A kind of scr catalyst production system

A technology of SCR catalyst and production system, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problems of unstable product quality, low automatic production capacity, process defects, etc., to improve automation The effect of production efficiency, compact and reasonable design, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings.

[0047] The following examples are only examples for clearly illustrating the present invention, rather than limiting the embodiment of the invention. For those of ordinary skill in the art, on the basis of the following description, other changes or changes in different forms can also be made, and these obvious changes or changes derived from the spirit of the invention are still within the protection scope of the invention.

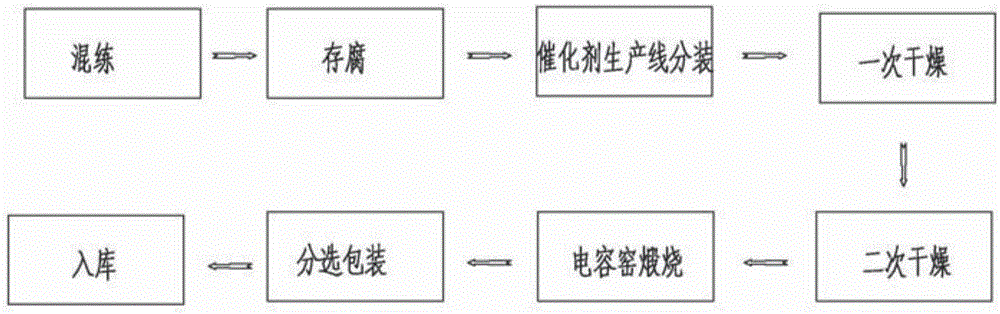

[0048] A SCR catalyst production system, comprising: a mixing machine, a storage room, a catalyst production line, a primary drying kiln, a secondary drying kiln, an electric furnace kiln, a cutting and packaging machine,

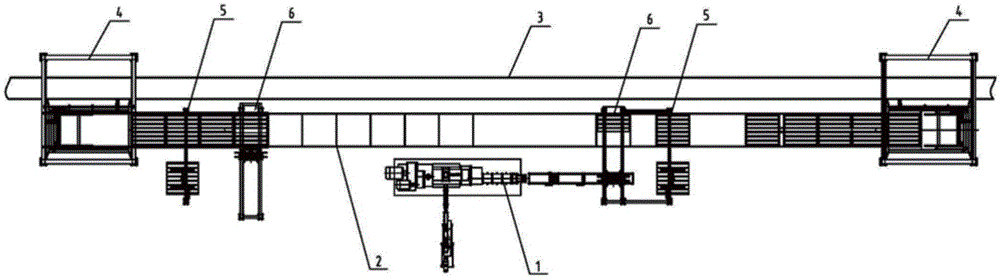

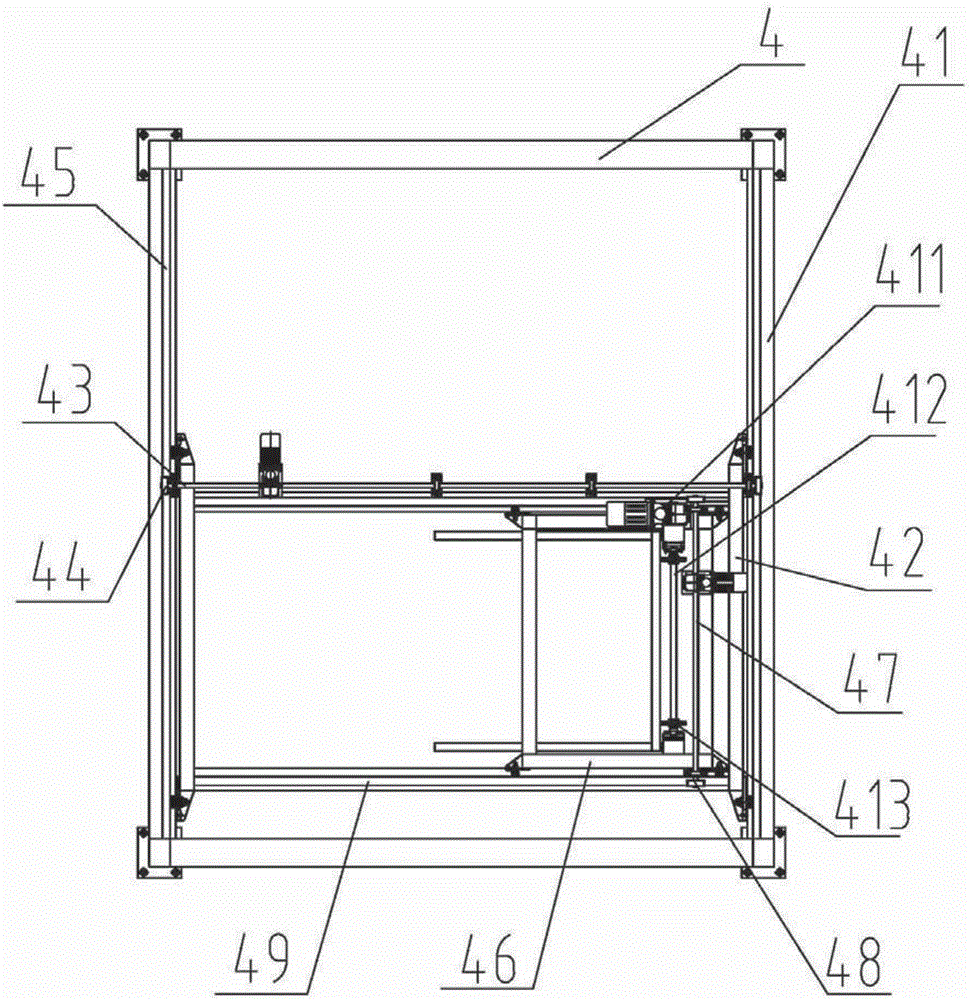

[0049] The catalyst production line includes: forming machine 1, product conveying line 2, kiln car track 3, pallet loading and unloading system 4, upper cover loading and unloading system 5, catalyst loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com