Preparation method for butadiene rubber

A technology of butadiene rubber and butadiene, which is applied in the field of butadiene rubber and its preparation, can solve the problems of easy hanging on the wall and poor cold flow of raw rubber, and achieve the goal of reducing molecular weight, improving cold flow of raw rubber, and low molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

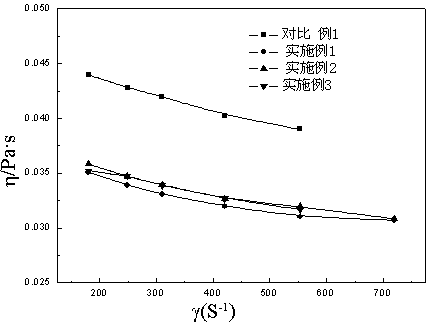

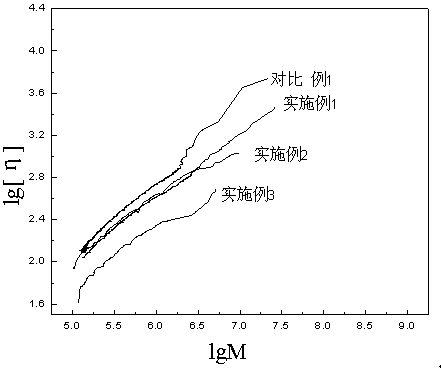

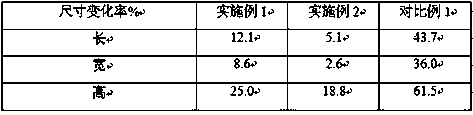

[0035] In a 5L polymerization kettle that has been vacuum pumped and replaced three times with high-purity nitrogen, 350g of butadiene, 6.8g of liquid polybutadiene (the mass content of 1,2-structure is 72%, and the number average molecular weight is 1.24 ×10 4 , molecular weight distribution 1.78) and 2250g hexane were mixed uniformly in the polymerization kettle, and then the catalyst aging solution 1) was added, Ni / Bd=1×10 -4 , at 50°C, the pressure is 0.25MPa, and the polymerization reaction is 5h; after the polymerization is completed, 100ml of 2,6-di-tert-butylhydroquinone ethanol solution with a mass concentration of 3% by weight is added to terminate the reaction, and the polymer gel is obtained. liquid. The polymer glue was precipitated, washed, and dried to obtain 343 g of branched nickel-based butadiene rubber. The properties of the obtained branched nickel-based butadiene rubber are listed in Table 1.

Embodiment 2

[0037] Adopt the same method as Example 1 to prepare branched nickel-based butadiene rubber, the difference is that, based on the amount of butadiene, the amount of liquid polybutadiene is 1% by weight, and the catalyst is a catalyst aging liquid 2), at 45°C, the pressure is 0.2MPa, and the polymerization reaction is 4h, the properties of the obtained branched nickel-based butadiene rubber are listed in Table 1.

Embodiment 3

[0039] Adopt the same method as Example 1 to prepare branched nickel-based butadiene rubber, the difference is that based on the amount of butadiene, the amount of liquid polybutadiene is 10% by weight, and the catalyst is catalyst aging Solution 3), at 30°C, pressure 0.4MPa, polymerization reaction 6h, the properties of the obtained branched nickel-based butadiene rubber are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com