Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "High degree of branching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon additive

InactiveUS6797853B2High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingAlkaneIonic liquid

Owner:HALDOR TOPSOE AS

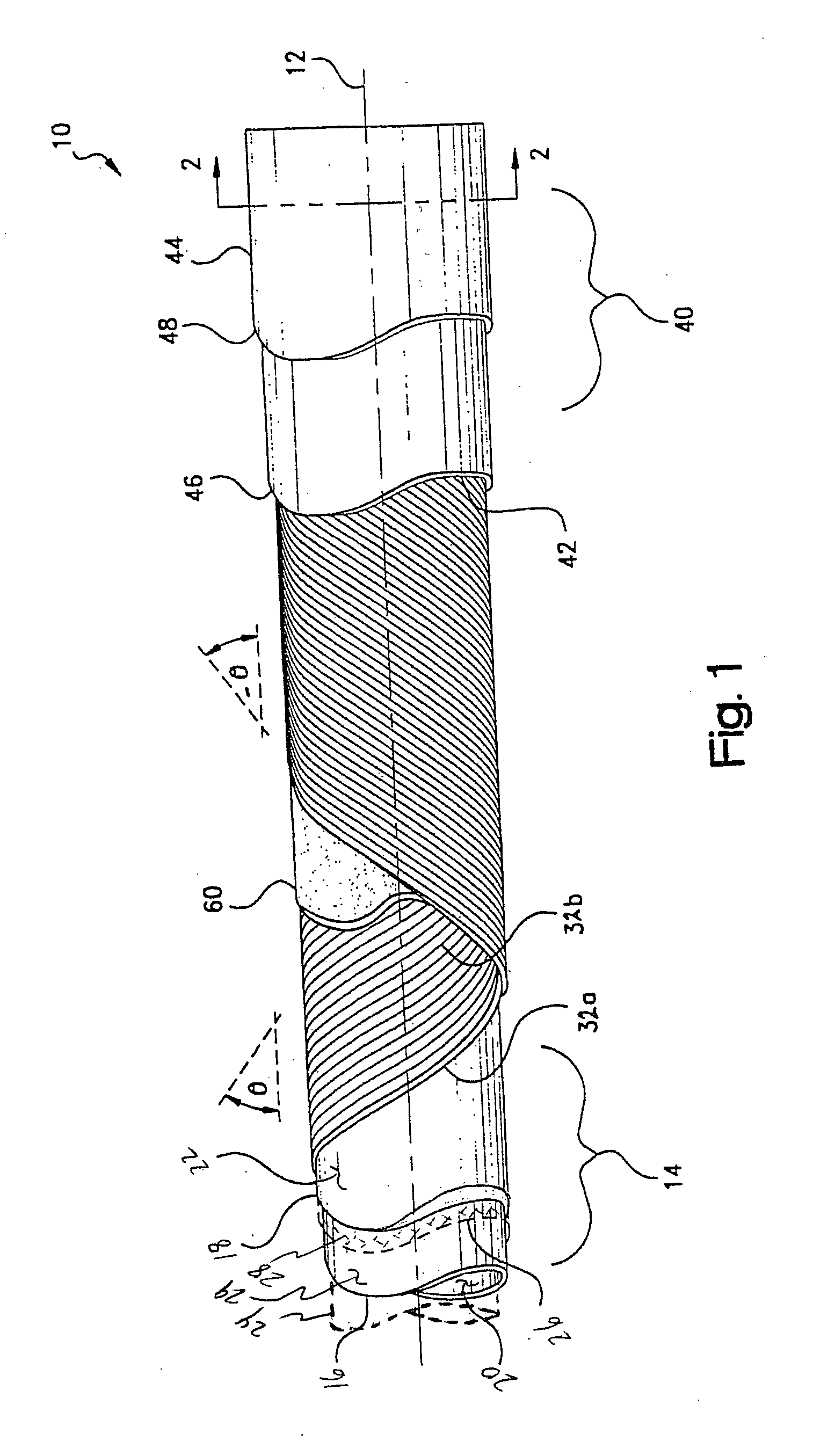

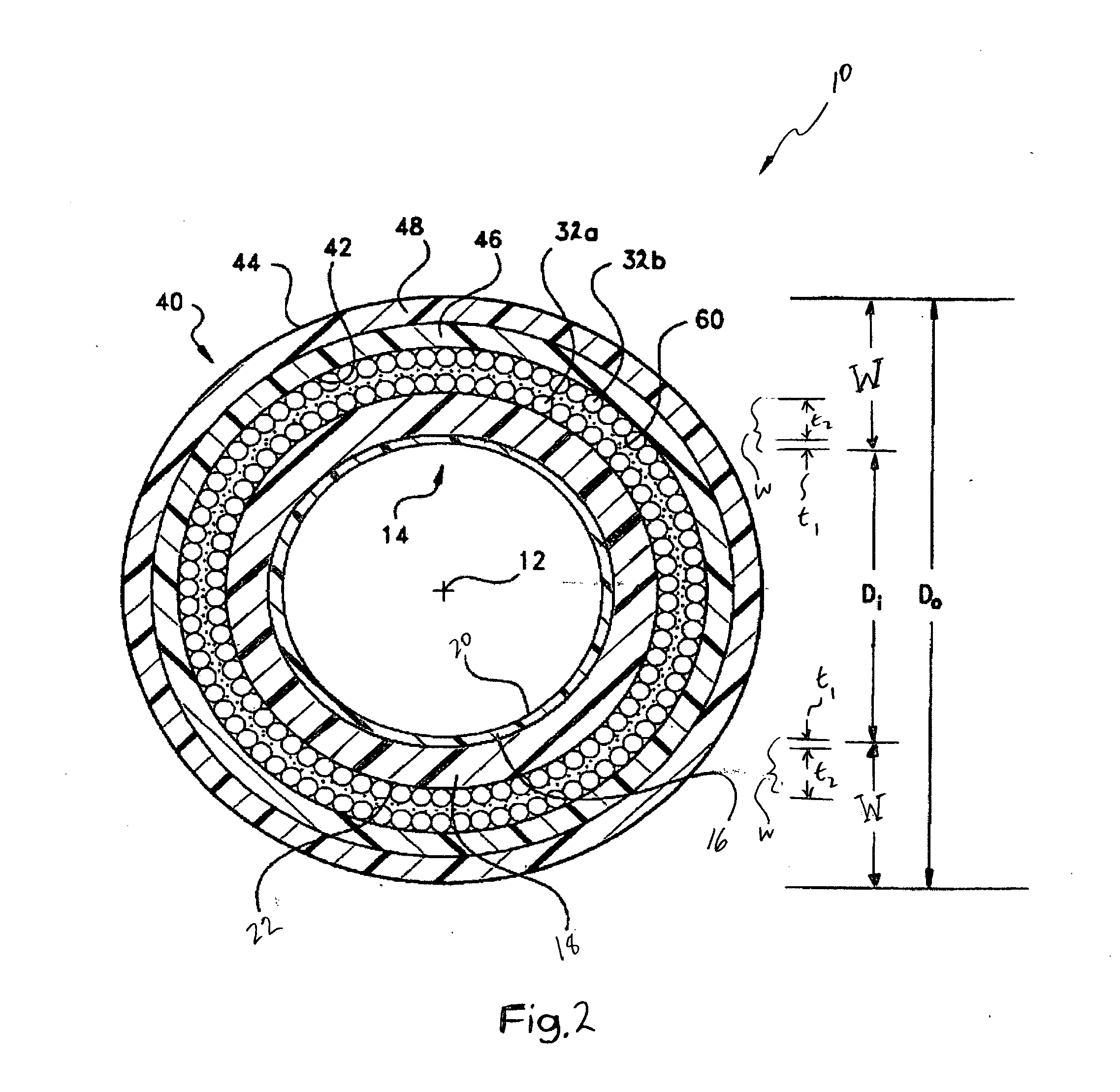

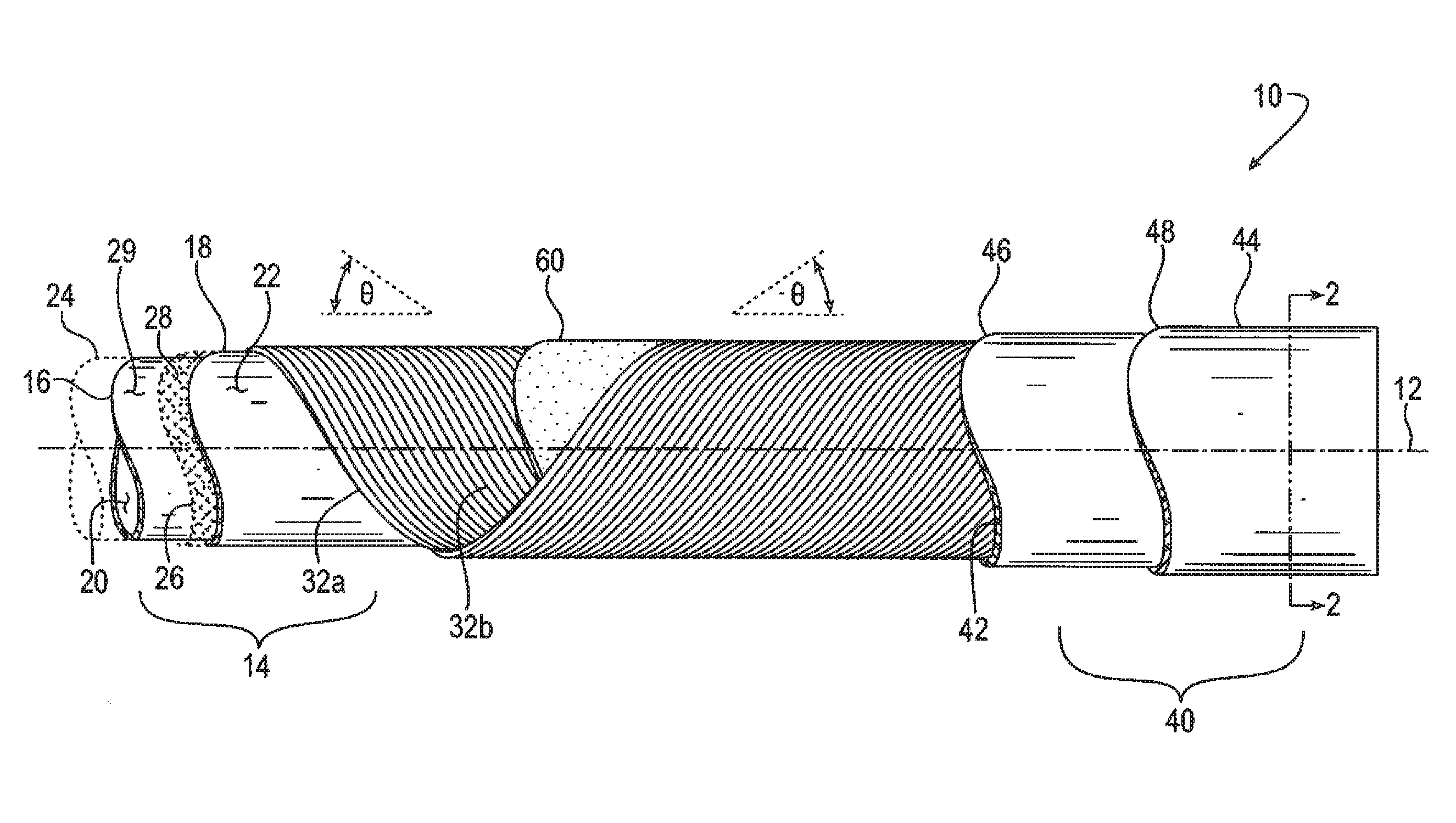

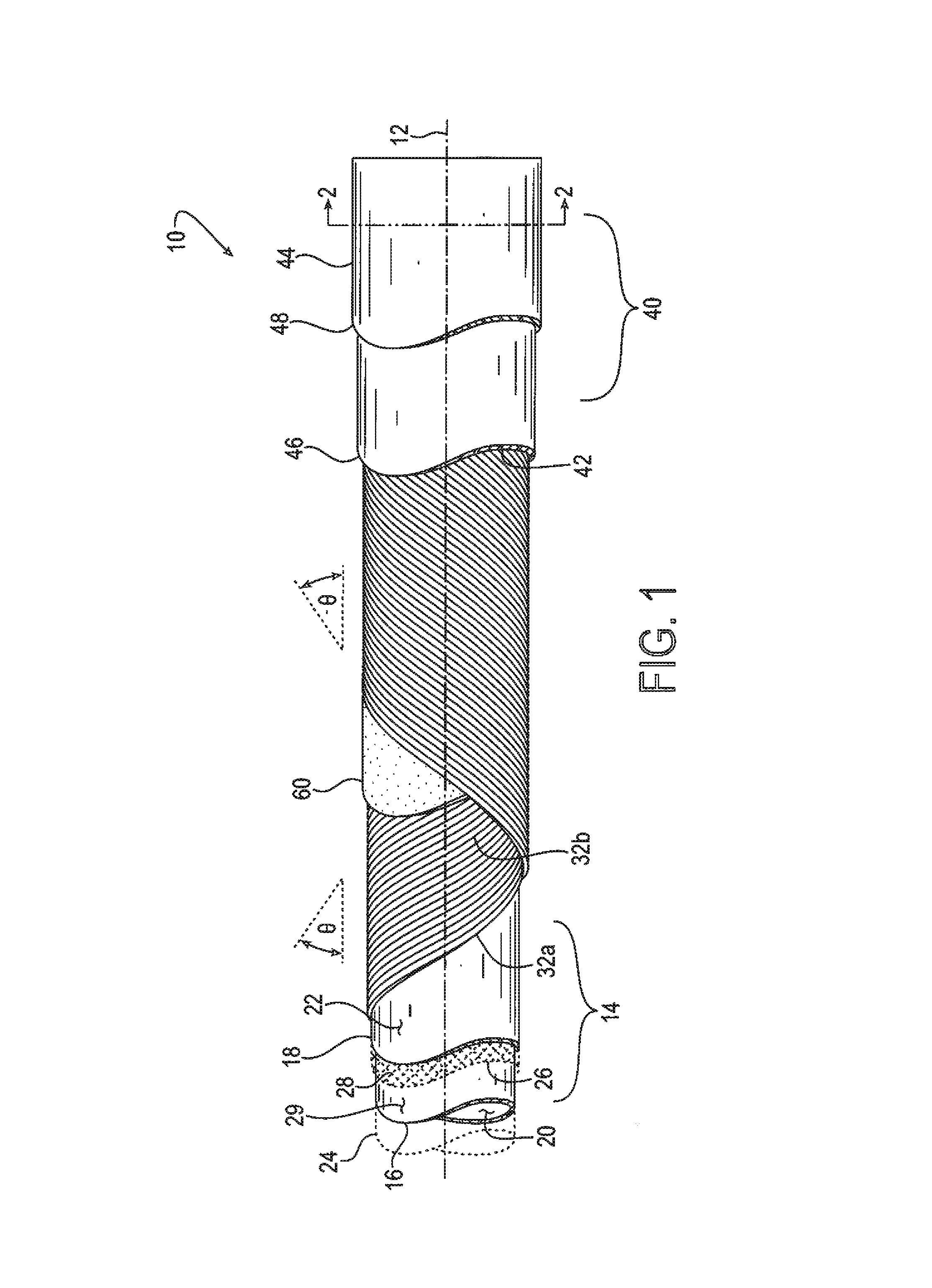

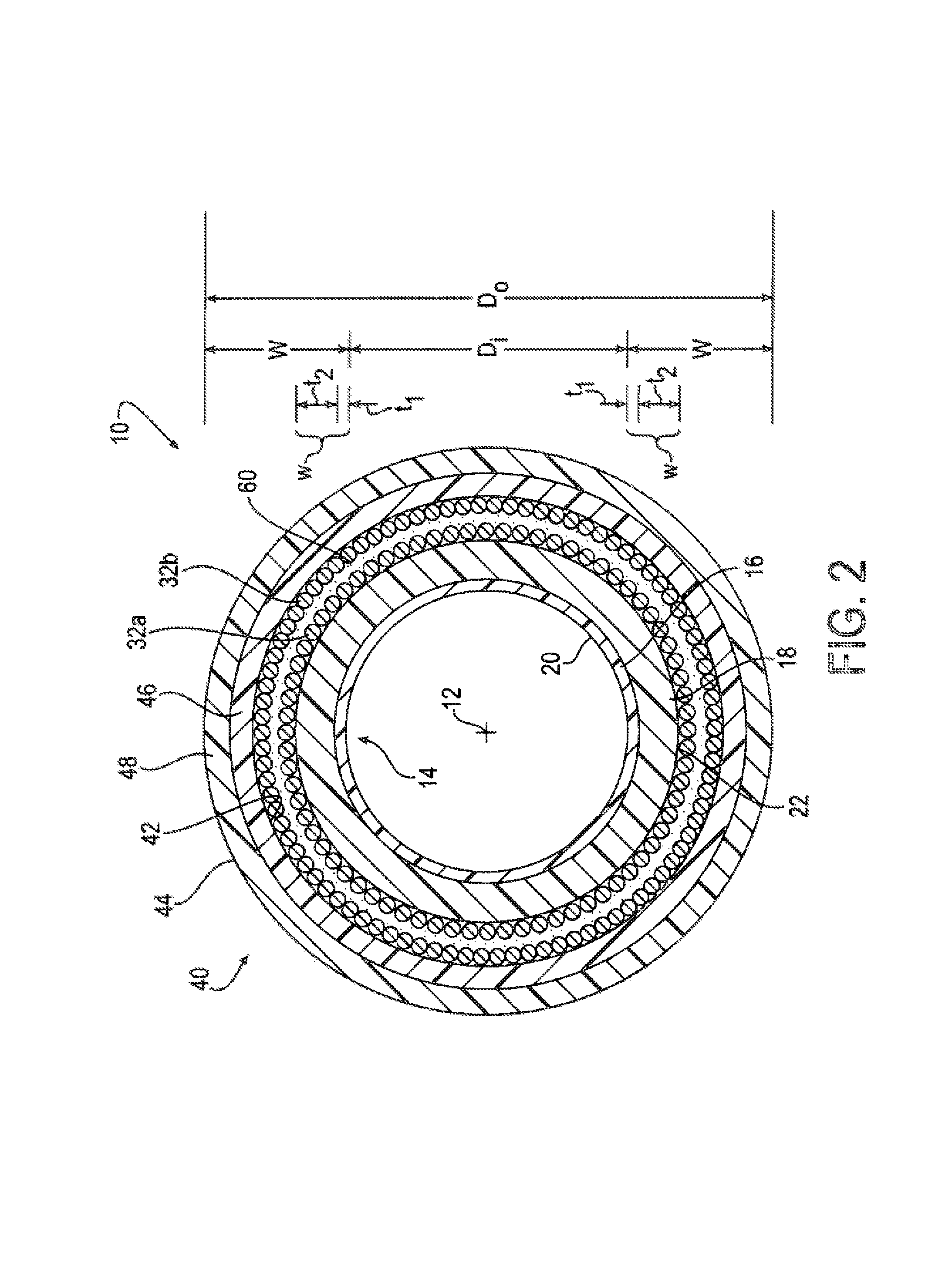

Electrically-conductive hose

InactiveUS20060127620A1Affect strengthAffect flexibilitySynthetic resin layered productsFlexible pipesPolyesterParticulates

Tubular polymeric composite for articles such as tubing and hoses. The composite is formed of a tubular first layer of a thermoplastic block polyether amide resin (PEBA) filled with a more structured carbon black particulate filler to render it electrically-conductive, and a tubular second layer of a thermoplastic polyamide, polyester, polyolefins, or other thermoplastic resin compatible with the PEBA resin of the first material, and which second material optionally may be filled with a less structured carbon black particulate filler to render it electrically-conductive.

Owner:PARKER HANNIFIN CORP

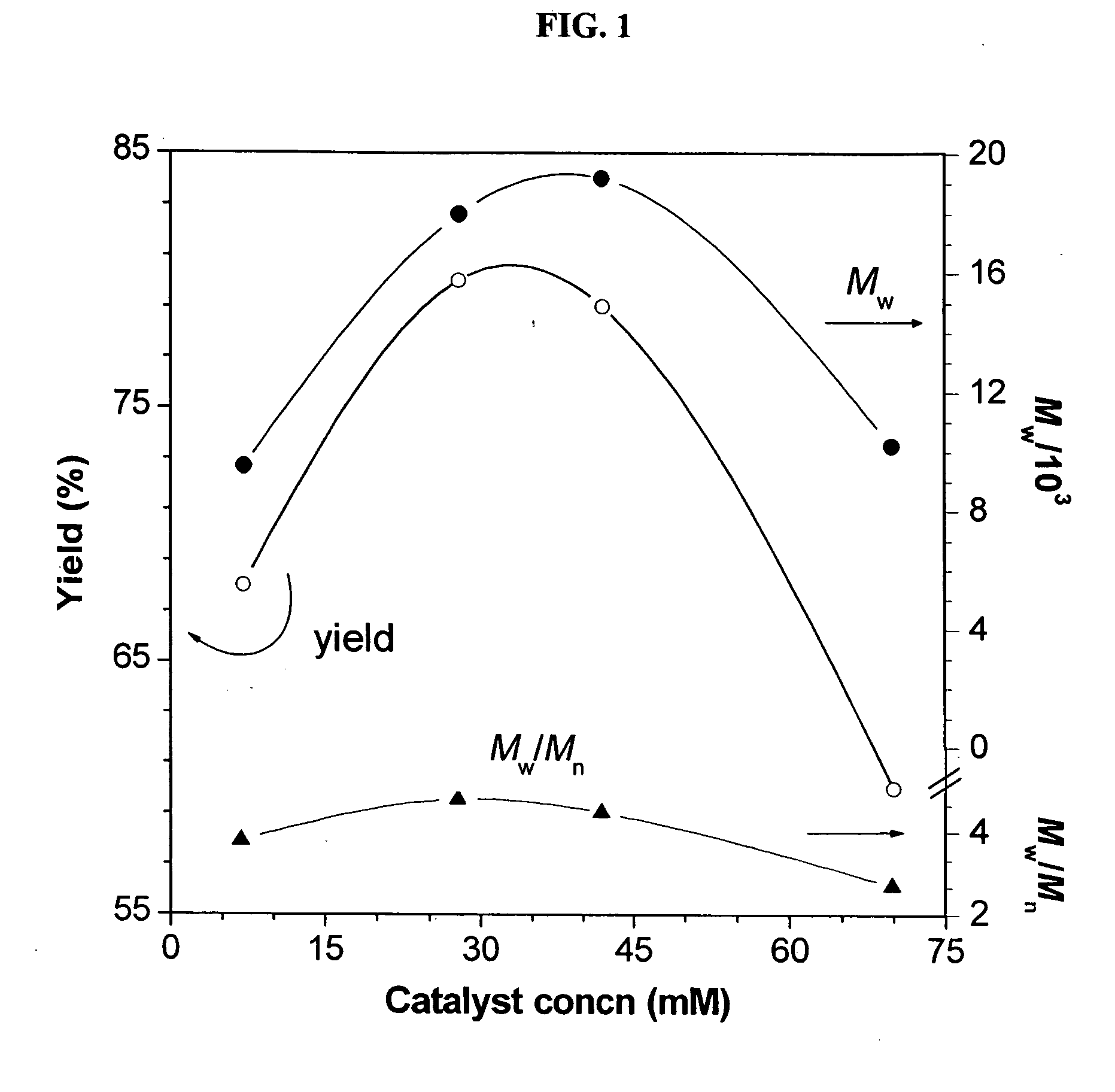

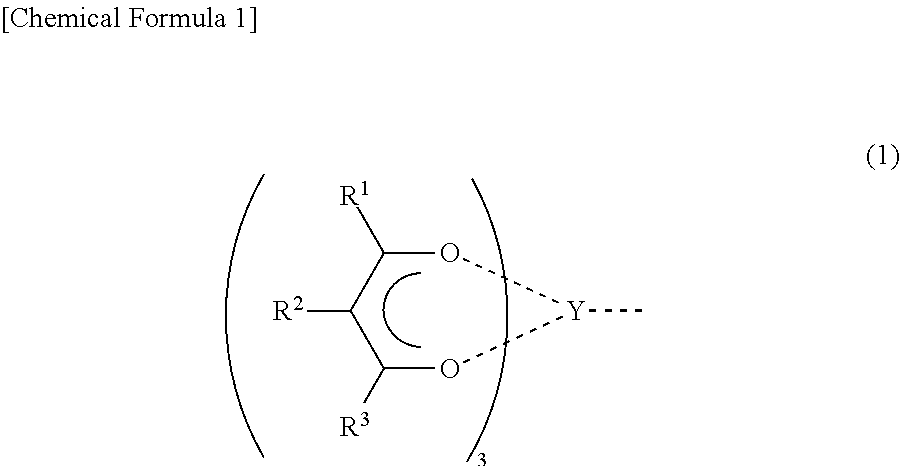

Soluble branched triaroylbenzene-based polymer and its synthetic method

ActiveUS20060247410A1High resolutionHigh molecular weightOrganic compound preparationCarbonyl compound preparationStructural unitHigh resolution

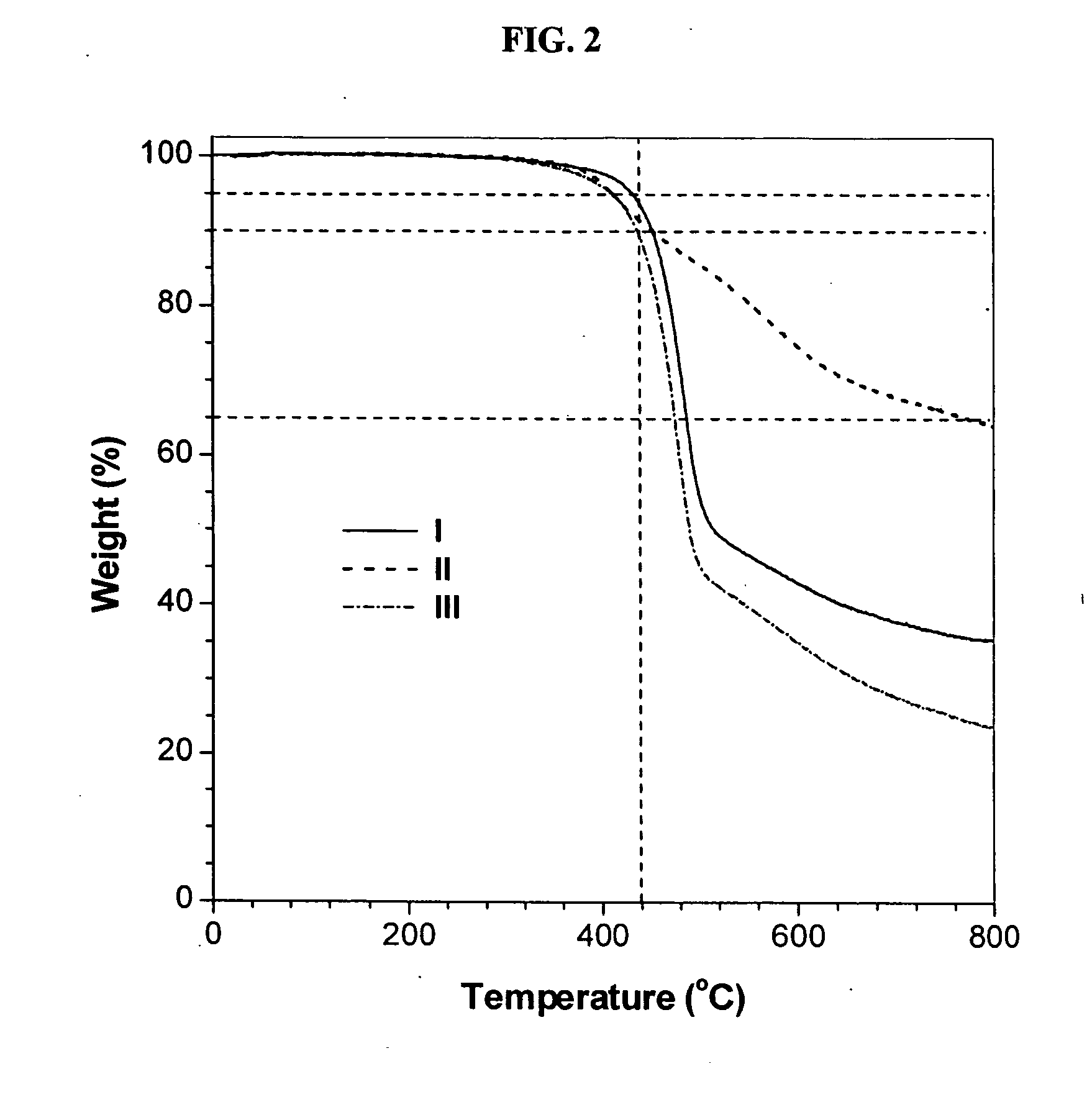

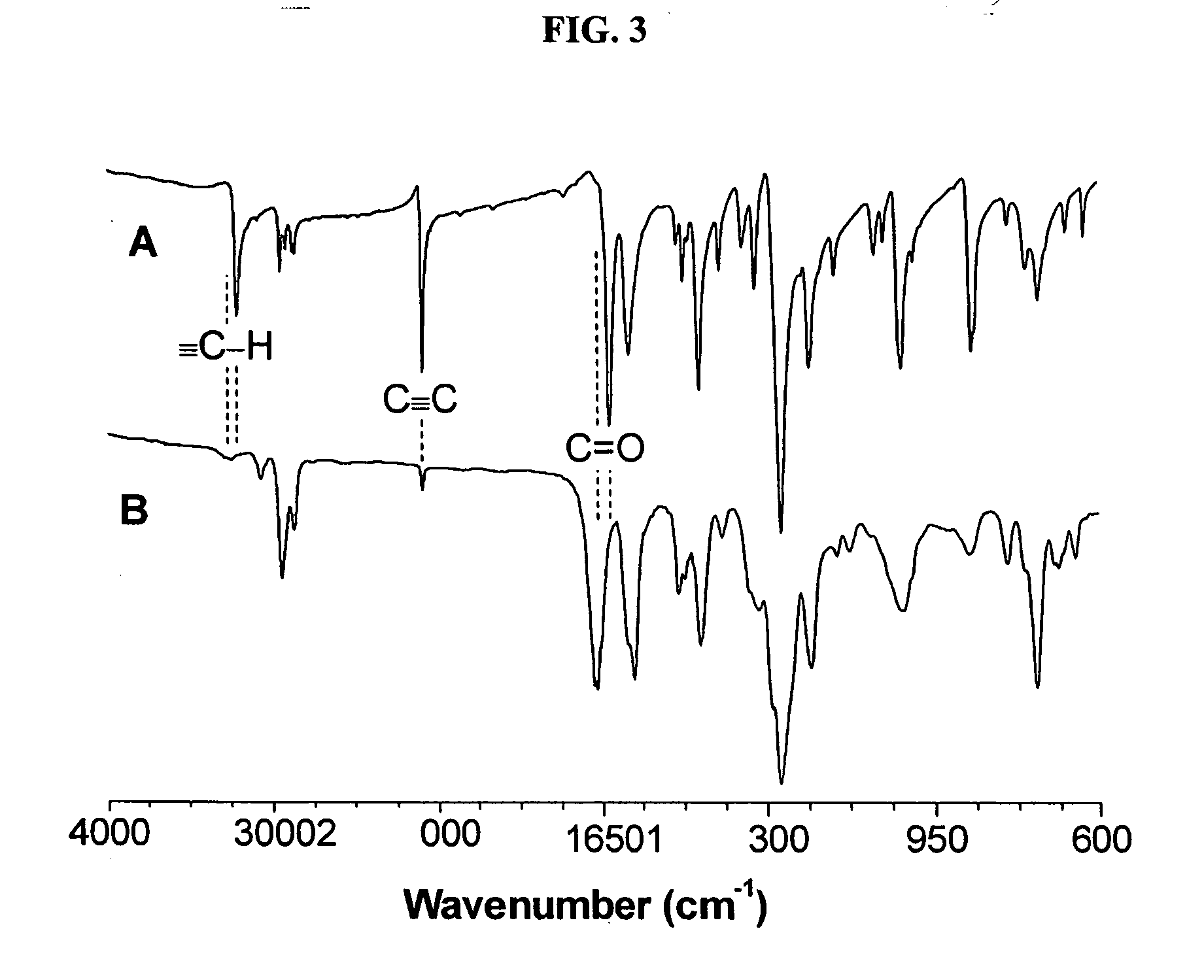

The present invention relates to a novel process of preparing branched polymers by cyclotrimerization and branched organic materials containing triaroylbenzene moieties as base structural unit. The polymerization is a simple one-pot reaction, strictly regioselective and highly functionality-tolerant giving oligomeric and polymeric polymers with high degree of branching (up to 100%) in high yields (up to 99%). The polymers are processible, easily film-forming, transformable (curable) into thermosets by heat or irradiation, and readily crosslinkable by UV irradiation to give patterns with nanometer resolution. The polymers of the present invention can be blend with a variety of macromolecules for general use. The polymers can be metallified utilizing organometallic acetylene as building blocks and ceramization of the patterns of the obtained polymers afford ferromagnetic ceramic patterns with high resolution.

Owner:THE HONG KONG UNIV OF SCI & TECH

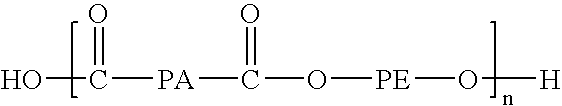

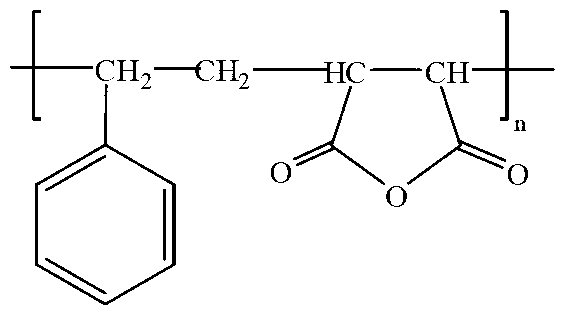

Water-soluble polymer and additive for paper manufacture

The present invention provides a method for preparing a water soluble polymer, which comprises: a first step of polymerizing: (a) 60 to 99.5 mol % of at least one selected from acrylamide and methacrylamide, (b) 0.5 to 20 mol % of at least one selected from α,β-unsaturated monocarboxylic acid, α,β-unsaturated dicarboxylic acid and salts thereof, and (c) 1 to 20 mol % of at least one selected from a water soluble cationic monomer and a salt thereof, (d) 0.01 to 1 mol % of a chain transfer agent, and (e) 0.005 to 5 mol % of a crosslinkable monomer, in the presence of a persulfate-based catalyst to obtain a prepolymer; and a second step of further adding the persulfate-based catalyst to the prepolymer obtained in the first step and the residual monomer, followed by the polymerization and termination of the polymerization. Consequently, it is made possible to suppress a rapid increase in viscosity during the polymerization thereby to obtain a water soluble branched polymer having high molecular weight and low viscosity.

Owner:HARIMA CHEM INC

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon addditive

InactiveUS20040059173A1High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingPARAFFIN HYDROCARBONSAlkane

A process for the conversion of linear and / or branched paraffins hydrocarbons, catalysed by an ionic liquid catalyst, in the presence of a cyclic hydrocarbon additive containing a tertiary carbon atom. The presence of the specific hydrocarbon additives influences the reaction mechanism by increasing the selectivity towards the formation of paraffin hydrocarbons with a higher degree of branching.

Owner:HALDOR TOPSOE AS

Process for controlling degree of branch of high 1,4-cis polybutadiene

InactiveUS20020016423A1Easy to processOptimizing physical propertyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePolybutadiene

Disclosed is a process of controlling the degree of branch of high 1,4-cis polybutadiene without any alternation in the 1,4-cis content and the polymerization yield, in which a dialkylzinc compound represented by the following formula I is added in a controlled amount as an agent for controlling the degree of branch of high 1,4-cis polybutadiene, thus guaranteeing the optimum processability and physical properties of polymer according to the use purpose. Formula I<paragraph lvl="0"><in-line-formula>R1-Zn-R2< / in-line-formula>wherein R1 and R2 are same or different and include an alkyl group containing 1 to 5 carbon atoms.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

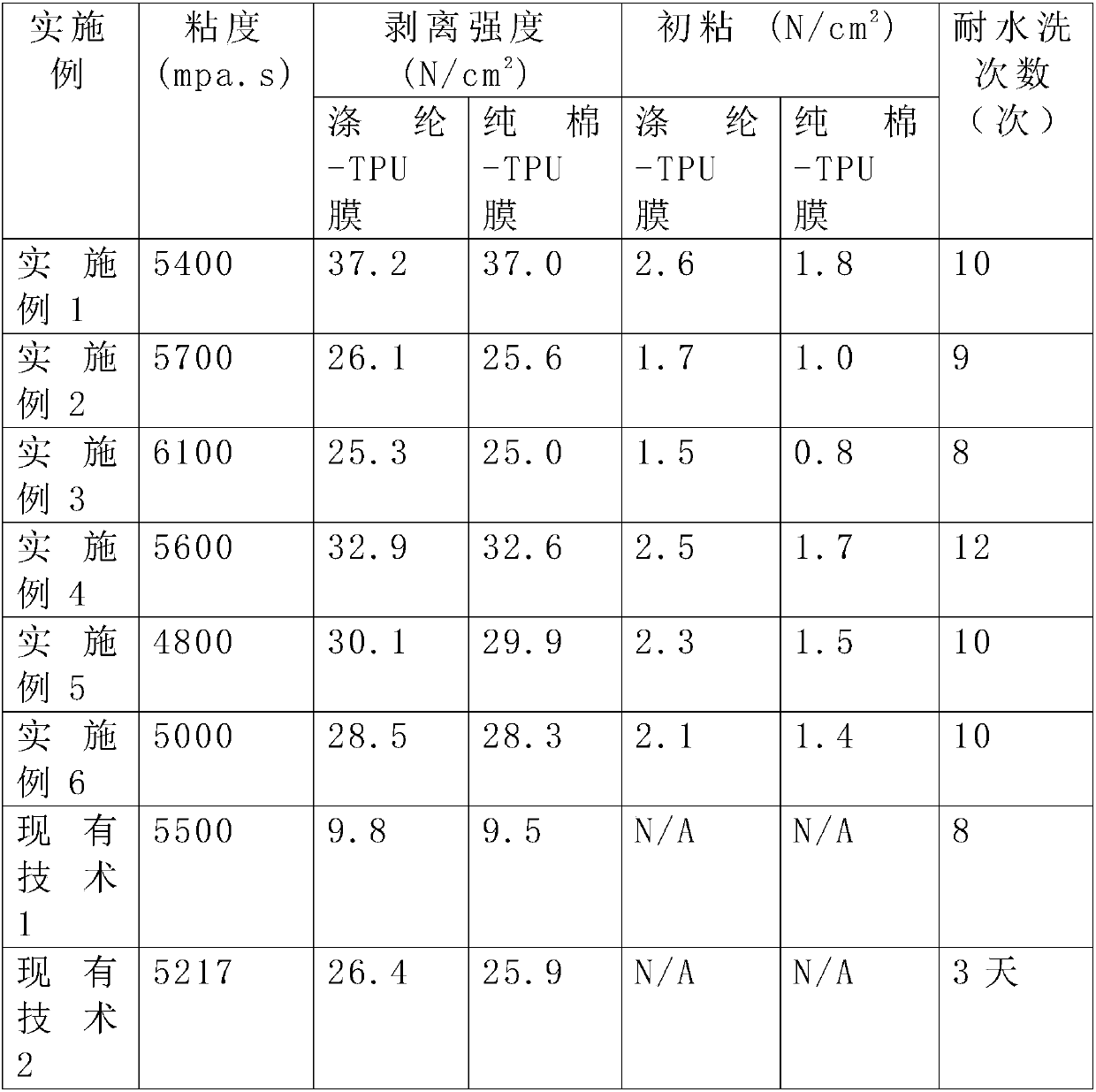

Hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and preparation method thereof

InactiveCN108084948AHighlight cohesionOutstanding initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and a preparation method thereof. The hyperbranched polyester hot-melt-type polyurethane adhesive comprises polyether polyol, hyperbranched polyester polyol, MDI and an additive. The preparation method comprises preheating hyperbranched polyester polyol at 100-150 DEG C until melting to obtain hyperbranched polyester polyol pre-melt, checking the hermeticity of a reactor, removing water through replacing with nitrogen gas, carrying out preheating to 50 DEG C, orderly adding MDI and polyether polyol into the reactor, carrying out stirring in vacuum under control of a jacket temperature to 60-80 DEG C for a reaction for 1-3h, fast cooling the reaction system to 55 DEG C to obtain a polyurethaneprepolymer, orderly adding polyester polyol and the hyperbranched polyester polyol pre-melt into the polyurethane prepolymer in vacuum, heating the mixture to 60-80 DEG C, carrying out stirring for areaction for 1-3h, breaking vacuum after the reaction, and removing air bubbles to obtain the hyperbranched polyester hot-melt-type polyurethane adhesive for weaving.

Owner:黄子昕

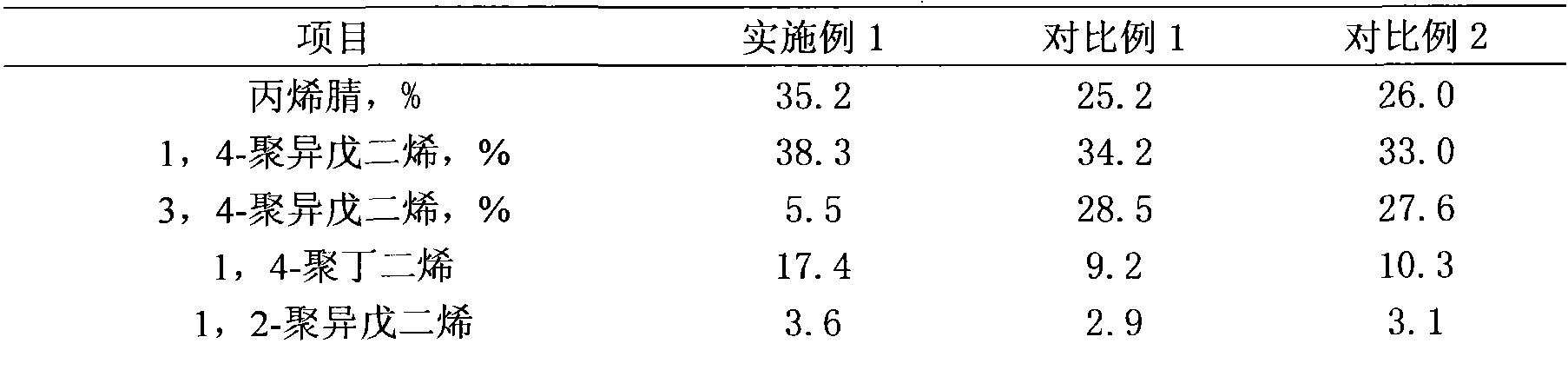

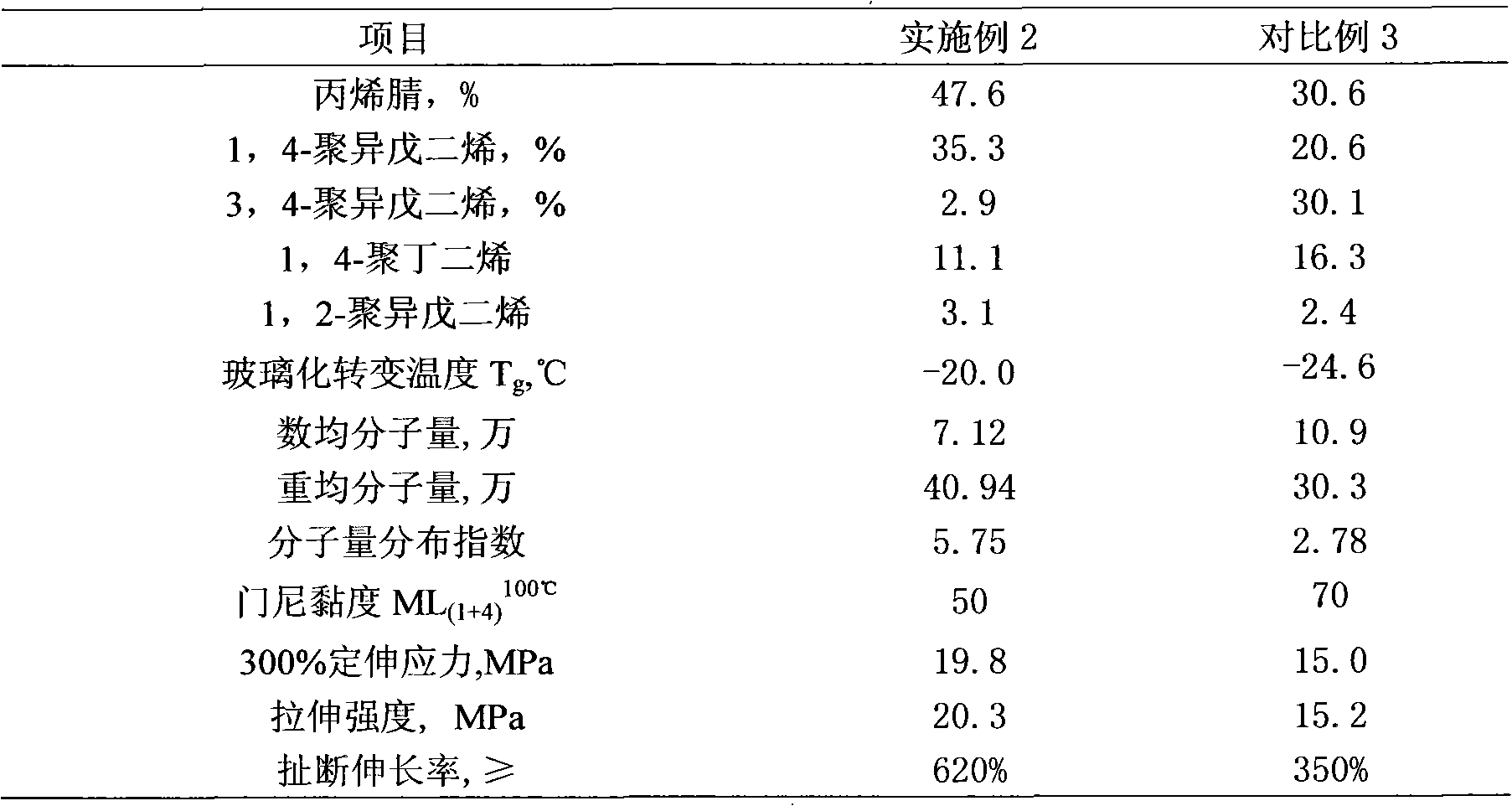

Preparation method of in-situ hybrid reinforced butadiene-acrylonitrile-isoprene copolymer

ActiveCN102167780AQuality improvementGood physical and mechanical propertiesPolymer scienceButadiene Dioxide

The invention provides an emulsion polymerization method for hybridizing and reinforcing a butadiene-acrylonitrile-isoprene copolymer in situ by using vinyl tetraethoxysilane and microcrystalline cellulose as a compounded reinforcing agent. The number average molecular weight of the prepared copolymer is 5*10<4> to 40*10<4>; the isoprene content is 10 to 60 percent; the butadiene content is 10 to 80 percent; the acrylonitrile content is 15 to 55 percent; and in the copolymer, the 1,4-polyisoprene content is 60 to 95 percent, the 3,4-polyisoprene content is 5 to 30 percent, the 1,4-polybutadiene content is 60 to 90 percent and the 1,2-polybutadiene content is 10 to 40 percent. The copolymer has the characteristics of excellent mechanical property and simpleness in process, meets the high-performance requirement of nitrile rubber and enlarges the application range.

Owner:PETROCHINA CO LTD

Process for controlling degree of branch of high 1,4-cis polybutadiene

InactiveUS6586542B2Optimizing processability and physical property of rubberEasy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePolybutadiene

Owner:KONINK PHILIPS ELECTRONICS NV +1

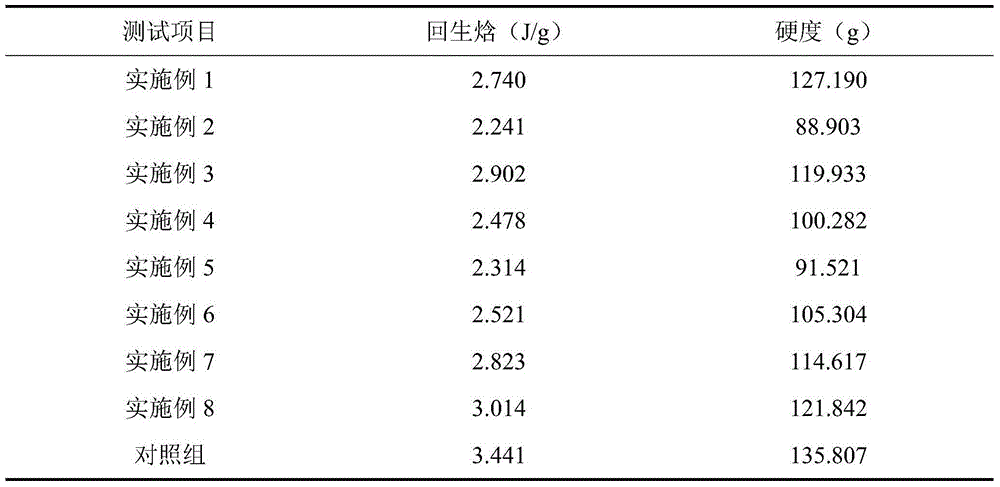

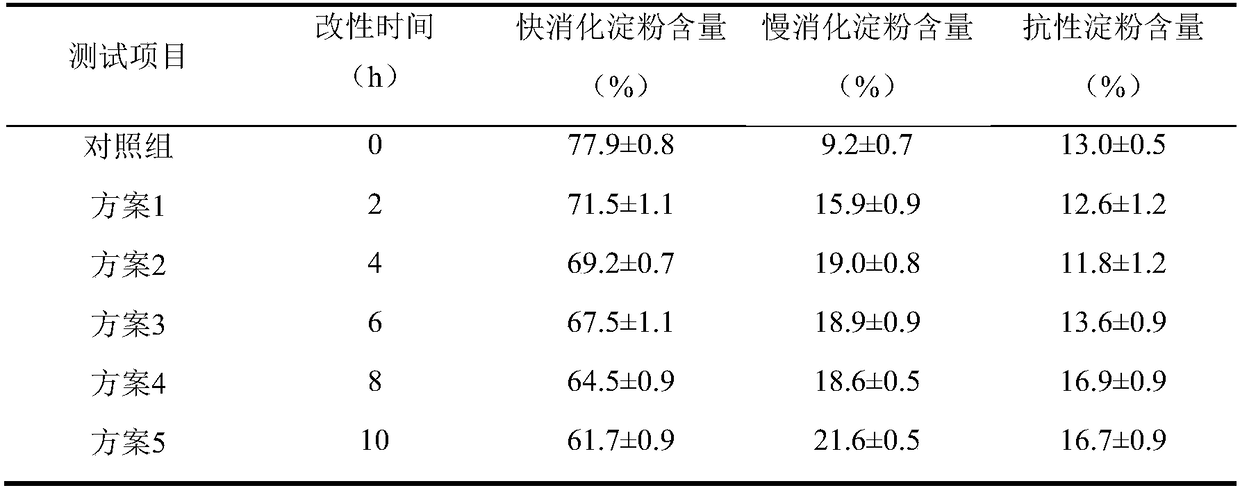

Biological modification method for inhibiting starch retrogradation

InactiveCN104544473AReduce the rate of respawnPrevent regenerationFood preservationRetrogradationVacuum drying

The invention discloses a biological modification method for inhibiting starch retrogradation, and belongs to the field of agricultural product processing and biology. The method comprises the steps of dissolving starch into water to obtain 30% (w / v) of starch milk, adjusting the pH to 7.5, adding 300-1,000U / g of starch branching enzyme of dried starch, treating at 50 DEG C for 4-10h to obtain a reaction solution, washing the reaction solution with deionized water, collecting solid and performing vacuum drying to obtain biological modified starch. By adopting the method, starch molecules have smaller branched chains and relatively high branching degree through the modification effect of the starch branching enzyme to hinder the rearrangement of amylopectin in the storage process, so that starch retrogradation can be well inhibited.

Owner:JIANGNAN UNIV

Electrically-conductive hose

InactiveUS8394471B2Affect strengthAffect flexibilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingParticulatesPolyester

Tubular polymeric composite for articles such as tubing and hoses. The composite is formed of a tubular first layer of a thermoplastic block polyether amide resin (PEBA) filled with a more structured carbon black particulate filler to render it electrically-conductive, and a tubular second layer of a thermoplastic polyamide, polyester, polyolefins, or other thermoplastic resin compatible with the PEBA resin of the first material, and which second material optionally may be filled with a less structured carbon black particulate filler to render it electrically-conductive.

Owner:PARKER HANNIFIN CORP

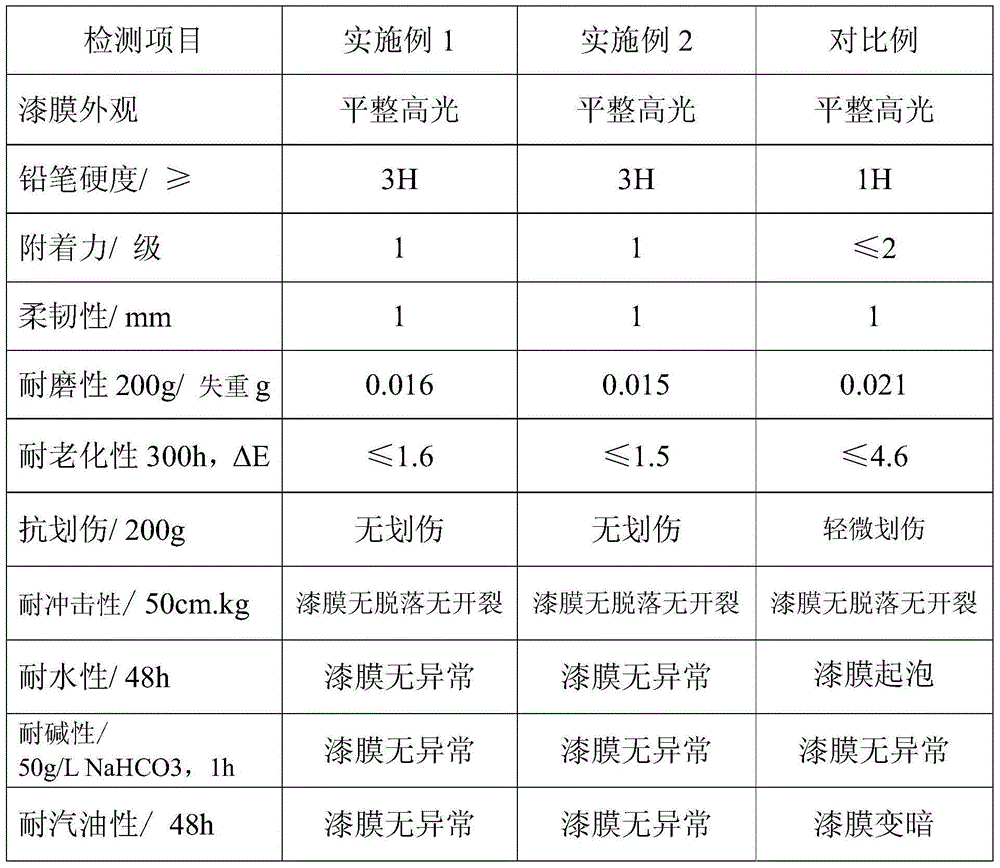

Method for preparing hyperbranched waterborne polyester resin

ActiveCN105694014AImprove hydrolysis resistanceGood storage stabilityPolyester coatingsWater dispersiblePolymer science

The invention relates to a method for preparing hyperbranched waterborne polyester resin which is composed of, by weight, 6-10% of TMP, 15-20% of DMPA, 0.1-0.5% of p-toluene sulfonic acid, 15-25% of neopentyl glycol, 12-20% of m-phthalic acid, 20-30% of maleic anhydride or phthalic anhydride, 6-10% of adipic acid, 0.1-0.5% of p-methoxyphenol, 20-30% of ethylene glycol monobutyl ether, 12-20% of dimethylethanolamine, and 70-130% of deionized water. The prepared hyperbranched waterborne polyester resin has the advantages of excellent hydrolysis resistance, water dispersibility and storage stability, has the characteristics of high glossiness, good abrasion resistance, strong adhesion powder, high fullness, excellent impact resistance and the like no matter the resin is made into a waterborne stoving varnish with amino resin or is made into a waterborne woodware paint with hydrophilic polyisocyanate, and is widely used in surface coating and protection of woodware, metals, zinc alloys, aluminum alloys, magnesium alloys, plastics and other products,.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

Method for preparing slowly-digested dextrin

ActiveCN108949861ADelayed digestionHigh degree of branchingFermentationMicroorganismResistant starch

The invention discloses a method for preparing slowly-digested dextrin and belongs to the field of bio-modified starch. The method comprises the step of carrying out synergistic modification on to-be-modified starch by adopting Ro (Rhodothermus obamensi)-GBE (Glucan Branching Enzyme) and Gt (Geobacillus thermoglucosidans)-GBE. According to the method disclosed by the invention, corn starch is synergistically treated by utilizing starch branching enzymes with two different microbial sources, the Ro-GBE is firstly added to pretreat, the Gt-GBE is added later, the to-be-modified starch is catalyzed by the Ro-GBE to form a chain segment structure which is more beneficial to the further utilization of the Gt-GBE and slender-type starch molecules are transformed into chunky-type more compact branching structures under the action of the Gt-GBE, so that the slow digestibility of the modified product is more obvious; and further, through changing the adding amount of the Ro-GBE, the modification time and the state of the to-be-modified starch, the synergistic effect between the Ro-GBE and the Gt-GBE is promoted, the branching degree of the amylopectin is increased and the content of the slowly-digested and resistant starch is further increased.

Owner:JIANGNAN UNIV

Preparation method for butadiene rubber

The invention provides a preparation method for butadiene rubber, belonging to the field of synthesis of polymers. The preparation method is characterized in that butadiene and a branching agent undergo polymerization in an organic solvent in the presence of a nickel-series catalyst, wherein the branching agent is liquid polybutadiene. Compared with nickel-series butadiene rubber prepared in the prior art, the branched nickel-series butadiene rubber prepared in the invention has a larger application scope since the butadiene rubber liquid has low viscosity and is not prone to adhesion on wallsand the raw butadiene rubber has improved cold flow properties and good processing performance; and when the branched nickel-series butadiene rubber prepared in the invention is applied to preparation of vulcanized rubber, the prepared vulcanized rubber has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP

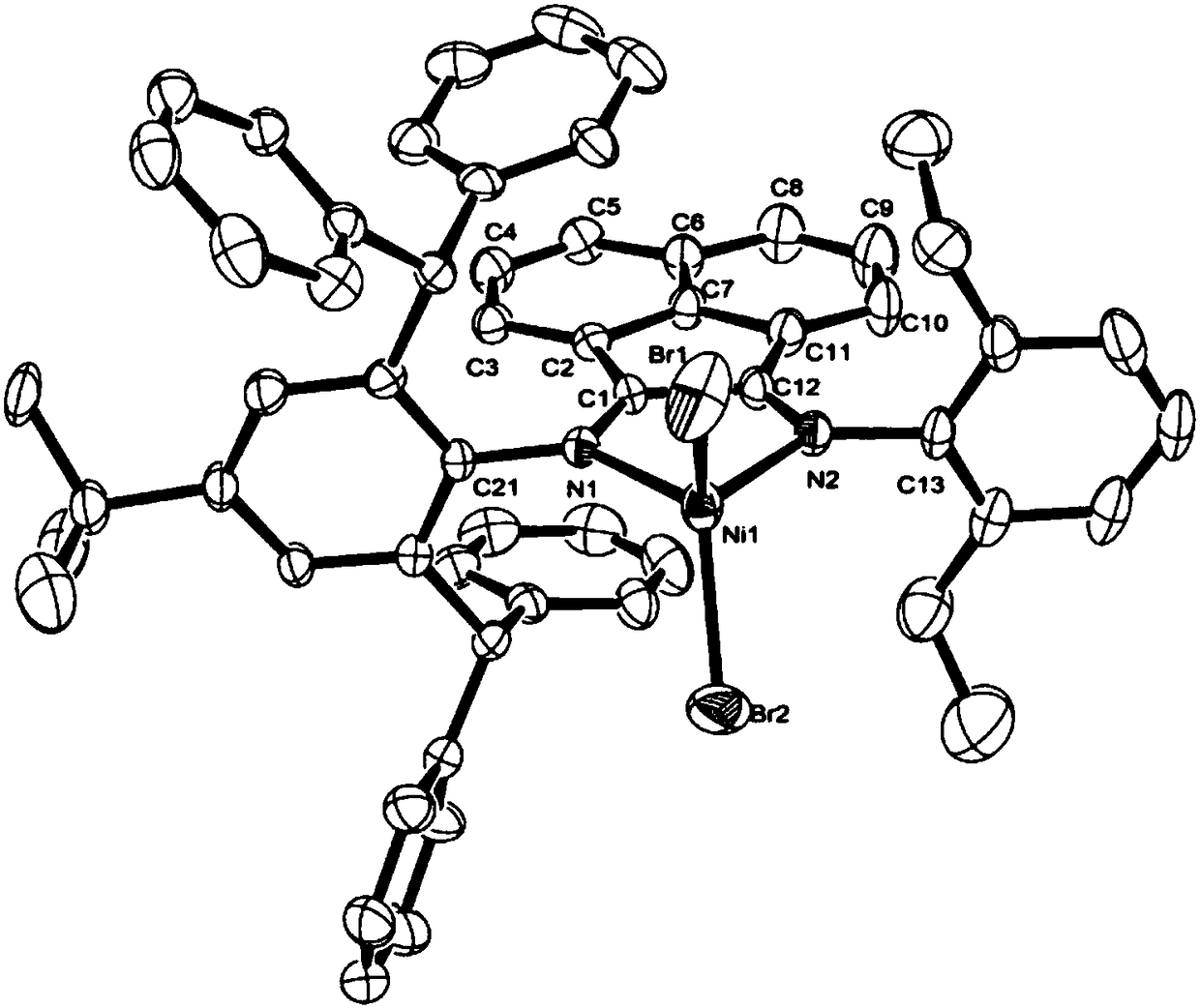

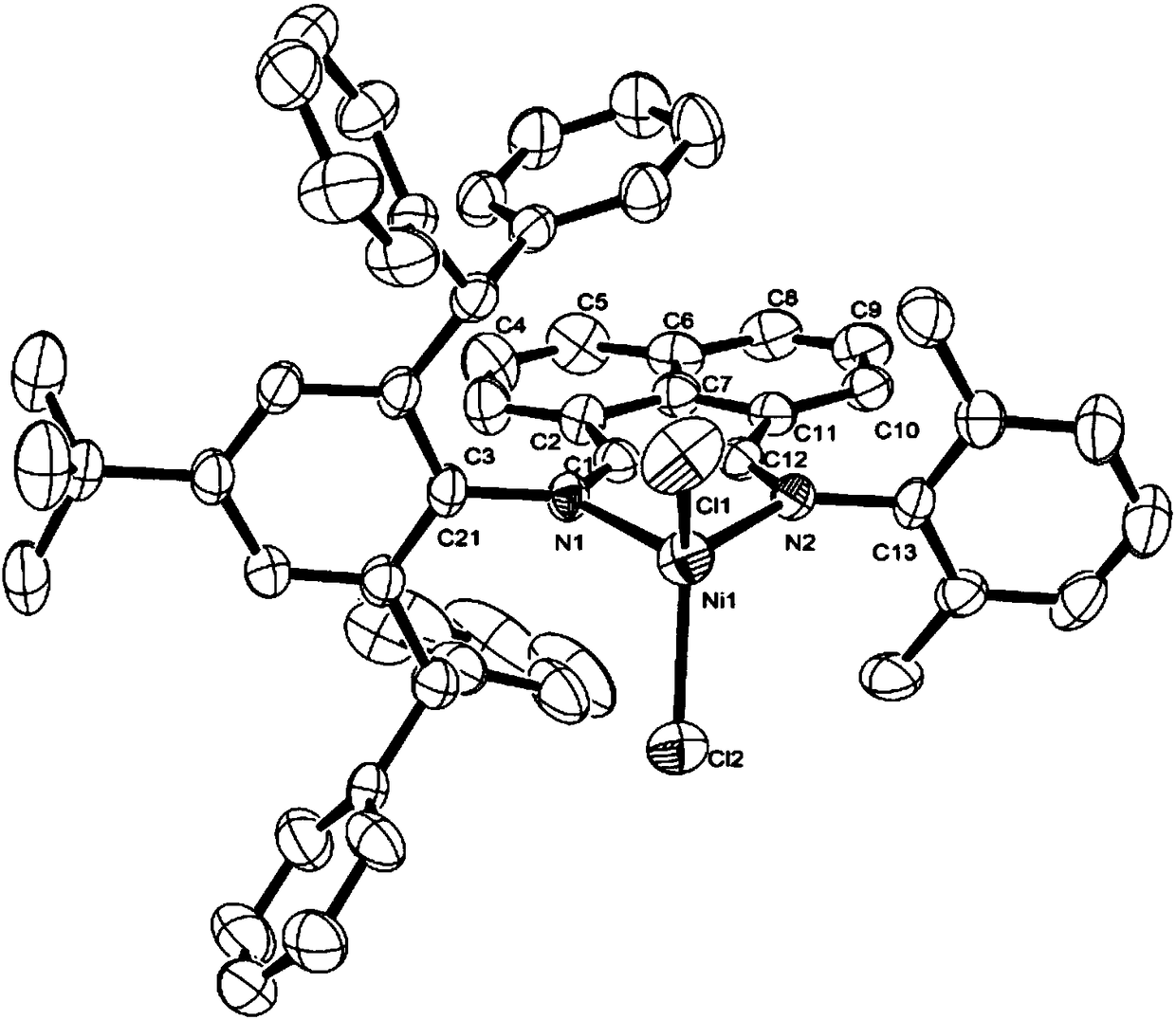

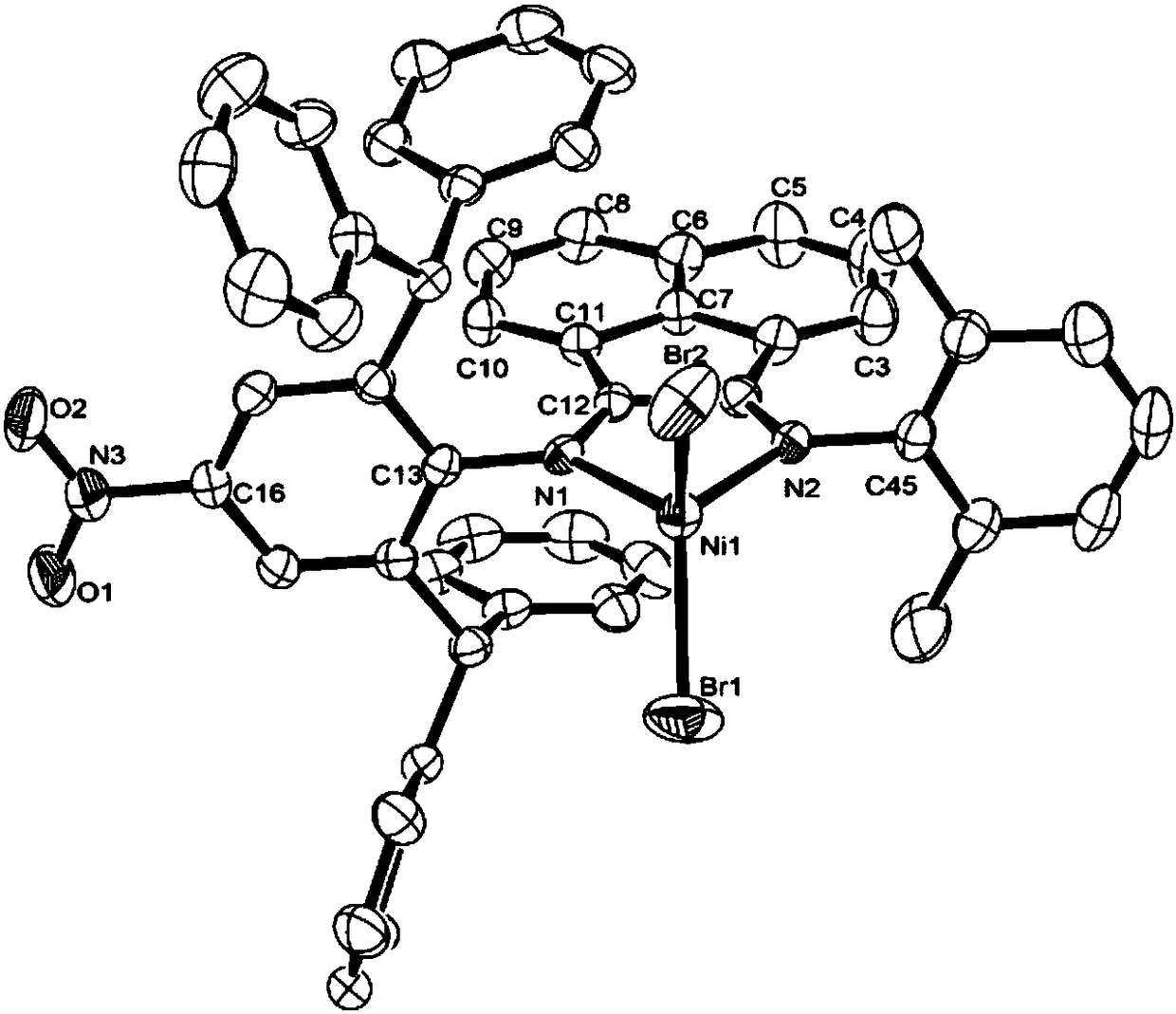

Tert-butyl asymmetric alpha-diimine nickel complex for preparation of ultrahigh-molecular-weight polyethylene elastomers and preparation method and application of tert-butyl asymmetric alpha-diimine nickel complex

ActiveCN108794545AHigh catalytic activityLow costNickel organic compoundsBulk chemical productionElastomerPolyolefin

The invention provides a tert-butyl asymmetric alpha-diimine nickel complex and an intermediate, a preparation method and application thereof. The prepared nickel complex has a single catalytic activecenter, regulation of polymer molecular weight and branching degrees can be realized through changing of a ligand structure and polymerization conditions, and high catalytic activity, low cost, performance stability and the like are achieved. The preparation method is mild in condition, short in period and simple in operation condition. The nickel complex can be applied to catalysts for vinyl polymerization, the catalytic activity is up to 1.26*10<7>g mol<-1>(Ni) h<-1>, the weight-average molecular weight Mw of prepared polyethylene fluctuates in a range of 1.0-30.8*10<5>g mol<-1>, molecularweight distribution is in a range of 1.9-5.0, the remarkable performance of polyethylene molecular weight control is achieved, the nickel complex can be used for preparation of ultrahigh-molecular-weight polyethylene, and obtained polyethylene is high in branching degree and is potential polyolefin elastomer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

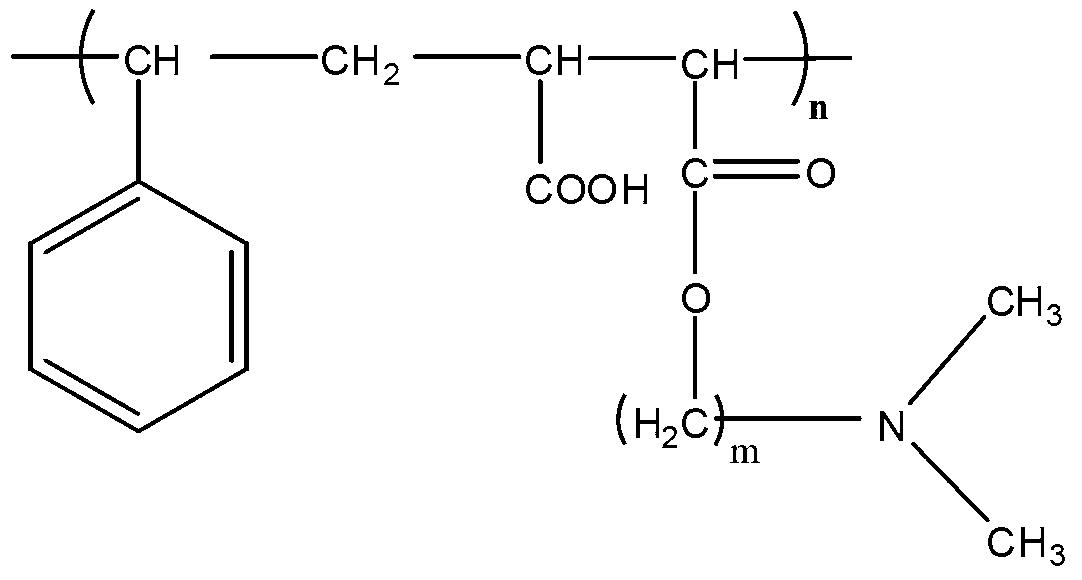

Amphiprotic leather tanning agent and preparation method thereof

InactiveCN103276119AGood retanningWith fatliquoring functionTanning treatmentPolymer SMAStyrene maleic anhydride

The invention discloses amphiprotic leather tanning agent and a preparation method thereof. The preparation method of the amphiprotic leather tanning agent comprises the following steps of: based on weight parts, adding an SMA (Styrene Maleic Anhydride) copolymer, N, N-dimethyl fatty alcohol amine and a catalyst to a reaction kettle in which a condensing device is installed; adding a solvent to react, and measuring a hydroxyl value in the reaction system; adding dimethyl sulfate to react when the hydroxyl value (in terms of solid) is smaller than and equal to 10 (mg KOH / g); distilling under reduced pressure under the vacuum condition to remove the solvent; and adjusting a pH value by using an alkali aqueous solution; and adjusting the mass concentration of the product to 20%-40%. The amphiprotic leather tanning agent disclosed by the invention not only retains the filling performance of the SMA tanning agent, but also improves the color fading defect of the SMA tanning agent. Meanwhile, the modified SMA tanning agent has good emulsifying dispersion; and the leather body, which is tanned again by the amphiprotic tanning agent, is full and soft, and is good in elasticity and higher in tensile strength and tearing strength.

Owner:SHAANXI UNIV OF SCI & TECH

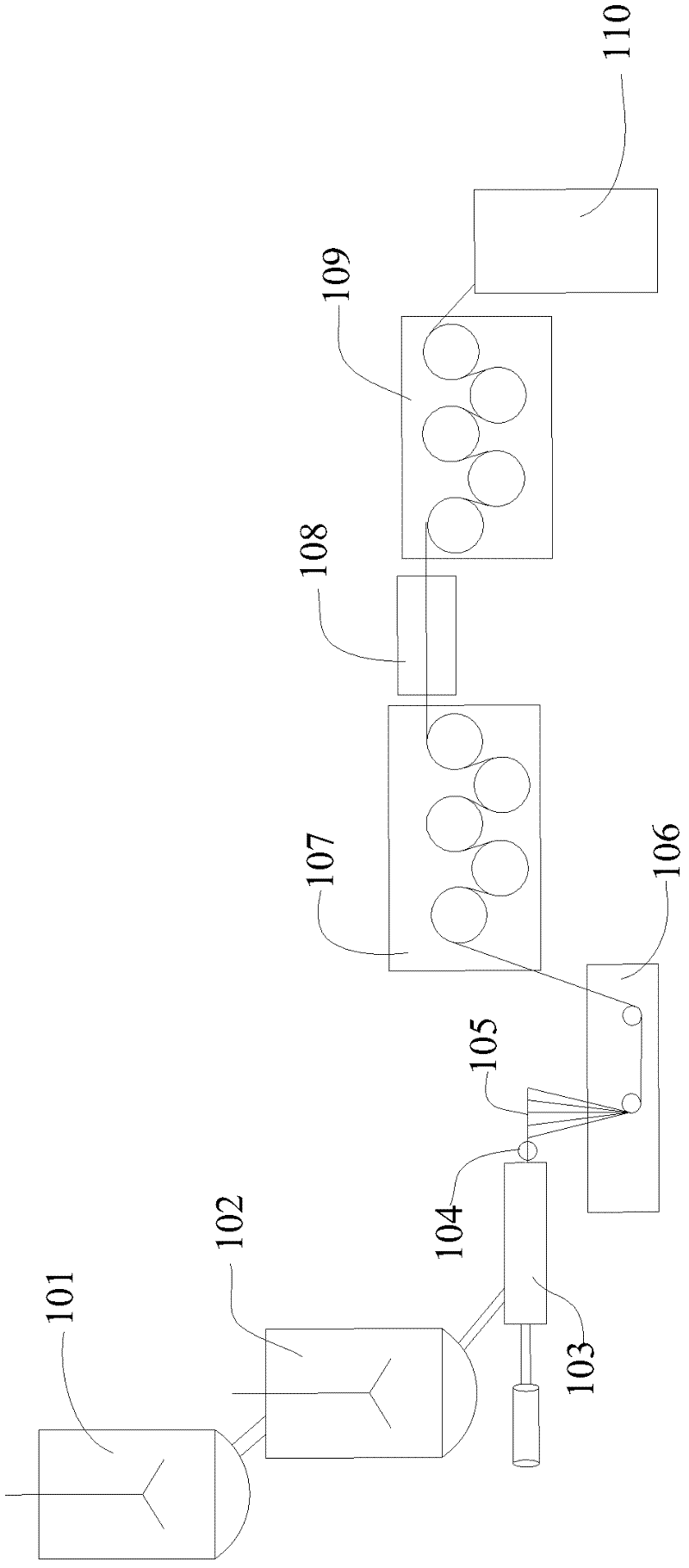

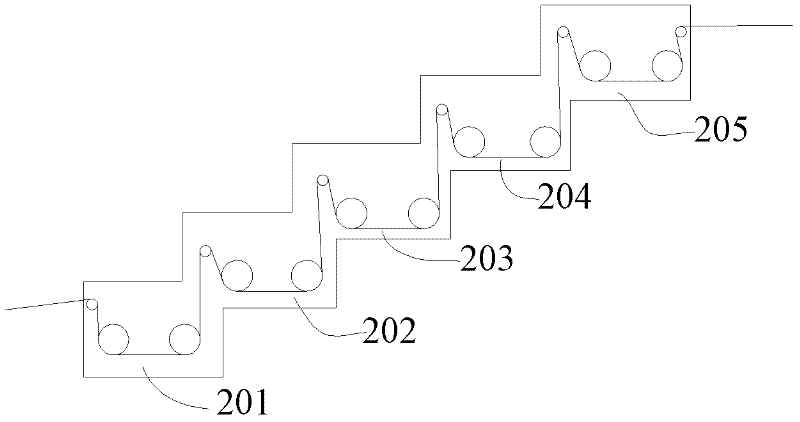

Preparation method of ultrahigh-molecule-weight polyethylene fibers

InactiveCN102517655AIncrease concentrationAvoid damageDry spinning methodsSpinning solutions preparationPolymer scienceLiquid hydrocarbons

The invention provides a preparation method of ultra-molecule-weight polyethylene fibers, which includes steps of a), mixing ultrahigh-molecule-weight polyethylene powder with solvent which is liquid hydrocarbon at room temperature, swelling the same to obtain spinning solution, extruding the spinning solution by a double-screw extruder and dissolving the same to obtain spinning solution with the concentration ranging from 70wt% to 97.6wt%; b) spraying the spinning solution and cooling the same to obtain gel fibers; c) washing the gel fibers by oil, drying to obtain as-spun fibers; and d) drawing the as-spun fibers five times to obtain the ultra-molecule-weight polyethylene fibers with fineness of 360D. The drawing multiple ranges from 10 to 13. The ultra-molecule-weight polyethylene fibers prepared by the preparation method have the total fineness of 360D and are high in modulus and strength and low in solvent usage.

Owner:杨珍芬

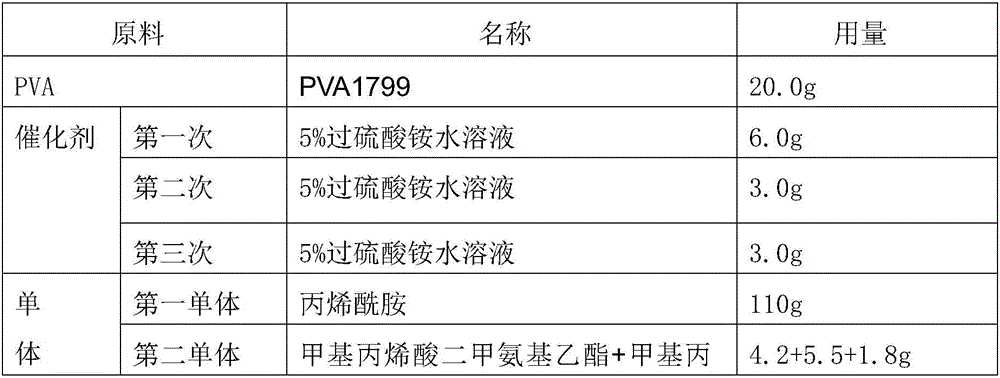

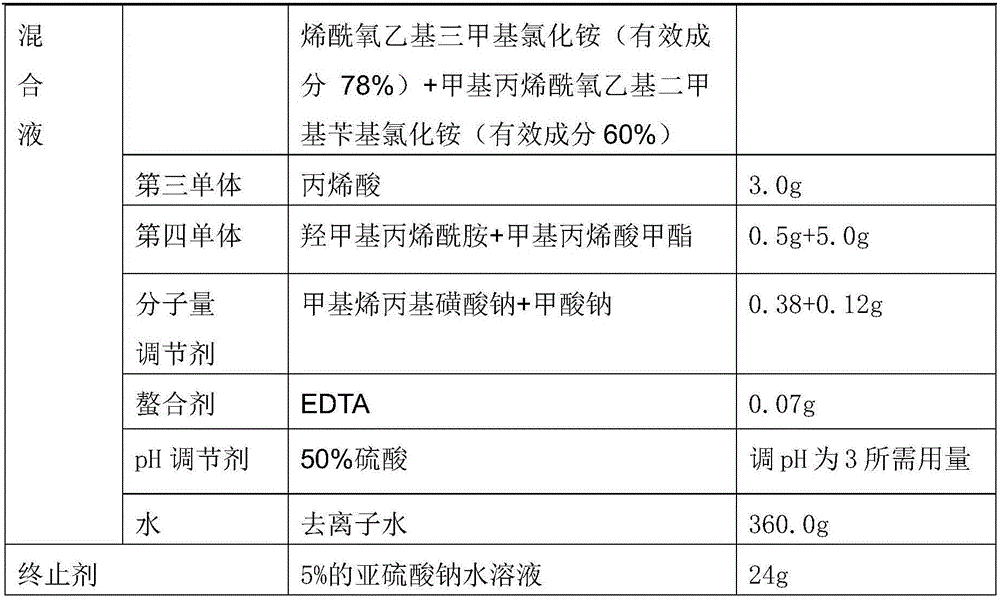

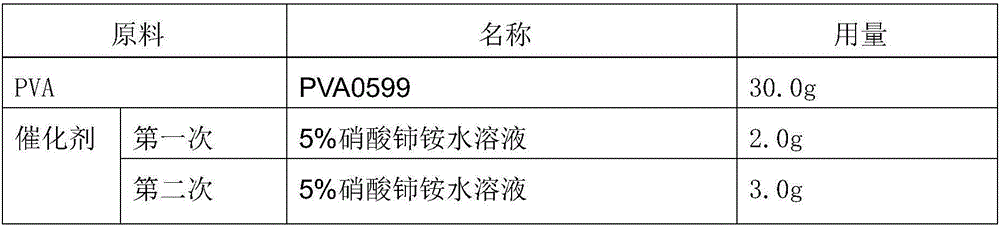

A kind of highly branched polyvinyl alcohol-acrylamide graft copolymer and its preparation method and application

ActiveCN104119480BHigh degree of branchingIncrease the lengthReinforcing agents additionPaper/cardboardInterference resistanceReaction temperature

The invention relates to a preparation method of a highly branched polyvinyl alcohol-acrylamide graft copolymer. After dissolving the polyvinyl alcohol in water, blowing nitrogen gas, lowering the temperature, adding a catalyst, reacting for 10-30 minutes, and then adding a monomer mixture solution dropwise , control the dropping time for 30-90 minutes, during which the reaction temperature is controlled between 65°C-95°C, after dropping, control the temperature between 85°C-95°C for 20-30 minutes, add catalyst, and continue at 80°C React at ‑95°C for 15-25 minutes, add catalyst, take samples during the reaction to measure the viscosity, after the viscosity reaches 1500-15000 mPa.s at 25°C, add a terminator to stop the reaction, adjust the solid content, and the product is ready. The graft copolymer of the present invention has high molecular weight, many branched chains, low viscosity, less gel, good retention, and strong anti-interference ability of impurities. As a dry strength agent for papermaking, it can also Satisfactory enhancement effect is achieved.

Owner:九洲生物技术(苏州)有限公司

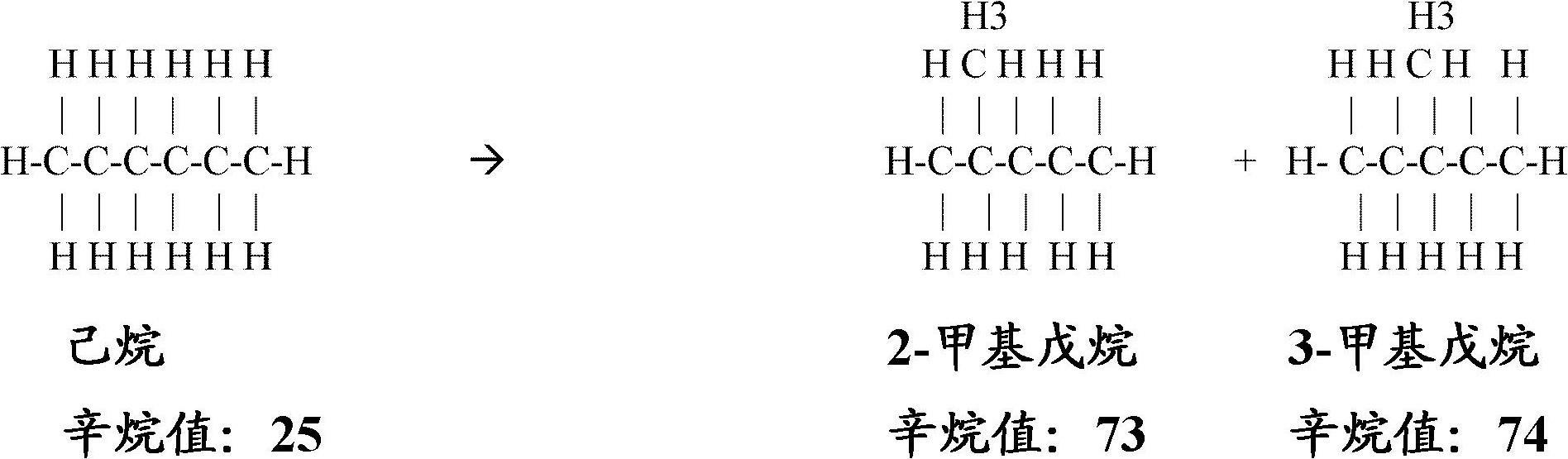

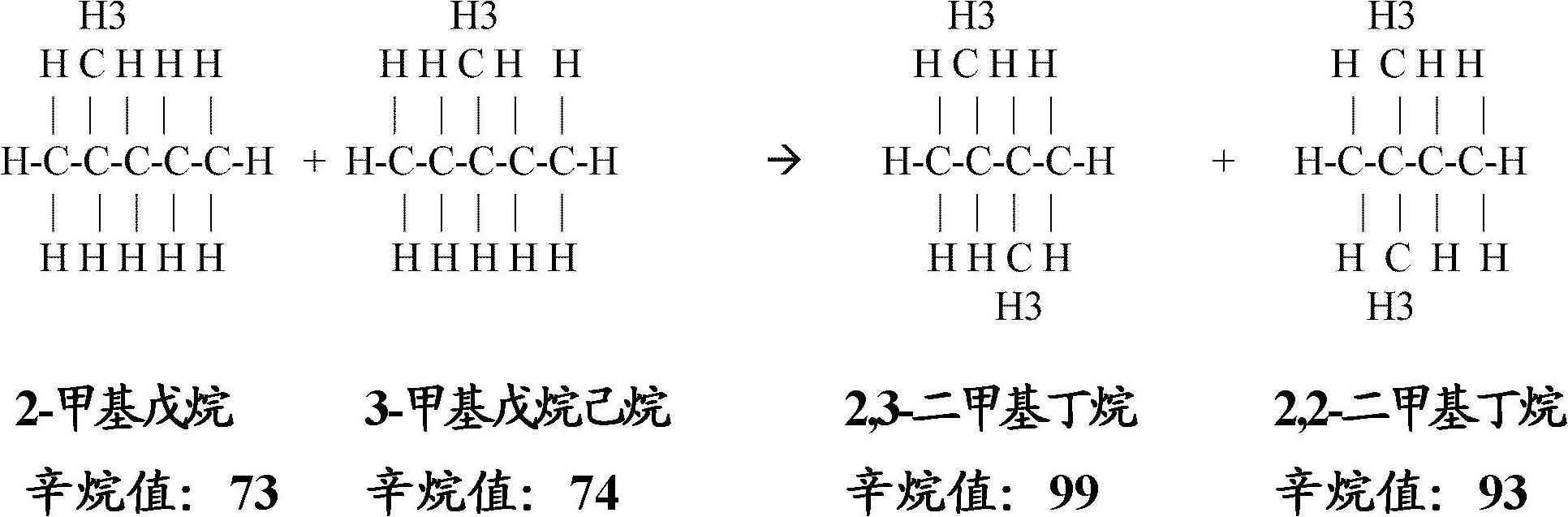

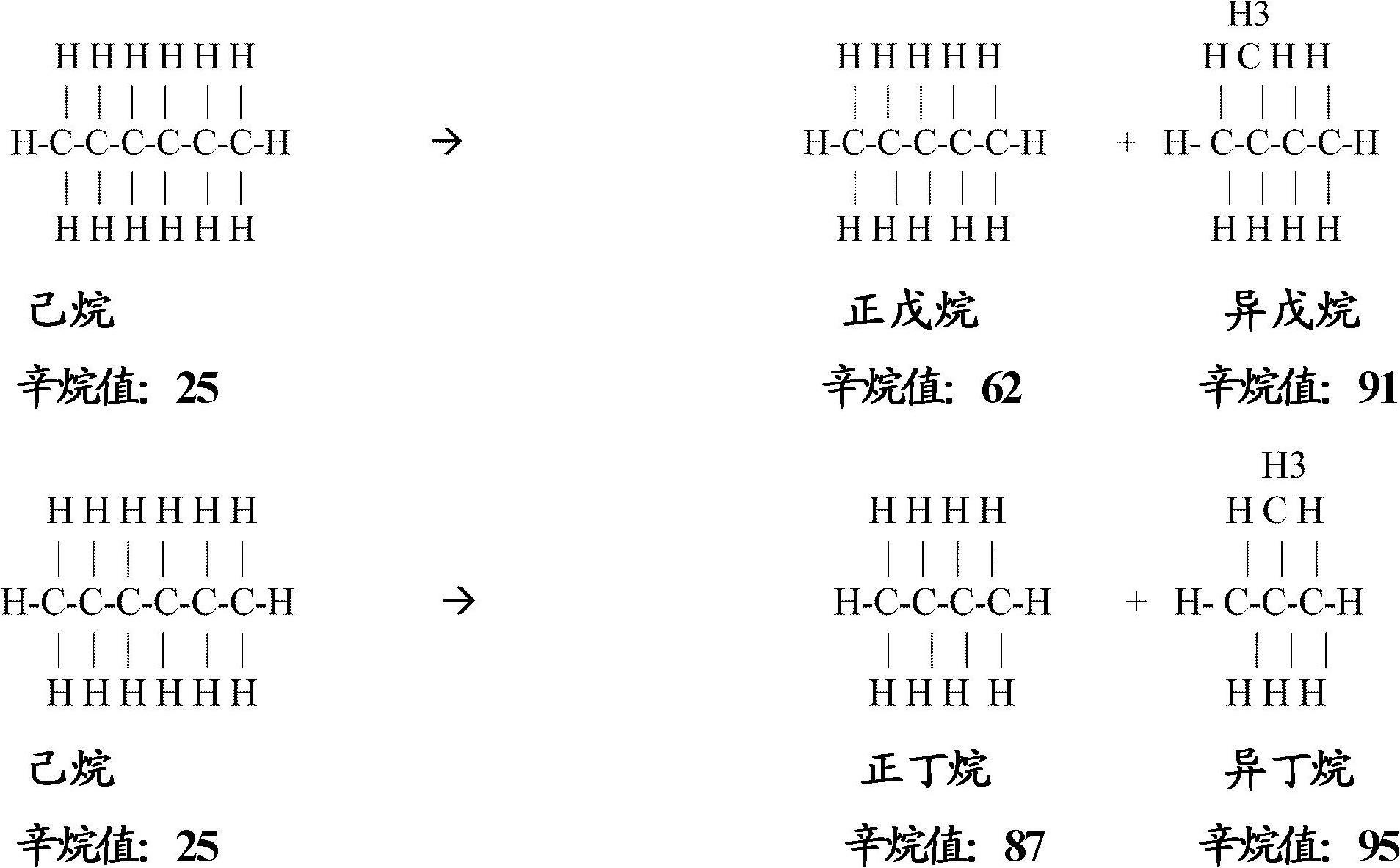

Increasing octane number of light naphtha using a germanium-zeolite catalyst

InactiveCN102639472ABoost octaneHigh degree of branchingMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneAlkaline earth metal

Owner:SAUDI BASIC IND CORP SA

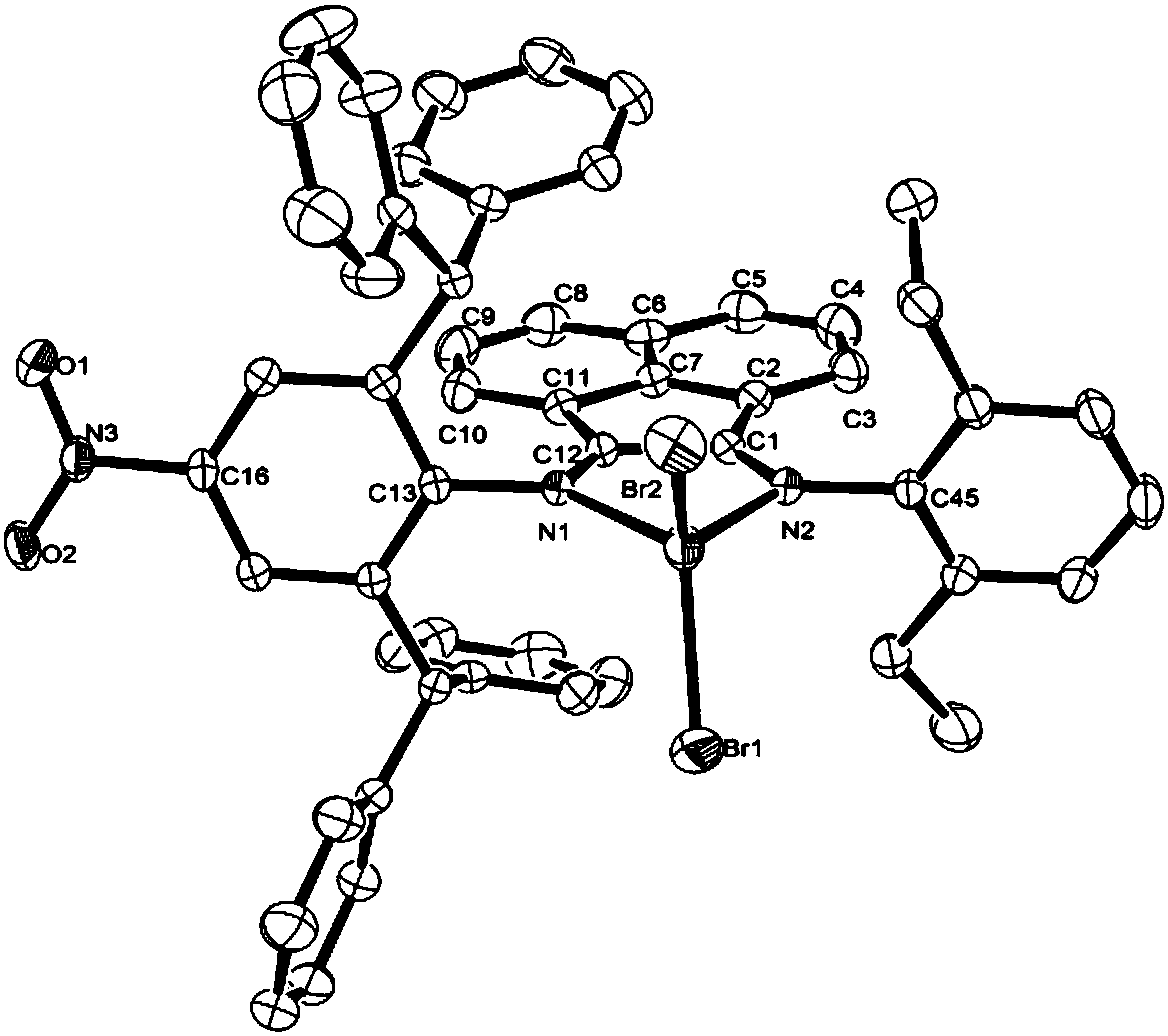

Nitryl asymmetric alpha-diimine nickel complex for preparation of ultrahigh-molecular-weight polyethylene and preparation method and application of nitryl asymmetric alpha-diimine nickel complex

ActiveCN108794544AHigh catalytic activityLow costNickel organic compoundsBulk chemical productionChemistryCoordination complex

The invention provides a nitryl asymmetric alpha-diimine nickel complex for preparation of ultrahigh-molecular-weight polyethylene and an intermediate, a preparation method and application of the nitryl asymmetric alpha-diimine nickel complex. The nickel complex has a single catalytic active center, regulation of polymer molecular weight and branching degrees can be realized through changing of aligand structure and polymerization conditions, and high catalytic activity, low cost, performance stability and the like are achieved. The preparation method is mild in condition, short in period andsimple in operation condition. The nickel complex can be applied to catalytic vinyl polymerization, the catalytic activity is up to 4.61*10<6>g mol<-1>(Ni) h<-1>, the weight-average molecular weightMw of prepared polyethylene fluctuates in a range of 8.2-32.8*10<5>g mol<-1>, molecular weight distribution is in a range of 1.8-2.8, the remarkable performance of polyethylene molecular weight control is achieved, and the nickel complex can be used for preparation of ultrahigh-molecular-weight polyethylene; obtained polyethylene is high in branching degree, the melt temperature Tm is in a range of 76.9-117.2 DEG C, and accordingly the polyethylene can be used as engineering plastic at a high environment temperature, and a promising industrial application potential is achieved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

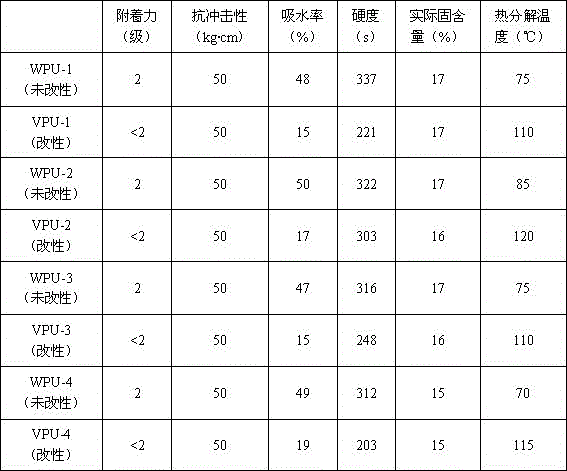

Method for preparing acrylate-modified waterborne polyurethane from soybean oil polyalcohol

The invention relates to a method for preparing acrylate-modified waterborne polyurethane from soybean oil polyalcohol. The method for preparing acrylate-modified waterborne polyurethane from soybean oil polyalcohol specifically comprises the steps that two kinds of soybean oil polyalcohol are mixed according to different proportions, and then the mixture and isocyanate are subjected to gradual addition polymerization to obtain waterborne polyurethane; waterborne polyurethane and an acrylate monomer are subjected to graft copolymerization to obtain acrylate-modified waterborne polyurethane. According to the method, acrylate-modified waterborne polyurethane is synthesized by taking renewable vegetable oil as a raw material, and acrylate-modified waterborne polyurethane is green, environmentally friendly and biodegradable. The prepared material is high in heat resistance, low in brittleness, high in transparency and scraping resistance, full in brightness and high in impact resistance and adhesion.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

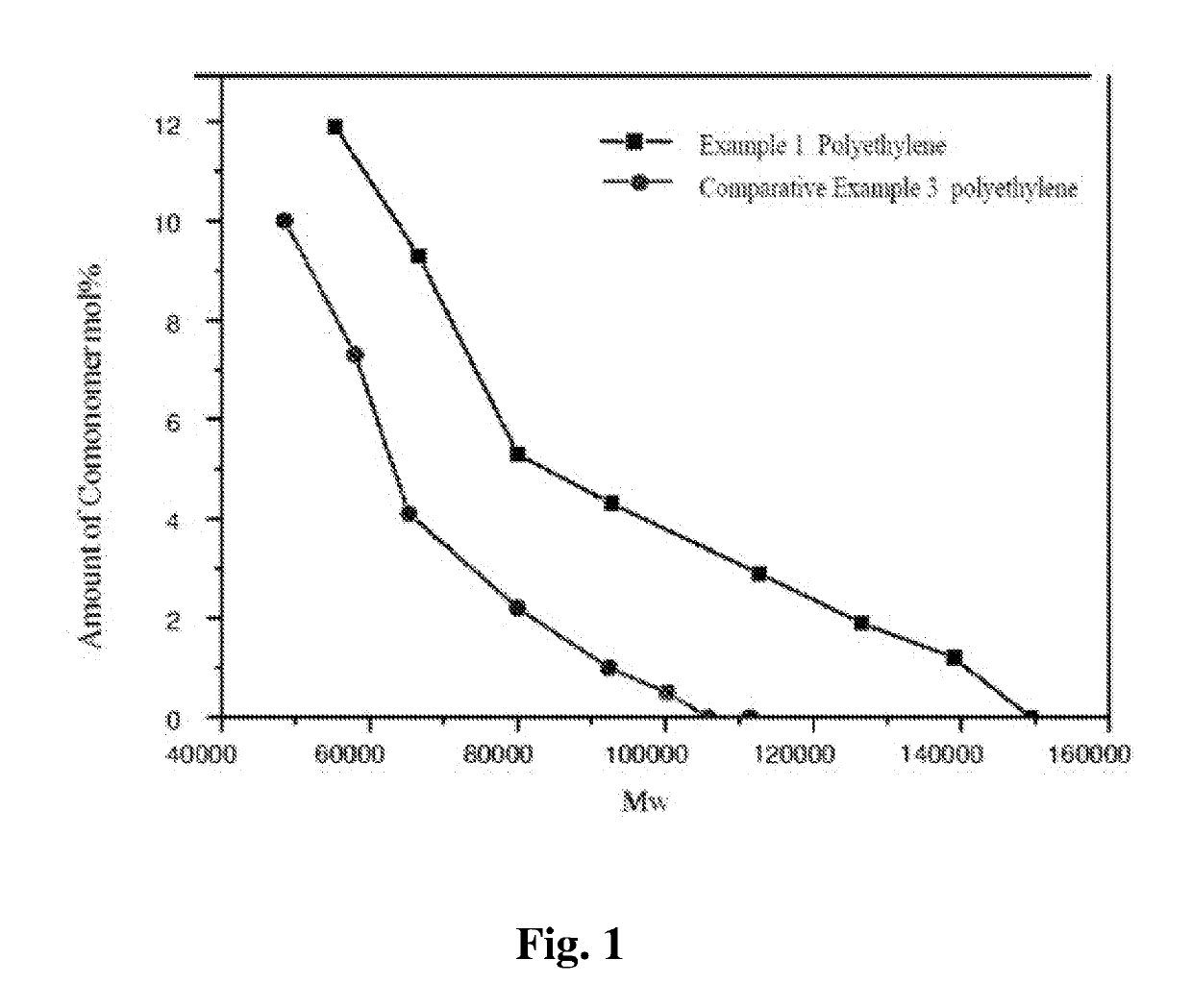

Polyethylene material and application thereof

ActiveUS20190127501A1Improve mechanical propertiesEasy to processPolymer scienceDensity distribution

Provided is a polyethylene material and application thereof. A density distribution of the polyethylene material is in a range of 0.880 g / cm3-0.960 g / cm3. An amount of a fraction at a temperature of 40° C. obtained by conducting temperature rising elution fractionation on the polyethylene material is in a range of 9.0 wt %-40.0 wt %, preferably in a range of 10.0 wt %-25.0 wt %, more preferably in a range of 9.9 wt %-20.0 wt %. A melting temperature of the polyethylene material is 110° C.-135° C., preferably 116° C.-130° C. The polyethylene material provided by the present application has distinctly improved amount of medium / low-molecular-weight fractions and high-degree-branching fractions, as well as relatively high-molecular-weight fractions which are highly branched. The polyethylene material thus has a relative high melting temperature.

Owner:CHINA PETROCHEMICAL CORP +1

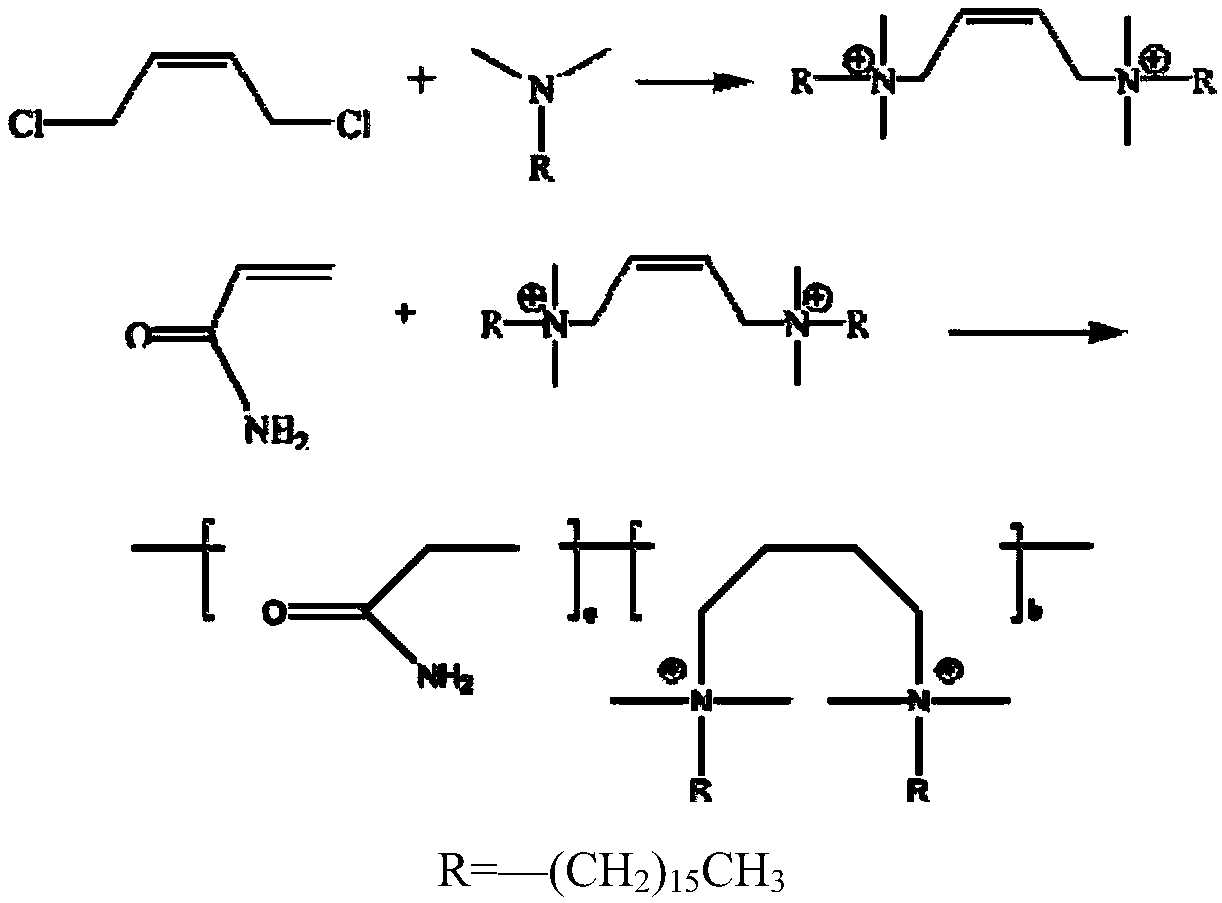

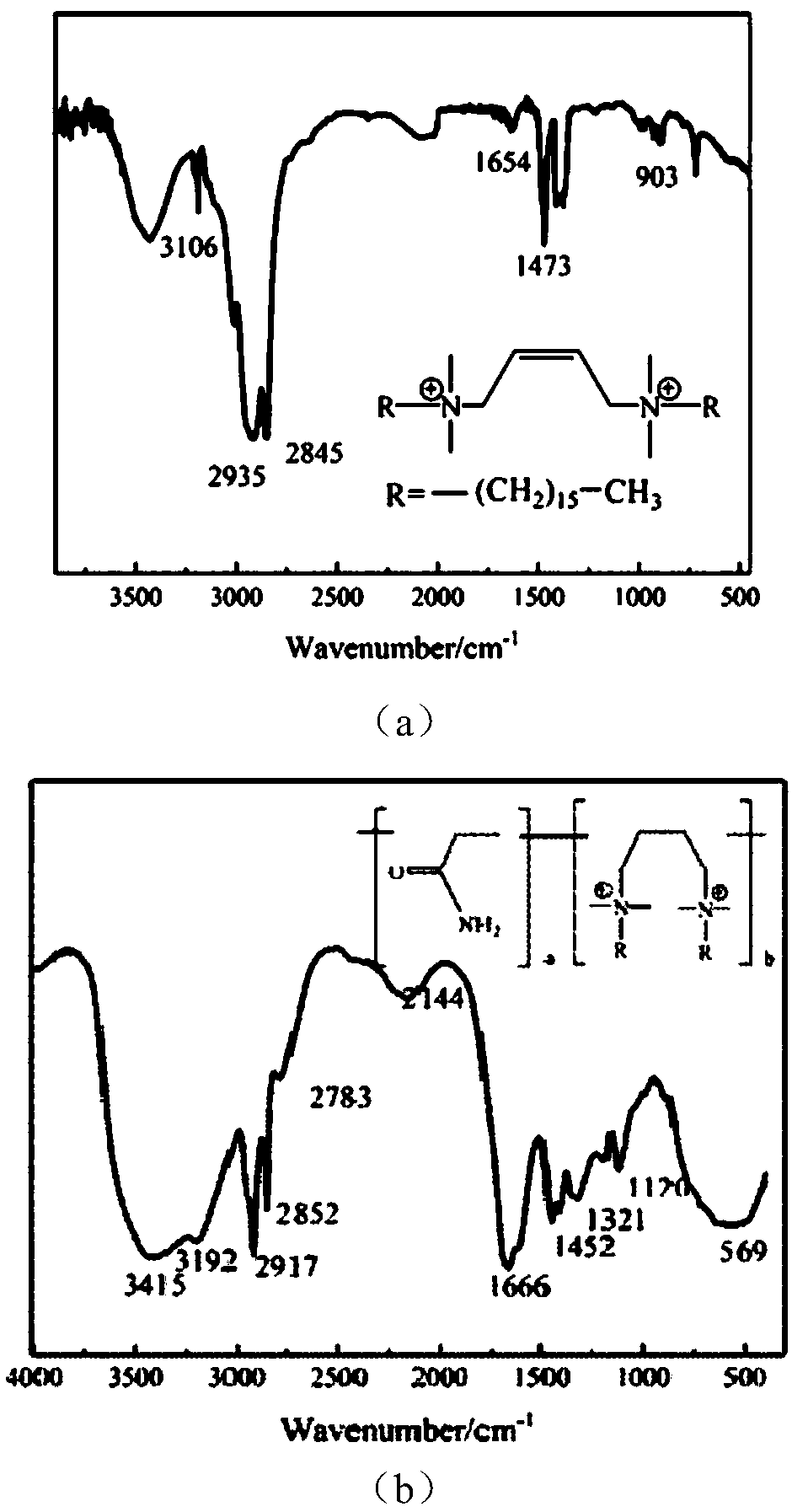

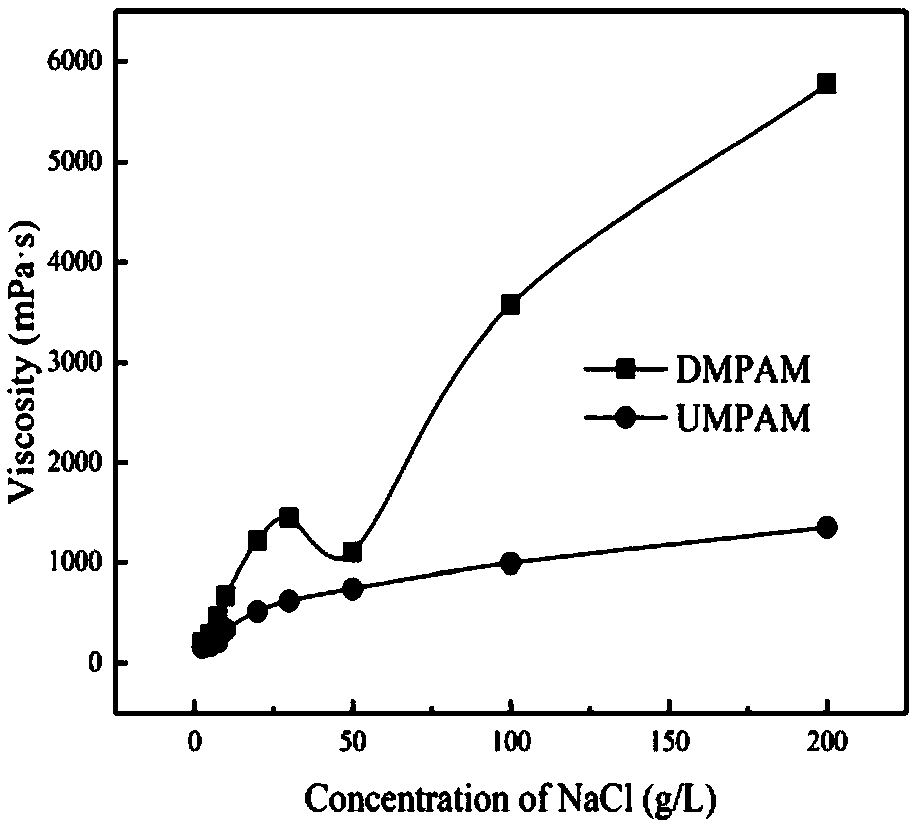

Amphiphilic polymer oil-displacing agent with biquaternary ammonium salt long chain structure and preparation method of amphiphilic polymer oil-displacing agent

ActiveCN109628081AEasy to form associationsHigh degree of branchingDrilling compositionIonSalt resistance

The invention belongs to the field of tertiary oil recovery, and particularly relates to an amphiphilic polymer oil-displacing agent with a biquaternary ammonium salt long chain structure and a preparation method of the amphiphilic polymer oil-displacing agent. For the technical problem that the salt resistance of an oil-displacing agent adopted in the prior art is frequently poor, the oil-displacing agent with good salt resistance, viscosifying action and shear resistance is provided. Firstly, N,N-dimethylhexadecylamine and cis-1,4-dichloro-2-butene are taken as raw materials to synthesize adouble-branched cationic hydrophobic monomer N,N'-bis(hexadecyl dimethyl)-1,2-chloride-2-butene-ammonium salt (CC16-DMBAC), then the CC16-DMBAC and acrylic amide (AM) perform copolymerization, a cationic group and a hydrophobic long chain are introduced onto an acrylic amide main chain, so that polymer molecules form a three-dimensional network structure with a certain strength by virtue of a hydrophobic interaction function among the molecules, and the oil-displacing agent has viscosifying action and good shear resistance and salt resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

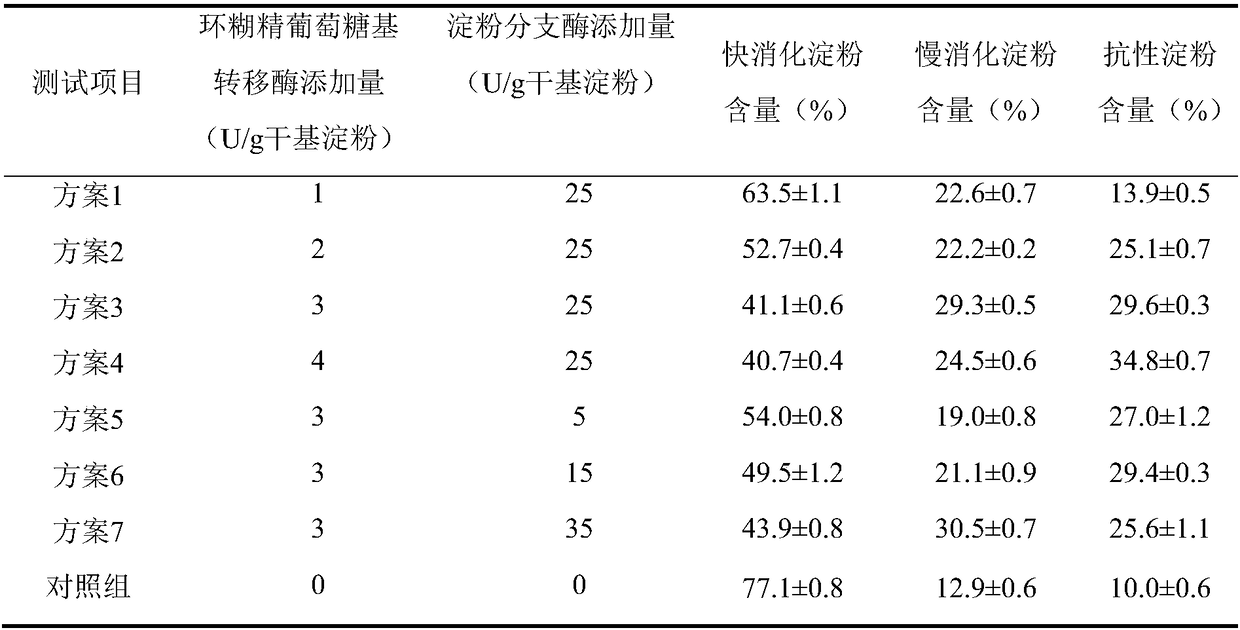

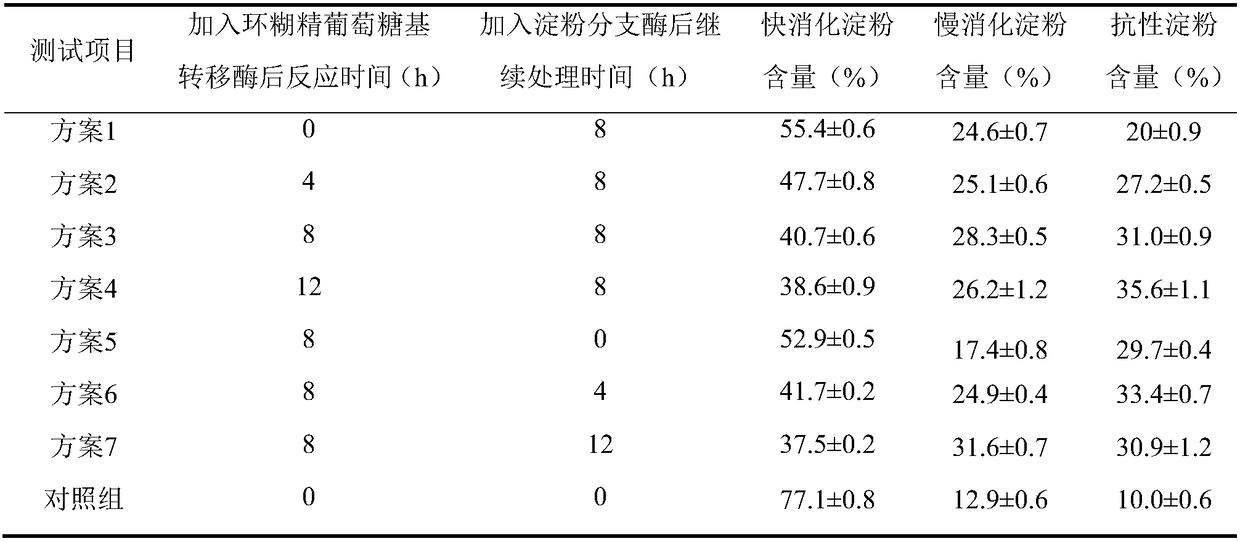

Method for preparing slowly digestible starch by utilizing double enzymes

ActiveCN108251475ADelayed digestionTightly branched structureOrganic active ingredientsMetabolism disorderDigestible starchCyclodextrin

The invention discloses a method for preparing slowly digestible starch by utilizing double enzymes and belongs to the field of biologically modified starch. According to the method disclosed by the invention, the starch is cooperatively treated by utilizing cyclodextrin glycosyltransferase and a starch branching enzyme; the cyclodextrin glycosyltransferase is catalyzed to generate cyclodextrin and a lot of short-chain segments are generated; a fine and long type starch molecule is converted into a short and fat structure which is a tighter branch structure under the action of the starch branching enzyme, so that the slow digestion of the starch is more remarkable. By changing an adding manner of the two enzymes, an enzyme adding amount and reaction time, a cooperative effect between the two enzymes is promoted, the content of the cyclodextrin and the branching degree of amylopectin are improved; the content of the slowly digestible starch and resisting starch is further increased andthe digestion speed of the starch is reduced; a novel concept is provided for preparing the slowly digestible starch through biological modification.

Owner:JIANGNAN UNIV

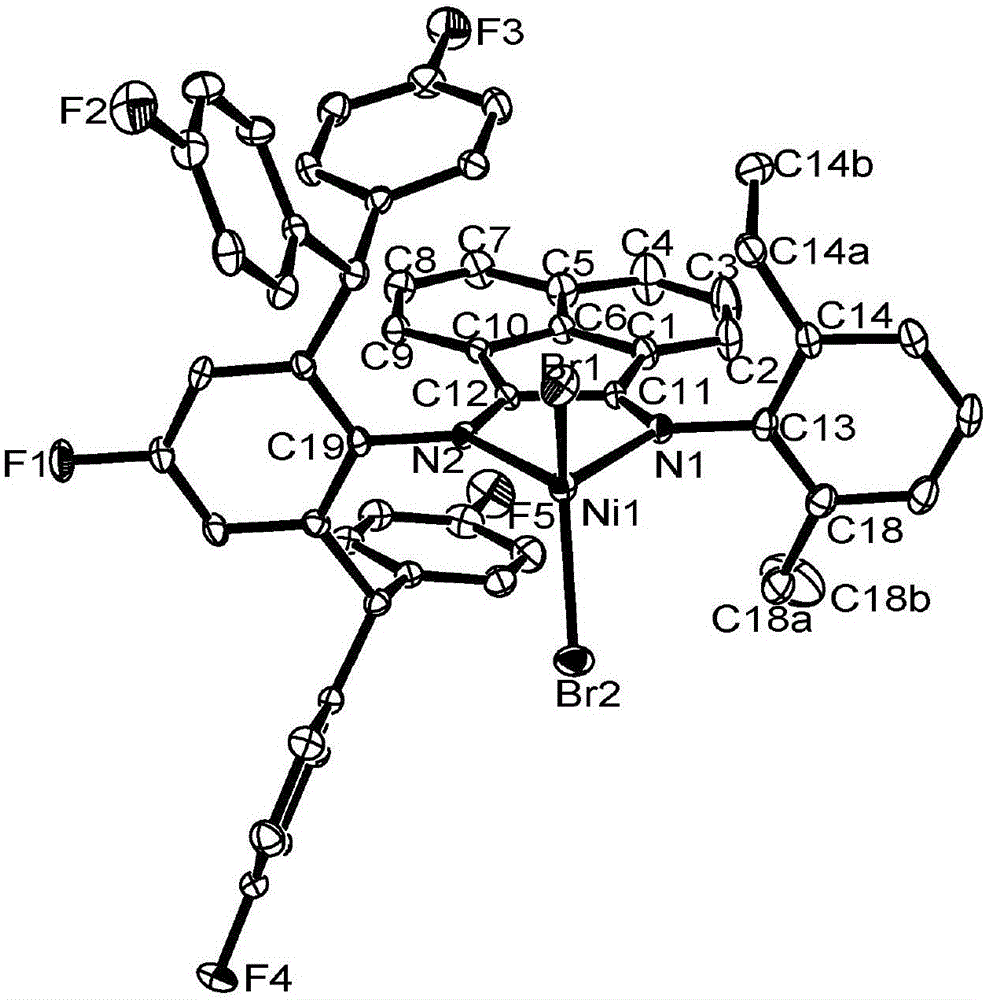

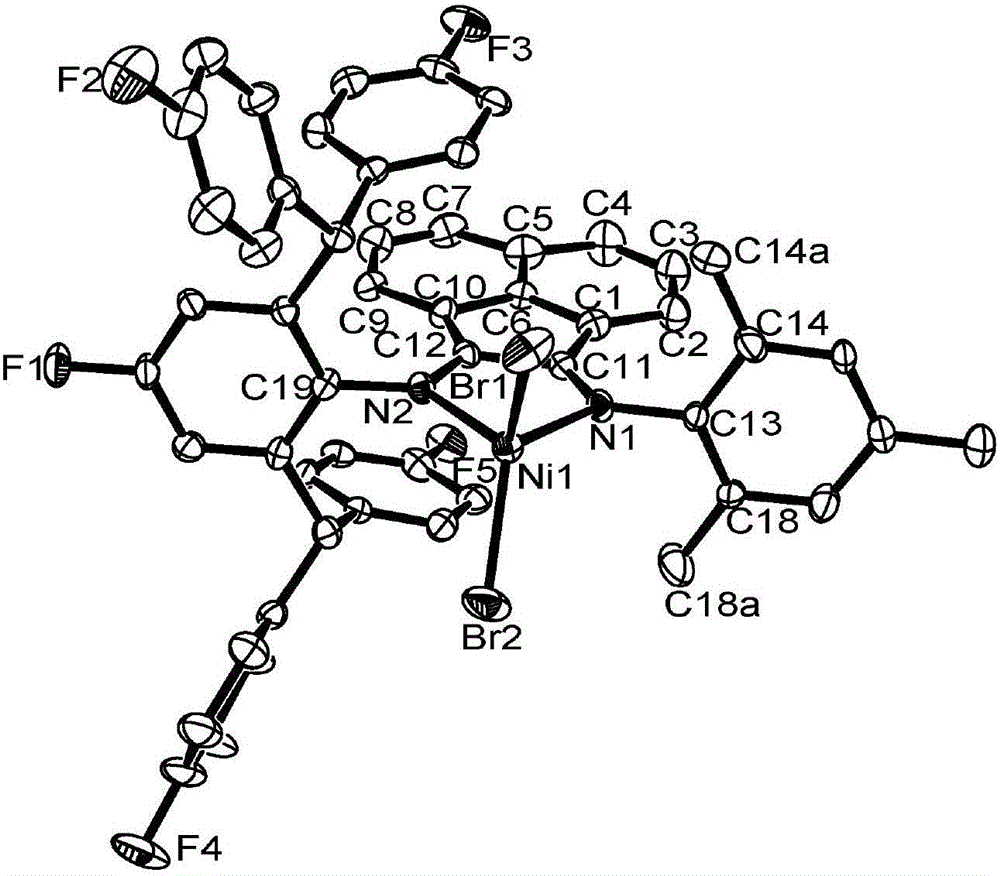

4,4'-difluorobenzhydryl containing asymmetric alpha-diimine nickel complex, and intermediate, preparation method and application thereof

InactiveCN106632506AHigh catalytic activityLow costOrganic-compounds/hydrides/coordination-complexes catalystsNickel organic compoundsDiimineOxygen

The invention provides a 4,4'-difluorobenzhydryl containing asymmetric alpha-diimine nickel complex, and an intermediate, a preparation method and an application thereof. The nickel complex prepared by using the method provided by the invention has a single catalytic active center, can realize control of polymer molecular weight and branching degree by changing a ligand structure and polymerization conditions, and has the advantages of high catalytic activity, low cost, stable performance, etc. The preparation method has the advantages of mild conditions, short cycle and simple operation conditions. The nickel complex prepared by using the method provided by the invention can be used in a catalyst used for ethylene polymerization, and has the activity of catalyzing ethylene polymerization up to 2.20 * 10<7> g.mol<-1>(Ni).h<-1> under the condition of no oxygen; and the prepared polyethylene has a weight-average molecular weight Mw fluctuating in a range of (1.35-10.50) * 10<5> g.mol<-1> and molecular weight distribution in a range of 1.9 to 2.5. The nickel complex provided by the invention has good industrial application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

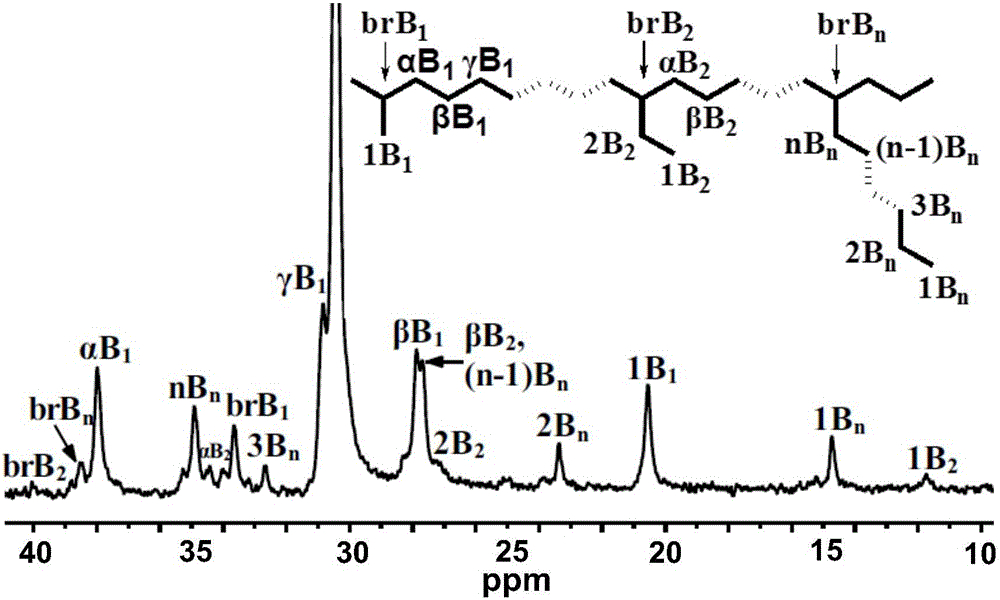

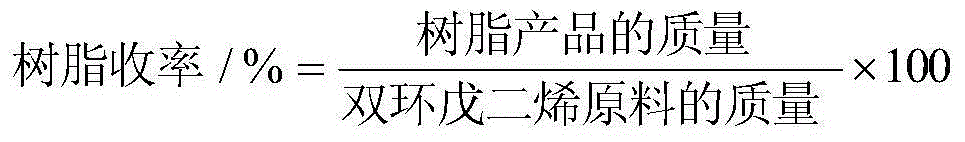

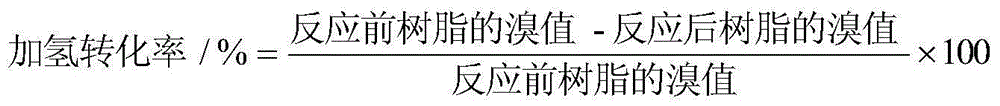

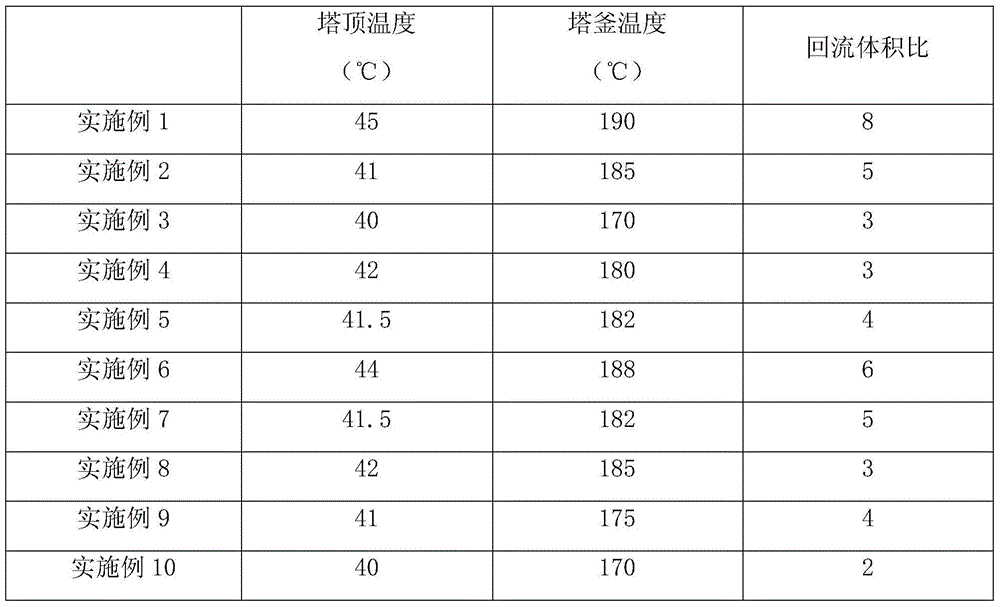

A preparing method of dicyclopentadiene hydrogenated petroleum resin

A preparing method of dicyclopentadiene hydrogenated petroleum resin is disclosed. The method mainly includes depolymerizing crude dicyclopentadiene into cyclopentadiene, mixing the cyclopentadiene and a solvent, feeding one part of the mixture into a reactor, reacting the one part of the mixture, adding the other part of the mixture in a batch manner after the reaction is started, and finally hydrogenating the reaction solution to prepare the hydrogenated petroleum resin. The method increases the product yield, ensures that the prepared resin is free of gel, sulfur and other impurities and can be directly used for hydrogenation without treatment, and prepares a hydrogenated petroleum resin product with excellent performance and stable quality under the premise of ensuring the service lifetime of a catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

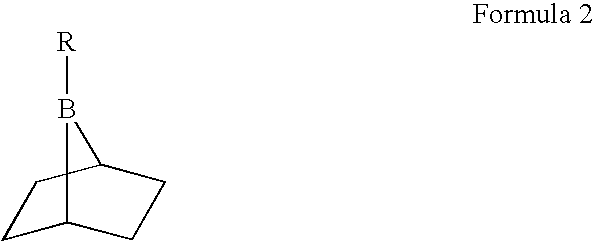

Method for preparing high 1,4-cis polybutadiene having controlled cold flow

The present invention relates to a method for preparing a high 1,4-cis polybutadiene having a controlled cold flow and, more particularly, to a novel method for preparing a high 1,4-cis polybutadiene having a controlled cold flow that involves initiating polymerization of a 1,3-butadiene in the presence of a non-polar solvent using, as a polymerization catalyst, a complex prepared by mixing a neodymium compound with or without a conjugated diene compound, a halogenated organoaluminum compound or a halogenated organic compound, and an organoaluminum compound irrespective of the addition order of the catalyst; and adding an organoborane compound as a cold flow controller of 1,4-cis polybutadiene after a predetermined time of the polymerization. Accordingly, a high 1,4-cis polybutadiene having an efficiently controlled cold flow can be prepared without causing a significant increase in the Mooney viscosity (molecular weight), an odor (bad smell), and a reduction in 1,4-cis content and polymerization yield.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

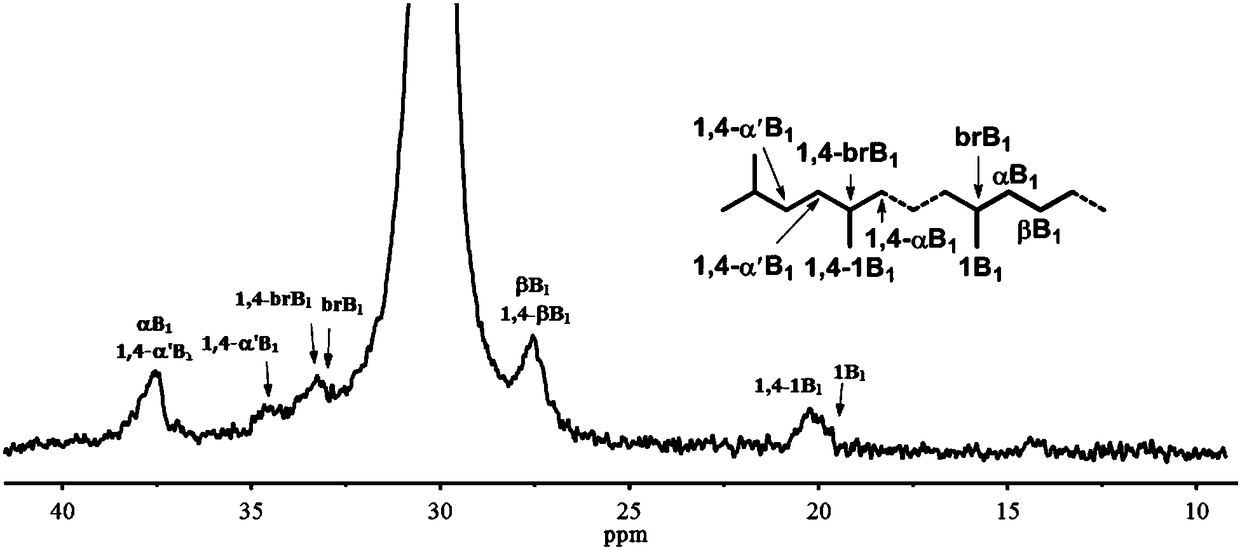

Conjugated diene polymer manufacturing method, polybutadiene, and rubber composition utilizing the same

InactiveUS8283401B2Maintain good propertiesImprove workabilitySpecial tyresPolymer scienceMooney viscosity

Provided by using a catalyst containing an yttrium compound is conjugated diene polymer with very low solution viscosity, improved workability, high degree of branching, and high content of cis-1,4 structures. Also provided is a rubber composition utilizing the polymer and allowing excellent dispersion of reinforcing agent. According to a method of manufacturing a conjugated diene polymer characterized by polymerizing a conjugated diene at 50 to 120° C. in the presence of a catalyst obtained from (A) an yttrium compound, (B) an ionic compound consisting of a non-coordinating anion and a cation, and (C) an organoaluminum compound, the conjugated diene polymer has the following characteristics that: (1) a ratio (Tcp / ML1+4) between a 5 wt % toluene solution viscosity (Tcp) measured at 25° C. and a Mooney viscosity (ML1+4) at 100° C. is 0.1 to 1.2; and (2) a content of cis-1,4 structures is 80% or higher, and a content of 1,2 structures is lower than 5%.

Owner:UBE IND LTD

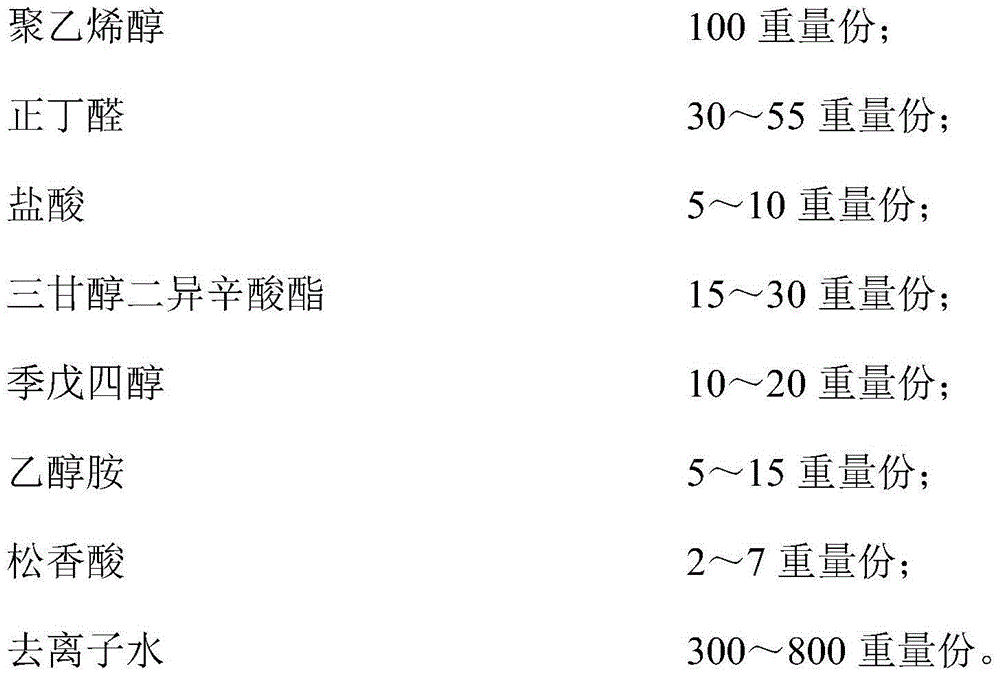

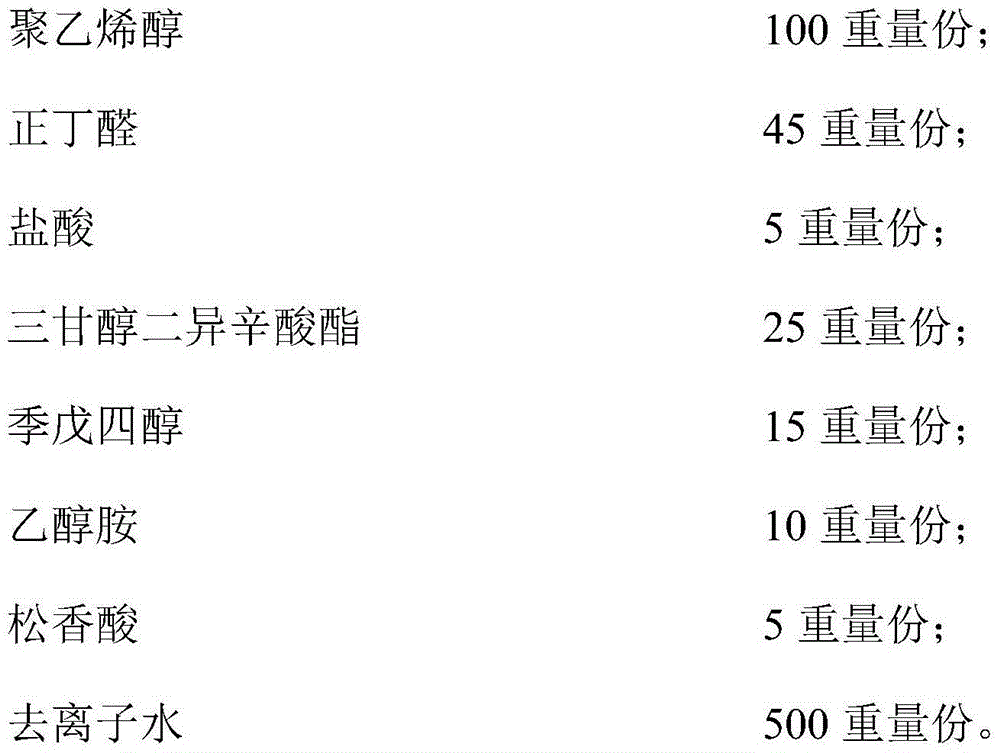

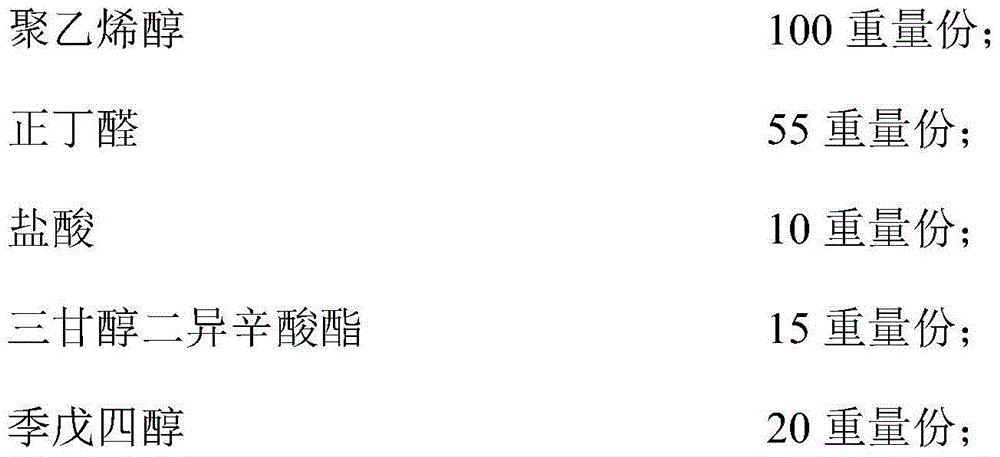

High-toughness polyvinyl butyral film and preparation method thereof

InactiveCN104910822AHigh viscosityGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolyvinyl butyralPentaerythritol

The invention discloses a high-toughness polyvinyl butyral film. The high-toughness polyvinyl butyral film is prepared from the following components in parts by weight: 100 parts of polyvinyl alcohol, 30-55 parts of butanal, 5-10 parts of hydrochloric acid, 15-30 parts of triethylene glycol di-2-ethylhexoate, 10-20 parts of pentaerythritol, 5-15 parts of ethanolamine, 2-7 parts of abietic acid and 300-800 parts of deionized water. The high-toughness polyvinyl butyral film has excellent adherence, has both softness and toughness, and also has excellent weather fastness. The invention also discloses a preparation method of the high-toughness polyvinyl butyral film.

Owner:ZHEJIANG VENECIA DECORATIVE MATERIAL

Yellowing-resistant elastic styrene-acrylic emulsion and preparation method thereof

The invention discloses a yellowing-resistant elastic styrene-acrylic emulsion and a preparation method thereof. The emulsion comprises the following components in parts by weight: 80-120 parts of deionized water, 15-25 parts of styrene, 55-65 parts of butyl acrylate, 3-10 parts of acrylonitrile, 25-35 parts of isooctyl acrylate, 0.1-1.5 parts of methacrylic acid, 0.1-1.5 parts of acrylamide, 0.5-3.5 of itaconic acid, 0.1-1.5 parts of an antioxidant, 2-10 parts of an emulsifier, 0.1-2 parts of an initiator, and 0.2-2.5 parts of sodium hydroxide. According to the method provided by the invention, the prepared elastic styrene-acrylic emulsion has excellent normal-temperature and low-temperature elasticity, and very good yellowing resistance; and the preparation process is simple, and the operability is high.

Owner:上海巴德富实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com