A method for preparing thermoplastic carbon fiber flat shrapnel by extrusion

A thermoplastic carbon fiber and carbon fiber technology, applied in the field of materials, can solve problems such as low lateral strength, achieve high production efficiency, improve lateral mechanical properties, and improve elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

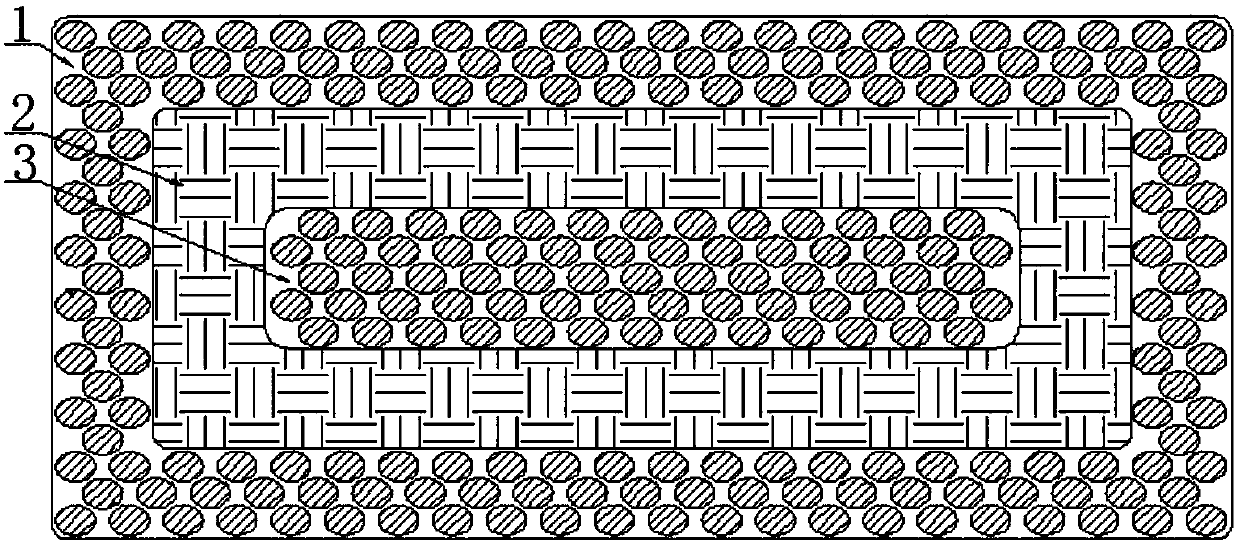

[0019] Step 1: Lead the continuous carbon fiber from the creel, the carbon fiber is soaked by the molten thermoplastic polyurethane resin through the size tank under isotensive state, and combine several bundles of carbon fiber into a bundle to form the carbon fiber core 3;

[0020] Step 2: The glass fiber fabric with a width of 15 mm is impregnated with molten thermoplastic polyurethane resin through the slurry tank, and then wound on the carbon fiber core obliquely from the side, thereby obtaining the carbon fiber core covered with the glass fiber fabric layer 2;

[0021] Step 3: After the carbon fiber used for the outer layer is infiltrated with molten thermoplastic polyurethane at 80-110°C, it is collected into the mouth of the flat mold through a circular bell mouth collector, and the carbon fiber core covered with a glass fiber fabric layer is also collected into the flat mold mouth;

[0022] Step 4: Coat the carbon fiber used for the outer layer on the carbon fiber core...

Embodiment 2

[0027] Step 1: Lead the continuous carbon fiber from the creel, the carbon fiber is soaked by the molten thermoplastic polyurethane resin through the size tank under isotensive state, and combine several bundles of carbon fiber into a bundle to form the carbon fiber core 3;

[0028] Step 2: The glass fiber fabric with a width of 20 mm is impregnated with molten thermoplastic polyurethane resin through the slurry tank, and then wound on the carbon fiber core obliquely from the side, thereby obtaining the carbon fiber core covered with the glass fiber fabric layer 2;

[0029] Step 3: After the carbon fiber used for the outer layer is infiltrated with molten polyurethane at 80-110°C, it is collected into the flat mold mouth through a circular bell mouth collector, and the carbon fiber core covered with a glass fiber fabric layer is also collected into the flat mold mouth;

[0030] Step 4: Coat the carbon fiber used for the outer layer on the carbon fiber core covered with the glas...

Embodiment 3

[0035] Step 1: Lead the continuous carbon fiber from the creel, the carbon fiber is soaked by the molten thermoplastic polyurethane resin through the size tank under isotensive state, and combine several bundles of carbon fiber into a bundle to form the carbon fiber core 3;

[0036] Step 2: The glass fiber fabric with a width of 20 mm is impregnated with molten thermoplastic polyurethane resin through the slurry tank, and then wound on the carbon fiber core obliquely from the side, thereby obtaining the carbon fiber core covered with the glass fiber fabric layer 2;

[0037] Step 3: After the carbon fiber used for the outer layer is infiltrated with molten polyurethane at 80-110°C, it is collected into the flat mold mouth through a circular bell mouth collector, and the carbon fiber core covered with a glass fiber fabric layer is also collected into the flat mold mouth;

[0038] Step 4: Coat the carbon fiber used for the outer layer on the carbon fiber core covered with the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com