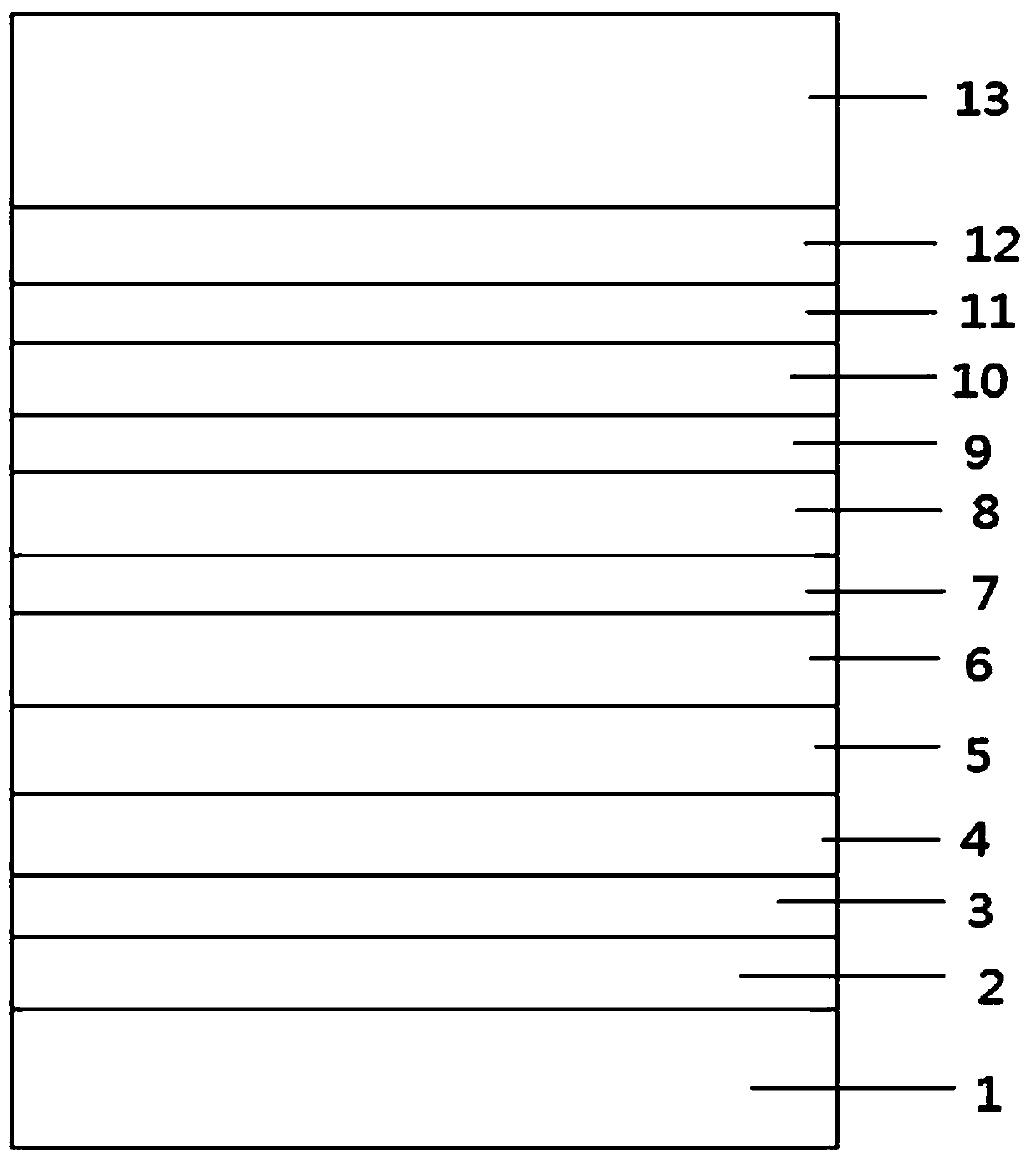

Green-yellow light LED epitaxial structure with optimal reflecting layer and preparation method thereof

ActiveCN108767075AImprove light outputReduce internal stressSemiconductor devicesGreen yellowHigh reflectivity

The invention discloses a green-yellow light LED epitaxial structure with an optimal reflecting layer and a preparation method thereof. The green-yellow light LED epitaxial structure is provided witha GaAs substrate, an AlGaAs buffer layer, a GaAsP buffer layer, an AlGaAsP / AlAsP DBR layer I, an AlGaAsP / AlAsP DBR layer II, an AlGaAsP / AlAsP DBR layer III, an AlInP / AlGaInP DBR layer, an N-AlInP limiting layer, an AlGaInP N waveguide layer, an AlGaInP quantum well active layer, an AlGaIn P waveguide layer, an AlIn P limiting layer and a GaP window from bottom to top in sequence, the AlGaAsP / AlAsPDBR layers consist of an AlAsP / AlGaAsP DBR layer I, an AlAsP / AlGaAsP DBR layer II and an AlAsP / AlGaAsP DBR layer III to form a compound Bragg reflector layer, the light, reflected to a substrate, ofan active layer is reflected and emitted out from the top by using a periodic stratified structure consisting of two materials with different refractive indexes, so that the light extracting rate is greatly improved, the inner stress of the reflector layer is effectively reduced through the intervention of micro PH3, the green-yellow light LED epitaxial structure has relatively high reflectivity,and long-time electrification reliability of a diode is realized.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

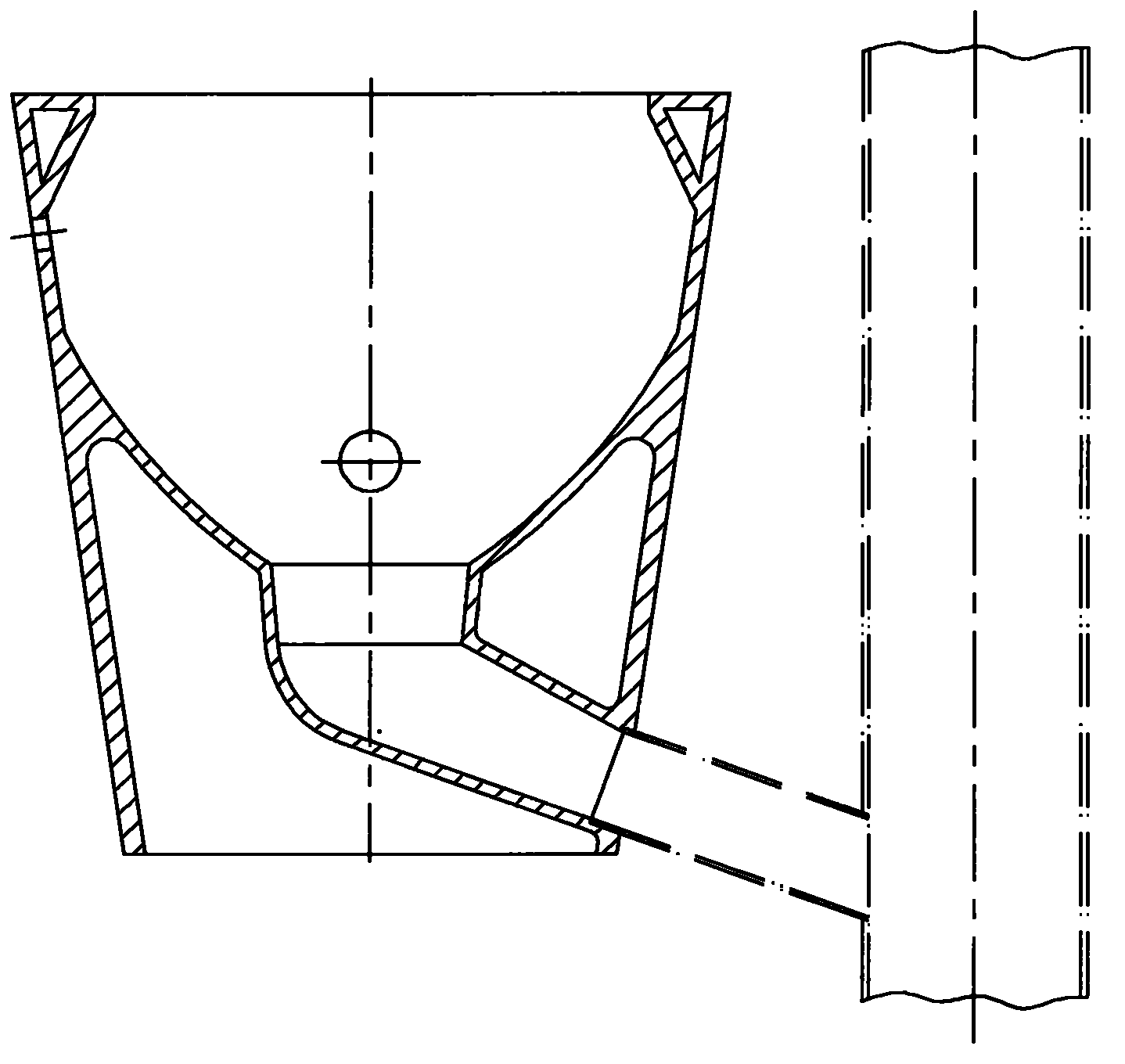

Zirconia base ceramic formula fineness composition for preparing cylinder jacket

InactiveCN1418847ASmall shrinkageImprove fracture toughnessPositive displacement pump componentsLiquid fuel engine componentsMicrometerYttrium

The grain size composition in zirconia base ceramic formula for preparing cylinder casing belongs t the field of structure ceramic preparation technology, and the grain size of main component zirconia powder body in the ceramic formula for preparing cylinder casing includes: one kind of 60-80 wt% of zirconia powder boby whose average grain size is 0.2-0.5 micrometer, and another kinds of 20-40 wt% of zirconia powder body whose average grain size is 0.6-1.2 micrometer, in the zirconia powder body 2-3 mol% of yttrium oxide, 0.5-5 mol% of magnesium oxide, 4-15 wt% of alumina and proper quantity of dispersing agent are added, and undergone the processes of ball-grinding, mixing, spray-granulating, isostatic pressure forming and firing at 1460-1520 deg.c so as to obtain the invented ceramic cylinder casing whose service life is above 2400 hr.

Owner:TIANJIN UNIV

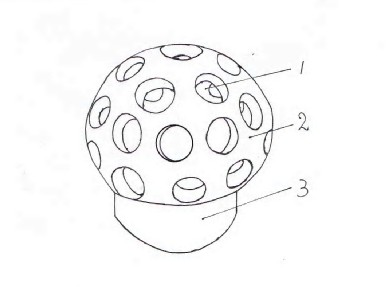

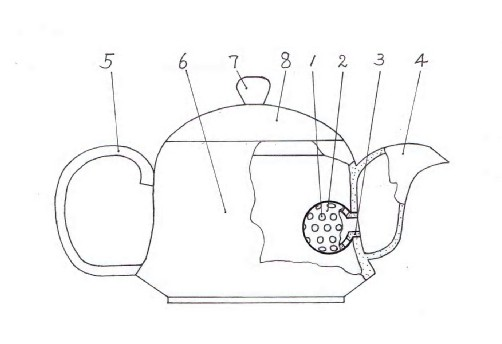

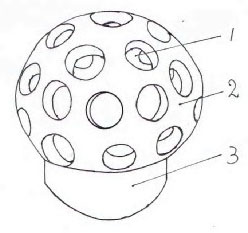

Ceramic mushroom-shaped teapot filter and teapot with same

ActiveCN102599815AImprove filtration efficiencyGood adhesionBeverage vesselsDomestic vesselsLap jointSlurry

The invention relates to a ceramic mushroom-shaped teapot filter and a teapot with the same. The mushroom-shaped filter is a mushroom-shaped hollow combination body and consists of a filter ball and a pin, filter holes are arranged on the filter ball and communicated with the pin, the filter ball is in the shape of a round ball or a similarly round ball or a cone or a circular truncated cone or a square table or a barrel, and the filter holes are uniformly distributed on the filter ball. The filter is a blank or a sintering part. The mushroom-shaped filter is arranged at a communicated position of a teapot mouth and a teapot body of the ceramic teapot, and the pin is integrally connected with a wall of the teapot body. Forming steps for the filter and the teapot include respectively manufacturing the teapot body, a teapot handle, the teapot mouth and the blank of the mushroom-shaped filter by ceramic slurry; punching a hole on the wall of the teapot body; inserting the pin of the filter into the hole; and folding and riveting the pin of the filter to be adhered onto the outer wall of the teapot body. The filter holes are fully distributed on the filter ball of the filter, filter area is large, filter directions are abundant, solid matters are not easy to be adhered on the filter, and filter holes are not easy to be blocked. The teapot with the filter has higher filter efficiency. A forming technological method is unique in design, contact points and contact surfaces are abundant, lap joint is accurate, forming is rapid, production efficiency is high, the filter and the teapot with the filter are formed neatly, and top sintering yield is high.

Owner:普鹭一蝶

Zirconia reinforced alumina ceramic liner

InactiveCN1702054AFormability adjustmentImprove fracture toughnessGranularityZirconia Toughened Alumina

The granularmetric composition of aluminum oxide as main constituent of ceramic jacket of drill pump comprises 60-70wt% of aluminum oxide with particle mean size of 0.8-1.0mum and 30-40wt% of aluminum oxide with particle mean size of 1.0-2.8mum. Moreover, 15mol% of zirconium oxide and disperser are added to it and the mixture is shaped by isostatic pressing after abrading-ball mixing and spray pelleting then treated under the temperature between 1550-1620 Deg.C to produce ceramic jacket with life duration of more than 2000h. Meanwhile, the invention has the advantages of high rate of finished products and low cost of material and process.

Owner:祝卫

High-temperature black-body porcelain and method of producing same by means of oxidizing flame firing

The invention discloses high-temperature black-body porcelain, prepared with a preform body and glaze. The preform body is made from, by weight, 18-20% of washed clay, 12-15% of lime mud, 36-44% of white clay, 18-25% of red purple-sand shale, 16-20% of quartz, and 5-8% of tillite. The glaze is made from, by weight, 20-25% of potassium feldspar, 15-22% of soda feldspar, 25-30% of quartz, 10-15% oflimestone, 5-13% of zinc, 5-12% of barium carbonate, 3-8% of talcum, 5-8% of kaolin, and 3-6% of titanium. The finished porcelain has authentic color, good attractiveness and good surface artistic effect; product firing rate is high, product performance is stable, and glaze surface is free of cracking.

Owner:醴陵市科镭陶瓷釉料有限公司

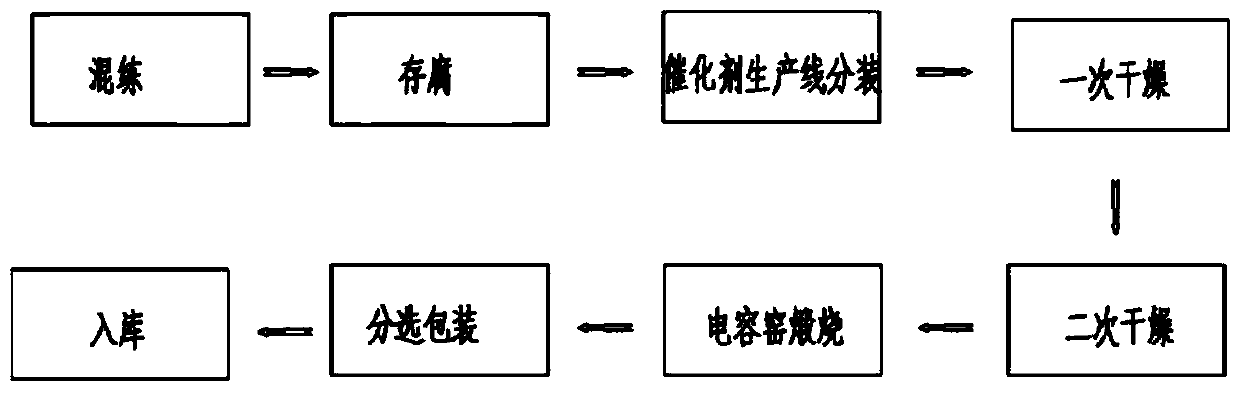

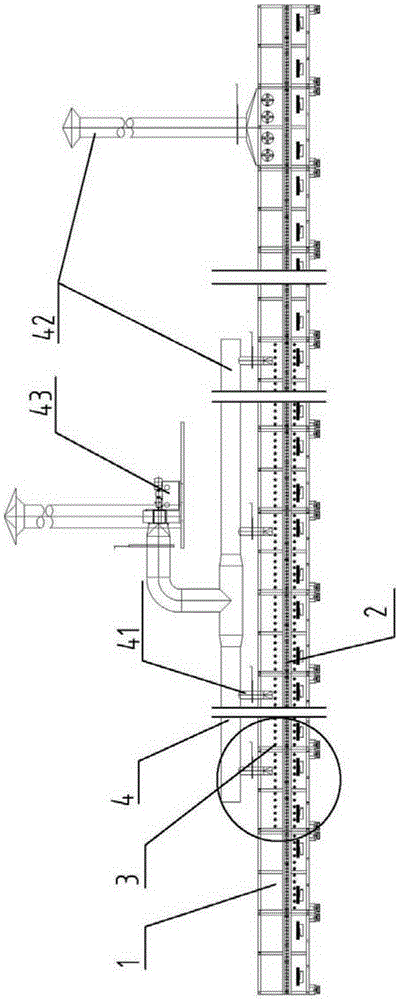

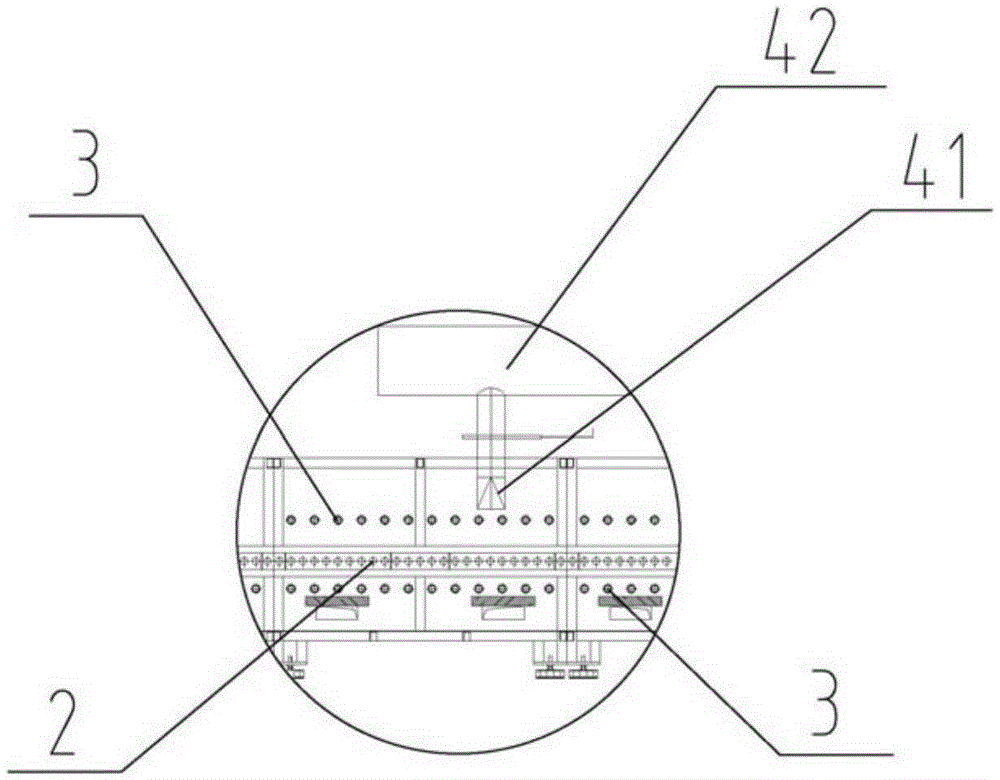

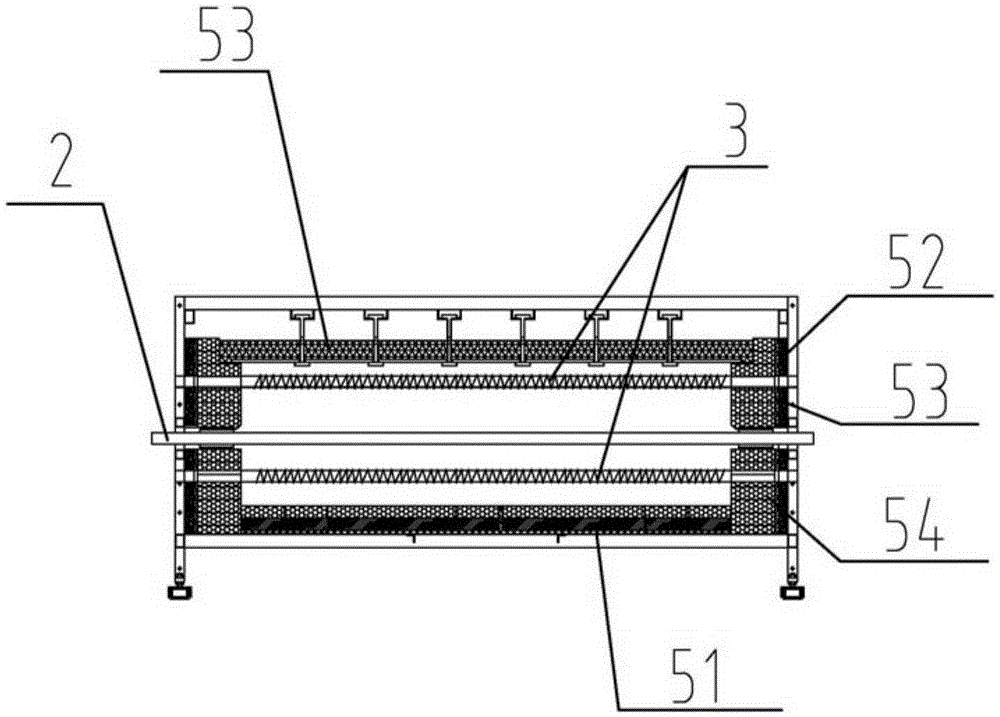

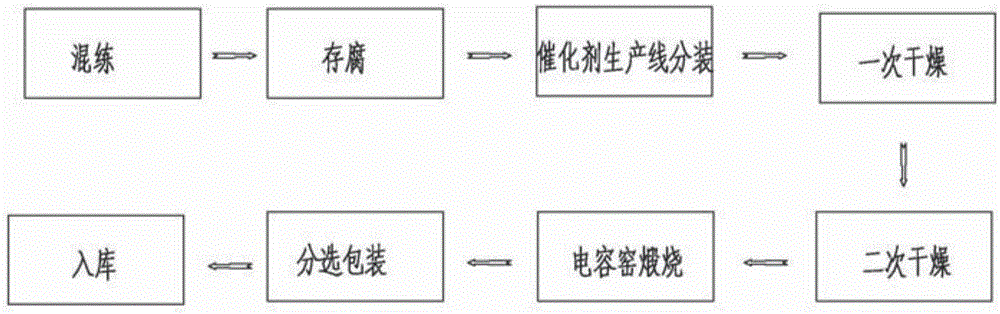

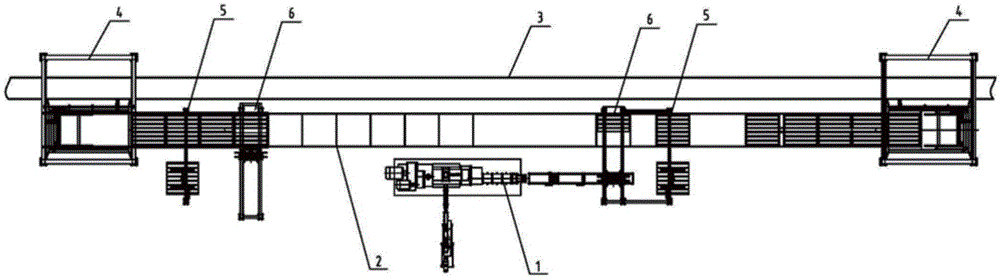

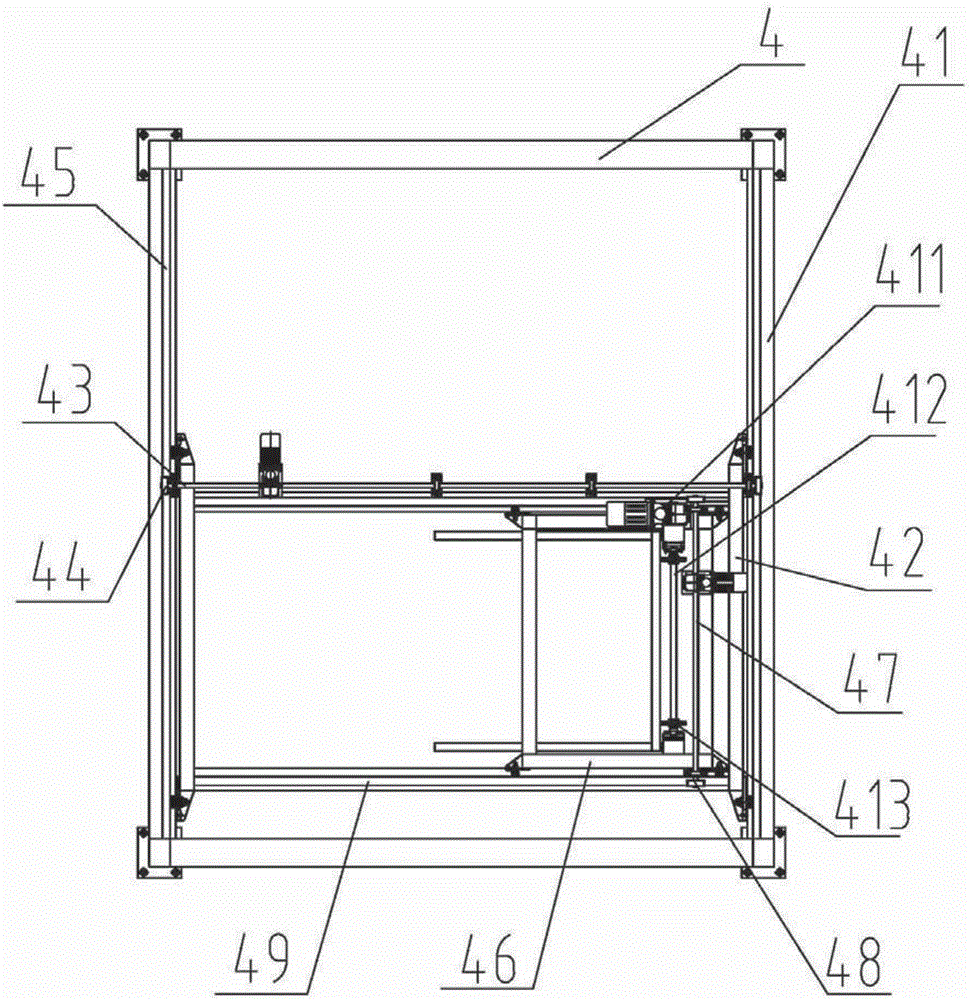

SCR catalyst production system

InactiveCN104190476AImprove automation production efficiencySmall amount of deformationDrying gas arrangementsCatalyst activation/preparationCapacitanceConveyor belt

The invention discloses an SCR catalyst production system which comprises a mixer, a storage room, an automatic production line, a primary drying kiln, a secondary drying kiln, a capacitance kiln and the like, wherein the production line mainly comprises a product conveying line, a tray loading and unloading system, an upper cover loading and unloading system and a catalyst loading and unloading system; the primary drying kiln comprises a primary drying kiln body, a product conveying system, a gas circulation control system, a temperature control system and a humidity control system; the secondary drying kiln comprises a kiln body, a steam pipeline, a frequency conversion control axial flow fan, a humidity control system and a kiln vehicle guide rail; and the capacitance kiln comprises a kiln body, a conveyor belt and a moisture removal system. A catalyst blank production line is automatically assembled, and the automatic production efficiency is greatly improved. According to the production process generated by the unique structure of the drying kilns, the product deformation is reduced, and the rejection rate is reduced. The products are conveyed in the capacitance kiln by adopting ceramic roller rods, the production system is stable in structure, difficult to deform and high in firing yield and achieves heating of heating wires.

Owner:江苏宇达环保科技股份有限公司

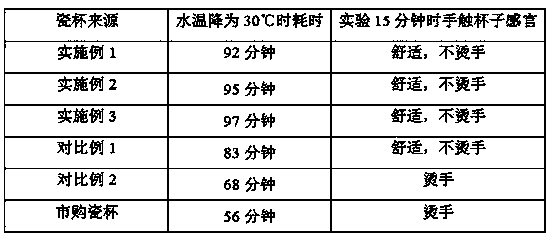

Magnesium jade porcelain and production method thereof

InactiveCN104291799AReduce manufacturing costImprove thermal stabilitySolid waste disposalThermal insulationTalc

The invention relates to a magnesium jade porcelain and a production method thereof. The blank of the magnesium jade porcelain comprises the following raw materials in parts by weight: 45-50 parts of calcninated talc, 30-35 parts of clay, 10-20 parts of feldspar, and 5-10 parts of serpentine waste (based on dry materials); the serpentine wastes is filter residue obtained after extracting serpentine mineral powder through inorganic acid. Due to use of serpentine waste, the production cost of the magnesium jade porcelain is lowered, the combination of the formula can ensure a high yield of the fired magnesium jade porcelain finished products and the cost is further lowered; the serpentine is of multiple colors and easy to dye, thus the prepared magnesium jade porcelain is colorful; serpentine has thermal insulation and heat preservation characteristics, so that the thermal insulation property of the magnesium jade porcelain is improved and the heat preservation effect is good. According to the method, the synergistic effect of all components in the formula can be fully played, the fired porcelain is high in yield, has many colors, good thermal insulation property, and is especially applicable to porcelain for cantering.

Owner:CHONGQING DUMAI PORCELAIN

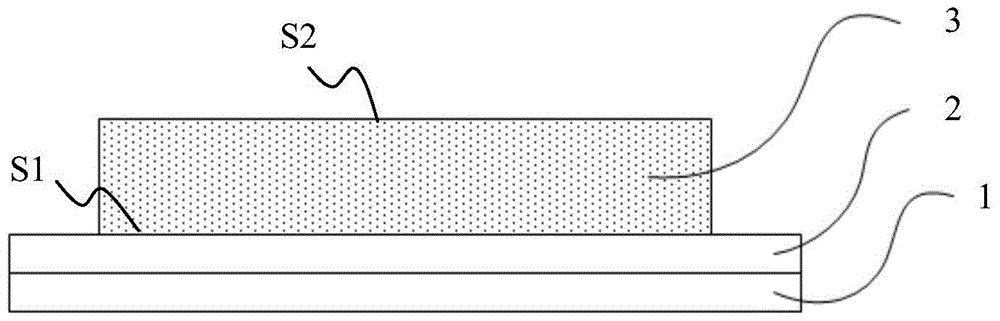

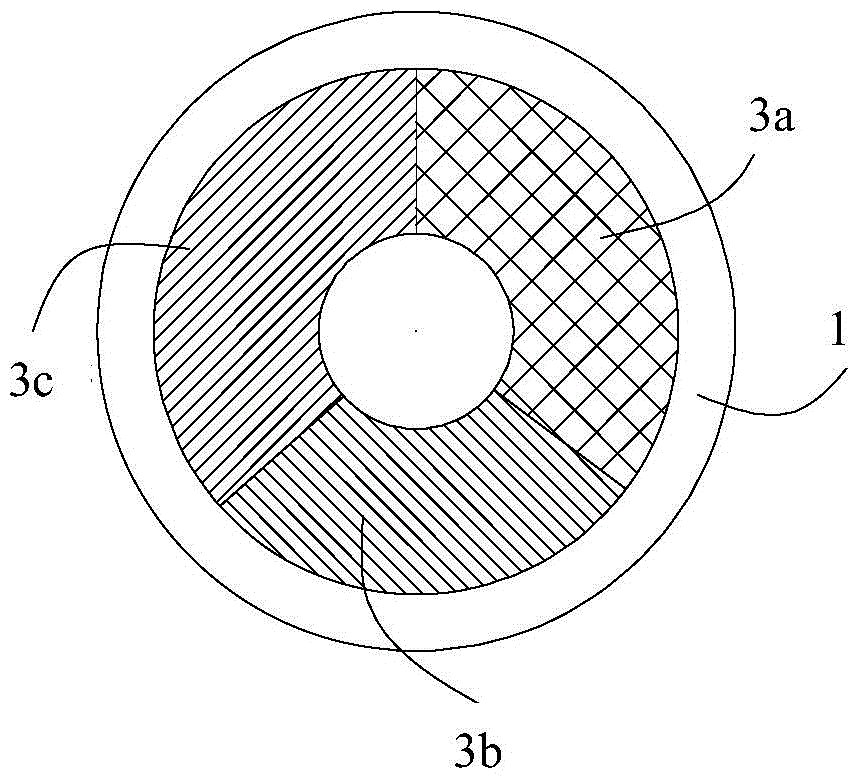

A wavelength conversion device, a diffuse reflection layer, a light source system and a projection system

ActiveCN104595852BHigh refractive indexHigh firing rateLighting heating/cooling arrangementsProjectorsHeat stabilityRefractive index

The embodiment of the invention discloses a wavelength conversion device, a diffuse reflection layer, a light source system and a projection system. The wavelength conversion device comprises a fluorescent layer containing fluorescent powder for realizing wavelength conversion, as well as the diffuse reflection layer attached to the backlight surface of the fluorescent layer; the diffuse reflection layer comprises white scattering particles and a first binding element bound with the white scattering particles; the ratio of the refractive index of the white scattering particles to that of the first binding element is greater than 1.2. After the invention is adopted, a thinner diffuse reflection layer can achieve high reflectivity, and the thinner diffuse reflection layer is beneficial to shortening of a heat conduction path of a luminous layer, so that the heat stability of the wavelength conversion device is improved.

Owner:APPOTRONICS CORP LTD

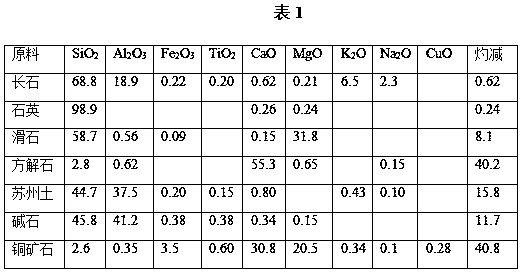

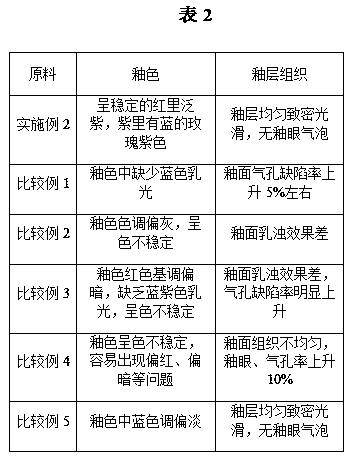

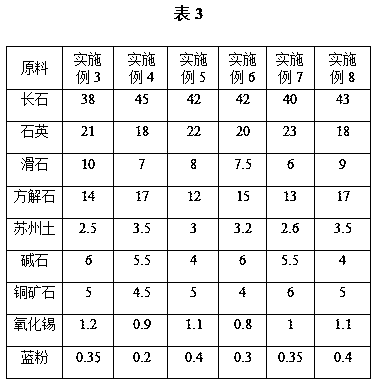

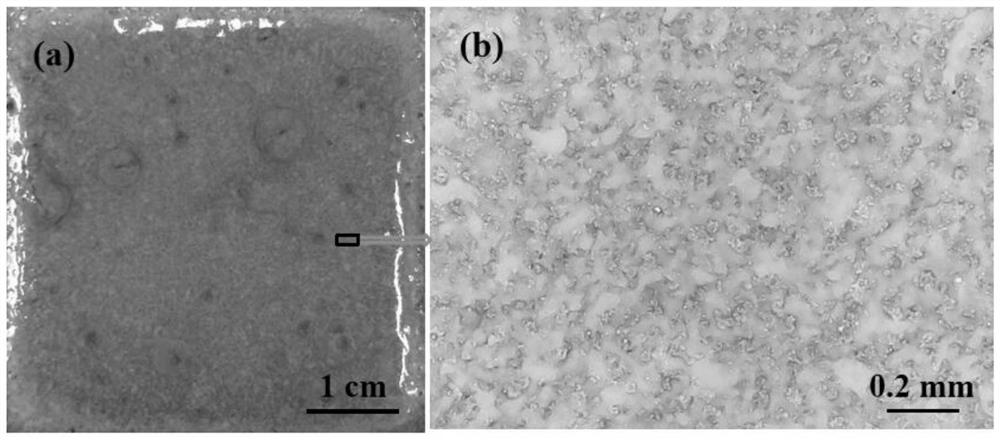

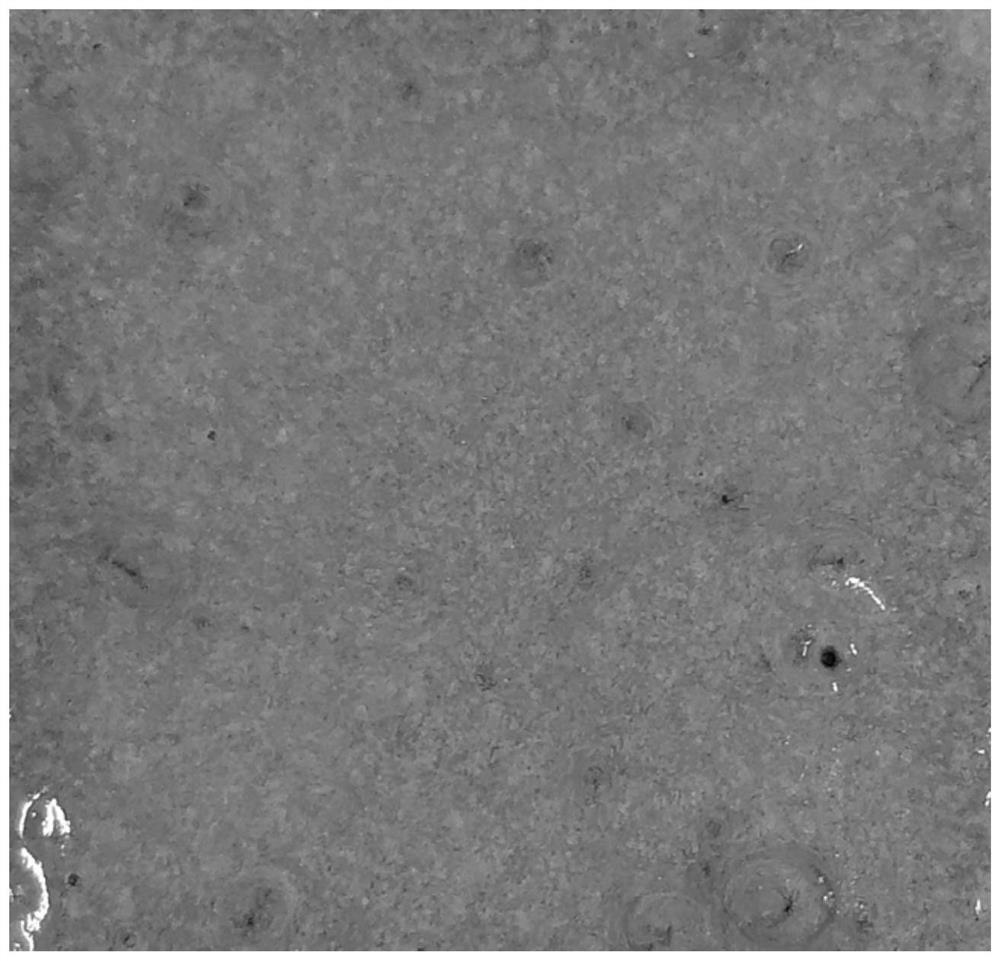

Jun porcelain rose violet glaze and preparation method thereof

The invention relates to Jun porcelain rose violet glaze. The Jun porcelain rose violet glaze is prepared from the following raw materials in parts by weight: 38 to 46 parts of feldspar, 17 to 23 parts of quartz, 6 to 10 parts of talc, 12 to 18 parts of calcite, 2.5 to 3.5 parts of Suzhou soil, 4 to 6 parts of soda lime, 4 to 6 parts of copper ore, 0.8 to 1.2 parts of stannic oxide and 0.2 to 0.4part of blue powder. On the basis of the traditional Jun porcelain raw materials such as the feldspar, the quartz, the talc and the calcite, the Jun porcelain rose violet glaze provided by the invention adopts the copper ore to cooperate with the blue powder and the stannic oxide to serve as coloring agents, uses the soda lime and the Suzhou soil cooperatively, adopts heat preservation for 1 to 2hours in the firing later period, adopts a method of opening a kiln door to perform oxidation and cooling, and increases the firing finished product rate and saves the cost on the basis of maintainingthe characteristics of the rose violet glaze.

Owner:禹州市土魂钧瓷有限公司

A formula of a glaze material showing bluish violet ripples in furnace transmutation

The invention relates to a formula of a glaze material showing bluish violet ripples in furnace transmutation. Raw materials of the glaze material include Yushan red feldspar, quartz, plant ash, glazestone, frit, iron oxide red powder, 'Rulan' stone, talc powder, stannic oxide and zinc oxide, and particularly include, by weight, 40-55 parts of the Yushan red feldspar, 15-20 parts of the quartz, 7-15 parts of the plant ash, 5-10 parts of the glaze stone, 5-9 parts of the frit, 5-8 parts of the iron oxide red powder, 5-7 parts of the 'Rulan' stone, 0.5-1 parts of the talc powder, 0.3-0.5 part of the stannic oxide and 0.1-0.3 part of the zinc oxide. The glaze material has bright and gorgeous color, novel and beautiful patterns, uniform cracks, high artistic value and ornamental and collection value, a high firing yield, and high production value, and the production efficiency is increased.

Owner:温书强

Jun porcelain bluish white glaze and preparation method thereof

The invention discloses Jun porcelain bluish white glaze and a preparation method thereof. The Jun porcelain bluish white glaze is prepared from the following raw materials in parts by weight: 43 parts to 48 parts of melilite, 13 parts to 19 parts of calcite, 15 parts to 21 parts of quartz, 2 parts to 3 parts of tin oxide, 2.5 parts to 3.5 parts of fired talc, 0.9 part to 1.1 parts of zirconium silicate, 1.5 parts to 2.5 parts of zinc oxide, and 1.5 parts to 2.5 parts of tourmaline. The preparation method of the Jun porcelain bluish white glaze comprises the following steps: (1) adding water into the raw materials and mixing; carrying out ball milling to obtain glaze slurry; (2) glazing; (3) firing at firing temperature of 1280 to 1300 DEG C. The Jun porcelain bluish white glaze and the preparation method of the Jun porcelain bluish white glaze disclosed by the invention have the beneficial effects that by adding chemical raw materials including tin oxide, zinc oxide and zirconium silicate into a conventional raw material, so that the finished product rate is increased from originally being less than 50 percent to 80 percent or above; by adding the tourmaline, the product can slowly release negative ions to surrounding environment, so that certain antibacterial and deodorizing effects are achieved.

Owner:燕俊峰

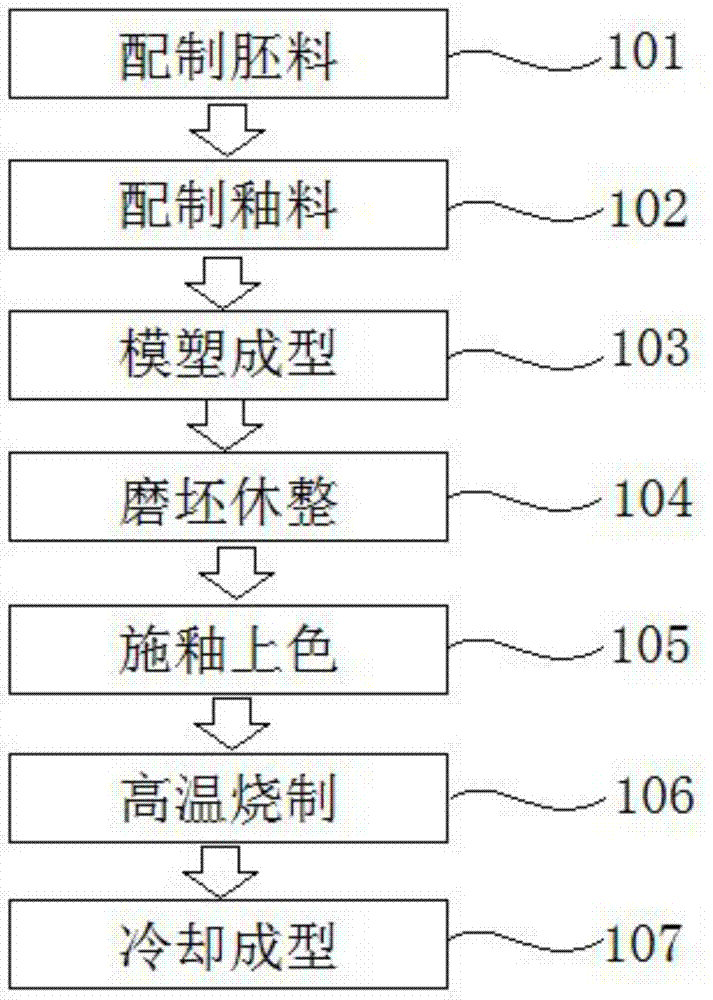

Firing method of multi-layer glaze ceramic

InactiveCN104496414AHigh strengthImprove fracture toughnessClaywaresShell moldingUltimate tensile strength

The invention relates to a firing method of a multi-layer glaze ceramic. The firing method comprises the following steps: blank preparation, glaze preparation, mold shaping, green milling and trimming, glazing, coloring, high-temperature firing and cooling formation, wherein blank preparation comprises: accurately weighing ceramic green raw materials in parts by weight, pretreating by virtue of a stirring technology or a milling technology, mixing, crushing, grinding and sieving. The firing method has the beneficial effects that with reasonable proportion of the ceramic green raw materials and a glaze layer raw material and pretreatment for many times, the firing finished product rate is increased, and the strength and the fracture toughness of the ceramic are also improved.

Owner:SHANGHAI YUYAO ARTWORK CO LTD

A formula of a glaze material showing purple-white ripples in furnace transmutation

The invention relates to a formula of a glaze material showing purple-white ripples in furnace transmutation. Raw materials of the glaze material include feldspar, calcite, iron ore, cattle bone ash,fluorite, kaolinite clay rock, glaze stone, frit, zinc oxide, talc powder, copper oxide and stannic oxide, and particularly include, by weight, 60-70 parts of the feldspar, 30-40 parts of the calcite,15-20 parts of the iron ore, 7-20 parts of the cattle bone ash, 8-15 parts of the fluorite, 7-15 parts of the kaolinite clay rock, 5-10 parts of the glaze stone, 5-9 parts of the frit, 3-5 parts of the zinc oxide, 0.5-1 part of the talc powder, 0.1-0.3 part of the copper oxide and 0.1-0.3 part of the stannic oxide. The glaze material has bright and gorgeous color, novel and beautiful patterns, uniform cracks, high artistic value and ornamental and collection value, a high firing yield, and high production value, and the production efficiency is increased.

Owner:温书强

Formula of glaze with blue-white fambe corrugations

InactiveCN108640517AFresh and elegant glaze colorThe texture is novel and beautifulFritMYRRH TINCTURE

The invention relates to a formula of glaze with blue-white fambe corrugations. The glaze is prepared from,by weight,50-55 parts of feldspar,20-25 parts of quartz,10-15 parts of calcite,6-8 parts of frits,2-4 parts of myrrh,2-4 parts of thermonatrite,2-5 parts of plant ash,0.8-1 part of talcum powder,0.5-1 part of copper oxide and 0.5-0.7 part of zinc oxide. The glaze is fresh,simple but elegant,novel and attractive in grain,uniform in hacking and high in firing yield,has the high art value and ornamental collection value and high production value,and improves the production efficiency.

Owner:温书强

Medium-temperature black-body ceramic and preparation method thereof

The invention discloses medium-temperature black-body ceramic. The medium-temperature black-body ceramic is prepared by a preform body and glaze, wherein the preform body comprise, by weight percentage, 20-23% of washed porcelain clay, 9-12% of grey clay, 28-35% of white clay, 20-28% of red purple-sand shale, 21-25% of quartz and 5-8% of tillite; the glaze comprises, by weight percentage, 30-35% of potassium feldspar, 25-30% of albite, 25-30% of quartz, 10-15% of limestone, 0-4% of zinc oxide, 5-12% of barium carbonate, 3-8% of talcum, 5-8% of kaolin and 5-12% of pigment or 3-6% of coloring oxide. The medium-temperature black-body ceramic is high in sintering yield, stable in performance and free of glaze cracking.

Owner:醴陵市科镭陶瓷釉料有限公司

High-temperature black body porcelain and its preparation method by oxidizing flame firing

Owner:醴陵市科镭陶瓷釉料有限公司

A kind of golden yellow ceramic glaze and preparation method thereof

The present invention relates to the technical field of ceramic glaze preparation, specifically a golden yellow ceramic glaze and a preparation method thereof. The specific process is to prepare the glaze according to a certain proportion of micronano silver powder, albite, quartz, talc and calcite, The glaze is made into a glaze slurry by planetary ball milling, and the glaze is applied to the surface of the ceramic biscuit by the glaze dipping method. After the glazed biscuit is dried, it is placed in a program-controlled high-temperature furnace and fired in an air atmosphere to obtain a golden yellow color. Ceramic glaze products with color effects. The present invention utilizes the phenomenon of synergistic reaction, diffusion effect and condensation of micro-nano silver and other components in the glaze formula and oxygen in the air during the high-temperature glaze firing process, and is prepared by using a program-controlled high-temperature furnace under air atmosphere conditions. It has a uniform golden yellow color on the glaze surface, good glossiness of the glaze layer, smooth enamel, ceramic glaze with a certain jade texture, and a ceramic glaze product without pinholes and orange glaze defects. The preparation method is simple and easy to operate, and has a wide range of applications prospect.

Owner:禹州市神后镇孔家钧窑有限公司

Manufacturing method of wood-grain-color pottery

InactiveCN112341142AHigh firing rateThe effect of wood grain color is remarkableClaywaresMaterials preparationSlurry

The invention relates to the technical field of pottery manufacturing, in particular to a manufacturing method of wood-grain-color pottery. The method comprises the following steps: step 1, manufacturing primary pug; step 2, preparing slurry; step 3, preparing materials for a finished molded product; step 4, manufacturing the finished molded product; step 5, trimming the manufactured finished molded product; and step 6, firing greenware. The method has the advantages that the raw materials for manufacturing the wood-grain-color greenware are wide in sources; red and white clay blocks for manufacturing the wood-grain-color greenware are fine and smooth and good in formability through treatment of the primary pug, foundation pug and the slurry; treatment steps are simple; the manufactured wood-grain-color greenware is high in firing yield and remarkable in wood grain color effect; and in addition, no additive is added, so manufacturing cost is effectively reduced.

Owner:邓泽明

A kind of high-brightness colorful ceramic product and its preparation method

The invention provides a high-brightness and colorful ceramic product and a preparation method thereof. The high-brightness and colorful ceramic product includes a green body and a glaze applied on the surface of the green body, and the green body includes the following components in parts by weight: kaolin 20-45 parts, 8-15 parts of albite, 15-25 parts of quartz sand, 5-10 parts of high-permeable silica powder and 4-8 parts of cordierite; the glaze includes the following components by weight: lead oxide 8‑15 parts, 5‑8 parts of zinc sulfide, 6‑10 parts of copper oxide and 4‑6 parts of cobalt oxide. The glaze of the present invention is composed of specific components, which can not only obtain colorful and colorful ceramic products, but also stimulate a certain amount of fluorescence. The glaze is glazed on the green body of the present invention, and high-permeable silicon micropowder and Viola The transparent refraction of bluestone can produce high-brightness and colorful ceramic products. The glaze color is shiny and bright, and it has a glass texture, which is pleasing to the eye.

Owner:福建省德化县优扬工艺品有限公司

A kind of medium-temperature plum celadon glaze and medium-temperature plum qinglongquan celadon

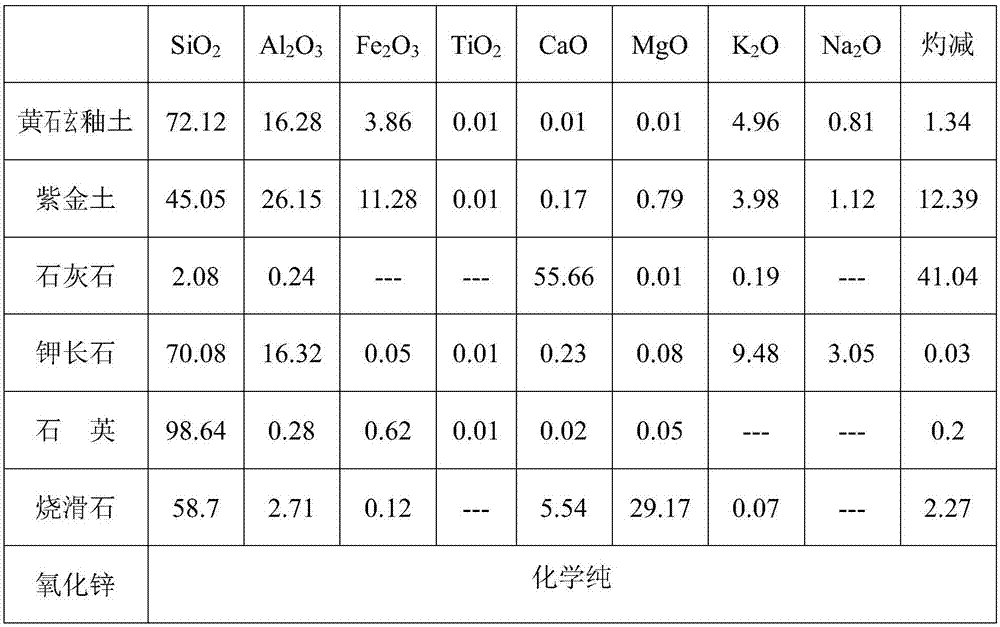

The invention discloses medium-temperature plum green glaze and medium-temperature plum green Longquan celadon.The medium-temperature plum green glaze is prepared from, by mass, 23-28% of yellowstone basalt glaze earth, 15-22% of limestone, 10-17% of Zijin earth, 20-25% of potassium feldspar, 6-12% quartz, 1-3% of calcined talc and 5-8% of zinc oxide.By increasing content of alkaline metal oxide and alkaline earth metal oxide in the glaze, firing temperature of the medium-temperature plum green glaze is lowered, the medium-temperature plum green glaze can be fired in reducing atmosphere at temperature of 1200-1230 DEG C, firing energy consumption is lowered, and firing cost is saved by 20-25% when compared with that of common formulations; the medium-temperature plum green glaze is stable in color and luster, high in fluidity and capable of meeting batch production requirements; Zijin earth with iron content higher than 10% is used as a main colorant, so that aesthetic requirements of the public on color, luster and texture of crude ore glaze can be met to greatest extent.

Owner:ZHEJIANG TIANFENG CERAMIC +1

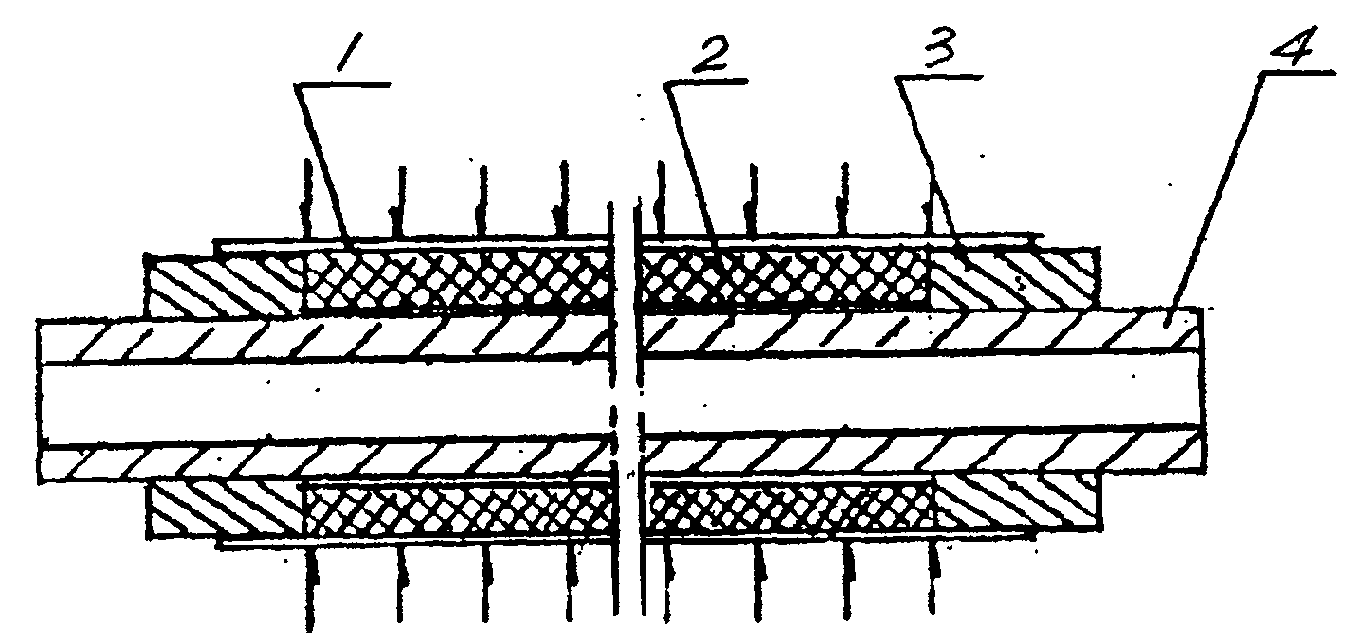

Shaping method of slight ceramic tube

InactiveCN100579750CImprove body strengthGuaranteed diameter uniform performanceCeramic shaping apparatusClay processing apparatusHigh densityHigh pressure

The invention discloses a slender ceramic pipe and a shaping method thereof. The slender ceramic pipe with high density and good roundness can be produced according to the shaping method. The manufacture method of bidirectional isopiestic shaping for the slender ceramic pipe comprises the steps that: briquettes disposed by vacuum refining mud and mossiness are formed and dried by a vacuum pipe extruder; a flexible internal die is arranged on the internal pore wall of the briquette; a flexible external die is sleeved on the external wall of the briquette pipe; furthermore, a flexible internal die piston and a flexible external die piston hermetically seal two ends of the briquette ; the flexible internal die piston is provided with a central through hole; the briquette shaping component is arranged in a high-pressure container to carry out the internal and external bidirectional isopiestic shaping; the finished slender ceramic pipe is then gained by demoulding, normal burning and long processing. The slender ceramic pipe provided by the invention can be widely applied to the ceramic roller in kilns or other situations which require the slender ceramic pipes.

Owner:何锡伶

Yellow-green LED epitaxial structure with optimized reflective layer and preparation method thereof

ActiveCN108767075BReduce internal stressAchieving power-on reliabilitySemiconductor devicesQuantum wellRefractive index

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

A kind of blue-gray section purple sand mud and its firing method

Owner:YIXINF FANGJING PURPLE

Magnesia jade porcelain and its production method

InactiveCN104291799BReduce manufacturing costImprove thermal stabilitySolid waste disposalTalcWaste material

The invention relates to a magnesia jade porcelain and a production method thereof. The blank of the magnesia jade porcelain is composed of the following raw materials in the weight ratio: 45-50 parts of calcined talc, 30-35 parts of clay, 10-20 parts of feldspar and serpentine 5-10 parts of stone waste (according to dry product); said serpentine waste is the filter residue after serpentine ore powder is leached with inorganic acid. The present invention reduces the production cost of magnesia jade porcelain due to the use of serpentine waste, and the combination of the formula also makes the yield of magnesia jade porcelain high in the firing process, further reducing the cost; the serpentine is rich in color and easy to dye, with Give magnesia jade porcelain rich colors; serpentine has the characteristics of heat insulation, which improves the heat insulation performance of magnesia jade porcelain, and has a good heat preservation effect. The method of the invention fully exerts the synergistic effect of the ingredients in the formula, and the fired porcelain has high yield, rich colors and good heat insulation, and is especially suitable for being used in catering porcelain.

Owner:CHONGQING DUMAI PORCELAIN

A method for removing fluorine, chlorine and valuable metals in secondary zinc oxide

ActiveCN104773751BSolve the problem of subsequent processingImprove efficiencyZinc oxides/hydroxidesIndiumChemistry

The invention provides a method for removing fluorine, chlorine and valuable metals in sub-zinc oxide, which solves the problems of low removal rate, high energy consumption, unenvironmental and economical problems in the prior art. The method of the present invention uses high-fluorine chlorine suboxide zinc oxide as raw material, adopts granulation, air drying, rotary kiln roasting, flue gas through sedimentation, dust collection, calcination indirect water cooling process, natural gas as heat source, mixed air heating method, Fluorine, chlorine, lead, and indium are removed, and valuable metals such as indium and lead are re-enriched at the same time. The present invention removes most of fluorine, chlorine, lead, and indium in one fell swoop through the roasting process, enriches lead and indium in roasted dust, solves the problem of subsequent treatment of high-fluorine chlorine suboxide zinc oxide, and requires less technological process. It has the advantages of high efficiency, smooth process and high degree of mechanization, and the environmental protection and economic benefits have been greatly improved.

Owner:QUZHOU YESHENG METAL MATERIAL CO LTD

High-temperature black body porcelain and its preparation method by reducing flame firing

The invention relates to high-temperature black body porcelain and a reduction flame firing preparation method thereof. The invention discloses the high-temperature black body porcelain which is prepared from a blank and a glaze material; production raw materials of the blank comprise: 15 to 20 weight percent of washing petuntse, 15 to 18 weight percent of plaster, 36 to 44 weight percent of whitemud, 18 to 25 weight percent of red purple sand shale, 16 to 20 weight percent of quartz and 3 to 6 weight percent of tillite; production raw materials of the glaze material comprise: 30 to 35 weightpercent of potassium feldspar, 31 to 37 weight percent of quartz, 10 to 15 weight percent of wollastonite, 3 to 5 weight percent of barium carbonate, 8 to 10 weight percent of talc, 8 to 10 weight percent of kaolin, 3 to 5 weight percent of alumina powder and 11 to 16 weight percent of red purple sand shale; the ceramic product not only is pure in color, attractive and excellent in surface artistic effect, but also is high in rate of fired finished products and stable in product performance and has glaze which is not cracked or opened.

Owner:醴陵市科镭陶瓷釉料有限公司

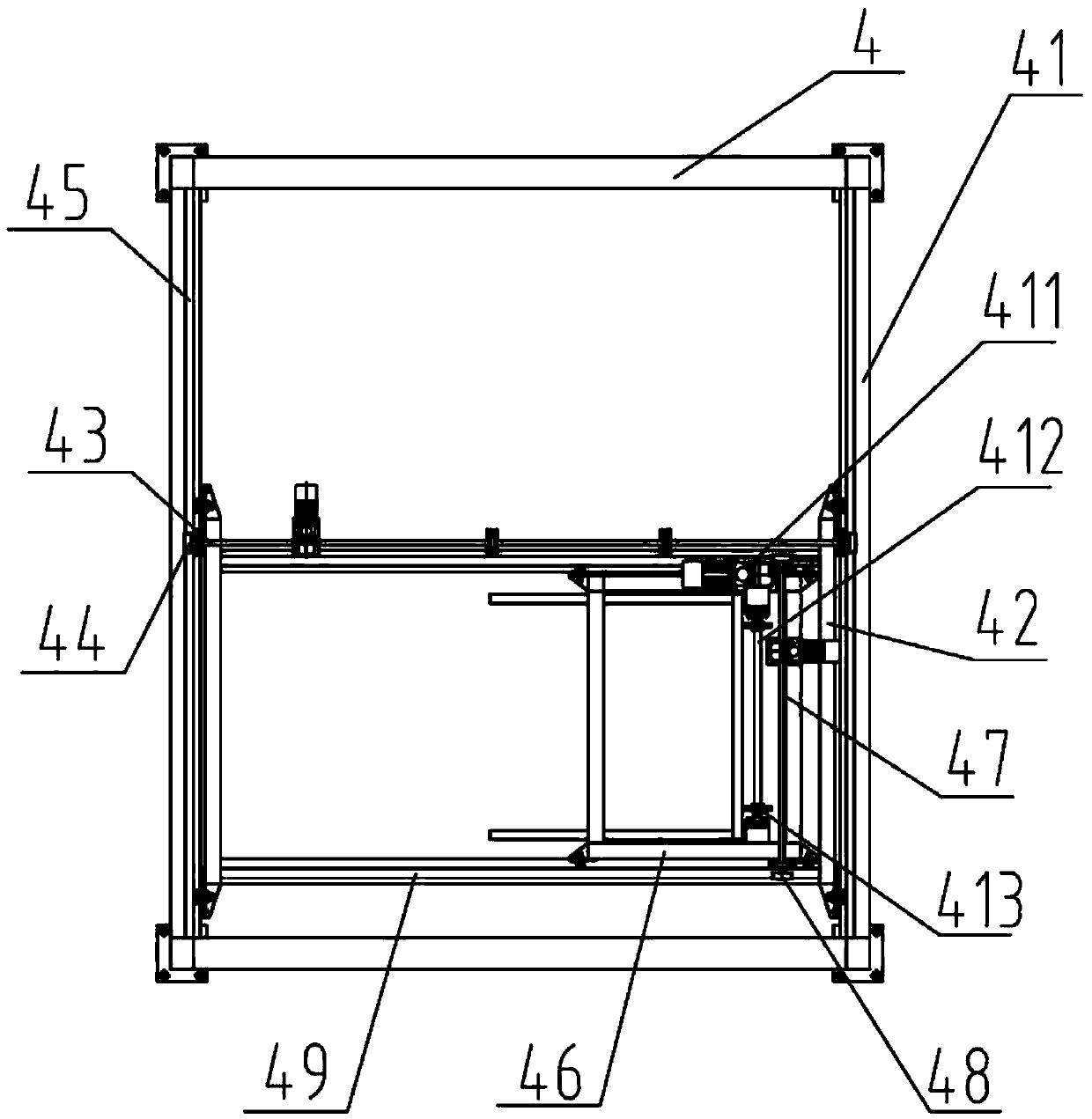

A scr automatic temperature control roller rod electric kiln

InactiveCN104154742BReduce distortionSolve the problem of poor yieldFurnace typesTemperature controlControl system

The invention discloses an SCR fully-automatic temperature control roller electrical kiln which comprises a kiln body, a conveying belt and a moisture removal system. The kiln body is a tunnel type kiln body, the conveying belt is arranged in the kiln body from a kiln head to a kiln tail, and the conveying belt is formed by multiple ceramic rollers arranged in parallel. A heating temperature control system is arranged in the kiln body and comprises electrical heating rods, cables and high-temperature cables, and a temperature area is formed by arranging the electrical heating rods in parallel. The moisture removal system comprises a damp exhausting pipeline, an air exhaust pipeline and a draught fan. According to the SCR fully-automatic temperature control roller electrical kiln, products can be heated evenly, product deformation can be lowered greatly, and the problem that the yield is poor is solved. The ceramic rollers are adopted for conveying products, ceramic is stable in structure under a high-temperature state, and deformation is not prone to occurring. The kiln body is made of high quality steel products and stainless steel, and is stable and reliable. Electrical heating wires are adopted for heating, and the sintering yield is high.

Owner:江苏宇达环保科技股份有限公司

A kind of scr catalyst production system

InactiveCN104190476BImprove automation production efficiencySmall amount of deformationDrying gas arrangementsCatalyst activation/preparationEngineeringConveyor belt

The present invention is a kind of SCR catalyst production system, including: mixing machine, rot room, automatic production line, primary drying kiln, secondary drying kiln, capacitor kiln, etc., the production line mainly includes: product conveying line, tray loading and unloading system, upper cover Loading and unloading system, catalyst loading and unloading system, primary drying kiln includes: primary drying kiln kiln body, product conveying system, gas circulation control system, temperature control system, humidity control system, secondary drying kiln includes: kiln body, steam pipeline, frequency conversion control shaft Air flow fan, humidity control system, kiln car guide rail, described capacitor kiln comprises: kiln body, conveyer belt, dehumidification system; adopts automatic assembly catalyst billet production line, greatly improves automatic production efficiency. The production process produced by the unique structure of the drying kiln reduces the amount of product deformation and the scrap rate. Capacitor kiln uses ceramic rollers to transport products, with stable structure, not easy to deform, heated by electric heating wire, and high firing rate.

Owner:江苏宇达环保科技股份有限公司

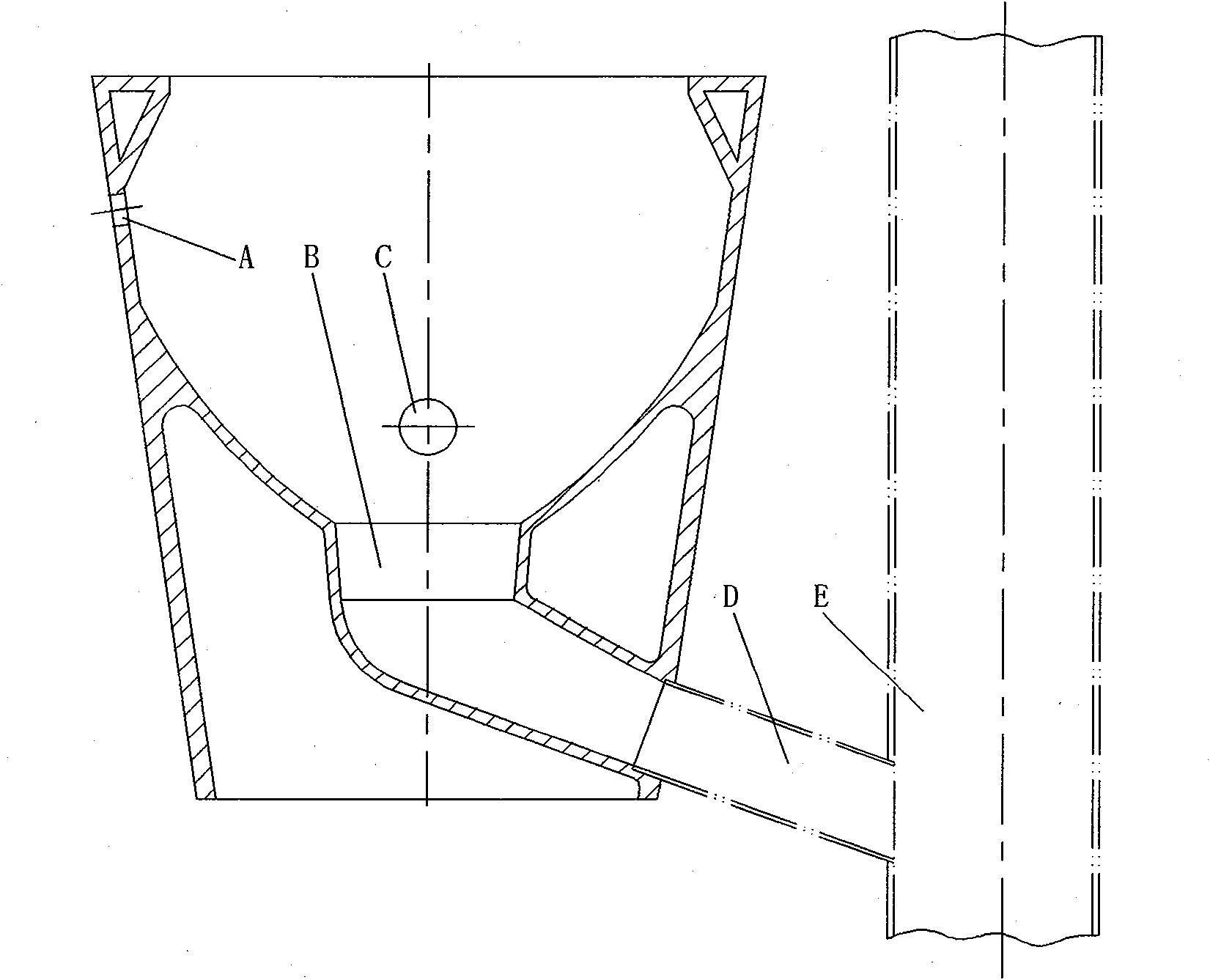

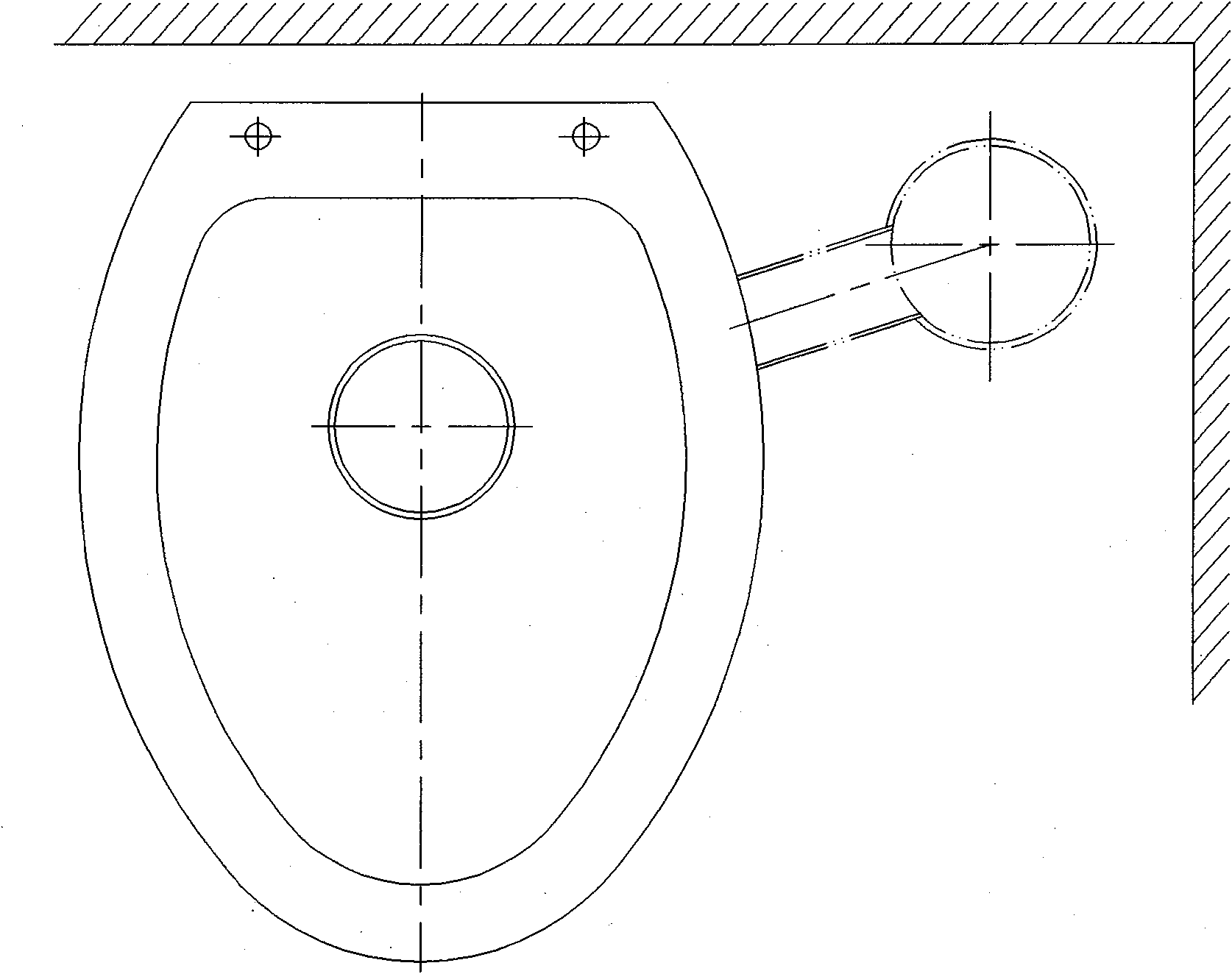

Horizontal-type water-tank-free water-saving stool

InactiveCN101886421ANo power consumptionSaving fireWater closetsDomestic plumbingRural areaWater saving

The invention relates to a horizontal-type water-tank-free water-saving stool. A lateral or rear drain outlet at the bottom is directly communicated with a vertical drain pipe of a toilet through an inclined pipe, an odor seal is saved, and an order-insulating valve interface for mounting an order-insulating valve is arranged at a drain inlet at the bottom and is used for draining excrement and urine and avoiding odor uprise. An odor remover interface for mounting an odor remover is arranged at the upper part, a waste water interface for connecting a drain pipe of a cleaner, such as a sink, and the like is arranged above the drain inlet. The stool is automatically flushed by waste water for washing faces, vegetables (the kitchen and the toilet are adjacent), and the like. The invention overcomes the defects of great water consumption, easy blockage, unsuitability for rural areas, and the like of a traditional stool and provides a horizontal-type water-tank-free water-saving stool which is water-saving, energy-saving, emission-reducing, environment-friendly and resource-saving, is odor-free, nonclogging and watertight in defecation, is clean, flavorless and space-saving, automatically utilizes the waste water and is suitable for cities and rural areas and suitable for the needs of water-saving-type society and new rural area construction.

Owner:王方

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com