Jun porcelain rose violet glaze and preparation method thereof

A technology of rose and purple glaze, applied in the field of Jun porcelain rose purple glaze and its preparation, can solve the problems of low yield rate, many influencing factors, complicated firing process, etc., and achieve the effect of improving firing yield and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

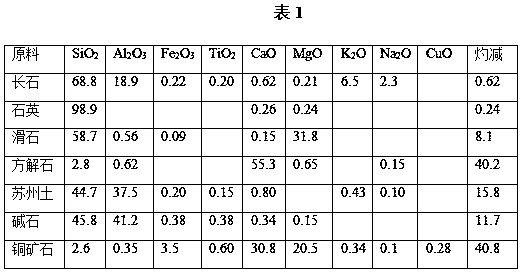

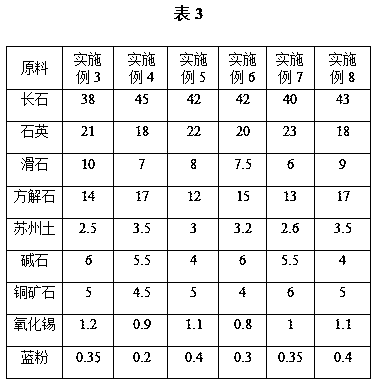

[0020] A Jun porcelain rose purple glaze prepared from the following raw materials in parts by weight: 38-46 parts of feldspar, 17-23 parts of quartz, 6-10 parts of talc, 12-18 parts of calcite, 2.5-3.5 parts of Suzhou soil, alkali 4-6 parts of ore, 4-6 parts of copper ore, 0.8-1.2 parts of tin oxide, and 0.2-0.4 parts of blue powder. Feldspar, quartz, talc, calcite, alkali stone, and copper ore are selected from Yuzhou, Suzhou soil is selected from the Yangshan area of Suzhou, and the blue powder is made of cobalt oxide (1 mass part) and kaolin (8-12 mass parts). It is made by high-temperature calcination at 1100-1300°C.

[0021] The preparation method of Jun porcelain rose violet glaze as mentioned above comprises the following steps:

[0022] (1) Mix the raw materials; ball mill and filter to obtain the glaze slurry;

[0023] (2) Glaze is applied to the carcass after bisque firing;

[0024] (3) Firing: Specifically includes the following stages:

[0025] ①Drying stage...

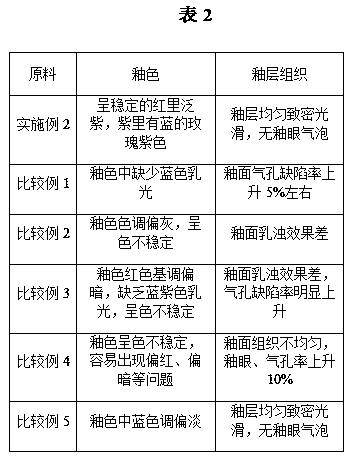

Embodiment 2

[0035] A Jun porcelain rose purple glaze, prepared from the following raw materials in parts by weight: 42 parts of feldspar, 20 parts of quartz, 8 parts of talc, 15 parts of calcite, 3 parts of Suzhou soil, 5 parts of soda stone, 5 parts of copper ore, 1 part of tin oxide, 0.3 parts of blue powder, the blue powder is made of 1 mass part of cobalt oxide and 10 mass parts of kaolin at a high temperature of 1200 ° C.

[0036] The preparation method of Jun porcelain rose violet glaze as mentioned above comprises the following steps:

[0037] (1) Mix the raw materials; ball mill and filter to obtain the glaze slurry;

[0038] (2) Glaze is applied to the carcass after bisque firing;

[0039] (3) Firing: Specifically includes the following stages:

[0040] ①Drying stage: Put the glazed carcass into the kiln, and raise the temperature evenly to 400°C in 2.5 hours under an oxidizing atmosphere;

[0041] ② Heating stage: in an oxidizing atmosphere, the temperature is evenly raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com