A scr automatic temperature control roller rod electric kiln

A fully automatic, electric kiln technology, applied in the direction of furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of inability to accurately control temperature and humidity, inability to automate production, uneven heating of products, etc., achieve compact and reasonable design, and solve the yield rate Poor, high firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

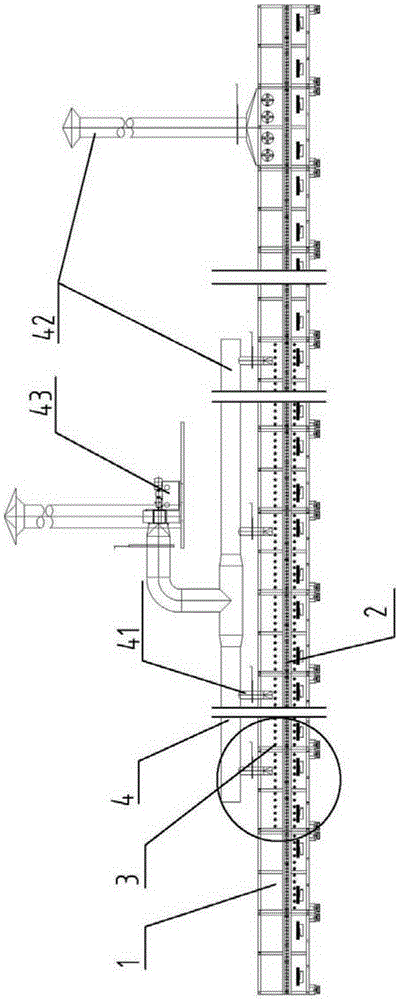

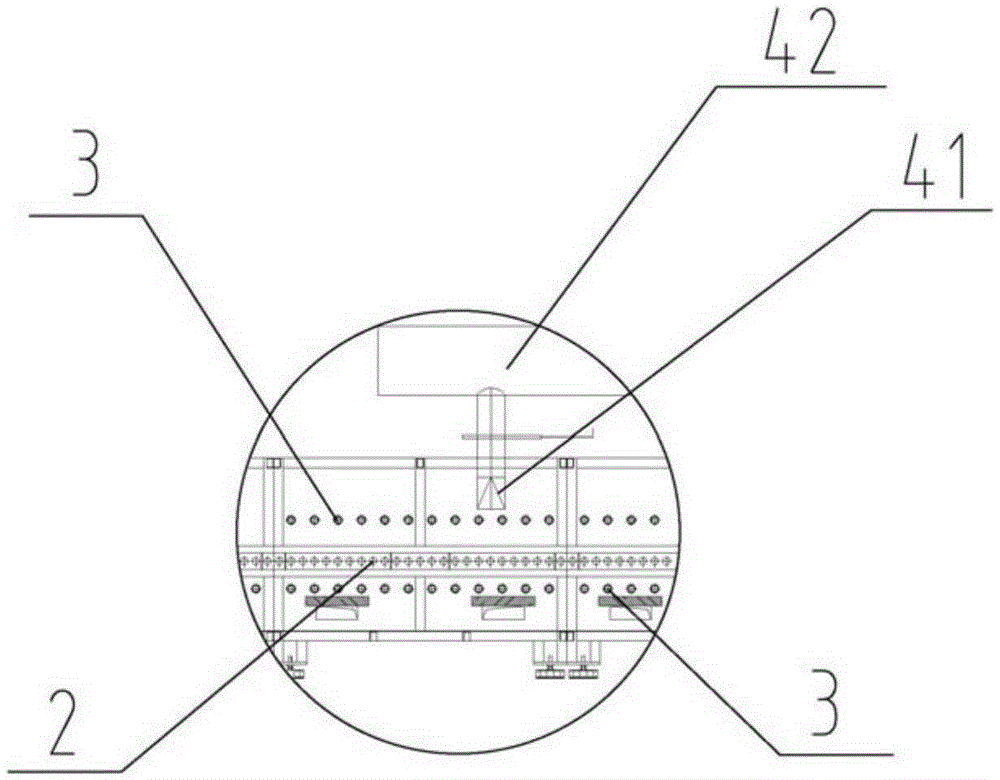

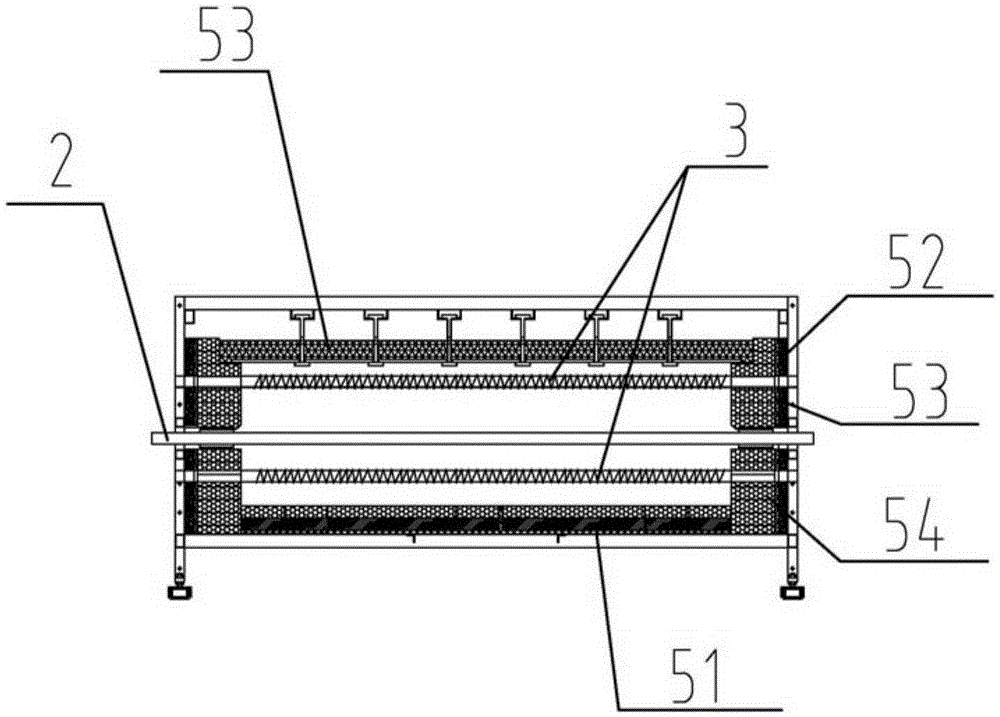

[0020] according to Figure 1-3 Shown; A kind of SCR full-automatic temperature control electric roller kiln, comprises: kiln body, conveyer belt, dehumidification system; Described kiln body 1 is tunnel type kiln body, and described kiln body is provided with conveyer belt from kiln head to kiln tail, The conveyor belt is composed of a plurality of ceramic rollers 2 arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com