A kind of medium-temperature plum celadon glaze and medium-temperature plum qinglongquan celadon

A plum and blue glaze technology, applied in the field of ceramic glaze, can solve the problems of high energy consumption and high preparation cost of plum blue glaze, and achieve the effects of lowering firing temperature, satisfying aesthetic requirements of color and texture, and stable color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

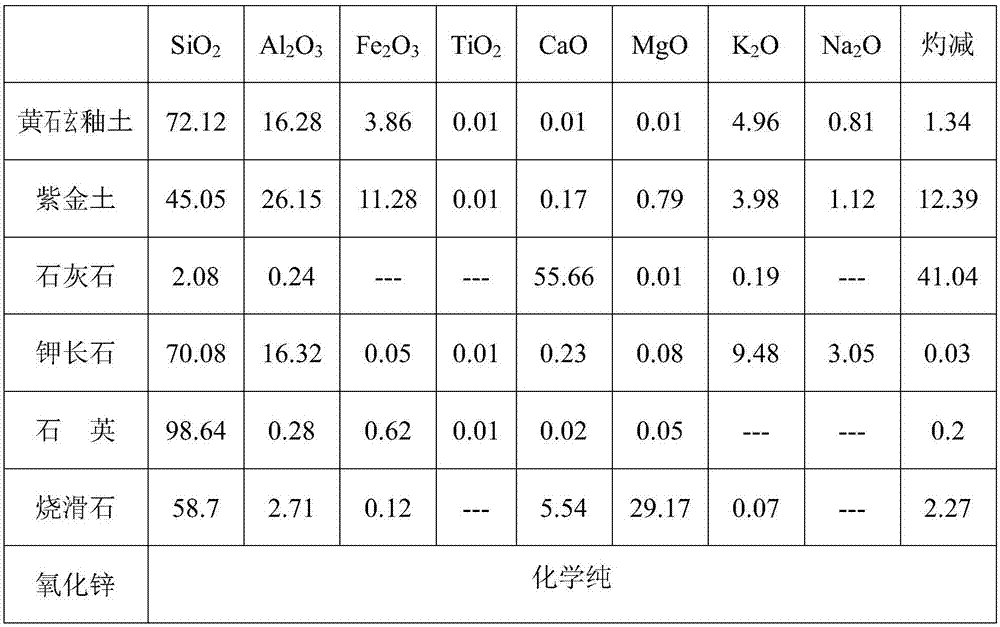

Method used

Image

Examples

Embodiment 1

[0057] A kind of preparation method of middle temperature plum green dragon spring celadon, comprises the following steps:

[0058] a. Green body preparation: the Longquan celadon blank is made into a green body by manual molding or mold molding as required;

[0059] In terms of mass percentage, the formula of the Longquan celadon blank is: 40% of Baoxi china clay, 30% of kaolin, 25% of burnt talc, and 5% of potassium feldspar;

[0060] b. Drying: dry the half-dried biscuit in the shade for 20-24 hours;

[0061] c. Blank trimming: Correct the semi-dry blank, so that the thickness of the blank is uniform, and the edge and ring foot of the blank are smooth;

[0062] d. Moisturizing: Use a sponge or a brush dipped in water to replenish water on the trimmed area of the biscuit to make the surface of the biscuit smooth and flat;

[0063] e. Biscuit firing: put the water-filled biscuit into the shuttle kiln, so that the temperature in the shuttle kiln is evenly raised to 750-800...

Embodiment 2

[0083] A kind of preparation method of middle temperature plum green dragon spring celadon, comprises the following steps:

[0084] a. Green body preparation: the Longquan celadon blank is made into a green body by manual molding or mold molding as required;

[0085] In terms of mass percentage, the formula of the Longquan celadon blank is: 38% of Baoxi china clay, 32% of kaolin, 23% of burnt talc, and 7% of potassium feldspar;

[0086] b. Drying: dry the half-dried biscuit in the shade for 20-24 hours;

[0087] c. Blank trimming: Correct the semi-dry blank, so that the thickness of the blank is uniform, and the edge and ring foot of the blank are smooth;

[0088] d. Moisturizing: Use a sponge or a brush dipped in water to replenish water on the trimmed area of the biscuit to make the surface of the biscuit smooth and flat;

[0089] e. Biscuit firing: put the water-filled biscuit into the shuttle kiln, so that the temperature in the shuttle kiln is evenly raised to 750-800...

Embodiment 3

[0106] A kind of preparation method of middle temperature plum green dragon spring celadon, comprises the following steps:

[0107] a. Green body preparation: the Longquan celadon blank is made into a green body by manual molding or mold molding as required;

[0108] In terms of mass percentage, the formula of the Longquan celadon blank is: 42% of Baoxi china clay, 28% of kaolin, 27% of burnt talc, and 3% of potassium feldspar;

[0109] b. Drying: dry the half-dried biscuit in the shade for 20-24 hours;

[0110] c. Blank trimming: Correct the semi-dry blank, so that the thickness of the blank is uniform, and the edge and ring foot of the blank are smooth;

[0111] d. Moisturizing: Use a sponge or a brush dipped in water to replenish water on the trimmed area of the biscuit to make the surface of the biscuit smooth and flat;

[0112] e. Biscuit firing: put the water-filled biscuit into the shuttle kiln, raise the temperature in the shuttle kiln evenly to 750-800°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com