Wire winding machine, wire winding machine production line and production method

A winding machine and production line technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., to achieve the effects of improving stability and precision, rapid control speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

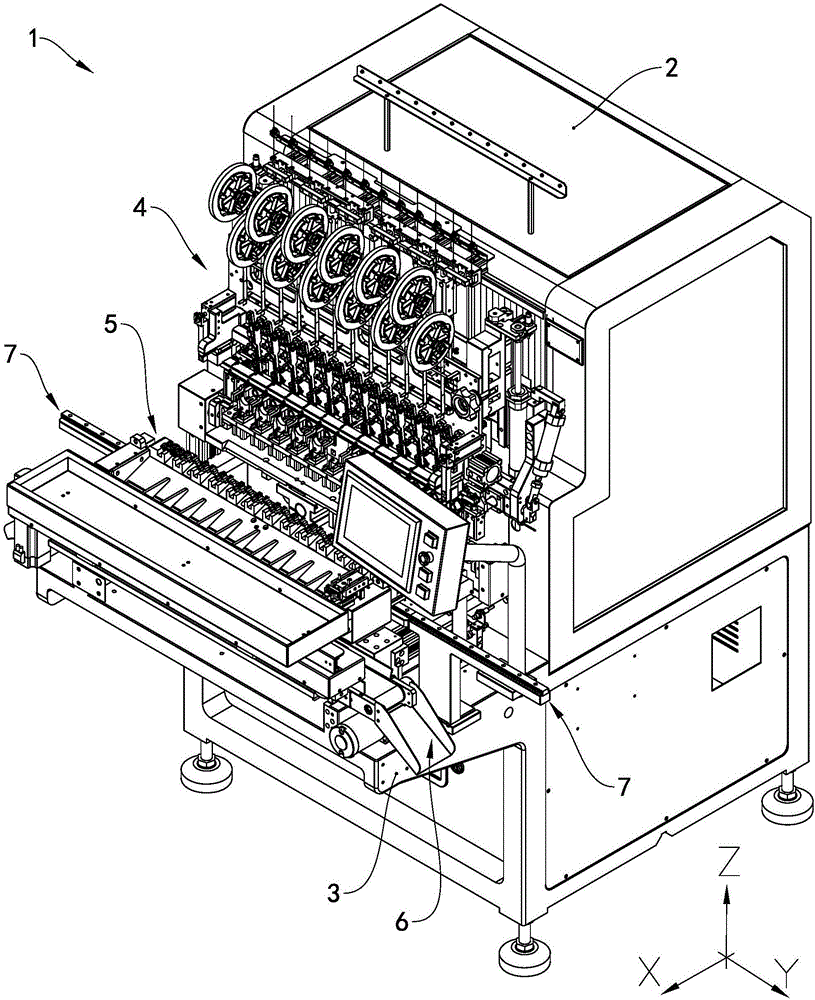

[0070] see Figure 12 , Figure 13 , Figure 14 and Figure 15 , The winding machine production line 10 includes a feeding machine 11, the winding machine 1 of the above-mentioned winding machine embodiment, and a post-processing machine. The post-processing machine in this embodiment is a soldering machine 12, but not limited to the soldering machine 12. The feeding machine 11 , the four winding machines 1 and the soldering machine 12 are connected in series, and the four winding machines 1 are located between the feeding machine 11 and the soldering machine 12 .

[0071] Feeding machine 11 comprises a first support frame 111, a first platform 112, a first guide rail 113, a first conveying mechanism 114 and a vibration plate 115, the first platform 112 is arranged on the first support frame 111, and the first guide rail 113 and the first conveying mechanism 114 are respectively arranged on the first platform 112 . The first guide rail 113 is connected in series with the e...

no. 2 example

[0077] As the description of the second embodiment of the winding machine production line of the present invention, only the differences from the first embodiment of the winding machine production line will be described below.

[0078] The winding machine production line includes a first feeding machine, a second feeding machine and a winding machine, and the winding machine is spliced between the first feeding machine and the second feeding machine through guide rails. The winding machine is the winding machine 1 of the above-mentioned winding machine embodiment, the first feeding machine and the second feeding machine are respectively the feeding machine 11 of the first embodiment of the above-mentioned winding machine production line, and the first feeding machine There is a workpiece fixture, which is used to clamp the workpiece to be processed and take out the processed workpiece.

[0079] When working, the transmission components of the first loader, the second loader ...

no. 3 example

[0083] As the description of the third embodiment of the winding machine production line of the present invention, only the differences from the first embodiment of the winding machine production line will be described below.

[0084] The winding machine production line includes a first winding machine, a second winding machine and a feeding machine, and the feeding machine, the first winding machine and the second winding machine are spliced in series through guide rails. The first winding machine and the second winding machine are respectively the winding machine 1 of the above-mentioned winding machine embodiment, and the feeding machine is the feeding machine 11 of the first embodiment of the above-mentioned winding machine production line.

[0085] When working, the transmission components of the first winding machine, the second winding machine, the second winding machine and the feeding machine cooperate with each other, and the workpiece fixtures of the first winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com