A method for removing fluorine, chlorine and valuable metals in secondary zinc oxide

A technology of secondary zinc oxide and valuable metal, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of insufficient environmental protection and economy, energy saving and emission reduction, long and complicated process, large equipment loss, etc., and achieves low heat loss and process flow. Less, less corrosion loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

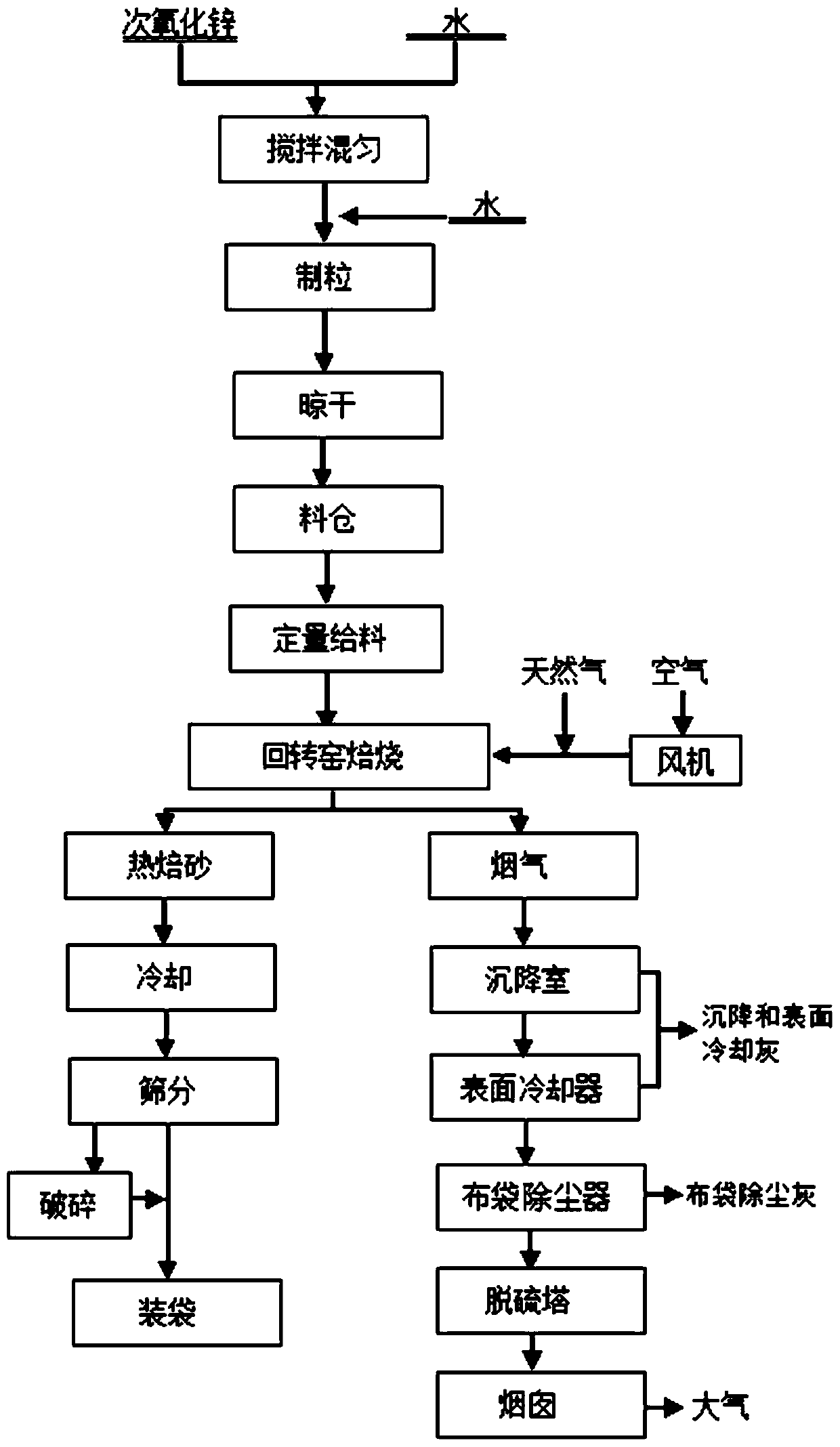

Image

Examples

Embodiment 1

[0055] An enterprise in Zhejiang uses high-zinc dust removal dust from steel mills as raw material for sub-zinc oxide, and the composition of each element of sub-zinc oxide is shown in Table 1:

[0056] Table 1 Elemental composition of secondary zinc oxide

[0057] Zn(wt%)

[0058] The above secondary zinc oxide is granulated, the particle size is 5mm, the weight ratio of the sum of the added water to the raw material secondary zinc oxide is 8:92, and the drying time is 2 days. The spherical material obtained by granulation is input into a rotary kiln (specification φ2.2×30m) for roasting. The heating device of the rotary kiln is a double-layer casing, the inner tube is a fuel channel, and the outer tube is an air channel. The fuel is natural gas , the natural gas supply pressure is 0.4MPa, the inlet pressure of the air fan supplying air to the outer pipe is 1500Pa, the kiln tail flue gas outlet temperature is 400°C, the kiln head temperature is 1000°C, the kiln tail...

Embodiment 2

[0071] An enterprise in Sichuan uses lean zinc oxide ore as raw material to produce secondary zinc oxide through the fuming method of a rotary kiln. The composition of each element of secondary zinc oxide is shown in Table 5:

[0072] Table 5 Elemental composition of secondary zinc oxide

[0073] Zn(wt%)

[0074] The above-mentioned secondary zinc oxide is granulated, the particle size is 5mm, the weight ratio of the sum of the added water to the raw material secondary zinc oxide is 9:91, and the drying time is 2 days. The spherical material obtained by granulation is input into a rotary kiln (specification φ2.2×34.5m) for roasting. The heating device of the rotary kiln is a double-layer casing, the inner tube is a fuel channel, and the outer tube is an air channel. The fuel is Natural gas, the gas supply pressure of natural gas is 0.4MPa, the inlet pressure of the air fan supplying air to the outer pipe is 1500Pa, the outlet temperature of the flue gas at the kiln t...

Embodiment 3

[0086] A certain enterprise uses lead-zinc ore smelting slag as raw material to process secondary zinc oxide. The composition of each element of secondary zinc oxide is shown in Table 9:

[0087] Table 9 Elemental Composition of Secondary Zinc Oxide

[0088] Zn(wt%)

[0089] The above-mentioned secondary zinc oxide is granulated, the particle size is 3mm, the weight ratio of the sum of added water to the raw material secondary zinc oxide is 7:93, and the drying time is 1 day. The spherical material obtained by granulation is input into a rotary kiln (specification φ2.2×30m) for roasting. The heating device of the rotary kiln is a double-layer casing, the inner tube is a fuel channel, and the outer tube is an air channel. The fuel is natural gas , the natural gas supply pressure is 0.2MPa, the inlet pressure of the air fan supplying air to the outer pipe is 1300Pa, the kiln tail flue gas outlet temperature is 350°C, the kiln head temperature is 950°C, the kiln tail fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com