A kind of golden yellow ceramic glaze and preparation method thereof

A ceramic glaze and golden yellow technology, which is applied in the field of golden yellow ceramic glaze and its preparation, can solve the problems of not being able to meet the pace of development and less research and development of new ceramic glazes, and achieve good gloss of the glaze layer, high firing rate, and excellent glaze quality. Glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

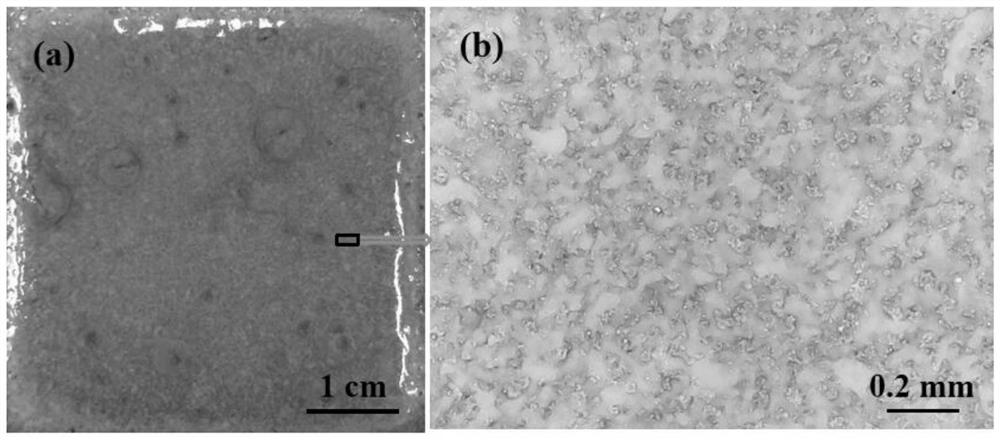

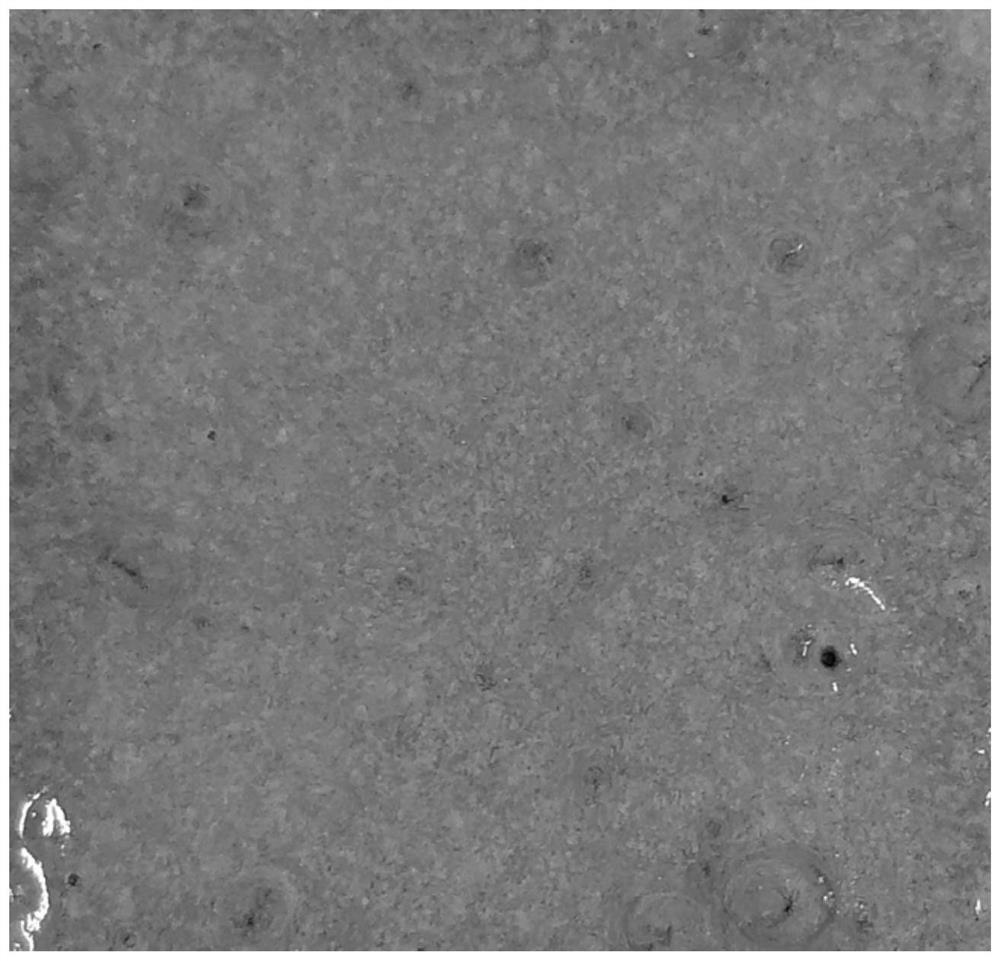

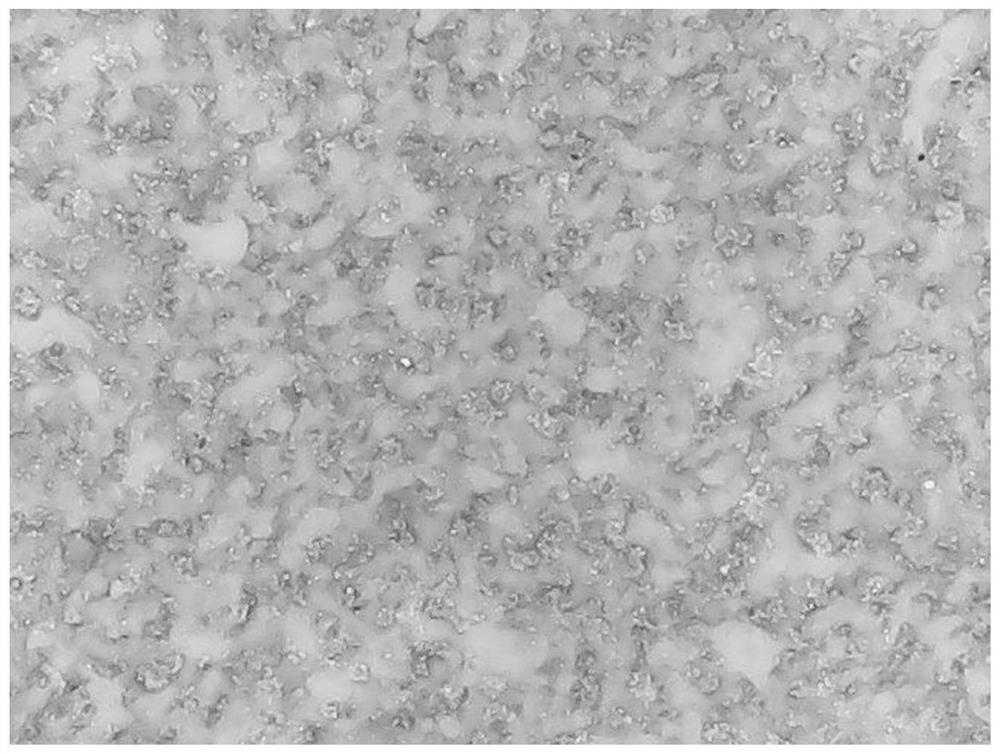

Image

Examples

Embodiment 1

[0032] A preparation method of golden yellow ceramic glaze, comprising the steps of:

[0033] Step 1, weigh the following components by mass percentage: 0.8% of nano-silver powder with a particle size of 30nm, 41.7% of albite, 23.5% of quartz, 21.5% of calcite, and 12.5% of talc, and mix the above components evenly to obtain a glaze ;

[0034] Mix the glaze, water, and agate balls according to the mass ratio of 1.0:1.2:1.5, and then use a planetary ball mill for ball milling. During the ball milling, the rotation speed is 300r / min, and the ball milling time is 16h. Go through a 250-mesh mesh sieve, and then adjust the density of the mesh-sieved slurry to 1.67g / cm with water 3 , the glaze slurry is obtained after preparation;

[0035] Put the ceramic green body whose raw material composition is 58% kaolin, 28.5% quartz, and 13.5% feldspar into a program-controlled high-temperature furnace, raise the temperature to 890°C at a heating rate of 3°C / min under air atmosphere cond...

Embodiment 2

[0040] A preparation method of golden yellow ceramic glaze, comprising the steps of:

[0041] Step 1, weigh the following components by mass percentage: 1.5% of nano-silver powder with a particle size of 9000nm, 45.5% of albite, 20% of quartz, 21.5% of calcite, and 11.5% of talc, and mix the above components evenly to obtain a glaze ;

[0042] Mix the glaze, water, and agate balls according to the mass ratio of 1.0:1.2:1.7, and then use a planetary ball mill for ball milling. The rotation speed of the ball mill is 350r / min, and the ball milling time is 10h. 250 mesh sieve, then adjust the density of the slurry through the mesh sieve to 1.66g / cm with water 3 , the glaze slurry is obtained after preparation;

[0043] Put the ceramic green body whose raw material composition is 58% kaolin, 28.5% quartz, and 13.5% feldspar into a program-controlled high-temperature furnace. Furnace cooling to obtain bisque fired ceramic green body;

[0044]Step 2: Apply the glaze slurry prepar...

Embodiment 3

[0048] A preparation method of golden yellow ceramic glaze, comprising the steps of:

[0049] Step 1, weigh the following components by mass percentage: 3.5% of nano-silver powder with a particle size of 100nm, 41% of albite, 23.5% of quartz, 21.5% of calcite, and 10.5% of talc, and mix the above components evenly to obtain a glaze ;

[0050] Mix the glaze, water, and agate balls according to the mass ratio of 1.0:1.2:1.6, and then use a planetary ball mill for ball milling. The rotation speed of the ball mill is 400r / min, and the ball milling time is 12h. 250 mesh sieve, then adjust the density of the slurry through the mesh sieve to 1.69g / cm with water 3 , the glaze slurry is obtained after preparation;

[0051] Put the ceramic green body whose raw material composition is 58% kaolin, 28.5% quartz, and 13.5% feldspar into a program-controlled high-temperature furnace, raise the temperature to 890°C at a heating rate of 3°C / min under air atmosphere conditions, and keep it fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com