Fire-resistant and bacteriostatic curtain cloth and preparation method thereof

A technology for curtains and fabrics, applied in the field of textile fabrics, can solve the problems of flame retardancy and antibacterial performance, and achieve the effect of inhibiting the growth of bacteria and some fungi and reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

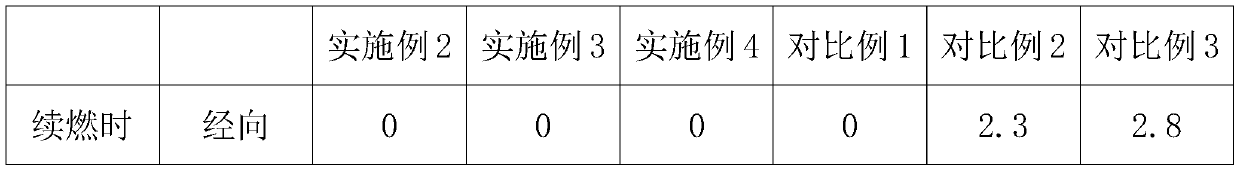

Examples

preparation example Construction

[0042] The preparation method of described refractory antibacterial type curtain cloth, comprises the steps:

[0043] The first step is to weave the polyimide fiber and antibacterial fiber on the double-sided circular machine according to the double rib weave, and weave it into a base fabric. The weaving parameters are: 32 needles / 26mm, tube diameter 86cm, yarn length 24cm / 100 coils;

[0044] The second step is to overlap the two layers of base fabrics as the surface and inner layer of the curtain fabric, and use photocatalyst fibers to connect the two layers of base fabrics;

[0045] The third step is to sizing the fabric obtained in the above steps through the flame-retardant finishing solution. Specifically, the two-dipping and two-rolling process is used for sizing, with a surplus rate of 90%, and then dried at 102 ° C for 3 minutes, and then dried at 135-145 Bake at ℃ for 2-3 minutes to obtain a fire-resistant and antibacterial curtain fabric.

[0046] Wherein, the flame...

Embodiment 1

[0051] Preparation of antibacterial fibers:

[0052] (1) Chitosan is dissolved in the acetic acid solution that mass fraction is 2%, is mixed with the chitosan solution that chitosan mass concentration is 60g / L, and regulates the pH of solution to 3-4 with dilute hydrochloric acid, slowly heats up to 80°C;

[0053] (2) Slowly drip epichlorohydrin in the above-mentioned solution, react 100min after dripping, obtain modified chitosan solution, then adjust the pH value of modified chitosan solution to 10 with NaOH solution, for subsequent use; (wherein , the dosage ratio of chitosan and epichlorohydrin is 1:0.8)

[0054] (3) According to the solid-to-liquid ratio of 1g: 15mL, place the bamboo pulp fibers in a sodium hydroxide solution with a mass fraction of 0.5% and boil for 60-70min, then centrifuge and dehydrate at a speed of 3000r / min, and then add deionized water for repeated centrifugal washing , until the pH value of the washing centrifugate is 10;

[0055] (4) Disperse...

Embodiment 2

[0057] The fire-resistant and antibacterial curtain fabric is made by the following steps:

[0058] The first step, the polyimide fiber and the antibacterial fiber prepared in Example 1 are woven on a double-sided large circular machine according to the double rib weave, and are woven into a base fabric. The weaving parameters are: 32 needles / 26mm, a barrel diameter of 86cm, and a yarn length of 24cm / 100 coil;

[0059] The second step is to overlap the two layers of base fabrics as the surface and inner layer of the curtain fabric, and use photocatalyst fibers to connect the two layers of base fabrics;

[0060] The third step is to sizing the fabric obtained in the above steps through the flame-retardant finishing solution. Specifically, the two-dipping and two-rolling process is used for sizing, with a surplus rate of 90%, and then dried at 102 ° C for 3 minutes, and then dried at 135-145 Bake at ℃ for 2-3 minutes to obtain a fire-resistant and antibacterial curtain fabric....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com