Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Good toughness balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

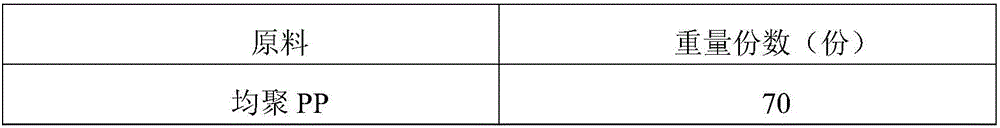

Low-shrinkage polypropylene composition and preparation method thereof

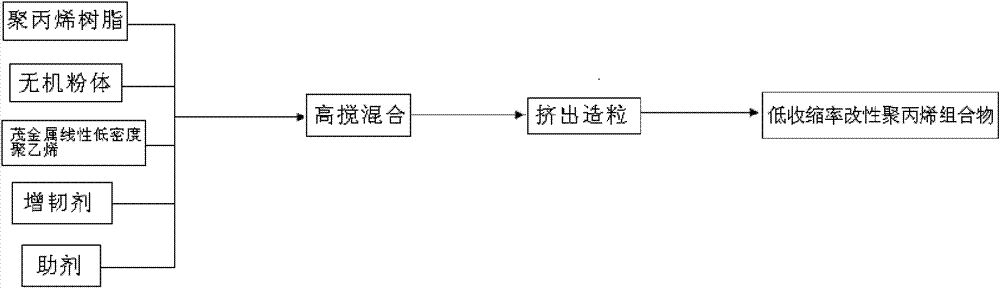

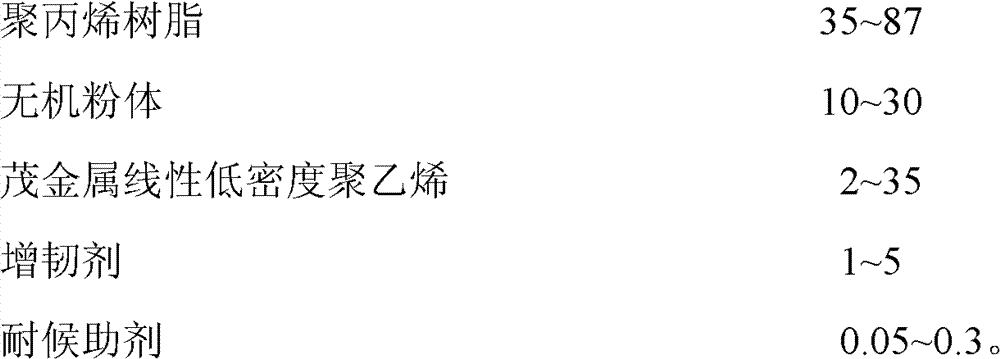

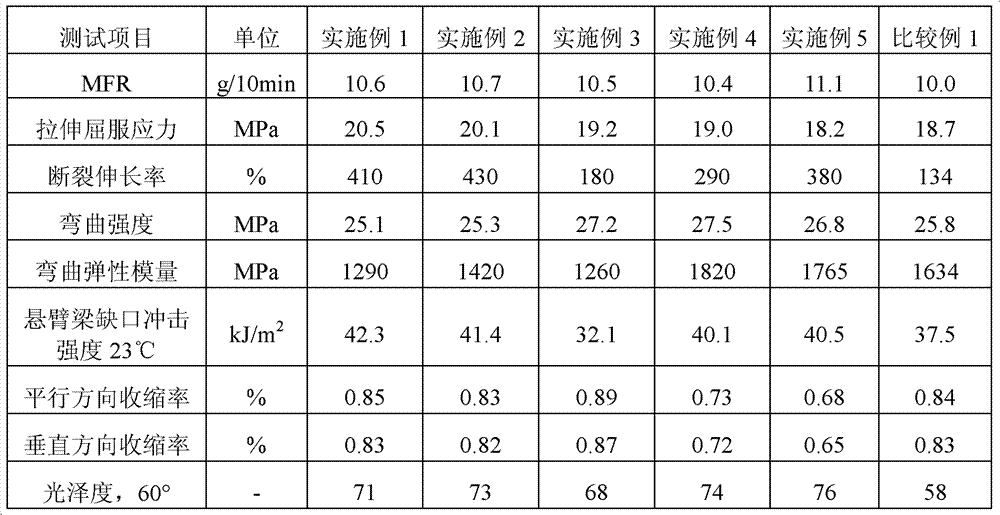

The invention relates to a low-shrinkage polypropylene composition and a preparation method thereof, belonging to the technical field of high polymer materials. The low-shrinkage polypropylene composition is prepared from the following raw materials in parts by mass: 35-87 parts of polypropylene resin, 10-30 parts of inorganic powder, 2-35 parts of metallocene linear low-density polyethylene, 1-5 parts of toughener and 0.05-0.3 part of weather-resistant assistant. According to the invention, the modified polypropylene composition having a low shrinkage is prepared by taking impact polypropylene copolymer as a base resin, adding the inorganic powder, the metallocene linear low-density polyethylene and the toughener and extruding and granulating with a double-screw extruder; the prepared polypropylene composition has low cost, low shrinkage, excellent rigidity-toughness balance, high glossiness and favorable processing flowability; and the preparation method is simple and easy to implement and easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP

Large hollow container blow molding material and preparation method thereof

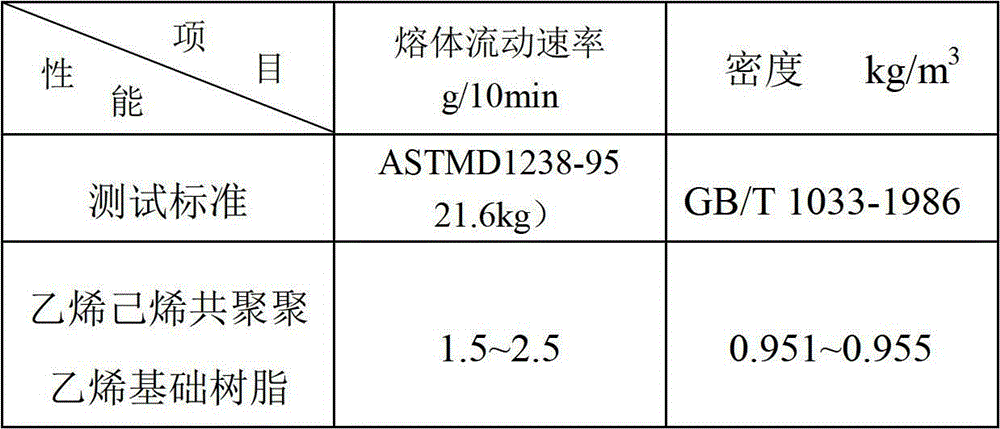

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

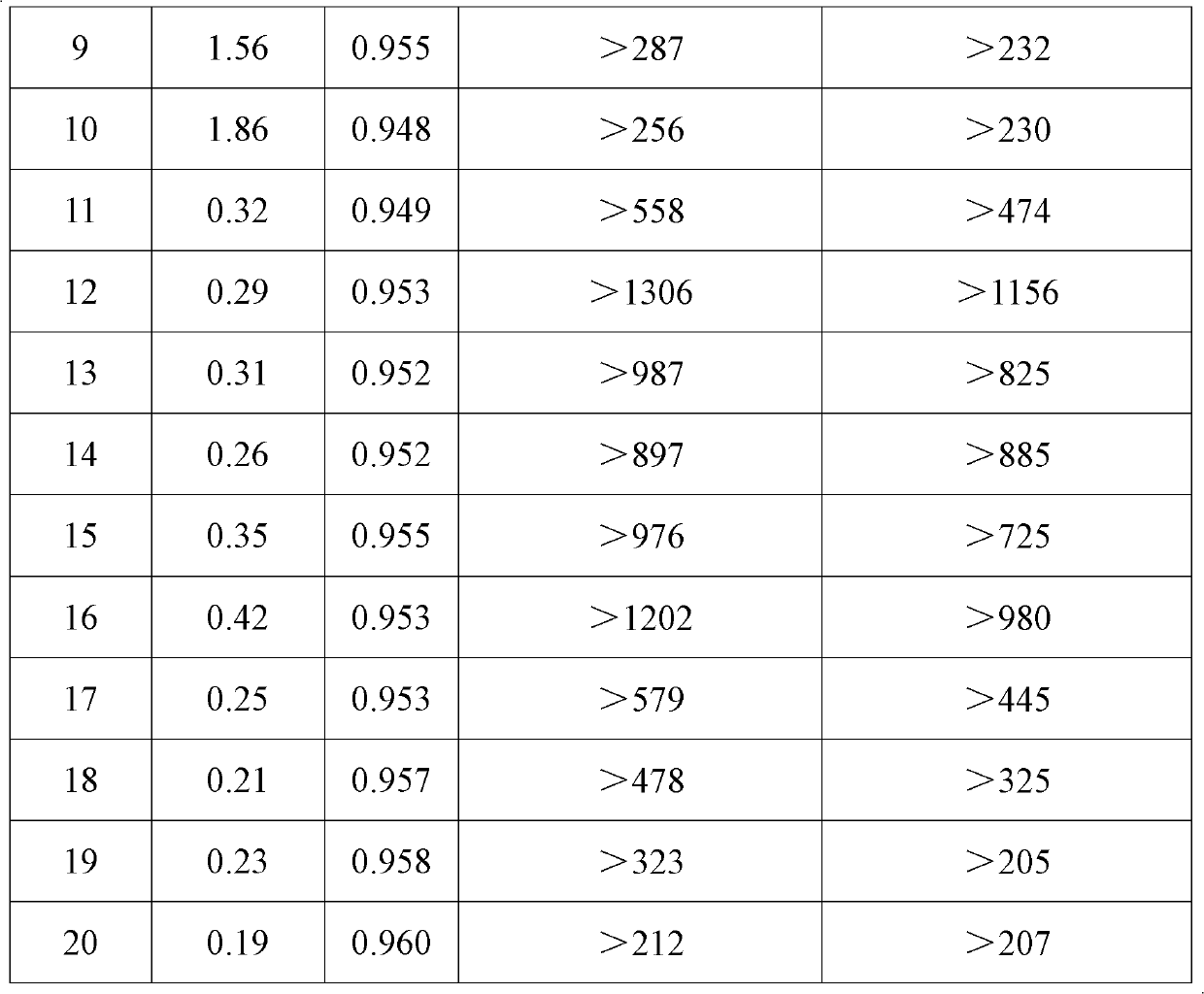

Multimodal polyethylene pipe resin composition and preparation method thereof

ActiveCN103304869AGood pressure resistanceExcellent resistance to long-term hydrostatic strengthRigid pipesWeight distributionGreek letter alpha

The invention relates to a multimodal polyethylene pipe resin composition and a preparation method and application thereof. The composition comprises component A, component B and component C, wherein the component A is an ethylene homopolymer, the component B is an ethylene copolymer formed through copolymerization of ethylene and alpha-alkene and has an average molecular weight greater than that of the component A, and the component C is an ethylene copolymer formed through copolymerization of ethylene and alpha-alkene and has an average molecular weight greater than that of the component B; the composition has density of 0.935 to 0.945 g / cm<3> and MFR5.0 of 0.1 to 0.5 g / 10 min, and the content of comonomers is 0.2 to 0.7% by mol; each component has narrow molecular weight distribution, and Mw / Mn is equal to or less than 5. A pipe prepared from the polyethylene composition has excellent pressure resistance, and time to failure of the pipe is greater than 500 h when the pipe is tested both under the conditions of a temperature of 20 DEG C and circumferential stress of 13.9 MPa and under the conditions of a temperature of 80 DEG C and circumferential stress of 5.6 MPa.

Owner:PETROCHINA CO LTD

Polypropylene composite material for automotive instrument panel and preparation method for polypropylene composite material

The invention discloses a polypropylene composite material for an automotive instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material comprises the following components in percentage by weight: 45 to 80 percent of polypropylene, 10 to 30 percent of inorganic filler, 5 to 20 percent of toughening agent polyolefin elastomer (POE), 2 to 10 percent of polybutylene-1, 0.1 to 2 percent of antioxidant, 0.1 to 1 percent of light stabilizer, 0 to 3 percent of anti-scratch aid and 0 to 3 percent of the balance. The polypropylene composite material has excellent rigid-tough balance; the low-temperature notch strength is far higher than that of general polypropylene composite materials; the injection molding cycle is short; apparent defects such as tiger skin and the like are avoided on the surfaces of injection-molded sample pieces; and the characteristics efficiently meet the requirements of automotive instrument panels.

Owner:SHANGHAI PRET COMPOSITES

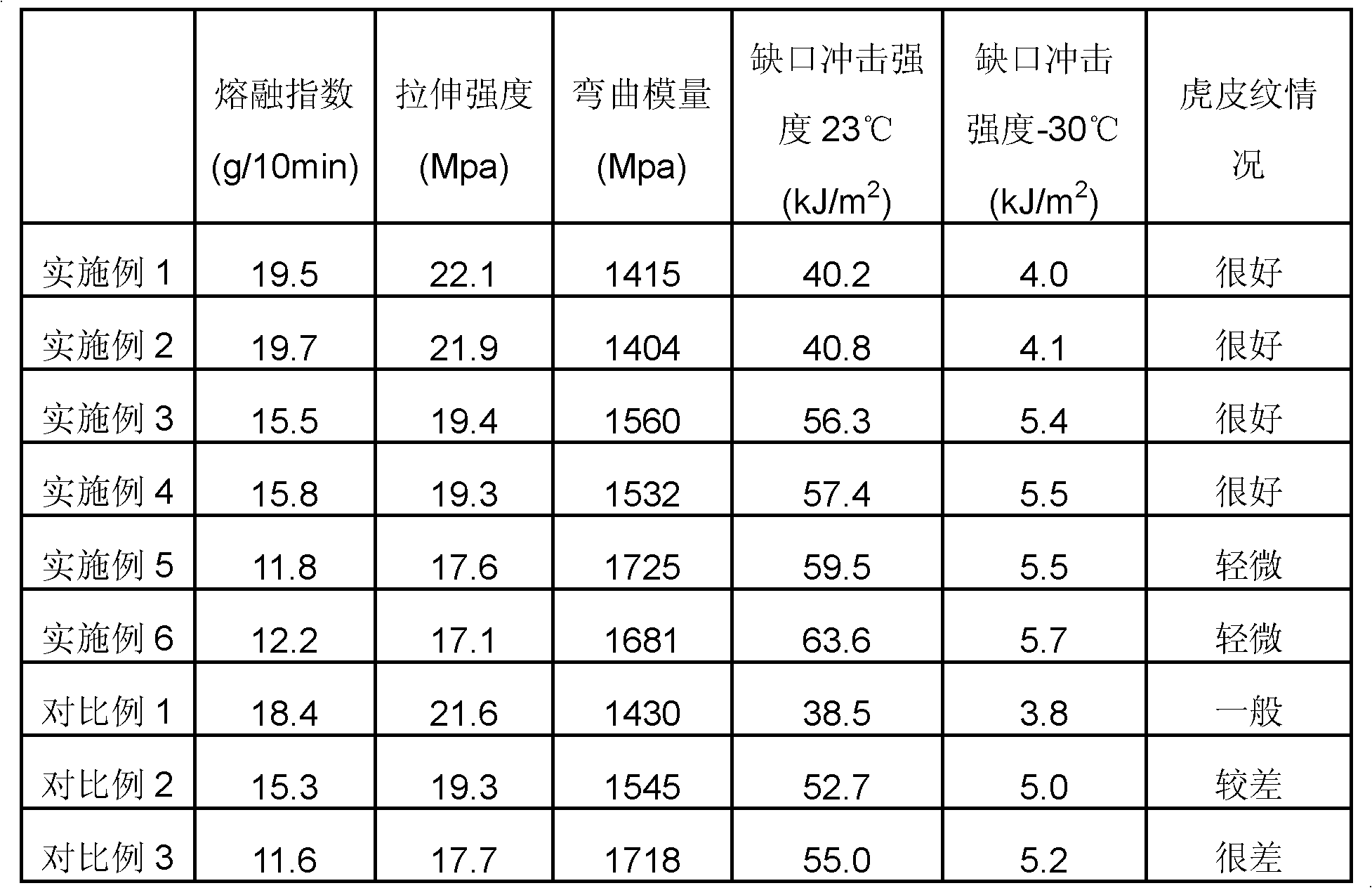

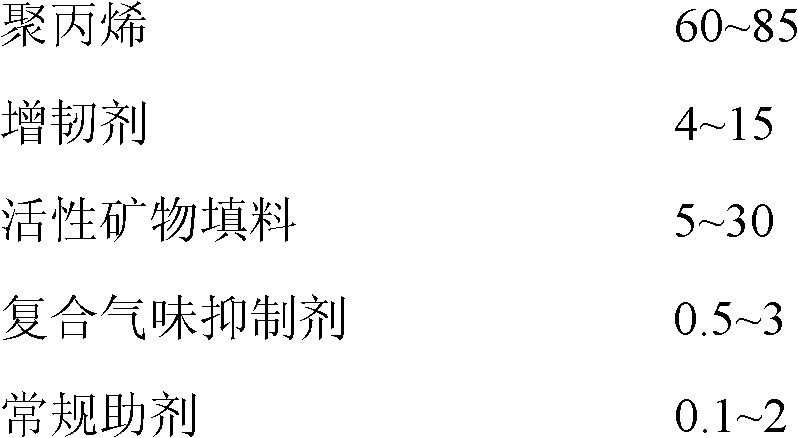

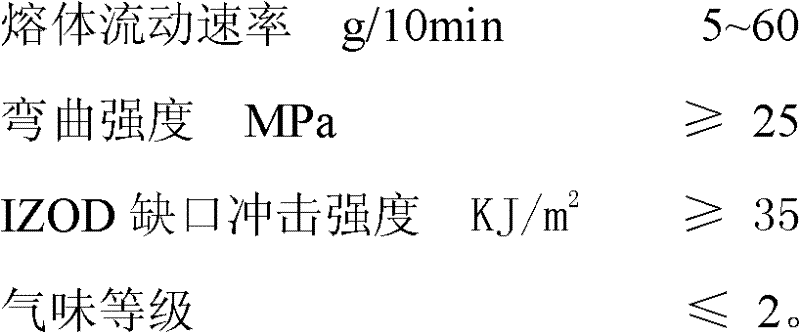

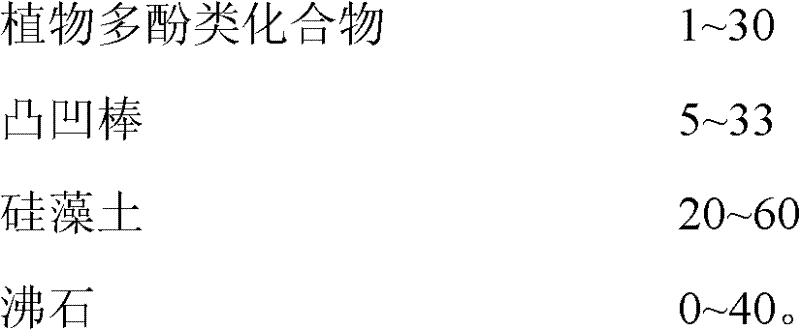

Low-smell rigid-tough high-performance polypropylene composite material and preparation method thereof

The invention is a low-smell rigid-tough high-performance polypropylene composite material and a preparation method thereof. The composite material of the invention belongs to a polypropylene composition without chemical post-processing. The composite material of the invention comprises the following raw materials by weight: 60-85 parts of polypropylene, 14-15 parts of toughening agents, 5-30 parts of active mineral fillers, 0.5-3 parts of composite smell inhibitors, and 0.1-2 parts of routine additives. By using low-smell rigid-tough balanced basic resin, through filling of wollastonite whiskers and compounding, matching and optimization of various smell adsorbents, the prepared polypropylene composite material has less smell and good balance between rigidity and toughness. Wollastonite whiskers are added in a mode of lateral feeding, which avoids the damage of the wollastonite long-needle shape caused by screw strong shearing, and thus the prepared polypropylene composite material not only has increased rigidity, but also has basically non-influenced toughness. The preparation process is simple, and the production cost is low. The composite material is suitable for the manufacturing of automobile bumpers, instrument panels, engine fans, washing machine inner drums, and refrigerator drawers.

Owner:CHINA PETROLEUM & CHEM CORP

Low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material and preparation method thereof

InactiveCN106366456AEvenly dispersedImprove interface compatibilityPolypropylene compositesPolymer science

The invention discloses a low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material and a preparation method thereof. The low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material comprises the following components in parts by weight: 80-90 parts of polypropylene, 5-8 parts of modifying montmorillonite, 4-10 parts of a compatilizer, 0.2-0.5 part of an antioxidant, 0.3-0.6 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material prepared by the preparation method provided by the invention, by a melting intercalation method, a polymer is inserted into spaces between montmorillonite layers and thus the montmorillonite is dispersed into the polymer in a layered structure, so that a similar fiber enhancement role can be played; in addition, a grafting reaction can also be performed on double bonds in a modifier and main chains of the polypropylene, the montmorillonite layers are splayed out by heat released during the grafting reaction, and through chemical bonding of grafts and polymer molecule, the montmorillonite layers are forcibly dispersed uniformly in the polymer matrix so as to form an intercalated nanocomposite material, so that the low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material has excellent mechanical properties, and thus the application range is widened.

Owner:ORINKO NEW MATERIAL CO LTD

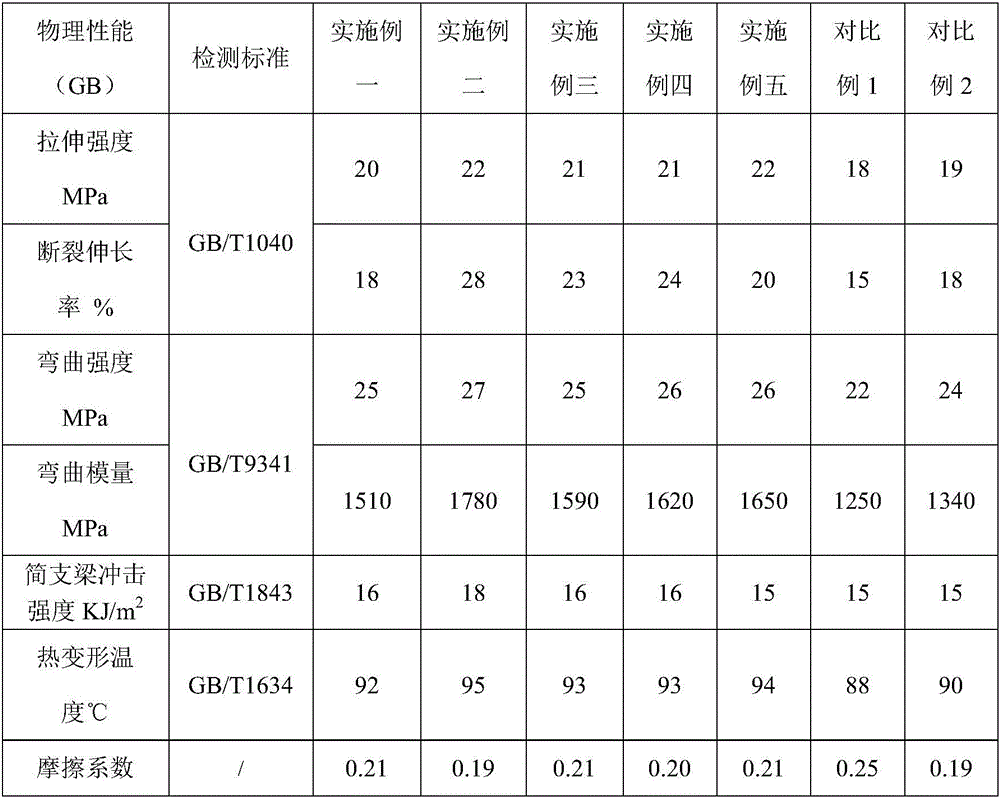

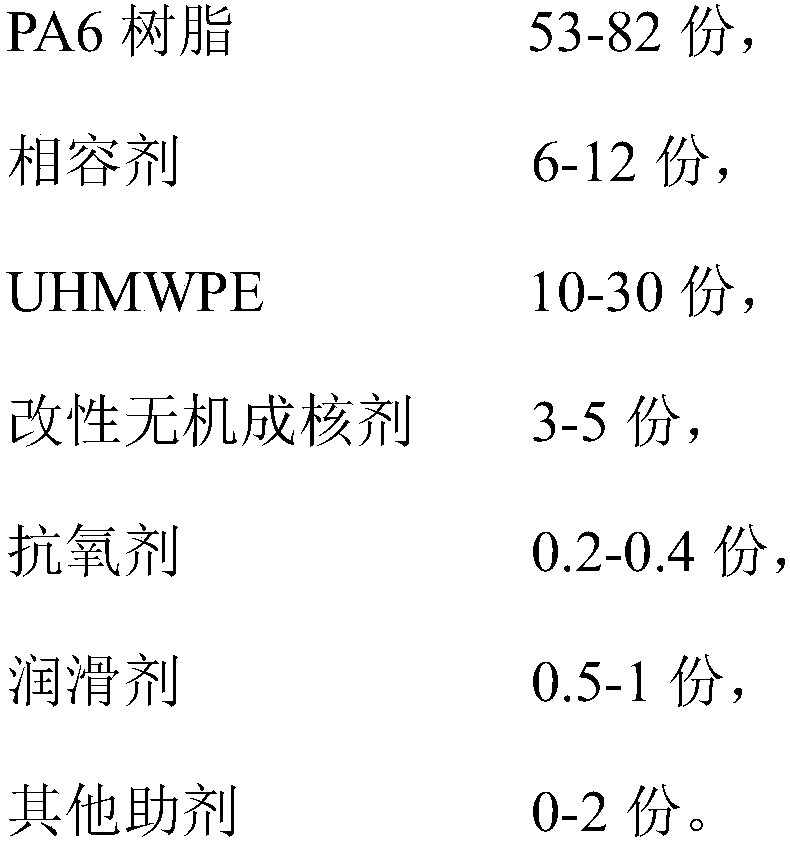

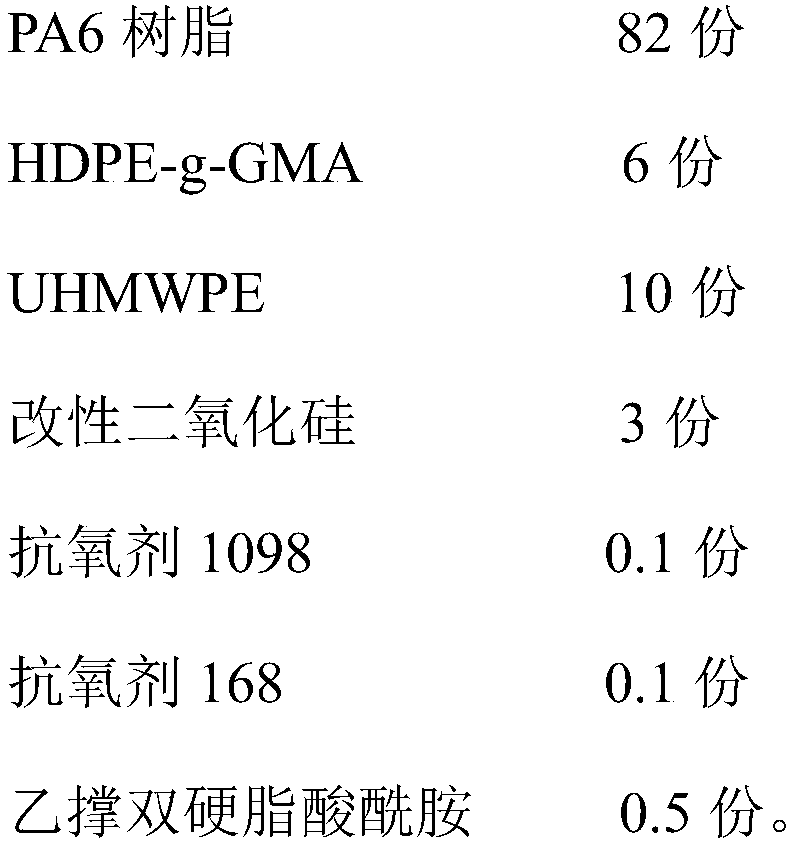

Light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene/nylon 6 micro-foaming composite material and preparation method thereof

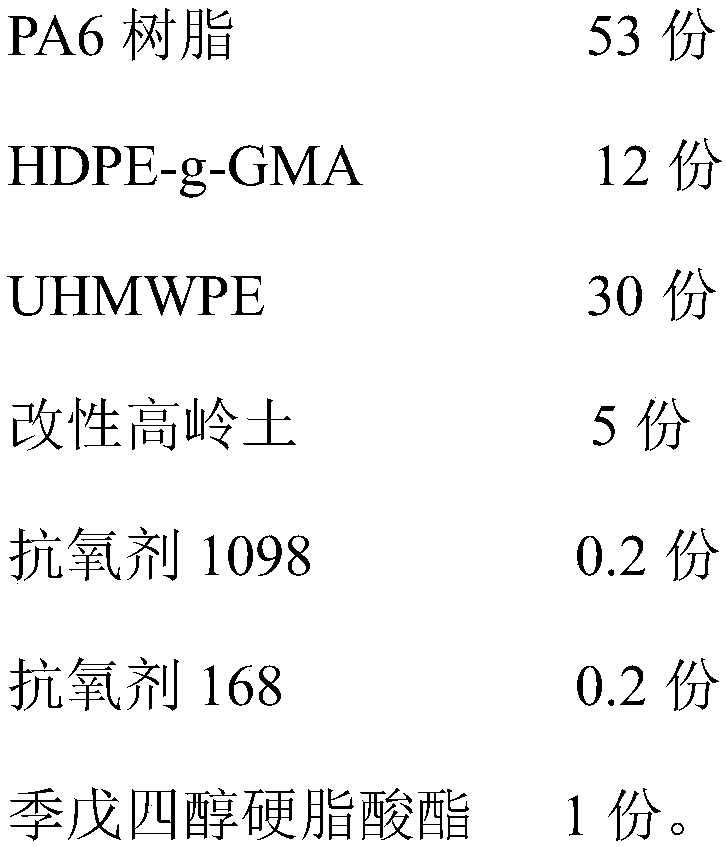

The invention discloses a light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene (UHMWPE) / nylon 6 micro-foaming composite material and a preparation method thereof. The composite material is prepared from 97 to 99 weight percent of a polyamide composite material and 1 to 3 weight percent of a chemical foaming agent, wherein the polyamide composite material is prepared from the following components in parts by weight: 53 to 82 parts of PA6 (Polyamide 6), 6 to 12 parts of a compatilizer, 10 to 30 parts of UHMWPE, 3 to 5 parts of a modified inorganicnucleating agent, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 2 parts of other auxiliary agents. According to the light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene / nylon 6 micro-foaming composite material, HDPE (High-density Polyethylene)-g-GMA (Glycidyl Methacrylate) is used as an interface bulking agent so that the interface binding force between the UHMWPE and the PA6 is enhanced, the impact strength of the PA6 is improved and the water absorption ratio of the PA6 is reduced; meanwhile, three-phase chain sections are mutually entwisted so that the melt strength of the PA6 is improved; the modified inorganic nucleating agent is subjected to chemical grafting modification through KH550 and GMA and the heterogeneous nucleation effect is remarkable; a dense bubble nucleation point is formed and the micro-foaming material with dense, fine and smooth bubble pores is obtained; the material has the characteristics of light weight, high impact strength, low water absorption ratio, high wear resistance and the like; foaming is realized through direct injection molding and a technology is simple; the material is widely applied to a lightweight technology of automobiles, household appliances, electronics and electrical appliances and the like.

Owner:ORINKO NEW MATERIAL CO LTD

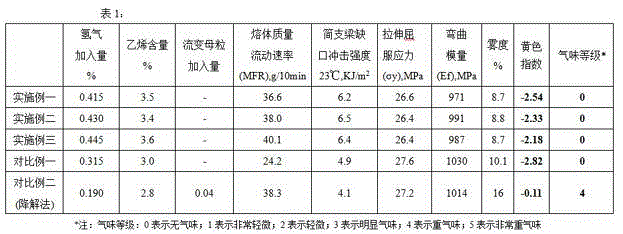

High-flow high-impact transparent polypropylene material produced by adopting hydrogen regulation method and method of high-flow high-impact transparent polypropylene material

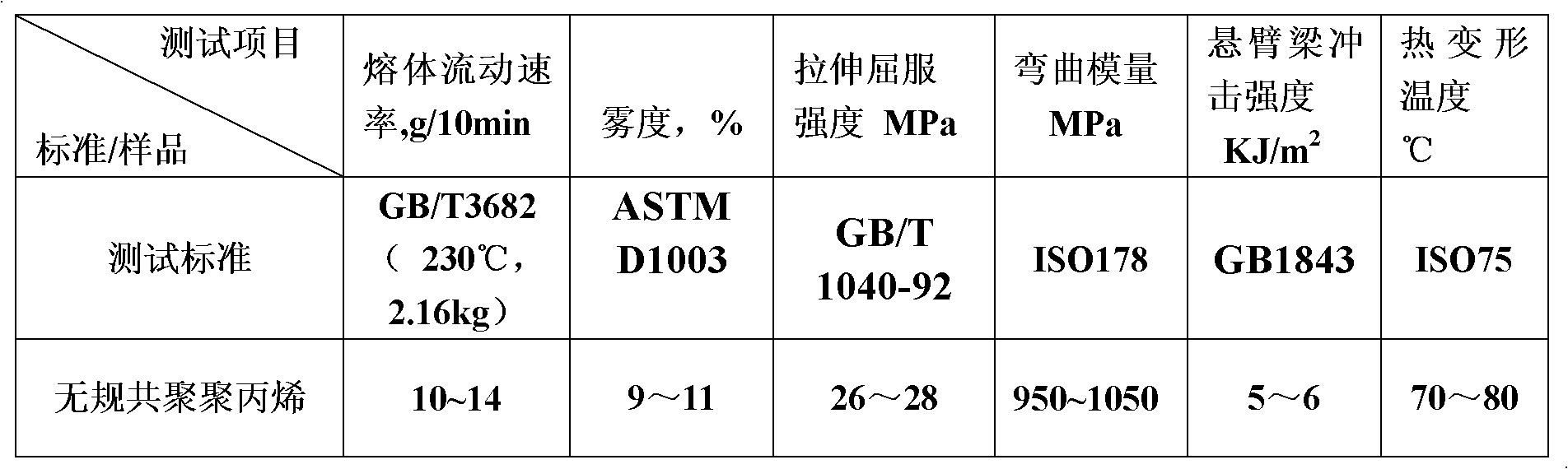

The invention discloses a high-flow high-impact transparent polypropylene material produced by adopting a hydrogen regulation method. The ethylene content is 3.0-4.0%, the melt flow rate is larger than or equal to 35g / 10min, the haze is less than 9%, and the notch impact strength of a simply supported beam is 6.0-6.5KJ / m<2>. The invention also discloses a method for producing the high-flow high-impact transparent polypropylene material by adopting the hydrogen regulation method. The polypropylene material is high in transparency, good in glossiness, non-yellowed, odor-free and good in impact and can be used for replacing high-flow high-impact transparent polypropylene produced by a degradation method.

Owner:CHINA PETROLEUM & CHEM CORP

Polypropylene composite material capable of realizing light weight and with low linear expansion coefficient and preparation method thereof

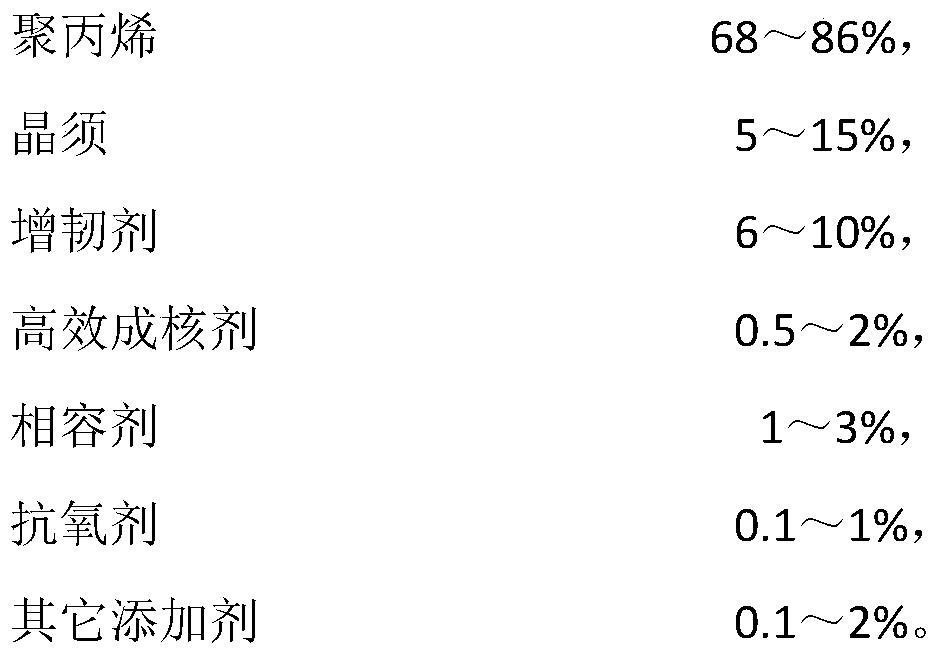

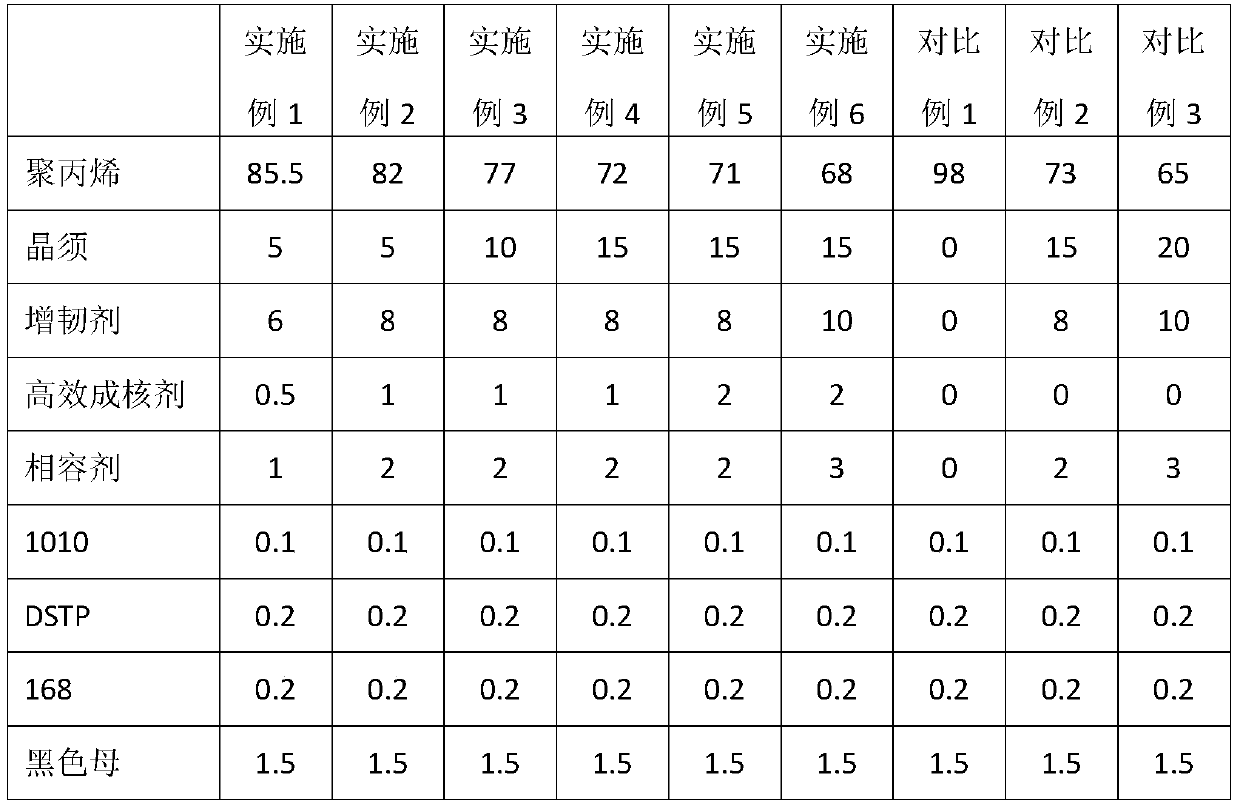

InactiveCN105504528ALow coefficient of linear expansionGood toughness balanceAntioxidantLinear expansion coefficient

The invention discloses a polypropylene composite material capable of realizing light weight and with low linear expansion coefficient and a preparation method thereof. The polypropylene composite material consists of the following raw materials in percentage by weight: 68-86% of polypropylene, 5-15% of whiskers, 6-10% of flexibilizer, 0.5-2% of efficient nucleating agent, 1-3% of compatilizer, 0.1-1% of antioxidant and 0.1-2% of other additives. In the invention, by adding the efficient nucleating agent and a few whiskers, the linear expansion coefficient of the polypropylene material can be effectively reduced while the material is endowed with the isotropy character in the case of relatively low density of the composite material. The polypropylene composite material disclosed by the invention has excellent rigid-rough balance and can be widely applied to the fields such as automobile interior and exterior trim to realize light weight.

Owner:SHANGHAI PRET COMPOSITES

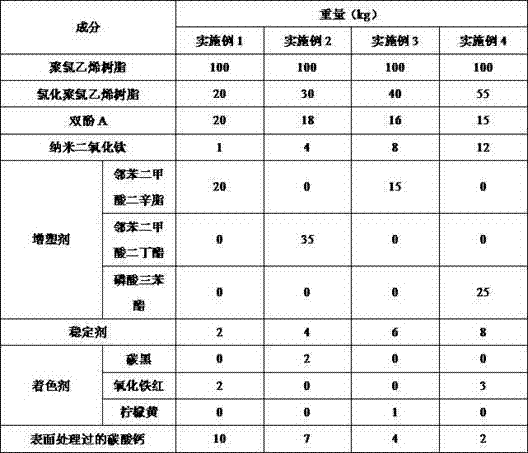

High-strength and high-stability modified PVC and preparation method thereof

The invention discloses high-strength and high-stability modified PVC (polyvinyl chloride) which comprises the following components in parts by weight: 100 parts of PVC resin, 20-55 parts of CPVC (chlorinated polyvinyl chloride) resin, 15-20 parts of phenolic antioxidant, 1-12 parts of titanium dioxide, 15-35 parts of plasticizer, 2-8 parts of stabilizer, 0-3 parts of colorant, and 2-10 parts of filling. The high-strength and high-stability modified PVC has the benefits that: the modified PVC has good mechanical property, high strength, good balance of stiffness and toughness, heat resistance, light resistance, corrosion resistance, and high stability; the service life of a product is ensured; in addition, the preparation method is good in repeatability; the process is controllable; the manufacturing cost is low; and the industrial large-scale application is facilitated.

Owner:SUZHOU SUNWAY POLYMER

Modified polypropylene material with high adhesion and preparation method thereof

The invention discloses a modified polypropylene material with high adhesion. The polypropylene material comprises the following raw materials in parts by weight: 60-80 parts of polypropylene resin, 10-30 parts of modified inorganic fillers, 4-8 parts of functional resin, 1-2 parts of epoxy resin, 0.5-1 part of a functional agent, 0.1-0.3 part of a nucleating agent, 0.1-1.0 part of an antioxidant and 0.1-1.0 part of a processing agent. In the modified polypropylene material, universal polypropylene is used as a basic material, so that the polarity of the polypropylene material is greatly improved by adopting a manner of adding the specific functional resin, epoxy resin, a functional agent and modified inorganic fillers and adjusting the ratio of the raw materials, therefore, the material has excellent surface adhesion and can be directly sprayed.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Low-density low-shrinkage high-gloss polypropylene compound as well as preparation method and product thereof

PendingCN114106456ALow densityLow Density Low Shrinkage High GlossPolypropylene compositesAntioxidant

The invention provides a low-density low-shrinkage high-gloss polypropylene compound as well as a preparation method and a product thereof. The compound is prepared from the following components in parts by weight: 14 to 40 percent of homo-polypropylene, 15 to 40 percent of block co-polypropylene, 10 to 35 percent of toughening agent, 5 to 45 percent of inorganic filler, 0.05 to 0.5 percent of nucleating agent, 0.1 to 0.5 percent of coupling agent and 0.1 to 0.4 percent of antioxidant. According to the polypropylene composite, through the toughening agent, the shrinkage of the product can be greatly reduced, the density is lower, the shrinkage rate of the polypropylene composite material can be reduced to be close to that of ABS resin by only adding a very small amount of inorganic filler, and meanwhile, very high glossiness and relatively low density are maintained. The low-density low-shrinkage high-gloss polypropylene compound can be used for manufacturing various plastic products, and is particularly suitable for manufacturing products such as automobile plastic products or household appliance shells.

Owner:浙江兴越材料技术有限公司

High-yield-strain low-temperature-impact-resistant talcum powder filled polypropylene material and preparation method thereof

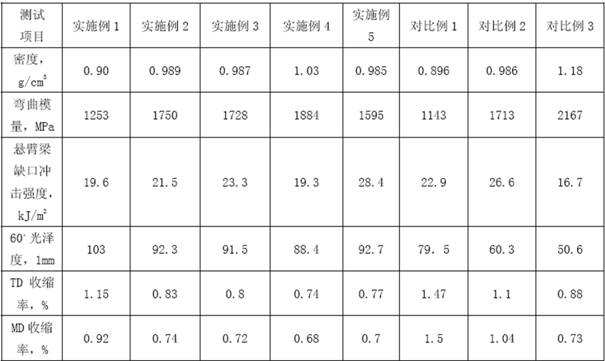

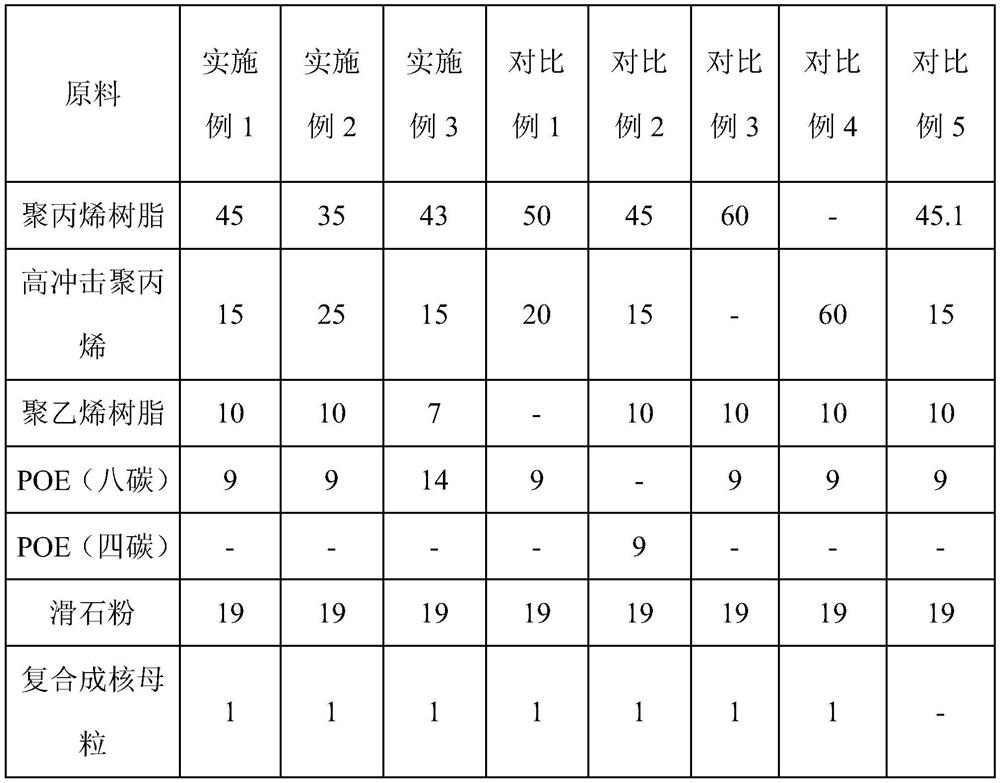

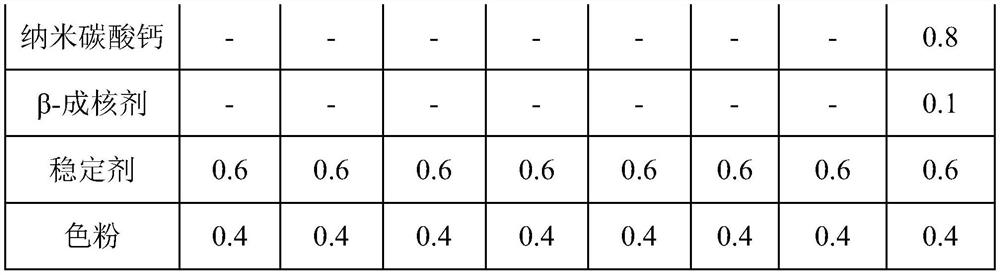

The invention provides a high-yield-strain low-temperature-impact-resistant talcum powder filled polypropylene material. The material is prepared from the following raw materials in parts by weight: 45-85 parts of polypropylene resin, 6-15 parts of polyethylene resin, 6-20 parts of polyolefin elastomer (POE), 3-25 parts of talcum powder, 0.5-2 parts of composite nucleating master batch, 0.2-2 parts of a stabilizer and 0.5-2 parts of a toner. The composite nucleating master batch is a compound of nano calcium carbonate, polypropylene resin and a beta-nucleating agent, and comprises 75 to 80 parts of nano calcium carbonate, 8 to 12 parts of polypropylene resin and 5 to 10 parts of beta-nucleating agent. The talcum powder filled polypropylene material with high yield strain and low-temperature impact resistance has high ductility and yield resistance, the yield elongation can reach 10% or above, meanwhile, the polypropylene material has excellent low-temperature toughness, and the low-temperature notch impact strength is larger than 3.5 KJ / m < 2 >.

Owner:TIANJIN KINGFA NEW MATERIAL

Polyethylene base resin powder and preparation method thereof

The invention relates to a polyethylene base resin powder for preparing an IBC barrel special material and a preparation method thereof. Polyethylene base resin is produced by a gas phase polyethylene process, the polymerization temperature is 96 DEG C-120 DEG C, and the polymerization pressure is 0.85-2.5 MPa. The prepared base resin powder is generated by copolymerization of ethylene and long-chain alpha-olefin, the weight-average molecular weight is 200-350 thousand, the molecular weight distribution index is 7-15, the alpha-olefin content is 0.5-1.5%, the melt flow rate is 5-8 g / 10 min, the density is 0.942-0.952 g / cm<3>, the low temperature impact strength (-30 DEG C) is more than 30 kJ / m<2>, and the melt strength is more than 15 cN. The special material is guaranteed to have high mechanical strength, good processing performance and high melt strength, can be guaranteed to have good antisagging property, and can meet various properties of the IBC barrel special material.

Owner:PETROCHINA CO LTD

Full biodegradable mulch material for crops in irrigated area and preparation method and application of full biodegradable mulch material

InactiveCN110105727AGood mouthSimple process conditionsClimate change adaptationPlant protective coveringsPolymer scienceZinc compounds

The invention relates to a full biodegradable mulch material for crops in an irrigated area and a preparation method and application of the full biodegradable mulch material. The material is preparedfrom poly terephthalic acid-adipic acid-butyl glycol ester, polyethylene furandicarboxylate ester, an aliphatic carboxylic acid zinc compound, a compatibilizer, a filler, an antioxidant and an ultraviolet absorber. The full biodegradable mulch film material has the advantages that PEF with stronger rigidity is used for performing rigidity enhancement and modification on PBAT under the action of the compatibilizer, thereby improving the rigidity of the PBAT and improving the rigidity and toughness balance of the PBAT. In addition, after the aliphatic carboxylic acid zinc compound is added, thephenomenon disappears that modified materials of PBAT and PEF adhere to equipment during membrane blowing processing, the blow-molded mulch has good opening performance, the mechanical properties of the modified material are not affected, and the cost can be greatly reduced through the cooperative use of the inorganic filler; the full biodegradable mulch material has simple processing conditions,excellent mechanical properties, low cost and a good development prospect.

Owner:LANZHOU XINYINHUAN RUBBER & PLASTIC PROD CO LTD

Modified polypropylene recycled material and preparation method thereof

The invention provides a modified polypropylene recycled material and a preparation method of the modified polypropylene recycled material. 30 to 75 parts of polypropylene recycled materials, 10 to 30 parts of polypropylene, 5 to 15 parts of polypropylene grafted acrylic acid, 10 to 25 parts of alkali-free glass fibers, 0.2 to 1 part of an antioxidant, and 0.5 to 2 parts of 2,5-dimethyl-2,5-bis(tert butyl peroxy) hexane are mixed, and subjected to extrusion pelletization to manufacture the modified polypropylene recycled material. According to the invention, the polypropylene grafted acrylic acid is added in the polypropylene recycled materials to introduce strong polar reactive groups, so that the material has high polarity and reactivity, and the compatibility of the polypropylene and fibers are greatly improved; furthermore, 2,5-dimethyl-2,5-bis(tert butyl peroxy) hexane is combined to improve the strength, cohesion and dispersion properties of the material, therefore, the modified polypropylene recycled material has good dispersion and compatibility and excellent rigid-tough balance.

Owner:HEFEI GENIUS NEW MATERIALS

Inorganic nanomaterial toughened HDPE (high-density polyethylene) double-wall corrugated pipe composite masterbatch and preparation method thereof

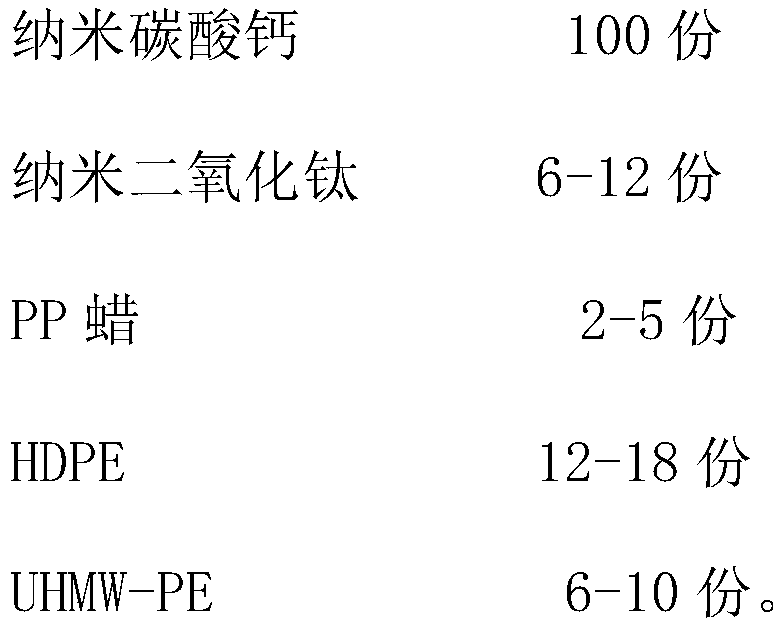

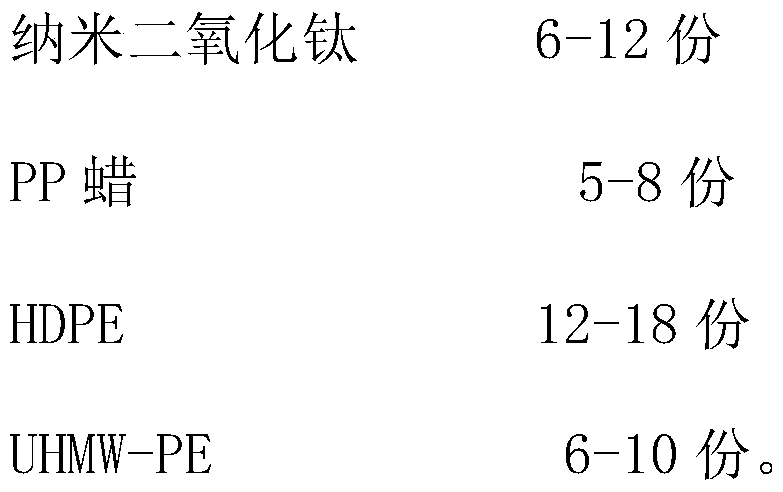

The invention provides an inorganic nanomaterial toughened HDPE (high-density polyethylene) double-wall corrugated pipe composite masterbatch and a preparation method thereof. The masterbatch comprises 100 parts of nano calcium carbonate, 6-12 parts of nano titanium dioxide, 5-8 parts of PP (polypropylene) wax, 12-18 parts of HDPE and 6-10 parts of UHMW-PE6 (ultrahigh molecular weight polyethylene-polyethylene 6). According to the technical scheme, preheating drying is implemented, the nano calcium carbonate and rutile nano titanium dioxide are too large in specific surface areas, and thus powder artesian change can be caused. Maleic anhydride grafted HDPE and UHMW-PE are wrapped by nano powder, and preheating drying is a mode of technical innovation of nano calcium carbonate and rutile nanometer titanium dioxide. A conventional mechanical mode that external heat or friction heat of a stirrer and an internal mixer is conducted through convection or conduction, the time is long, the energy consumption is high,, the yield is low, and serious dust pollution can be caused. Most importantly, material moisture cannot be completely dried out, material heat is not uniform, and a material can be coked inside and unripe inside. By adopting the masterbatch, techniques of toughening and rigidity reduction of organic materials are effectively solved, the cost can be reduced, and materials are all localized.

Owner:浙江德清金科塑胶材料有限公司

High-strength high-tenacity high-conductivity graphene membrane and preparation method thereof

The invention relates to the technical field of fine chemical engineering, in particular to a high-strength high-tenacity high-conductivity graphene membrane and a preparation method thereof. The method comprises the following steps: mixing a few rare earth metal ions, macromolecules and graphene oxide to prepare uniform hydrosol, pouring, air drying and membrane forming, and then enabling the hydrosol to be successively subjected to the steps of reduction, cleaning and drying to obtain the graphene membrane. Three interactions are simultaneously constructed, comprising a coordinate bond between the graphene oxide and rare earth ions, a hydrogen bond between the graphene oxide and the macromolecules and pi-pi action between the graphene oxide and the macromolecules, so that the prepared modified graphene membrane has high strength, high tenacity and excellent conductivity simultaneously. According to the method, the raw materials are cheap, the operation is simple, and the method is suitable for large-scale production and has a good industrial production foundation and a broad application prospect.

Owner:FUDAN UNIV

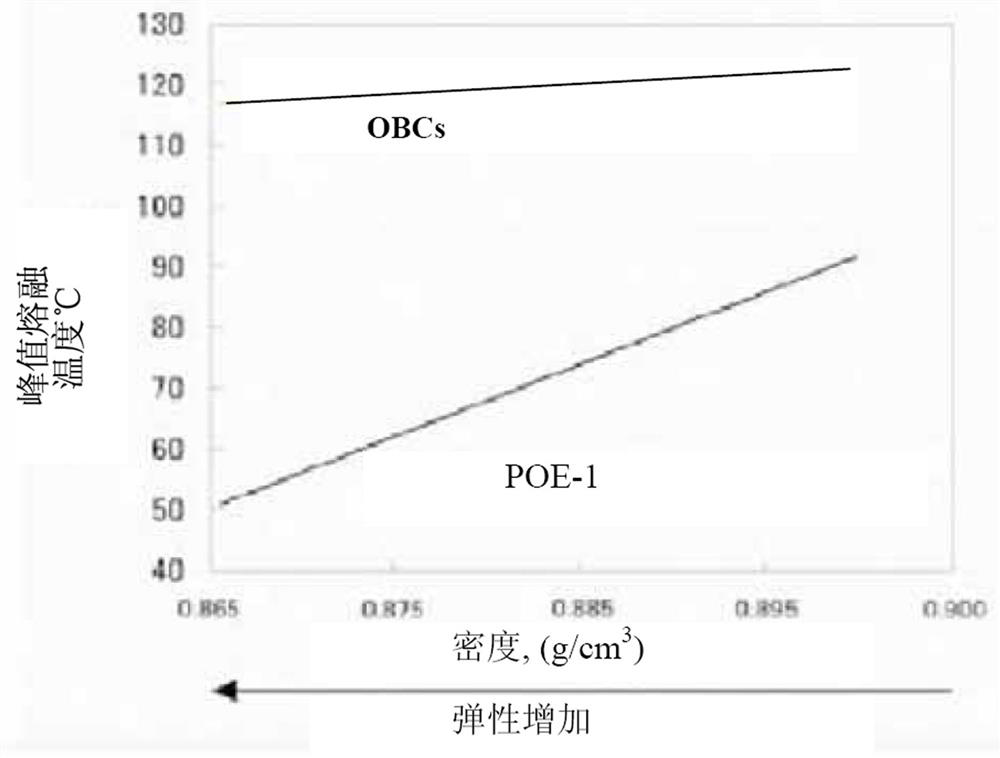

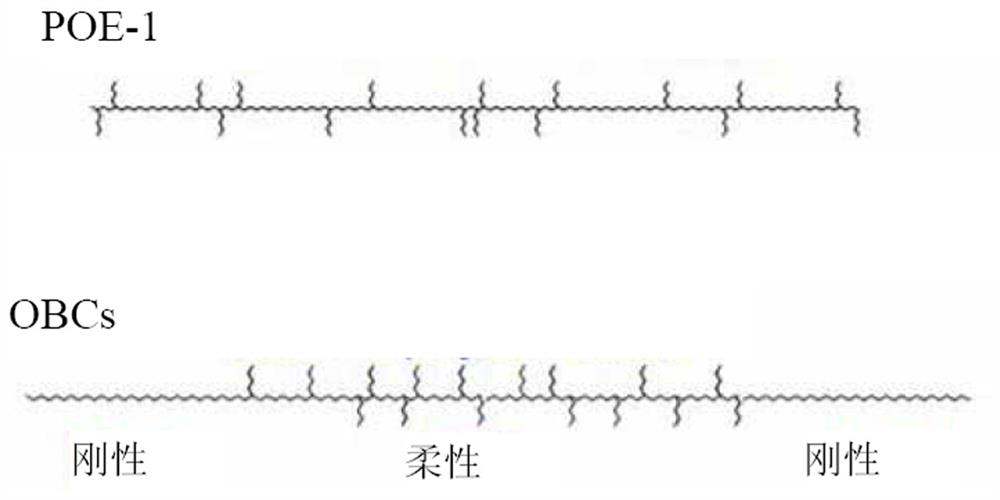

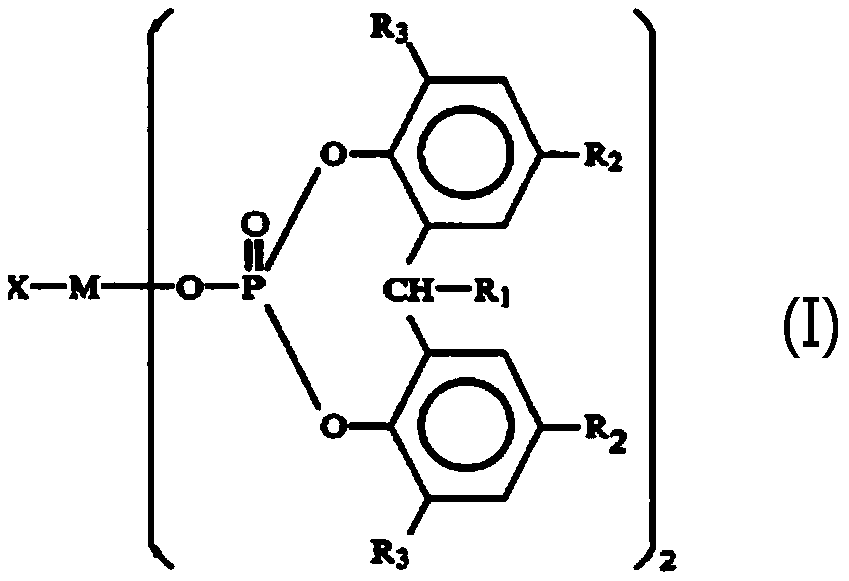

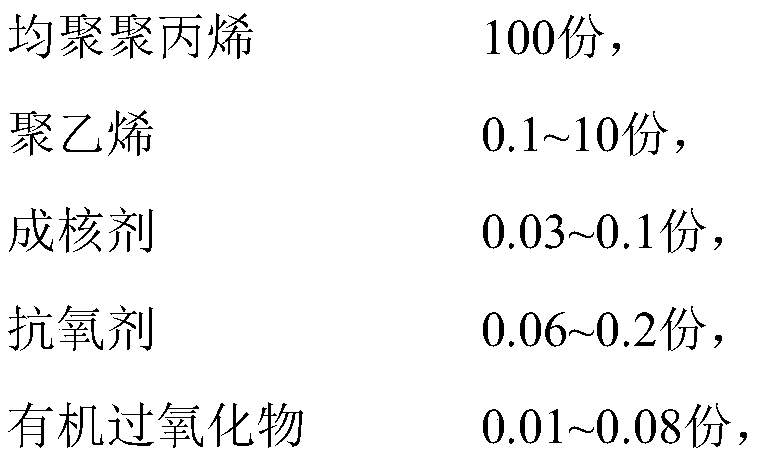

Toughening polypropylene material and preparation method thereof

ActiveCN109851913ALower crystallization temperature and longer crystallization timeIncrease production costPolypropyleneCrystallite

The invention discloses a toughening polypropylene material, comprising the following components in parts by weight: 100 parts of homo-polypropylene, 0.1-10 parts of polyethylene, 0.05-0.2 part of nucleating agent, 0.04-0.3 part of antioxygen, and 0.01-0.04 part of organic peroxide. The invention also discloses a preparation method of the toughening polypropylene material, and the preparation method includes the following steps: adding homo-polypropylene, polyethylene, a nucleating agent, an antioxygen and an organic peroxide into a high speed mixer for mixing, and conducting melting blendingextruding pelletizing on the uniformly mixed premix by a twin screw extruder, so as to obtain the final product. According to the invention, a low proportion of polyethylene is added into the formulacomponents and is used as a toughening agent of polypropylene, thereby realizing impact modification of polypropylene, refining grain size of polypropylene crystal, increasing impact resistance of thepolypropylene material, enhancing low-temperature resistance, and decreasing the melting point of the polypropylene material, decreasing the processing temperature and correspondingly reducing energyconsumption.

Owner:东华能源(宁波)新材料有限公司 +2

Edible oil high-temperature swelling-resistant modified polypropylene material applied to household appliances and preparation method thereof

InactiveCN106633397AChange the surface microstructureImprove surface crystallinityHigh resistanceProcedure Agents

The invention relates to the field of high-molecular materials and discloses an edible oil high-temperature swelling-resistant modified polypropylene material applied to household appliances. The modified polypropylene material comprises the following components in parts by weight: 50-70 parts of polypropylene resin, 15-30 parts of swelling-resistant modified masterbatch, 7-15 parts of inorganic filler, 3-8 parts of a compatilizer, 0.1-0.3 part of a nucleating agent, 0.1-1.0 part of an antioxidant and 0.1-1.0 part of a processing aid. The invention also discloses a preparation method of the edible oil high-temperature swelling-resistant modified polypropylene material applied to the household appliances. The method comprises the following steps: uniformly mixing the polypropylene resin, the swelling-resistant modified masterbatch and the compatilizer, then adding the nucleating agent, the antioxidant and the processing aid, then continuing to stir, then adding the inorganic filler, uniformly stirring, finally adding the mixed materials in an extruder for extruding and granulating to obtain the polypropylene material. The polypropylene material prepared by the invention has high resistance to edible oil high-temperature swelling, high gloss, good scratch resistance, good heat resistance and good rigid-tough balance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Building template material and preparation method thereof

The invention discloses a building template material. The building template material is prepared from the following components in parts by weight: 100 parts of fiberglass reinforced diamantine polyamide grafted polyolefin resin, 1 to 3 parts of a toughening agent and 1 to 3 parts of an antioxidant. A preparation method of the material collection tank comprises the following steps: adding all components in a high-speed mixer for uniformly mixing after weighing the components in proportions, feeding the mixed materials into a double-screw extruder through a feeder in accurate metering, carryingout high-speed shearing and mixing by double screws, and carrying out extruding, bracing, air-cooling, sized dicing, drying and packaging by a machine head, thus obtaining the building template material. The building template material disclosed by the invention is higher in strength, higher in toughness, excellent in ultraviolet aging resistance and flame resistance and easy in machining shaping.

Owner:青州市第一建筑工程有限公司

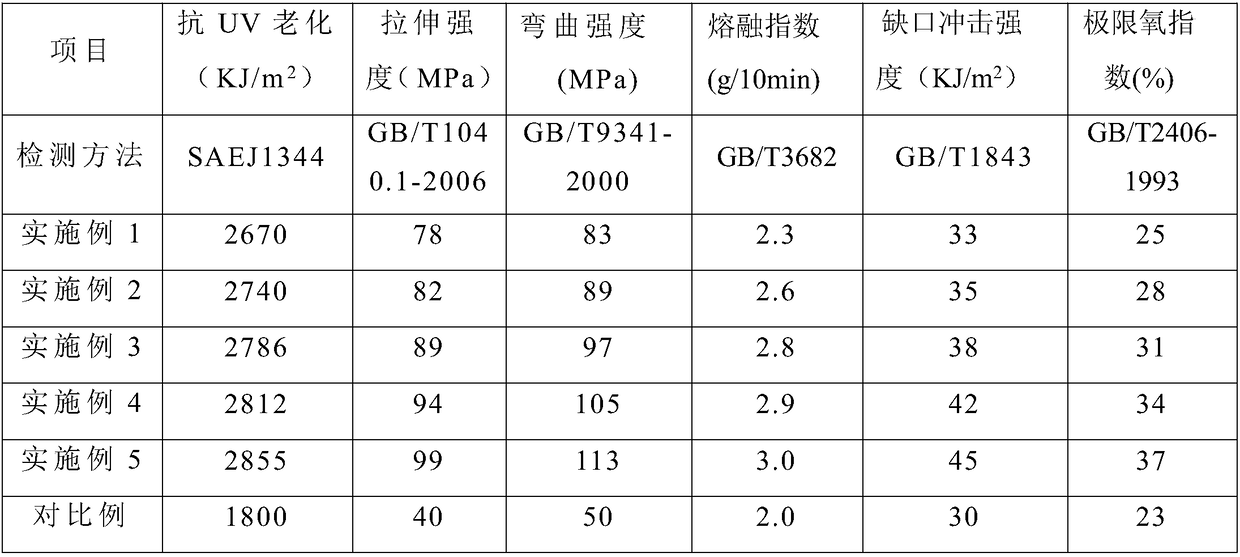

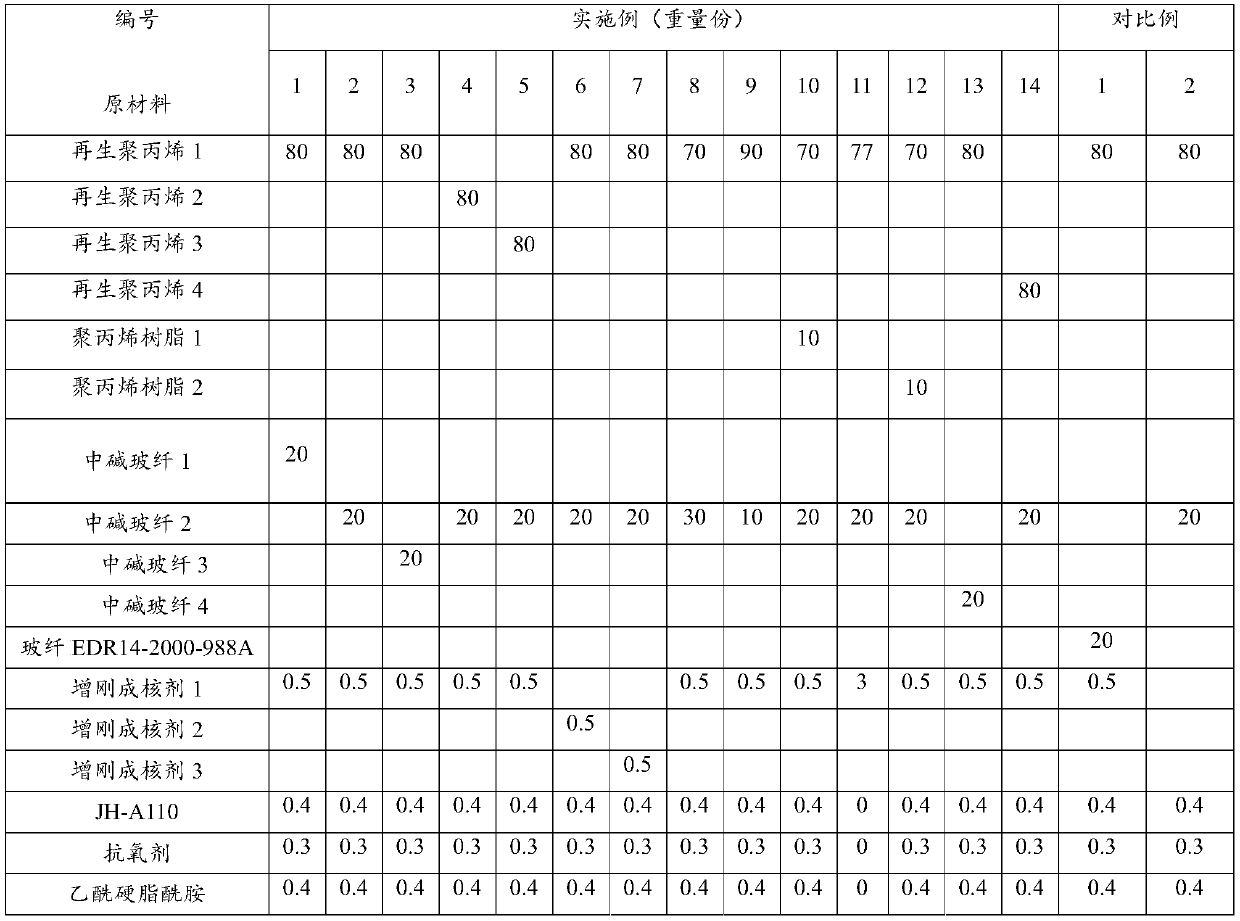

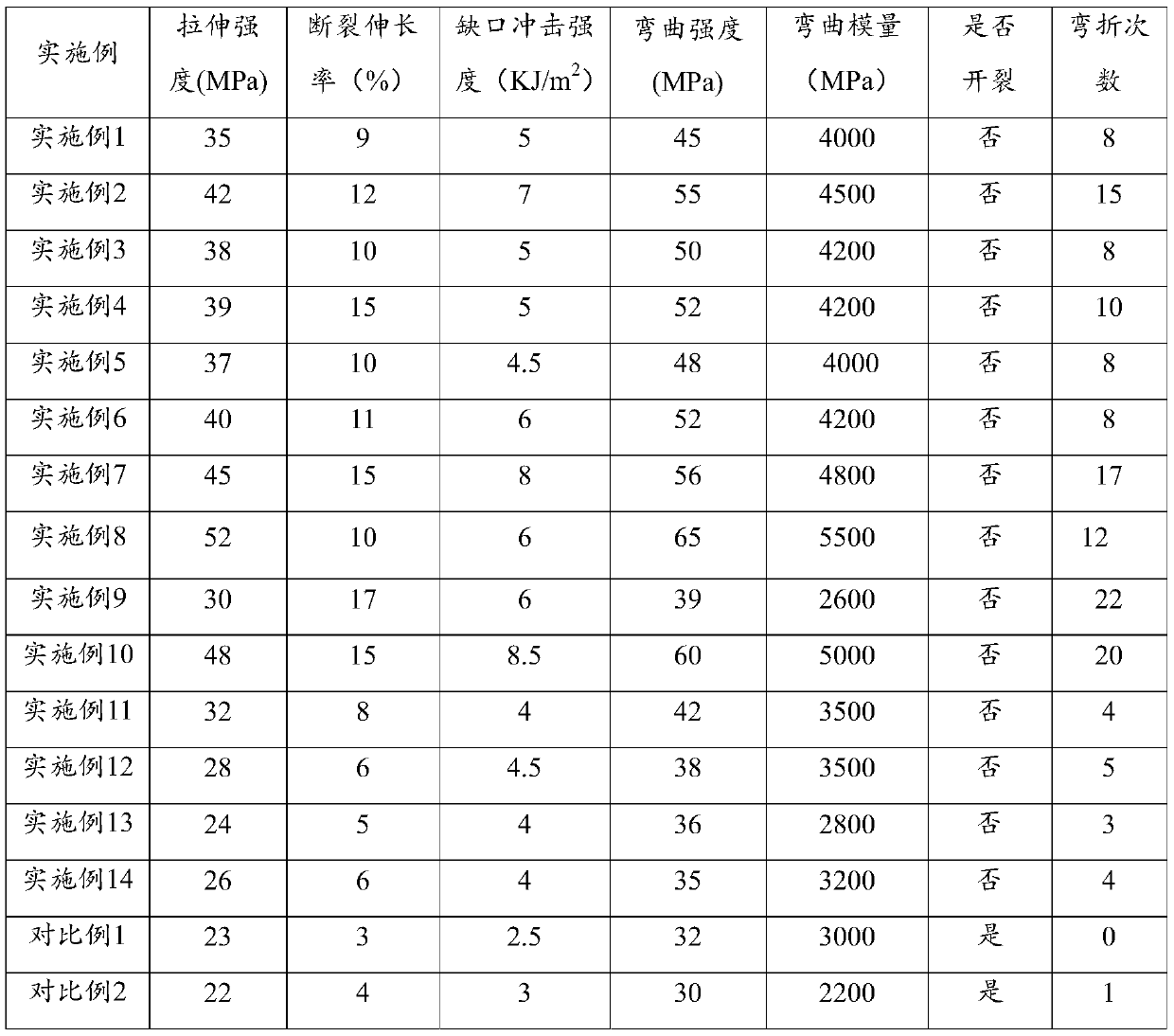

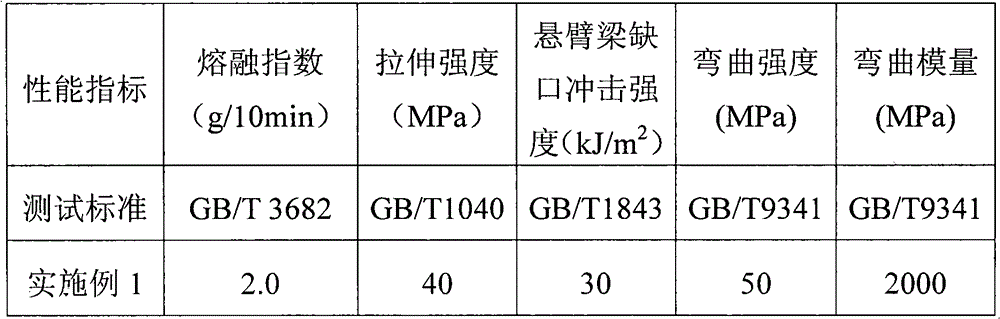

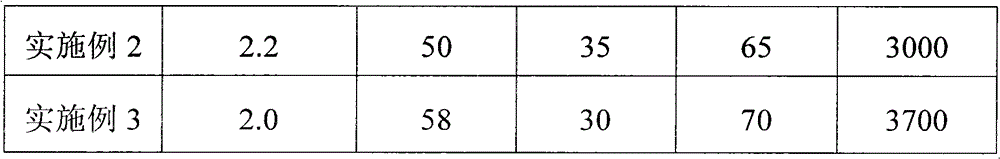

Medium-alkali glass fiber reinforced regenerated polypropylene composite material as well as preparation method and application thereof

ActiveCN111004443AGood toughness balanceImprove toughnessPlastic recyclingPolypropylene compositesGlass fiber

The invention discloses a medium-alkali glass fiber reinforced regenerated polypropylene composite material, which comprises the following components in parts by weight: 70-90 parts of polypropylene,10-30 parts of medium-alkali glass fibers and 0.5-3 parts of a stiffening nucleating agent. According to the invention, the regenerated polypropylene material is synergistically modified by the medium-alkali glass fiber with good toughness and low cost and the stiffening nucleating agent, and the prepared glass fiber reinforced regenerated polypropylene material has an excellent rigidity-toughnessbalanced performance, and can be used in reinforcing material parts needing nailing and bending. Meanwhile, the invention further discloses a preparation method and application of the medium-alkali glass fiber reinforced regenerated polypropylene composite material.

Owner:GUANGDONG KINGFA TECH CO LTD +1

Polyolefin wood-plastic composite material and preparation method thereof

The invention discloses a polyolefin wood-plastic composite material and a preparation method thereof. The polyolefin wood-plastic composite material is prepared from polyolefin resin, a coupling agent, a compatilizer, a lubricating agent, wood powder and inorganic filler, wherein the polyolefin resin comprises an impact propylene copolymer and polyethylene; the polyethylene is high-density polyethylene; the polyolefin resin accounts for 30 to 70 weight percent of the polyolefin wood-plastic composite material. The preparation method comprises the following steps: preparing or presetting the polyolefin resin, the coupling agent, the compatilizer, the lubricating agent, the wood powder and the inorganic filler according to a set proportion; drying the wood powder and the inorganic filler; mixing the wood powder and the inorganic filler with the impact propylene copolymer, the high-density polyethylene, the coupling agent, the compatilizer and the lubricating agent in a high-speed mixer to obtain a mixture, and adding the mixture into an extruder for extrusion granulation or product molding.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

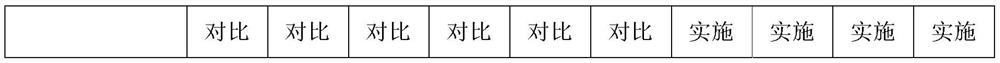

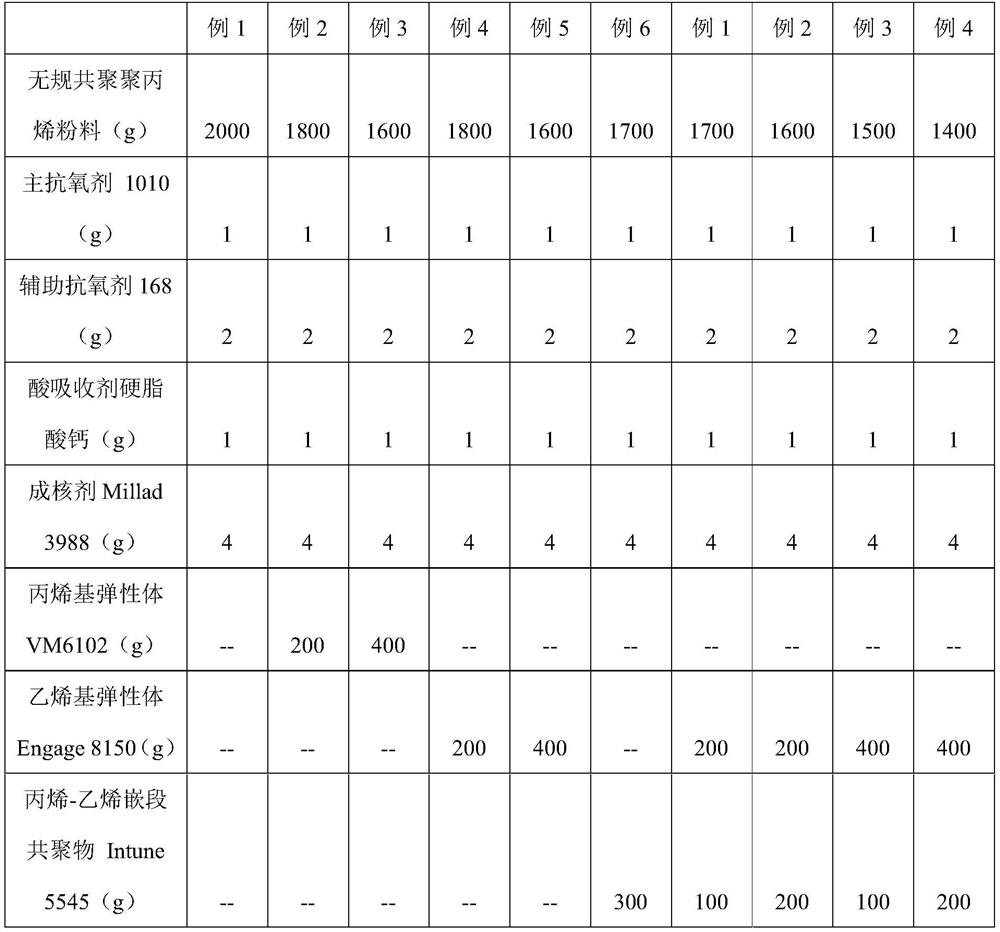

Impact-resistant, low-temperature-resistant and high-transparency polypropylene composition

The invention discloses an impact-resistant, low-temperature-resistant and high-transparency polypropylene composition which comprises the following components in parts by weight: 100 parts of polypropylene random copolymer, 0.001-0.2 parts of a main antioxidant, 0.001-0.2 parts of an auxiliary antioxidant, 0.001-0.2 parts of a nucleating agent, 0.001-0.2 parts of an acid absorbent, 3-20 parts ofpolypropylene- ethylene / propylene block copolymer and 3-40 parts of a vinyl elastomer. The polypropylene composition disclosed by the invention has the characteristics of excellent rigidity and toughness balance, high transparency, excellent low-temperature toughness and the like, overcomes the defects of low rigidity, poor low-temperature toughness and the like of the current transparent polypropylene, and can enable the high-transparency polypropylene to meet the use requirements of an environment with the temperature of -20 DEG C or below.

Owner:茂名骐锋新材料有限公司 +1

Alkali-free glass fiber modified polypropylene recycling material and preparation method of alkali-free glass fiber modified polypropylene recycling material

The invention provides an alkali-free glass fiber modified polypropylene recycling material and a preparation method of the alkali-free glass fiber modified polypropylene recycling material. The alkali-free glass fiber modified polypropylene recycling material is prepared from the following components by mixing, extruding and granulating: 30 to 75 parts of a polypropylene recycling material, 10 to 30 parts of polypropylene, 5 to 15 parts of polypropylene grafted maleic anhydride, 10 to 25 parts of alkali-free glass fiber, 0.2 to 1 part of an antioxygen and 0.5 to 2 parts of 2,5-dimethyl-2,5-bi(tert-butylperoxy)hexane. According to the alkali-free glass fiber modified polypropylene recycling material, the polypropylene grafted maleic anhydride is added into the polypropylene recycling material to introduce a strong-polarity reactive group, so that the material has high polarity and reactivity, and the compatibility of the polypropylene and the fibers is extremely improved; meanwhile, the 2,5-dimethyl-2,5-bi(tert-butylperoxy)hexane is combined so that the strength, adhesive force and dispersion performance of the material are improved; good dispersity, compatibility and excellent rigid-tough balance are obtained.

Owner:HEFEI GENIUS NEW MATERIALS

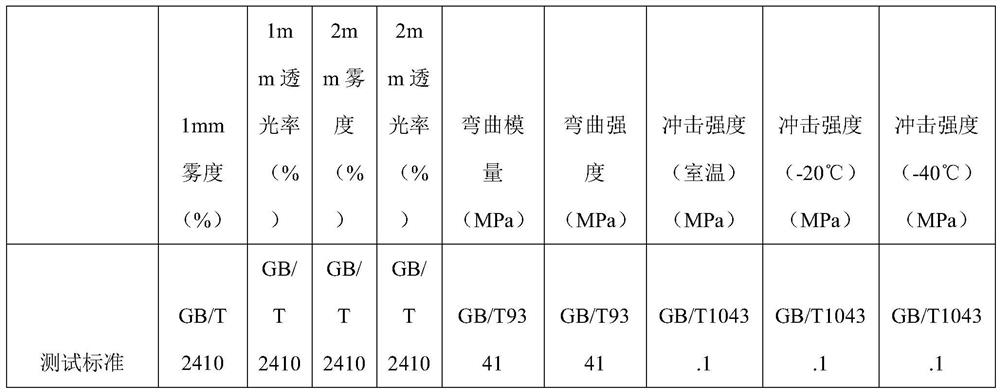

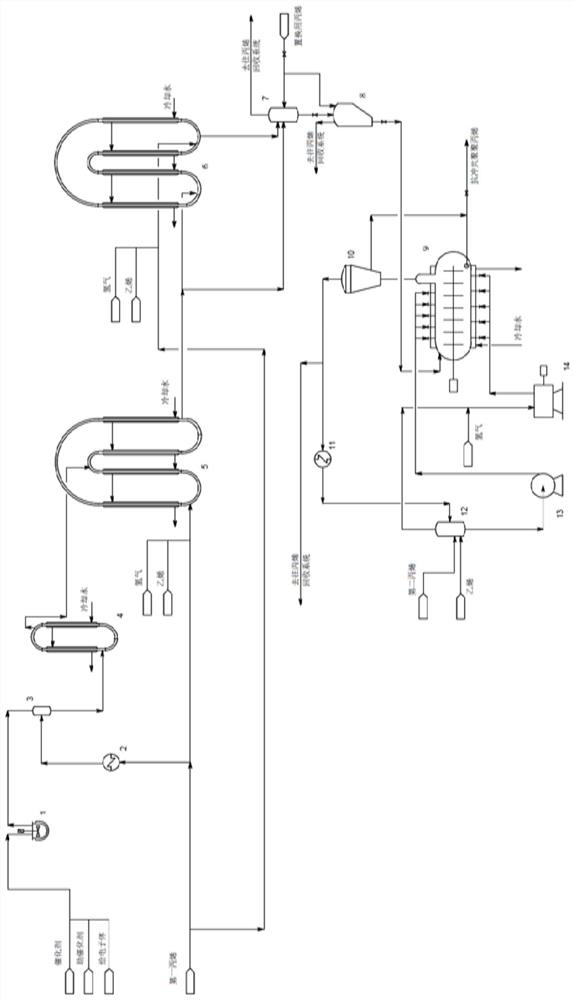

Preparation method of polypropylene

The invention relates to a preparation method of polypropylene. The method comprises the following steps: cooling first liquid-phase propylene, mixing the cooled first liquid-phase propylene with a polypropylene catalyst, and carrying out low-temperature prepolymerization reaction, feeding an obtained slurry containing the low-molecular-weight polypropylene prepolymer into a double-loop reactor, carrying out liquid-phase bulk slurry polymerization on the slurry and supplemented second liquid-phase propylene, hydrogen and ethylene monomers, and feeding part or all of polypropylene slurry flowing out of the first loop reactor into a second loop reactor, carrying out directflash evaporation on the polypropylene slurry flowing out of the second loop reactor to remove non-condensable gas and most of propylene monomers, and carrying out purification and granulationan obtained polypropylene intermediate to obtain the product; or carrying out copolymerization reaction on the polypropylene intermediate, and then carrying out powder purification and granulation to obtain the product. According to the preparation method disclosed by the invention, high-melt-index / high-rigidity and high-rubber-content impact-resistant co-polypropylene can be produced through flexible switching of devices, and meanwhile, high-isotacticity homo-polypropylene and random co-polypropylene can also be produced.

Owner:PETROCHINA CO LTD

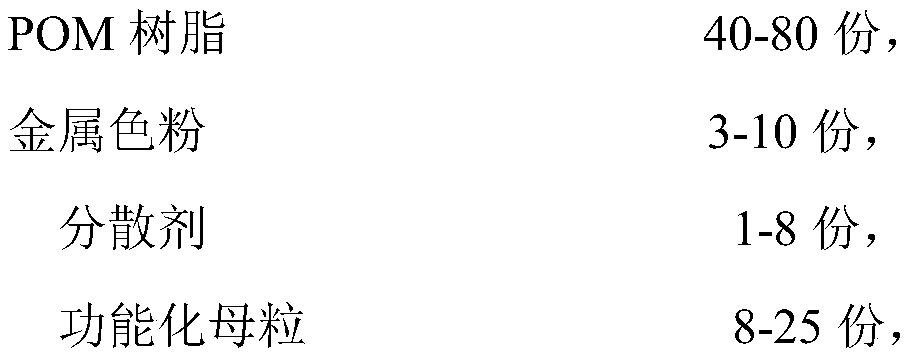

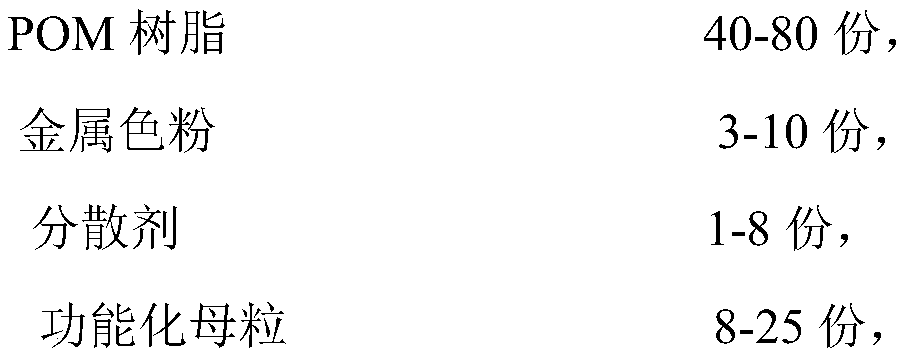

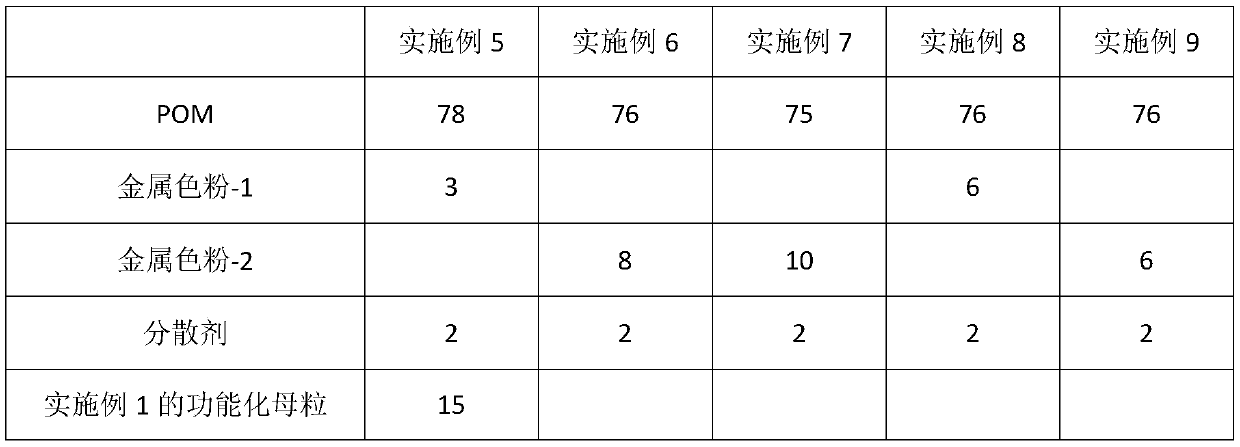

High-performance antibacterial spraying-free POM composite material and preparation method thereof

ActiveCN110819063AHigh content of active ingredientsAchieve broad-spectrum antibacterial effectEscherichia coliIonomer

The invention discloses a high-performance antibacterial spraying-free POM composite material and a preparation method thereof, wherein the high-performance antibacterial spraying-free POM composite material specifically comprises the following raw materials by weight: 40-80 parts of a POM resin, 2-10 parts of metal toner, 1-8 parts of a dispersing agent and 5-15 parts of functionalized master batch, wherein the functionalized master batch comprises, by weight, 2-8 parts of an elastic ionomer, 2-6 parts of a nano-state aerogel and 2-6 parts of a silver ion antibacterial agent. According to theinvention, the key antibacterial agent component and the aerogel with a nanometer mesoporous structure are subjected to effective master batch premixing and adsorption, so that the good spraying-freeeffect is achieved, and the POM material has broad-spectrum antibacterial effect, wherein the long-acting antibacterial rates of the POM material to three different strains (escherichia coli, staphylococcus aureus and aspergillus niger) are respectively more than 99%; and by using the special toughening agent-ionomer, the spraying-free POM composite material has good rigidity and toughness balance.

Owner:华合新材料科技股份有限公司

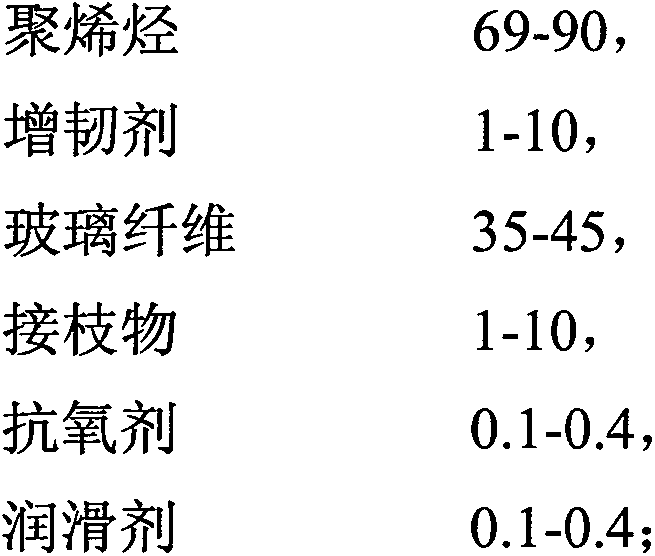

A building formwork material

The invention discloses a novel building template material, which comprises the following components in parts by weight: 50-90 parts of polyolefin, 1-10 parts of toughening agent, 5-45 parts of glass fiber, 1-10 parts of graft, 0.1-0.4 part of antioxidant and 0.1-0.4 part of lubricating agent. The glass fiber reinforced polyolefin material has favorable mechanical property and processability, can be manufactured into a plastic template through carrying out continuous extrusion molding by using an extruder and has multiple advantages of high strength and high tenacity under extremely thin wall thickness, low cost, light weight, good rigidity and tenacity balance, easy demolding, capability of recycling multiple times, changeable size, recyclability and the like. Compared with the template made of other materials, the novel building template material which has the same area as that of the template made of the other materials is thinner, lighter and convenient to transport and construct and has favorable application prospect.

Owner:HEFEI GENIUS NEW MATERIALS

Glass fiber reinforced rigid-tough balance type polyester composition and preparation method thereof

The invention discloses a glass fiber reinforced rigid-tough balance type polyester composition and a preparation method thereof. The polyester composition is prepared from 100 parts of polyester, 0.5-5 parts of isopropyl palmitate, 20-100 parts of glass fibers, 0.1-0.5 part of an antioxidant, 1-3 parts of a lubricating modifier and 0.1-0.2 part of a coupling agent through mixing and extrusion granulating. Isopropyl palmitat has the effects of preventing glass fibers from being exposed, improving processing fluidity, reducing screw torque and improving the surface finish of a product; meanwhile, the problem of layering of a composition system can be solved, and the mechanical properties, especially, impact resistance of the composition can be substantially improved; the prepared polyester composition is an engineering plastic with good rigid-tough balance.

Owner:HEFEI GENIUS NEW MATERIALS

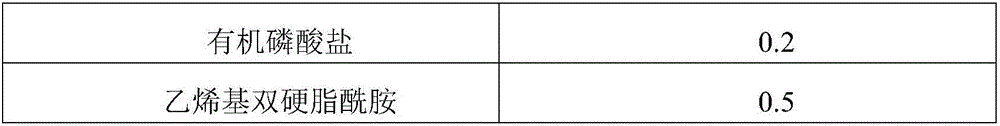

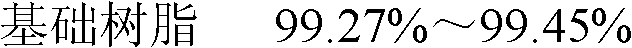

Polypropylene material for transparent bottles and preparation method thereof

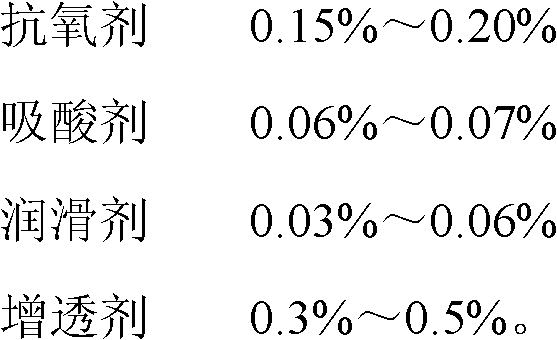

The invention discloses a polypropylene material for transparent bottles, which is prepared from the following raw materials in percentage by mass: 99.27 to 99.45 percent of basic resin, 0.15 to 0.20 percent of antioxygen, 0.06 to 0.07 percent of acid acceptor, 0.03 to 0.06 percent of lubricating agent, and 0.3 to 0.5 percent of transparent agent. The invention also discloses a preparation methodof the polypropylene material for transparent bottles. The transparency of the polypropylene material for transparent bottles is 30 to 40 percent higher than that of common polypropylene, and the quality of the polypropylene material for transparent bottles meets the requirement for producing baby bottles, sports water bottles, students' water bottles, food containers and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com