Preparation method of ultrahigh-molecule-weight polyethylene fibers

A technology of ultra-high molecular weight and polyethylene fibers, which can be used in spinning solution preparation, dry spinning, stretching spinning, etc., and can solve problems such as crystallization disorder, uneven structure, PE modulus and strength decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

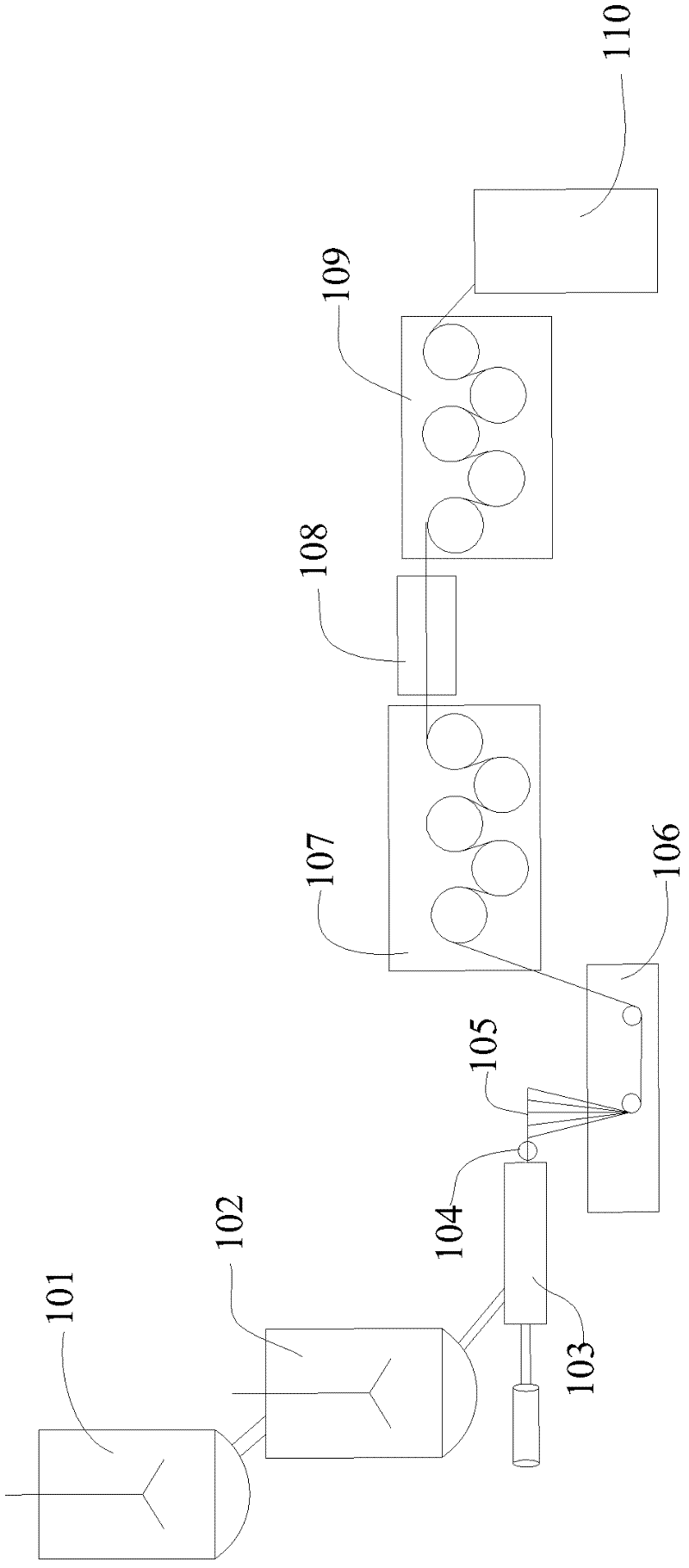

[0062] After preheating 230kg of No. 7 solvent oil to 112°C, put 40000kg of ultra-high molecular weight polyethylene and No. 7 solvent oil in the swelling kettle 101 and stir for initial swelling. The initial swelling time is 20 minutes. After the initial swelling, add 690 kg of No. 7 solvent oil at a temperature of 98°C to the swelling kettle for re-swelling to obtain a spinning solution. The re-swelling time is 30 minutes, and the stirring speed remains unchanged. The ambient temperature of the kettle dropped to 98°C.

[0063] After re-swelling, a uniform spinning solution is obtained, and the spinning solution is sent into the storage tank 102 to cool to 25° C. and then sent into the twin-screw extruder 103 for extrusion and dissolution. Wherein, the inlet temperature of the twin-screw extruder is 100° C., the intermediate temperature is 185° C., and the outlet temperature is 165° C., the residence time in the twin-screw extruder is 5 minutes, and the twin-screw rotation sp...

Embodiment 2

[0071]Preheat 270kg No. 7 solvent oil to 118°C, then put 40000kg ultra-high molecular weight polyethylene in the swelling kettle and stir for preliminary swelling. After the initial swelling, add 630kg of the second No. 7 solvent oil with a temperature of 95°C into the swelling kettle for re-swelling to obtain a spinning solution. The re-swelling time is 35 minutes, and the stirring speed remains unchanged. The ambient temperature in the kettle dropped to 95°C.

[0072] The spinning solution was sent into a storage tank and cooled to 25° C., and then sent into a twin-screw extruder for extrusion and dissolution to obtain a jelly spinning solution. The process was the same as in Example 1.

[0073] The jelly spinning solution was spun to obtain jelly yarn, and the spinning process was the same as in Example 1.

[0074] The jelly silk is left still and extracted, and the standing and extraction processes are the same as in Example 1.

[0075] After extraction, the jelly silk i...

Embodiment 3

[0080] In this example, the steps of preparing the spinning solution are the same as those in Example 1. The difference is that ultra-high molecular weight polyethylene is 5666.7kg.

[0081] The steps of sending the spinning solution into a twin-screw extruder for extrusion and dissolving to prepare the jelly spinning solution are the same as in Example 1.

[0082] The steps of spinning the jelly spinning solution to prepare jelly filaments are the same as in Example 1.

[0083] The standing and extraction steps of this embodiment are the same as in Example 1.

[0084] Drying procedure is identical with embodiment 1.

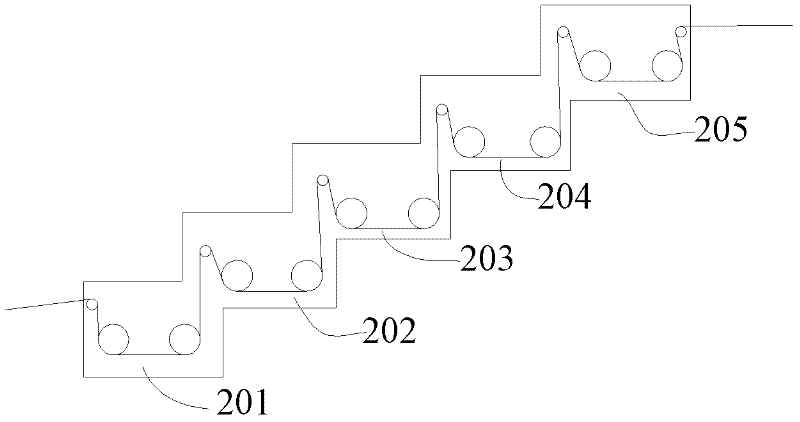

[0085] When the jelly yarn is superheated, the difference from Example 1 is that the second drafting machine applies a draft of 3.4 times to the as-spun fiber, and the third drafting machine applies a draft of 3.8 times to the fiber. , the fourth drafting machine is 4.7 times the draft applied to the fiber, and the others are the same as in Example 1.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com