Method for preparing hyperbranched waterborne polyester resin

A water-based polyester resin and formulation technology, used in polyester coatings, coatings, etc., can solve problems such as water-based polyester limitations, and achieve the effects of strong adhesion, improved brittleness, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] In the reaction kettle, add 3 parts of TMP and 18 parts of DMPA, pass through nitrogen protection, heat up to 130°C, add 0.2 parts of p-toluenesulfonic acid, keep warm for 4 hours, turn off the nitrogen, continue the reaction for 2 hours, then cool to 40°C Add 16 parts of isophthalic acid, 24 parts of maleic anhydride, 6 parts of adipic acid, 3 parts of trimethylolpropane, 20 parts of neopentyl glycol and 0.2 part of p-methoxyphenol, and add 5 parts of reflux di Toluene, and nitrogen protection; heat up to 140°C, wait for most of the solid matter to melt, start stirring, heat up to 160°C and keep the temperature constant for 0.5h, heat up to 180°C, react for 2h until the water output reaches 80% of the theoretical amount; then gradually Raise the temperature to 230-240°C, keep it warm for 2 hours, start sampling to measure the acid value, when the acid value is 40±0.5mgKOH / g, quickly cool down to below 100°C, add 20 parts of ethylene glycol butyl ether, at this time the ...

Embodiment 2

[0013] In the reaction kettle, add 2 parts of TMP and 16 parts of DMPA, pass through nitrogen protection, heat up to 130°C, add 0.2 parts of p-toluenesulfonic acid, keep warm for 4 hours, then turn off the nitrogen, continue the reaction for 2 hours, then cool to 40°C ; Then add 15 parts of isophthalic acid, 25 parts of phthalic anhydride, 7 parts of adipic acid, 5 parts of trimethylolpropane, 20 parts of neopentyl glycol and 0.2 part of p-methoxyphenol, and add 5 parts of reflux xylene at the same time , and nitrogen protection; heat up to 140°C, wait for most of the solid matter to melt, start stirring, heat up to 160°C and keep the temperature for 0.5h, heat up to 180°C, react for 2h until the water output reaches 80% of the theoretical amount; then gradually heat up To 230 ~ 240 ℃, keep warm for 2 hours, start to take samples to measure the acid value, when the acid value is 40±0.5mgKOH / g, quickly cool down to below 100 ℃, add 20 parts of ethylene glycol butyl ether, at thi...

Embodiment 3

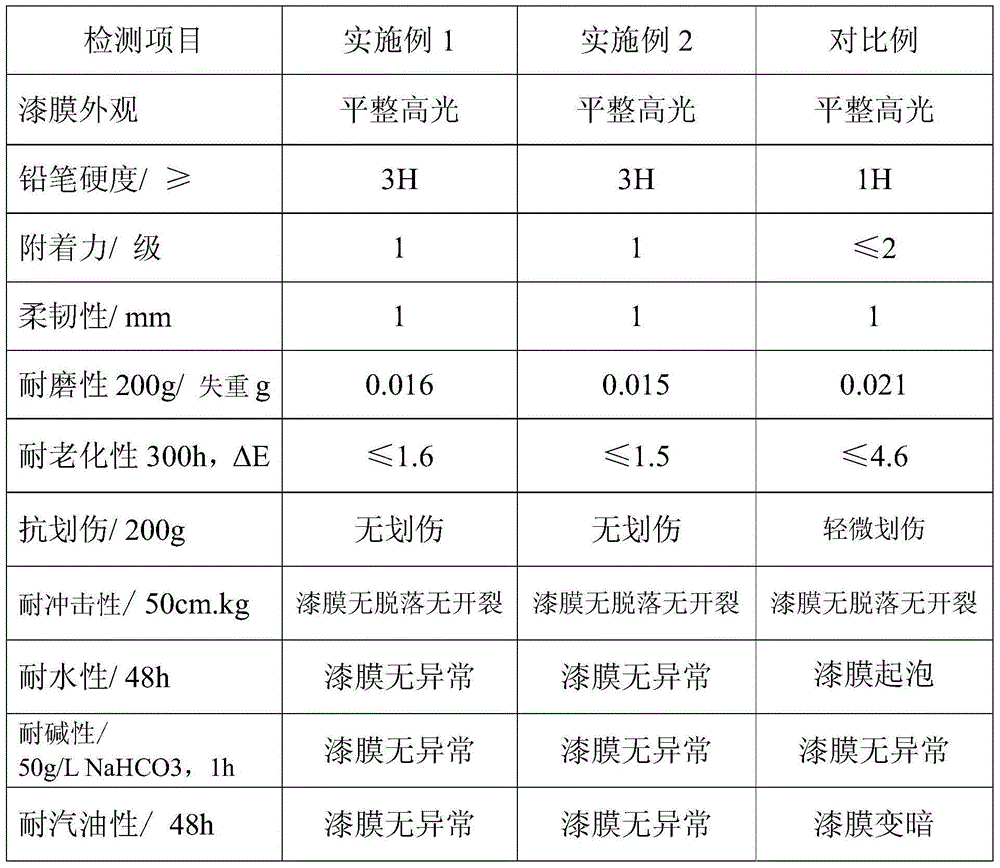

[0015] The hyperbranched water-based polyester resin prepared in the embodiment of the present invention is formulated into a water-based polyester-amino drying varnish, and the formula is as follows: 65-80 parts of hyper-branched water-based polyester resin, 12-15 parts of hexamethyl etherified melamine resin , 0.2 parts of substrate wetting agent, 0.3 parts of defoaming agent, 1 part of film-forming aid, 0.2 parts of leveling agent, and deionized water to 100; according to relevant national standards and solvent-based polyester-amino drying varnishes on the market A comparison test of coating film performance was carried out (drying conditions: 160-180°C, 12 minutes), and the test results are shown in Table 1.

[0016] Table 1: Coating film performance test results

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com