Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Has a broad-spectrum antibacterial effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fence preservation method for prolonging shelf life of cold fresh poultry

InactiveCN101990930AAntibacterialImprove freshnessMeat/fish preservation using chemicalsBiotechnologyCold chain

The invention discloses a fence preservation method for prolonging shelf life of cold fresh poultry. The fence preservation method for prolonging the shelf life of the cold fresh poultry comprises the following steps of: placing fresh poultry which is obtained by slaughtering, washed completely and cut into a refrigeration storage at the temperature of between 2 and 5 DEG C and precooling the poultry for 1 to 2 hours, so that the surface temperature of the poultry is reduced below 5 DEG C and the internal temperature of the poultry is reduced below 10 DEG C; transferring the precooled poultry to a purification room and performing surface sterilization on the poultry through ozone or ozone solution of an ozone generator; immersing the poultry subjected to ozone sterilization into chitosan glutamate solution to retain freshness; taking out and draining the poultry; placing the poultry after corrosion prevention and freshness preservation into a food plastic packaging box; introducing carbon dioxide (CO2) and nitrogen (N2) into the food plastic packaging box and performing sealing package; and storing the packaged poultry into a cold chain at the temperature of between 2 and 5 DEG C. The fence preservation method for prolonging the shelf life of the cold fresh poultry has good effect and is suitable for retaining freshness of the fresh cut poultry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

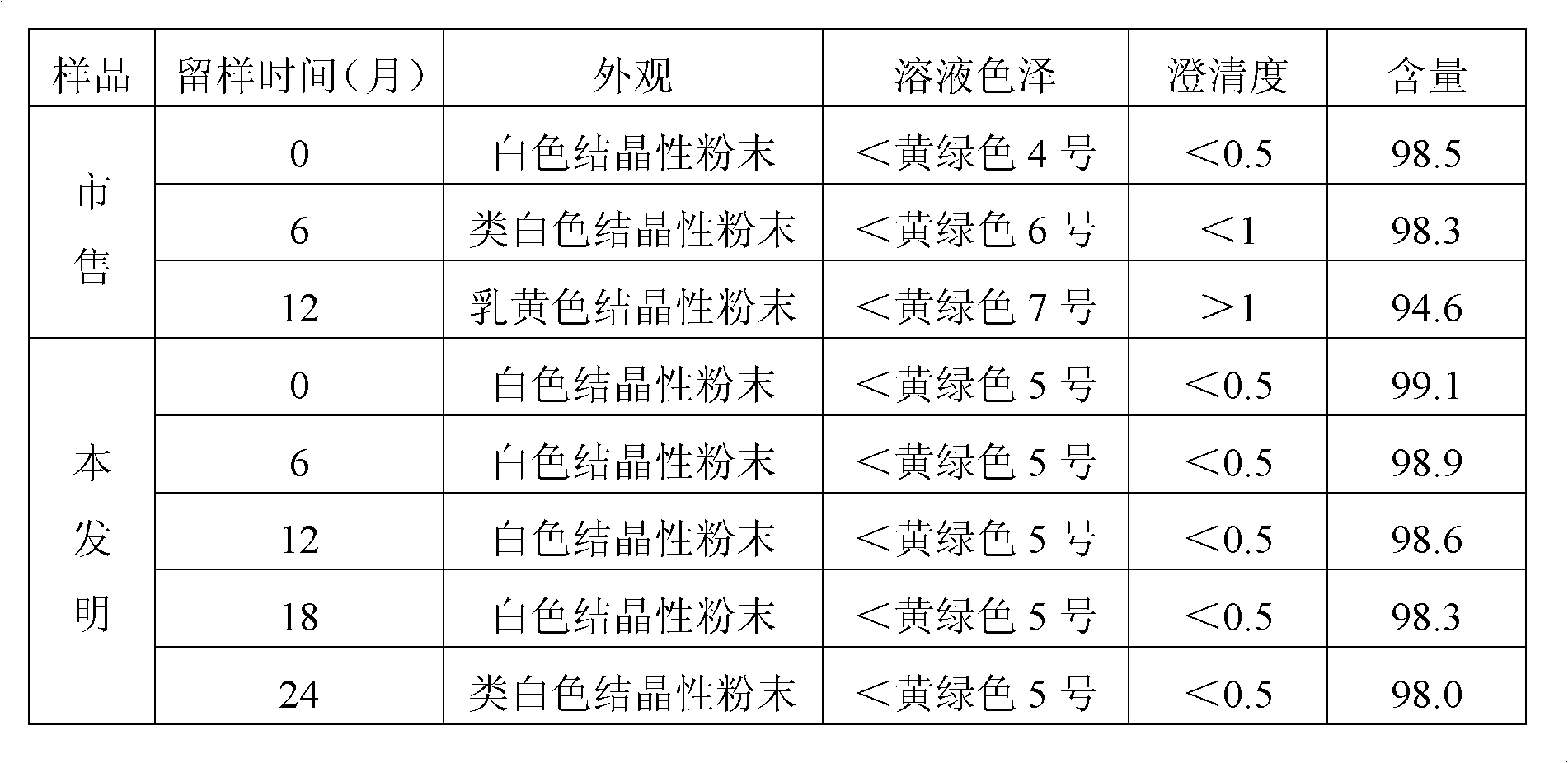

Ceftizoxime sodium composition sterile powder for injection

ActiveCN101843589AThe production process is simple and easy to controlFacilitates filtration and dryingAntibacterial agentsOrganic active ingredientsSolventChemistry

The invention relates to ceftizoxime sodium composition sterile powder for injection. The powder contains 99.0 to 99.9 weight percent of ceftizoxime sodium and 0.10 to 1.00 weight percent of sodium benzoate, wherein the ceftizoxime sodium is in a crystallized form. As for the ceftizoxime sodium in the crystallized form, the temperature of solution of ceftizoxime sodium is controlled by adjusting the pH value of the solution and the saturation process of the solution is controlled by a method of adding appropriate amounts of different solvents into the solution in multiple times so as to obtain a ceftizoxime sodium crystal form with uniform grain size distribution. A method for preparing the powder has simple, convenient and easily-controlled production process and low preparation cost and the obtained ceftizoxime sodium in the crystallized form has uniform grain size distribution and is more stable than the ceftizoxime sodium in the market.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

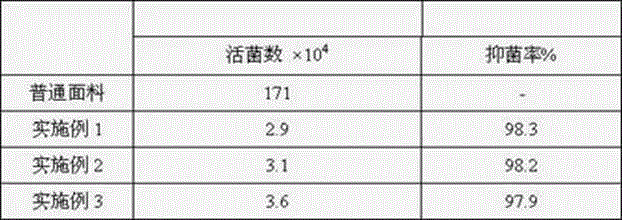

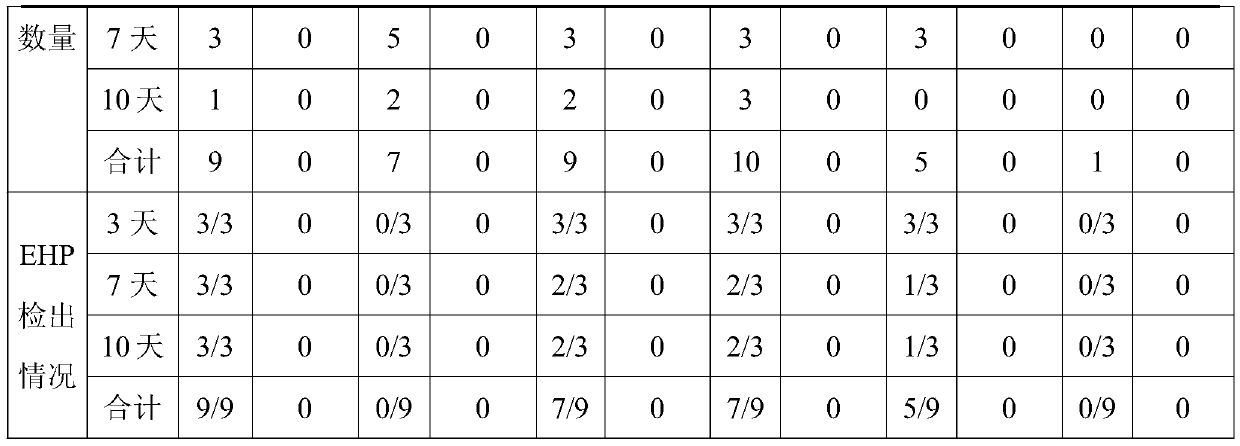

Anti-radiation antibacterial deodorizing fabric and preparation method thereof

The invention provides anti-radiation antibacterial deodorizing fabric. The anti-radiation antibacterial deodorizing fabric comprises a base fabric layer, a fabric layer and an anti-radiation antibacterial deodorizing layer arranged between the base fabric layer and the fabric layer. The anti-radiation antibacterial deodorizing layer is composed of warps, wefts and wool yarns by cross knitting. The warps are antibacterial fibers containing nano-silver particles, and the nano-silver particles account for 0.015-0.020%o of the antibacterial fibers. The wefts are antibacterial fibers treated by deodorizing finishing liquid, and the wool yarns are silver-plated fiber filament, and the silver-plated fibers use chinlon filaments as carrier. Silver is arranged on fibers on the surface of the carrier by the electrolysis method. The anti-radiation antibacterial deodorizing fabric is simple in structure, low in cost, excellent in antibacterial effect, long in antibacterial time and convenient in raw-material sourcing and has wide-spectrum antibacterial function.

Owner:广州傲加科技有限公司

Antiviral substitutional tea and preparation method thereof

The embodiment of the invention discloses antiviral substitutional tea, which comprises honeysuckle flower and liquoric root in a weight ratio of 1-3:2-4. The embodiment of the invention also discloses a method for preparing the antiviral substitutional tea. The method comprises the following steps of: (1) weighing the honeysuckle flower and liquoric root respectively, selecting and cleaning the honeysuckle flower and liquoric root; (2) drying and sterilizing the treated honeysuckle flower and liquoric root at the temperature of 70 DEG C respectively for later use; and (3) uniformly mixing the prepared honeysuckle flower and liquoric root in the weight part ratio of 1-3:2-4 and packaging the mixture. The substitutional tea provided by the embodiment of the invention has an antiviral effect and has the characteristics of convenient use, small side effect, simple preparation process and the like compared with a traditional compound Chinese medicament.

Owner:李宏良

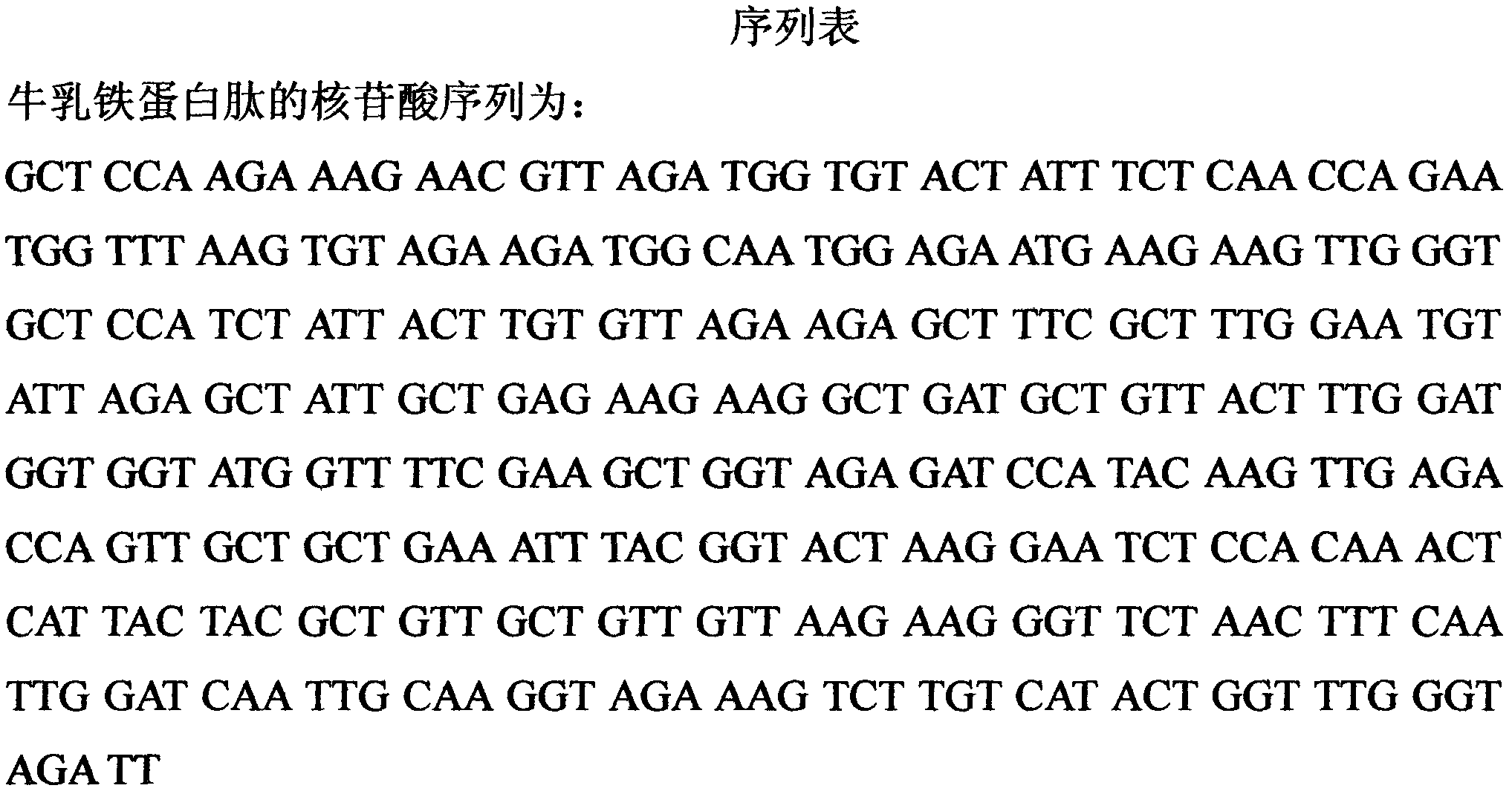

Bovine lactoferricin and preparation method thereof

InactiveCN102993296AHeat resistantHas a broad-spectrum antibacterial effectBacteriaTransferrinsFusion Protein ExpressionPepsin

The invention relates to bovine lactoferricin and a preparation method thereof. Bovine lactoferricin (Lfcin B) is 25 amino acid residues hydrolyzed from a bovine lactoferrin (BLF) N-terminal (17-41) by pepsin, and has a molecular weight of approximately 3.1kd. The preparation method comprises the steps of: (2) recombinant expression vector construction; (2) fusion protein expression induction; and (3) protein separation and purification. Bovine lactoferricin has the advantages that: Lfcin B has the highest activity among all the Lfcins, and an antibacterial effect 400 times that of bovine lactoferrin, such that Lfcin B can play an important role in gastrointestinal tracts.

Owner:GUANGZHOU GLAM BIOTECH

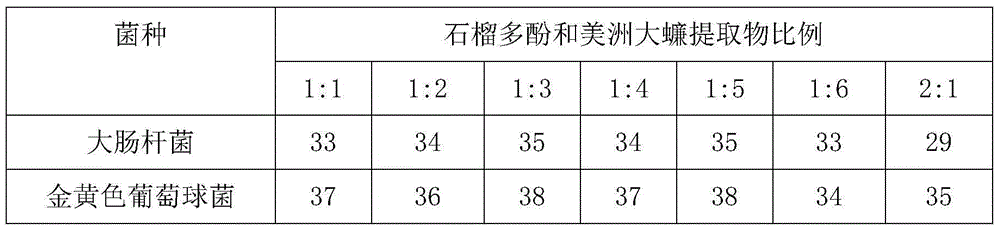

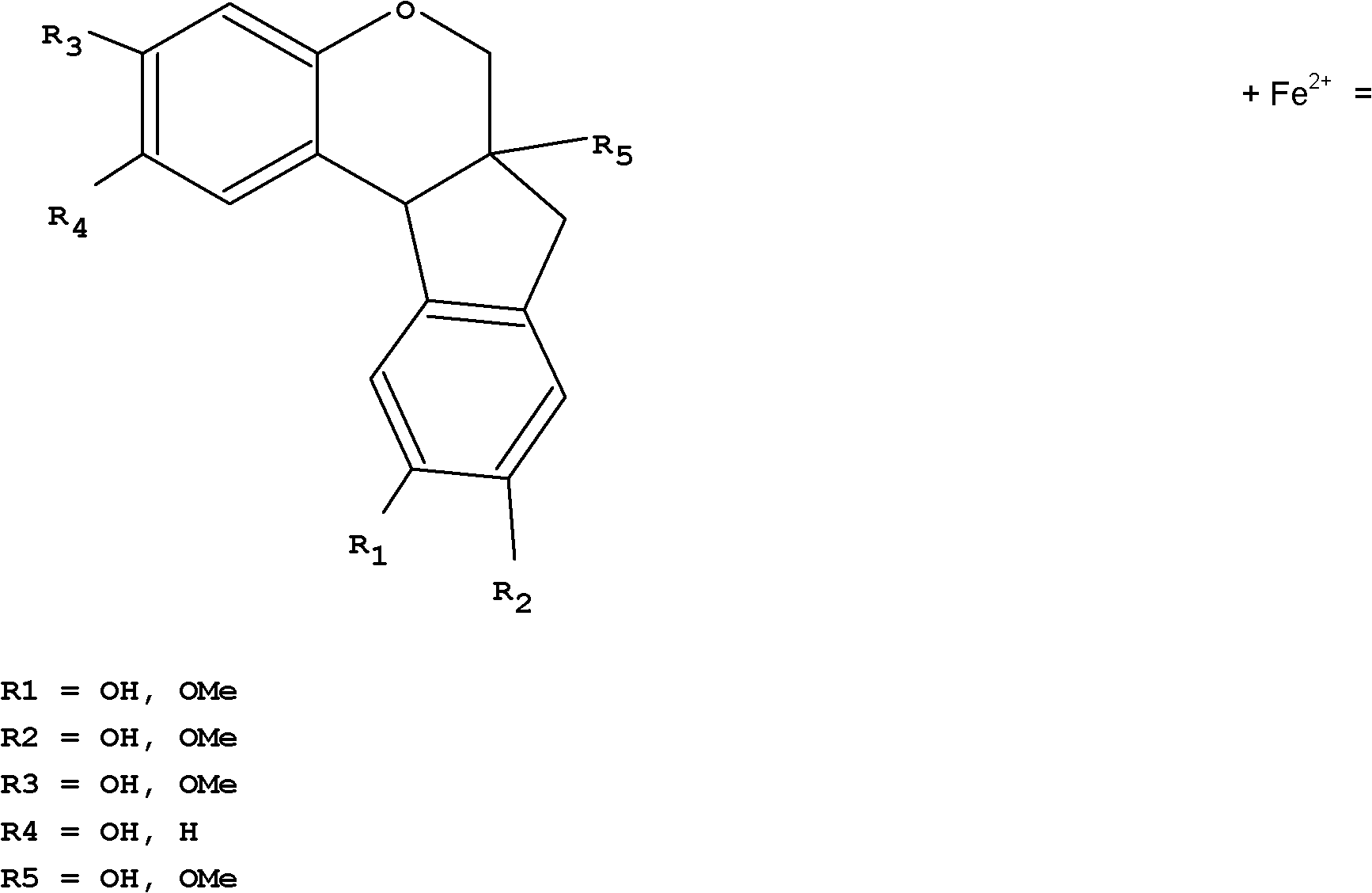

Oral composition and preparation method thereof

ActiveCN104688648AImprove antioxidant capacityHigh activityCosmetic preparationsToilet preparationsAdditive ingredientToothpaste

The invention provides an oral composition which is an oral preparation prepared by taking Periplaneta americana extract and Punicosides as active ingredients, wherein the weight ratio of the Periplaneta americana extract to Punicosides is 1:1-1:5. The invention also provides a preparation method and application of the oral composition. According to the oral composition disclosed by the invention, toothpaste can perform synchronous nursing on the oral cavity, teeth and gingiva and can effectively solve dental ulcer, the Punicosides have high in-vivo anti-oxidation and free radical cleaning activities, and the oral composition has a broad-spectrum antibacterial effect, has obvious effects of inhibiting staphylococcus aureus, hemolytic streptococcus, comma bacillus and shigella dysenteriae and has the effects of astringing, stopping bleeding, improving eyesight and the like.

Owner:耿福能

Natural preservative edible food packaging paper and preparation method thereof

ActiveCN104928988ARaw materials are easy to getEasy to operateFlexible coversWrappersBiotechnologyFiber

The invention provides natural preservative edible food packaging paper. The natural preservative edible food packaging paper comprises a dietary fiber layer, a protein membrane layer and a preservative liquid layer arranged between the dietary fiber layer and the protein membrane layer. The invention also provides a preparation method of the natural preservative edible food packaging paper. The natural preservative edible food packaging paper is a green and safe food packaging product, raw materials are easily obtained, the natural preservative edible food packaging paper is easy to operate, low in cost, economic and environment-friendly, the problems of conflicts between food packaging wastes and environmental protection and the like are fully solved, and the packaging paper is high in paper forming strength, high in flexibility, unlikely to break and wide in application range.

Owner:JURONG MAOYUAN WEAVING FACTORY

Method for producing flavorful flammulina velutipes leek flower paste

ActiveCN103039952APromote intellectual developmentEnhance detoxification abilityFood preparationGreen Tea PolyphenolsHealthful food

The invention relates to a method for producing a flavorful flammilina velutipes leek flower paste. According to the method, the materials including flammulina velutipes and leek flowers as the main materials, and perilla, ginger, garlic, chilli as the auxiliary materials are proportioned and pickled, and then are treated by using tea polyphenol in tea to reduce nitrite, and finally a healthful food with unique taste, which is carried conveniently for travel and used as an appetizer and has long shelf life, is obtained. According to the method, flammulina velutipes and leek flowers as the main materials are produced into flavorful food, and the paste has good taste and unique flavor and is nutritious; the paste has the functions of relieving nerves and eliminating the nervous mood due to the addition of perilla; and the paste has unique fresh mellow taste due to the addition of green tea juice, and the palatability is improved.

Owner:平南县科学技术情报研究所

Filter material of energy cup filter element and agglomeration technology

InactiveCN101381222AIncrease the amount of electrophoresisEnergeticClaywaresTunnel kilnMaterials preparation

The invention relates to a sintering process for a filter core and a filter material of an energy cup. The sintering process comprises the following: 1. a step of grain material preparation; 2. a step of crushing and grinding: the three grain raw materials prepared are put in a ball mill for crushing and grinding respectively until the grain diameters of the raw materials meet the certain grain diameter requirements; 3. a step of granulation: the three prepared grain raw materials which are obtained by crushing and grinding and of which the grain diameters meet the corresponding grain diameter requirements are put in a stirrer respectively, are added with water and evenly stirred, and are sent into a granulator to prepare grains with certain grain diameter requirement; and 4. a step of sintering: A. far infrared grains are subjected to high-temperature sintering in a tunnel kiln at a temperature of between 1, 000 and 1, 140 DEG C for 1 to 2 hours; B. tourmaline grains are subjected to low-temperature sintering in the tunnel kiln at a temperature of between 50 and 350 DEG C for 14 to 16 hours; C. nano silver grains are subjected to low-temperature sintering in the tunnel kiln at a temperature of between 250 and 350 DEG C for 1 to 2 hours; and D. rare earth grains are subjected to high-temperature sintering in the tunnel kiln at a temperature of between 1, 300 and 1, 500 DEG C for 1 to 2 hours. The sintering process has the advantages that the activated water in which the filter material is soaked can activate human body cells, improve immunity of the body, restrain bacterium, restrain excessive free radicals in human body, delay ageing and so on.

Owner:林真宇

Anemonefish puffed pellet feed and preparation method thereof

The invention discloses an anemonefish puffed pellet feed and a preparation method thereof. The anemonefish puffed pellet feed comprises, by mass, 30-60% of fish meal, 7-20% of alpha-starch, 7-15% of acanthaster planci powder, 5-20% of fermented soybean meal, 3-10% of peanut meal, 2-10% of whole shrimp powder, 0.5-2% of oceanic red yeast, 0.5-2% of spiral algae powder, 0.5-1% of garlic powder, 0.5-1% of a special marine fish feeding attractant, 0.5-1% of a mixture comprising a plurality of vitamins, and 0.5-1% of a mixture comprising a plurality of minerals. After the anemonefish puffed pellet feed of the present invention is adopted to feed the anemonefishes, the anemonefishes snatch, the palatability is food, no anorexia circumstance is generated after the long-term feeding, the anemonefishes can grow healthily, the vitality is strong, and the bright body color can be maintained.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Natural moistureproof degradable food packaging paper and preparation method thereof

The invention provides a natural moistureproof degradable food packaging paper, which includes a fiber layer, a protein film layer, and a moistureproof liquid layer arranged between the fiber layer and the protein film layer. The invention also provides a preparation method of the natural moistureproof degradable food packaging paper. The natural moistureproof degradable food packaging paper is completely a green and safe food packaging supply, and has the characteristics of easily available raw materials, simple operation, low cost, economical efficiency and environmental protection, fully solves the contradiction between food packaging wastes and environmental protection and other problems, and has the advantages of high paper strength, good flexibility, difficult breaking and wide range of application.

Owner:HUBEI HENGDA PACKING CO LTD

Antibacterial hydrogel containing organic quaternary ammonium salt or silane terminated organic quaternary ammonium salt and preparation method thereof

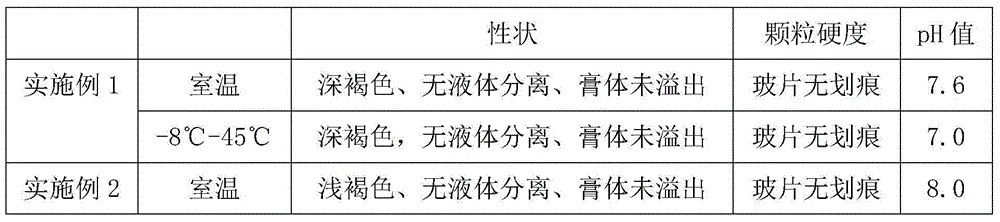

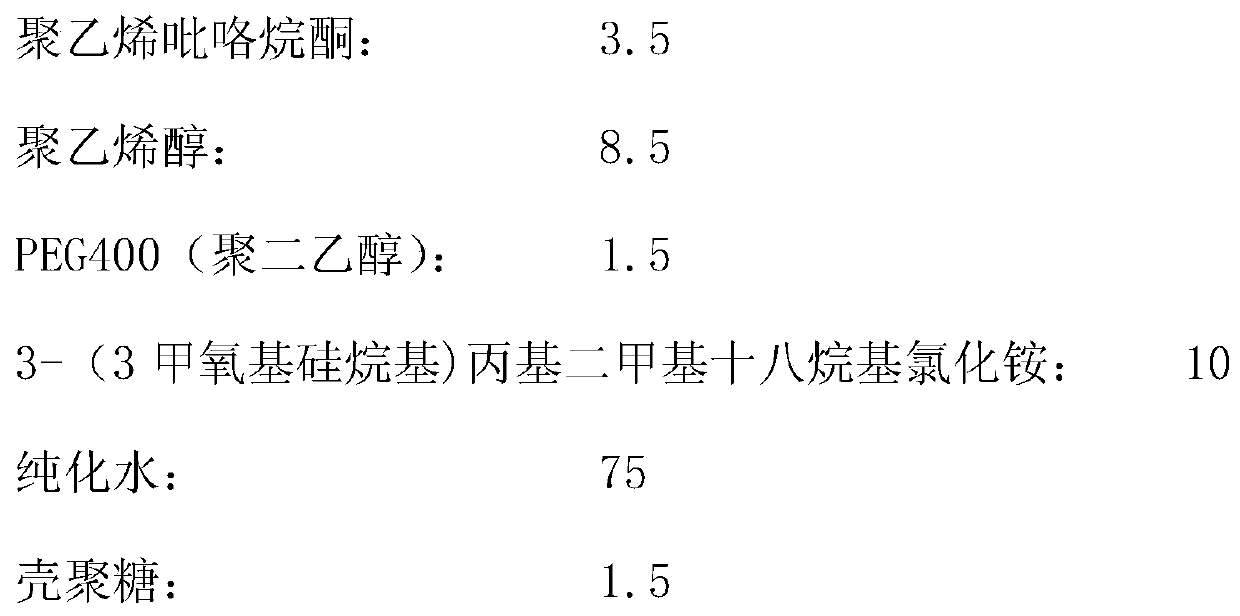

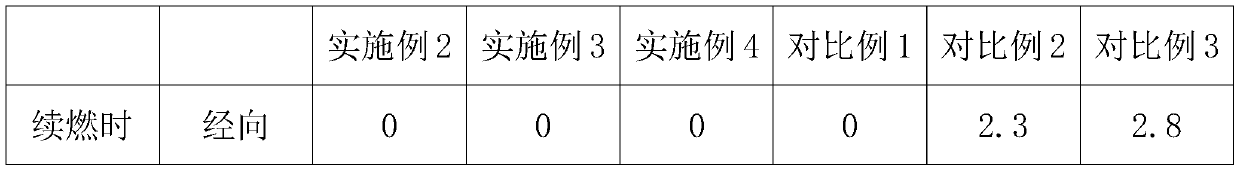

PendingCN110064070AAchieve broad-spectrum antibacterial effectHas a broad-spectrum antibacterial effectBandagesSide effectWound dressing

The invention relates to the technical field of antibacterial hydrogel manufacturing, in particular to an antibacterial hydrogel containing organic quaternary ammonium salt or silane terminated organic quaternary ammonium salt and a preparation method thereof. The hydrogel is characterized by being prepared from, by mass, 0.1-65% of 3-(3 methoxy-silicyl)propyl dimethyl octadecyl ammonium chlorideor alkyl dimethyl benzyl ammonium chloride. Compared with the prior art, the hydrogel has the broad-spectrum antibacterial effect and the long-lasting antibacterial performance, is applicable to wounddebridement and wound dressing and has no toxic or side effect and high adhesion force and other remarkable advantages.

Owner:董英

Anti-acne composition containing epidermal growth factors and tea tree oil and preparation method thereof

InactiveCN102178930APromote divisionStay youngOrganic active ingredientsCosmetic preparationsCuticleIrritation

The invention discloses an anti-acne composition containing epidermal growth factors and tea tree oil and a preparation method thereof. The anti-acne composition disclosed by the invention comprises the following components: epidermal growth factors, tea tree oil, metallothionein, chlorhexidine, humectant, tackifier, alpha-carboxylic acid, pH value regulator, surfactant and deionized water. The preparation method of the anti-acne composition disclosed by the invention comprises the following steps of: mixing and heating the epidermal growth factors, the tea tree oil, the metallothionein, the chlorhexidine and the surfactant to be used as an oil phase; dissolving and heating the humectant, the tackifier and the alpha-carboxylic acid in water to be used as a water phase; adding the oil phase into the water phase, and stirring uniformly; and adding the pH value regulator for regulating the pH value, thereby obtaining the anti-acne composition containing epidermal growth factors and tea tree oil. The epidermal growth factors contained in the anti-acne composition disclosed by the invention can accelerate the metabolism of skin cells, and the natural tea tree oil capable of resisting bacteria and diminishing inflammation can efficiently sterilize bacteria, diminish inflammation and remove acnes, thus the anti-acne composition has good moisture retention and small skin irritation.

Owner:SOUTH CHINA UNIV OF TECH

Fire-resistant and bacteriostatic curtain cloth and preparation method thereof

ActiveCN109774282AHas a broad-spectrum antibacterial effectHas a spectrum antibacterial effectLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses fire-resistant and bacteriostatic curtain cloth, The cloth is composed of two layers of fabrics, and the surface-layer fabric and the inner-layer fabric are connected through photocatalyst fiber; the surface-layer fabric and the inner-layer fabric are formed by weaving polyimide fiber and bacteriostatic fiber, the content of the polyimide fiber is 70%, and the content of the bacteriostatic fiber is 30%. The invention further discloses a preparation method of the fire-resistant and bacteriostatic curtain cloth. The curtain cloth is composed of two layers of fabrics, thesurface-layer fabric and the inner-layer fabric are connected through the photocatalyst fiber, and the photocatalyst fiber not only increases the air permeability of the curtain cloth, but also has the bacteriostatic effect under light conditions. The surface-layer fabric and the inner-layer fabric are made from the polyimide fiber and the antimicrobial fiber, the polyimide fiber serves as one ofmain raw materials, the fire resistance of the curtain cloth can be effectively improved on the basis of guaranteeing the mechanical properties, and the bacteriostatic fiber refers to bamboo pulp fiber grafted with chitosan and has excellent anti-bacterial properties. At the same time, flame retardant finishing is carried out on the cloth to enhance the fire resistance of the curtain cloth.

Owner:HANGZHOU YOUPU PLASTIC NEW MATERIAL CO LTD

Natural moisture-proof edible food packaging paper and preparation method thereof

ActiveCN104846686ARaw materials are easy to getEasy to operateNon-fibrous pulp additionFlexible coversFiberProcess engineering

The invention provides natural moisture-proof edible food packaging paper comprising a dietary fiber layer, a protein film layer and a moisture-proof liquid layer arranged between the dietary fiber layer and the protein film layer. The invention also provides a preparation method of the natural moisture-proof edible food packaging paper. The natural moisture-proof edible food packaging paper can be a complete pollution-free and safe food packaging supply, raw materials are easily available, the operation is simple, and the cost is low, so that the edible food packaging paper is economical and environmentally friendly, the problems of the contradiction between food wrapping wastes and environmental protection and the like are completely solved, and finished paper is high in strength, good in flexibility, difficulty to break and wide in application range.

Owner:JURONG MAOYUAN WEAVING FACTORY

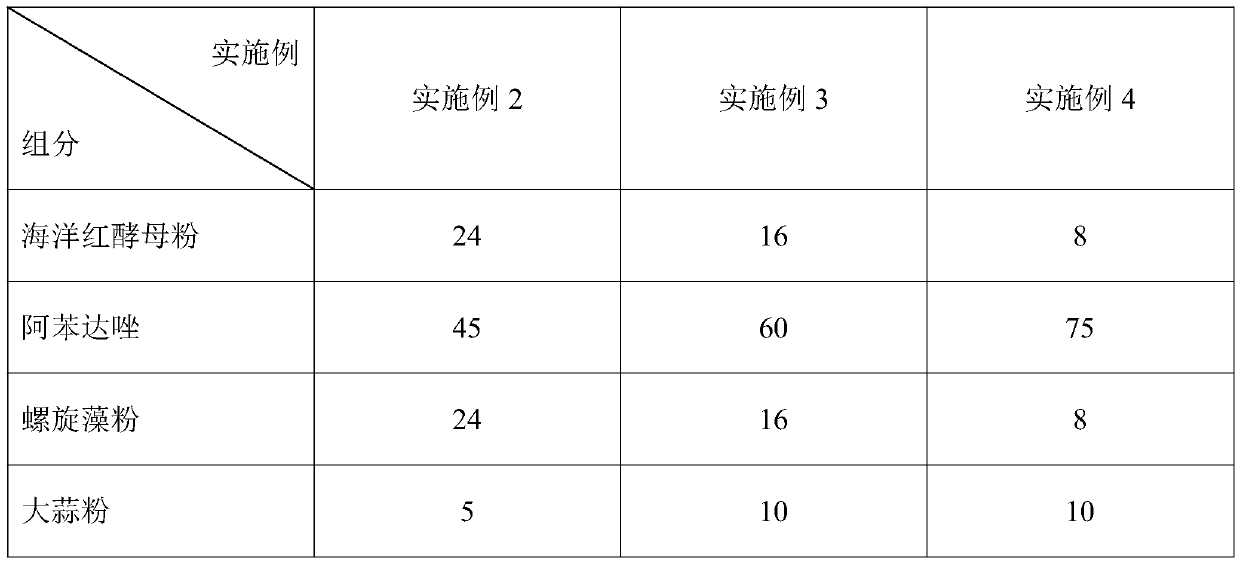

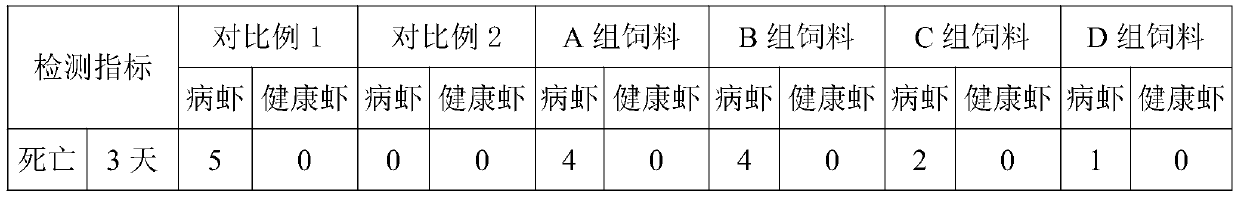

Medicinal bait additive for preventing and treating enterocytozoon hepatopenaei of litopenaeus vannamei

InactiveCN110178973AGuaranteed healthy growthHigh in proteinOrganic active ingredientsClimate change adaptationPrawnGARLIC POWDER

The present invention discloses a medicinal bait additive for preventing and treating enterocytozoon hepatopenaei of litopenaeus vannamei. The medicinal bait additive comprises the following components in parts by weight: 8-32 parts of marine red yeast powder, 30-75 parts of albendazole, 8-32 parts of spirulina powder and 5-10 parts of garlic powder. The medicinal bait additive is used in a compound feed for the litopenaeus vannamei and has an addition amount of only 6-12%; and the medicinal bait additive can also be mixed with the feed at a weight ratio of 1:10 for feeding before feeding. Themedicinal bait additive uses an internal administration route, so that a medicine internal environment is formed in a host body, the medicinal bait additive is subjected to blood circulation to reachtarget organs and parasites cannot survive. The medicinal bait additive can effectively kill the enterocytozoon hepatopenaei in the litopenaeus vannamei body, is non-toxic to the litopenaeus vannameibody, does not cause medicine residues in the litopenaeus vannamei body, at the same time also does not cause pollution to the breeding environment, and can effectively play a therapeutic role in thediseased litopenaeus vannamei infected by the enterocytozoon hepatopenaei.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

DSK paddy rice seedling-strengthening agent

The composition of DSK rice shoots strenthening agent with clear disease-resisting effect, durable acid-regualting time and obvious fertilizer-raising action contains medicine; organic substance and fertilizer according to the mixing ratio of 1:7:7 as effective components, in which the medicine is formed from 20% of compounded preparation prepared with 3.3% thiram and metalaxyl and 80% of potter's earth additive; the organic substance is formed from discards of plant straw and slalks, its pH value is 5.0-6.0; and the fertilizer is formed from 70% of macroelements, 20% of secondary elements and 10% of trace elements. It can raise adverse resistance of rice, and possesses obvious effect for preventing and curing seedling blight and rhizoctonia disease of rice.

Owner:黑龙江省沃必达农业科技开发有限公司

Anti-bacterium deodorization fabric and preparation method thereof

ActiveCN104824892ASimple structureLow costSynthetic resin layered productsWoven fabricsBiotechnologyFiber

The invention provides anti-bacterium deodorization fabric which comprises a basic cloth layer, a fabric layer and an anti-bacterium deodorization layer arranged between the basic cloth layer and the fabric layer. The anti-bacterium deodorization layer is woven from warp and weft. The warp is antibacterial fibers containing nano-silver particles. The mass of the nano-silver particles accounts for 0.0015% to 0.0020% of the total mass of the antibacterial fibers. The weft is antibacterial fibers treated through a deodorization finishing liquid. The anti-bacterium deodorization fabric has the advantages that the structure is simple, cost is low, raw materials are acquired conveniently, the antibacterial effect is quite excellent, anti-bacterial time is long, and the broad-spectrum antibacterial effect is achieved.

Owner:天派针织股份有限公司

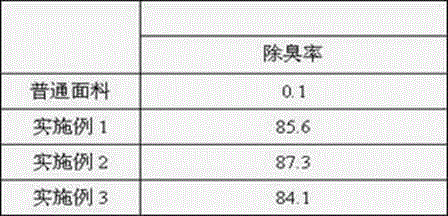

Plant hair dye with isomerized C10 ethoxylate as penetrating agent and its preparation method

InactiveCN102366382AImprove dyeing effectImprove timelinessCosmetic preparationsHair cosmeticsHair dyesChinese Gall

The invention discloses a plant hair dye with isomerized C10 ethoxylate as a penetrating agent. Employing a plant color coupler, the hair dye is characterized in that the penetrating agent promoting the penetration of the plant color coupler into dyed hair is isomerized C10 ethoxylate. The plant color coupler is formed by subjecting a metal salt and plant extract to a color development reaction, and also can be plant henna powder. And the plant extract can be sappan wood extract or Chinese gall extract. In the plant hair dye with isomerized C10 ethoxylate as the penetrating agent in the invention, the employed raw materials are classified into two components: agent A and agent B. The agent A is composed of 0.5-5 parts of a metal salt, 0.02-0.25 part of isomerized C10 ethoxylate, and 10 parts of deionized water by weight, with a pH value of 0.02-8. And the agent B is composed by 0.01-5 parts of silicone oil and 10-100 parts of plant extract by weight. Containing no aniline compound and hydrogen peroxide, the plant hair dye of the invention does not damage hair, and can be colorfast for over two months compared with ordinary plant hair dyes, and is characterized by better dyeing effect and longer effectiveness.

Owner:谢建武

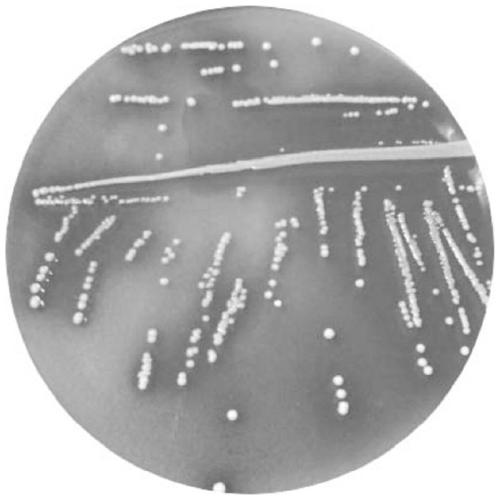

Lactobacillus paracasei and application thereof

ActiveCN111286474AHas a broad-spectrum antibacterial effectBacteriaFood preservationBiotechnologyLactic acid bacterium

The invention provides lactobacillus paracasei and application thereof, belongs to the field of microorganisms, and provides a new strain with an antibacterial effect on the basis of the problems of few varieties, low yield and narrow application of existing lactic acid bacteria, and the preservation number of lactobacillus paracasei is CCTCC NO: M 2016667.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Anti-radiation, antibacterial and skin care shell fabric and preparation method thereof

Owner:常州瑞联新材料有限公司

Fishing antibacterial agent of Chinese medicine effective ingredient

InactiveCN1939297AEffective controlImprove non-specific immunityAntibacterial agentsOrganic active ingredientsGallic acid esterAdditive ingredient

An antibacterial medicine containing Chinese-medicinal component for preventing and treating the bacterial diseases of aquatic animals including fish contains gallic acid (10-12 mass %), flavones (4-5), anthraquinones (1-2) and water (rest).

Owner:SOUTHWEST UNIVERSITY

Fermented feed for pig and preparation method of fermented feed

InactiveCN106615852AStrong anti-fungal efficacyInhibit the production of Aspergillus flavusAnimal feeding stuffBiologyCorn flour

The invention discloses a fermented feed for a pig. The fermented feed is prepared from the following raw materials in part by weight: 25-35 parts of corn flour, 15-24 parts of sweet potato residue, 6-12 parts of garlic, 4-8 parts of rhizoma atractylodis, 10-26 parts of folium artemisiae argyi, 5-8 parts of artemisia apiacea, 4-7 parts of fructus cnidii, 14-30 parts of molasses, 8-12 parts of litsea cubeba oil, and 3-5 parts of a microbial preparation. The fermented feed for the pig inhibits the growth of mildew.

Owner:陆川县三农畜牧服务有限公司

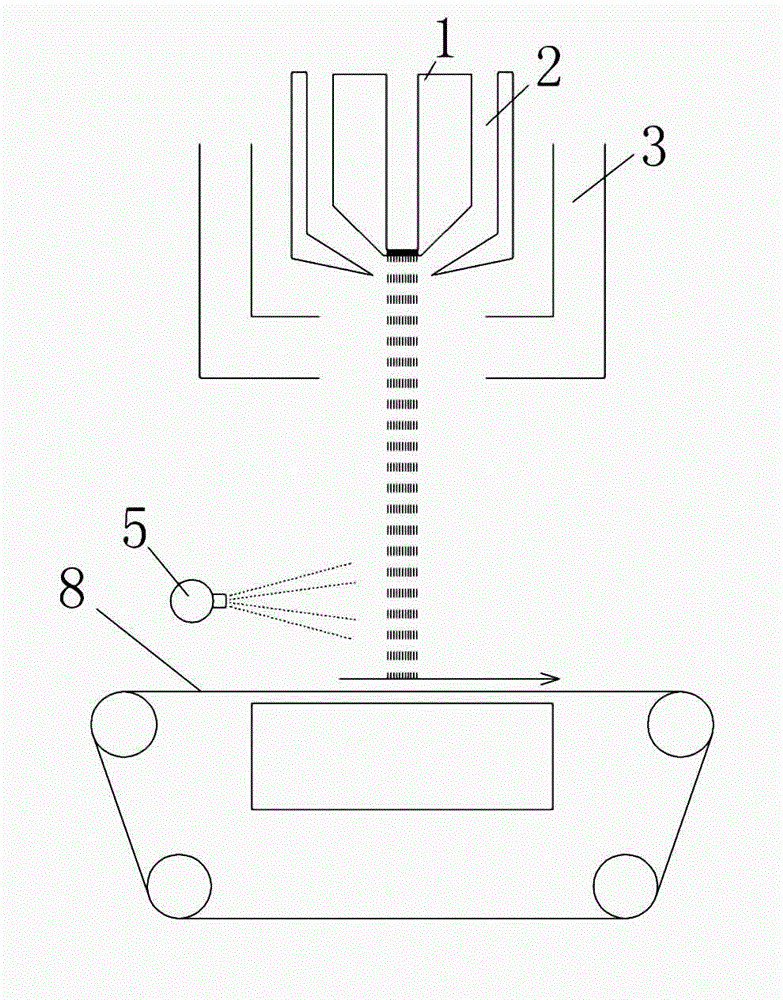

Bacteriostatic air filtering material made from rhizoma coptidis-nanometre zinc oxide ultra-fine fibre glass

InactiveCN103816718AWith air filtration performanceReduce filtration efficiencyDeodrantsFiltration separationAir filterZno nanoparticles

The invention relates to a bacteriostatic air filtering material made from rhizoma coptidis-nanometre zinc oxide ultra-fine fibre glass. Four substances namely, rhizoma coptidis extracts, nanometre zinc oxide particles, xanthan gum and fibre glass are mixed and melt-blown, so that the ultra-fine fibre glass filtering material formed by melt-blowing and weaving not only has air filtering performance, but also has bacteriostasis performance for bacteria and viruses, such as golden staphylococcus, pseudomonas aeruginosa and the like. In the conventional bacteriostatic air filtering material, since the fibre surface of the air filtering material is coated in a sprayed manner with bacteriostatic materials, such as nanometre zinc oxide and the like, or the bacteriostatic materials, such as the nanometre zinc oxide and the like, are woven into a new air filtering screen to cover the surface of the air filtering material to form a composite filtering layer in the conventional bacteriostatic air filtering material, so that problems that windage resistance is easy to enlarge, microorganism pollution gathered on the filtering layer is easy to cause drug tolerance and an high-efficient air filter is easy to cause secondary pollution to environment because the filtering route of the air filtering material is decreased, are solved after the adoption of the bacteriostatic air filtering material.

Owner:GUANGDONG SECOND PROVINCIAL TRADITIONAL CHINESE MEDICINE HOSPITAL

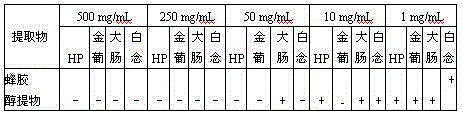

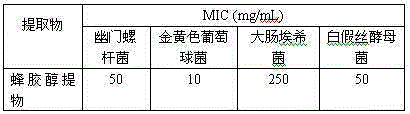

Oral care product containing propolis alcohol extract and having anti-Hp (helicobacter pylori) efficacy

ActiveCN104997716ASimple extraction methodStable dose compositionAntibacterial agentsCosmetic preparationsMouth careOral ulcers

The invention discloses an oral care product containing propolis alcohol extract and having anti-Hp (helicobacter pylori) efficacy. The oral care product is characterized by containing the propolis alcohol extract. The invention provides a kind of traditional Chinese medicine oral care products, a medicine extracting method is simple, dosage and ingredients are stable, and the products can go deep into an oral cavity directly. The oral care product cannot cause internal environment disturbance of the oral cavity when used for a long time and has no side effects. Propolis contains a large quantity of flavonoid, aromatic acid, fatty acid and terpene compounds and has a broad-spectrum antibacterial function. The oral care product not only has similar functions including halitosis removal, oral ulcer treatment, resistance to common pathogenic bacteria in the oral cavity and inflammation diminishing to the conventional oral care products such as Chinese herbal medicine health care toothpaste and the like, but also has the functions of Hp killing and effective prevention of oral transmission of Hp. Natural propolis is applied to the oral care products such as the toothpaste and the like, the oxidation resistance of the products is improved, and the shelf life is prolonged.

Owner:杭州华胄生物科技有限公司

Traditional Chinese medicine enema for treating exogenous fever of infants

The invention relates to the technical field of a traditional Chinese medicine preparation, and discloses a traditional Chinese medicine enema for treating exogenous fever of infants. The enema is prepared by taking radix scutellariae, honeysuckle, forsythia, dandelion, gypsum and rhizoma anemarrhenae as raw materials through the steps of soaking, decocting and filtering. The invention is characterized in that each dose of enema is prepared from the following raw materials in proportioning by weight: 2-5g of radix scutellariae, 5-8g of honeysuckle, 2-5g of forsythia, 5-8g of dandelion, 9-12g of gypsum and 2-5g of rhizoma anemarrhenae. The enema has the functions of clearing away heat and toxic material, diminishing inflammation and allaying the fever, and is a preferred medicament for allaying the exogenous fever of infants. Compared with the existing treatment method, the enema disclosed by the invention can be quickly absorbed through rectal administration, has a good treatment effect, reduces the 'first pass effect' of general medicaments, has high bioavailability and low price, is convenient and easy to implement, does not have toxic side effects, has an obvious effect on allaying the fever, and also solves the problem that infants are afraid of needles and medicaments. Observed by 200 clinical cases, the antipyretic effective rate within 36 hours is 100%.

Owner:冯陆冰 +2

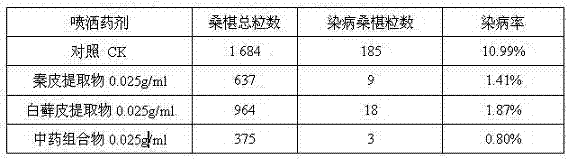

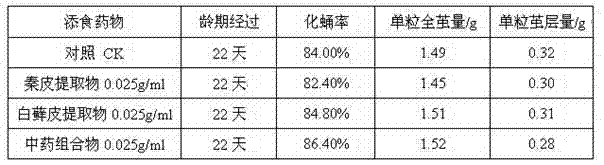

Traditional Chinese medicine composition preventing stalk penicillium digitatum and sclerotinia sclerotiorum, preparation method and application thereof

InactiveCN102379316AHas a broad-spectrum antibacterial effectEnhanced inhibitory effectBiocideFungicidesSide effectPenicillium digitatum

A traditional Chinese medicine composition preventing stalk penicillium digitatum and sclerotinia sclerotiorum comprises active component cortex fraxini and its extract and active component cortex dictamni and its extract, the mass percentage is respectively as follows: cortex fraxini and its extract 30 to 90% and cortex dictamni and its extract 10 to 70%. The preparation thereof is soaked in ethanol, extracted by ultrasonic and concentrated. The bacterial inhibition rate of the preparation can reach 90%. The preparation has exact effect, long effective term, non-toxic and non side effect andlow production cost, and overcomes the problems that the present chemical pesticide is easy to induce the drug resistance of pathogenic bacteria, the chemical agent residual exceeds the standard and does not meet the non-pollution requirement.

Owner:SOUTHWEST UNIVERSITY

Traditional Chinese medicine extract for preventing hypertrophic Sclerotinia sclerotiorum

InactiveCN101513196AHas a broad-spectrum antibacterial effectGood inhibitory effectBiocideFungicidesAlcoholCortex Fraxini

A traditional Chinese medicine extract for preventing hypertrophic Sclerotinia sclerotiorum adopts the methods of heating alcohol, continuous refluxing for extracting, etc. The extract is obtained from the cortex fraxini through a series of process flows. The antimicrobials prepared by the extract can effectively prevent the hypertrophic Sclerotinia sclerotiorum. The efficacy test indicates that the control rate to hypertrophic Sclerotinia sclerotiorum is above 95% and the total control rate can obtain more than 85%. The preparation belongs to the pure traditional Chinese medicine preparation and has the advantages of prevention of application of chemical pesticide, reduced environment pollution, abroad source of raw material for production and low cost for manufacturing.

Owner:SOUTHWEST UNIVERSITY

Fermented traditional Chinese medicine feed additive for young quail and preparation method thereof

InactiveCN107373023AImprove and enhance the body's immune functionImprove and increase speedMetabolism disorderDigestive systemDiseaseAdditive ingredient

The invention discloses a fermented traditional Chinese medicine feed additive for young quail. The fermented traditional Chinese medicine feed additive is prepared from the following raw materials in parts by weight: 10-16 parts of herba epimedii, 10-15 parts of garlic, 5-11 parts of medical stone, 8-12 parts of rhizoma cyperi, 10-15 parts of radix acanthopanacis semticosi, 12-18 parts of radix astragali, 5-12 parts of herba taraxaci, 7-11 parts of sulfur and 9-15 parts of medicated leaven; the raw materials are fermented by lactobacillus acidophilus, bacillus subtilis and saccharomycetes. According to the fermented traditional Chinese medicine feed additive disclosed by the invention, the traditional Chinese medicine effective ingredients are decomposed into easily absorbable small molecular substances to supplement nutritional ingredients of the feed; the intestinal flora balance is regulated, the disease resistance of young quail is enhanced, and the digestion-absorption function of the young quail is improved; on the basis of promoting the growth and development of the young quail, the breeding cost is lowered, and the breeding benefits are increased.

Owner:HENAN UNIV OF SCI & TECH

Crucian carp feed capable of preventing and treating branchia hyperemia disease and preparation method of crucian carp feed

InactiveCN106509486AImprove adhesionIncrease productivityFood processingClimate change adaptationPumpkin seedPropolis

The invention discloses a crucian carp feed capable of preventing and treating a branchia hyperemia disease and a preparation method of the crucian carp feed, and belongs to the technical field of preparation of the crucian carp feed. The crucian carp feed is prepared from the following main raw materials of trash fish powder, corn protein powder, soybean flour, rice bran, yellow rapeseed meal, wheat bran powder, bentonite, radix isatidis, croton fruits, heartleaf houttuynia herbs, garlic, pumpkin seeds, chinaberry bark, common andrographis herbs, common cnidium fruits, radix sophorae flavescentis, Chinese galls, macleaya cordata, akebia stems, cyrtomium rhizomes, dioscorea zingiberensis, trehalose, propolis and calcium dihydrogen phosphate. According to the crucian carp feed disclosed by the invention, the bentonite is added, so that the production efficiency of a granulator can be effectively improved; Chinese herbal medicine substances having effects of resisting bacteria and killing insects and a natural antibacterial agent are added, so that pathogenic bacteria and pests of the branchia hyperemia disease can be effectively prevented and treated; effective components in Chinese herbal medicine substances are extracted by an ethanol backwashing method, so that the extraction rate is high. The crucian carp feed disclosed by the invention is rich in nutrition, can be used for effectively preventing and treating the branchia hyperemia disease of crucian carps and reducing the breeding risk of the crucian carps, and is worth popularization and application.

Owner:GUANGXI ZHIBAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com