Increasing octane number of light naphtha using a germanium-zeolite catalyst

A catalyst, octane number technology, applied in reformed naphtha, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of catalyst not being tolerant to sulfur and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

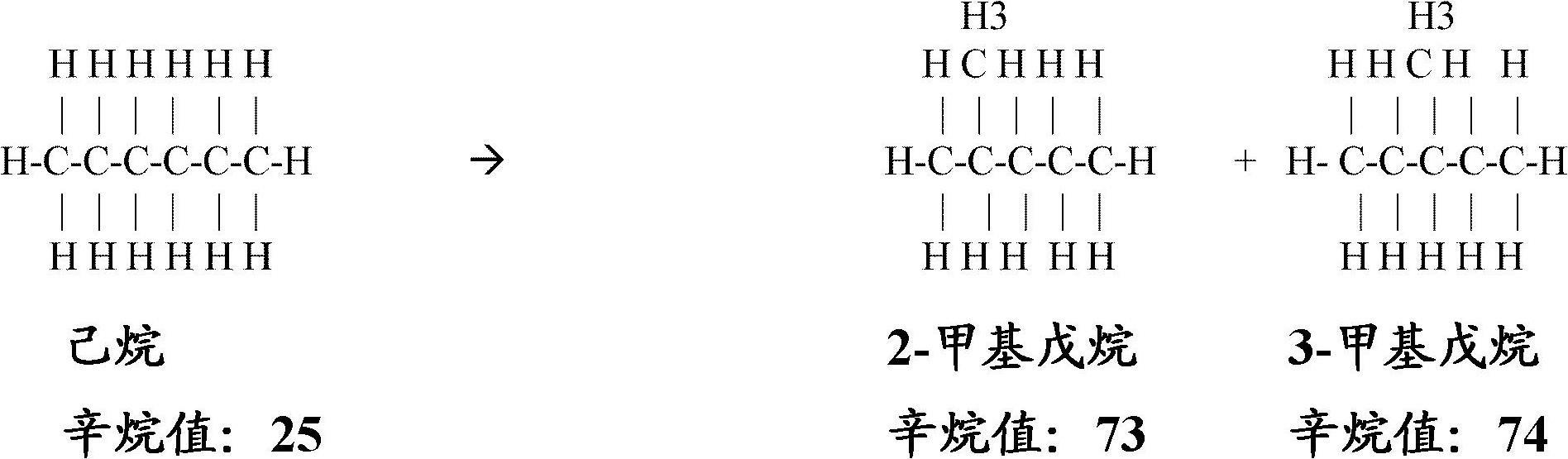

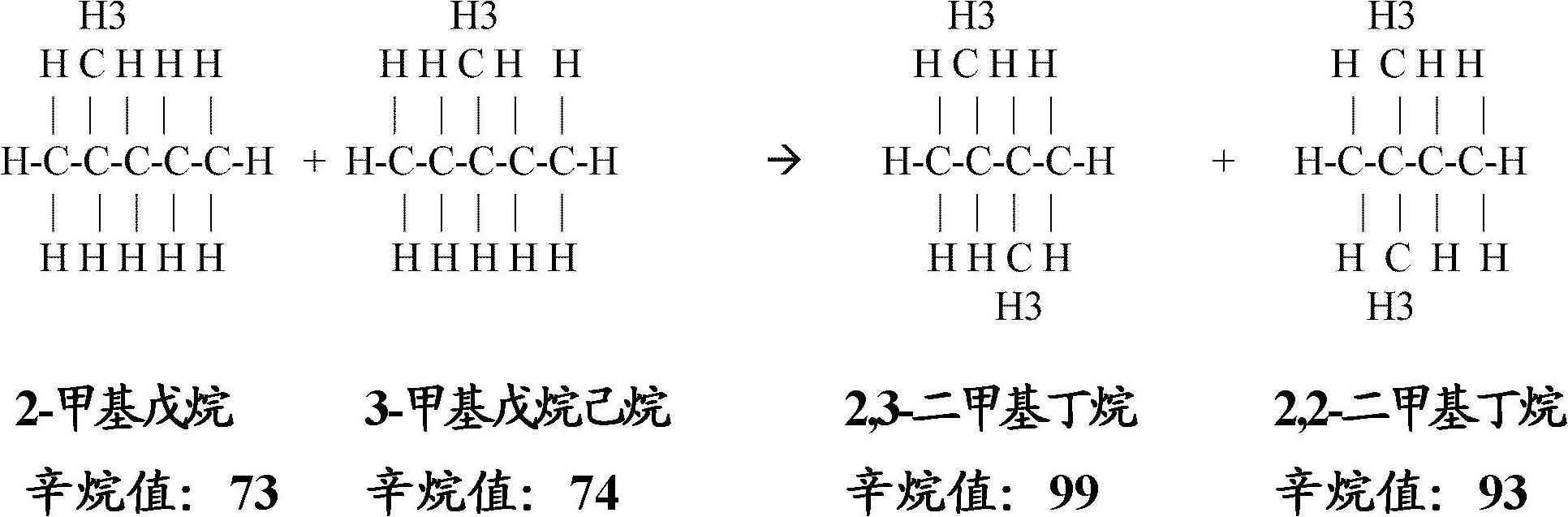

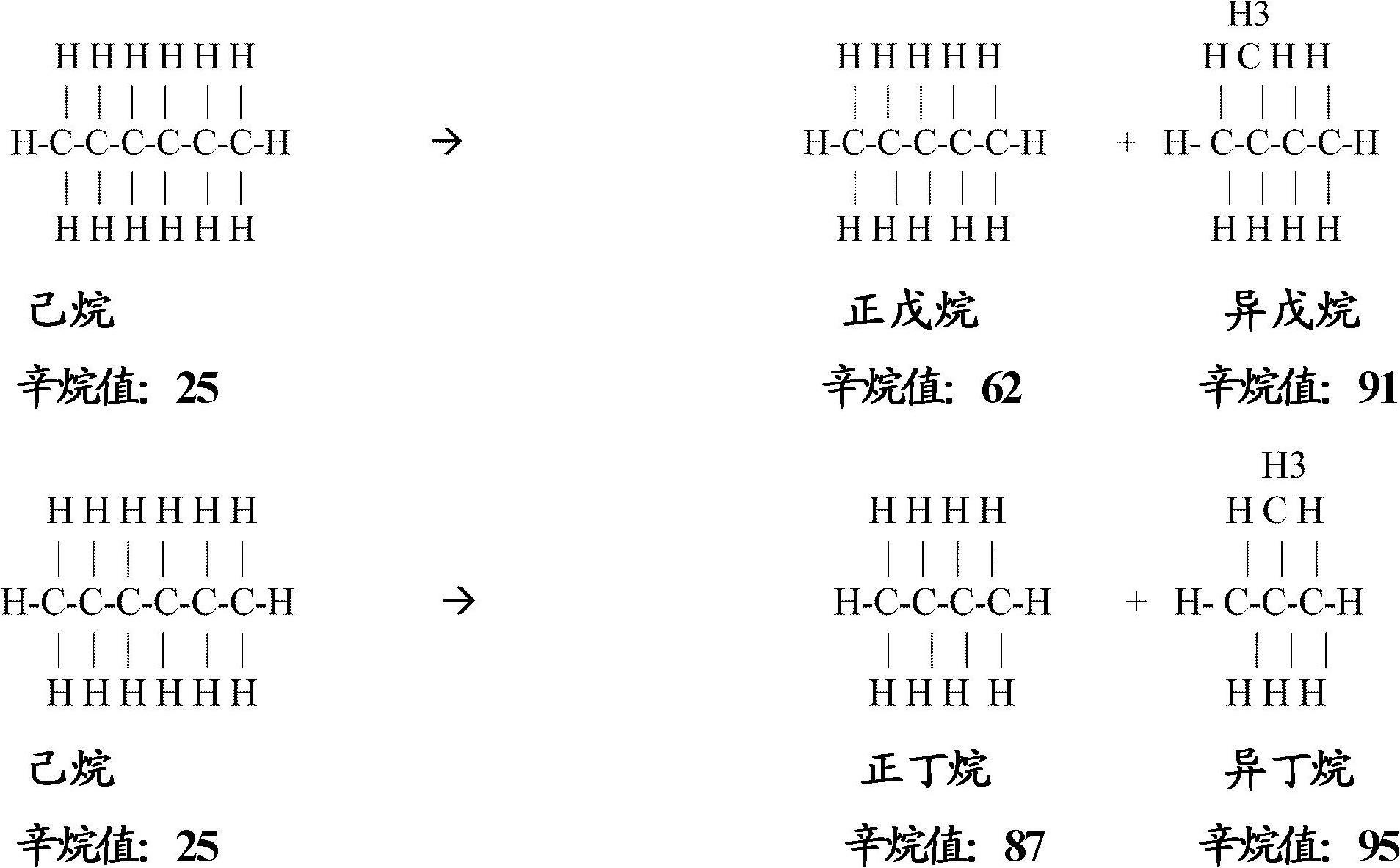

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Zeolite is a crystalline hydrated aluminosilicate whose crystal framework can also contain other elements besides aluminum and silicon. The term "zeolite" includes not only aluminosilicates, but also substances in which aluminum is substituted by other trivalent elements, and substances in which silicon is substituted by other tetravalent elements. Generally speaking, zeolite is TO 4 Tetrahedral structure, they form a three-dimensional network by sharing oxygen atoms, where T represents a tetravalent element (such as silicon) and a trivalent element (such as aluminum). Zeolites are known catalysts for isomerization, toluene disproportionation, transalkylation, hydrogenation, and alkane oligomerization and aromatization. Some zeolite catalysts, especially those containing Group VIII deposited metals, are prone to sulfur poisoning.

[0014] The germanium zeolite (Ge-zeolite) catalyst on which noble metals are deposited is alkali-exchanged using alkali metals or alkaline ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com