Low-smell rigid-tough high-performance polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of rigid tough high performance polypropylene composite materials and its preparation, can solve the problems of not considering the balance of rigidity and toughness of modified PP, comprehensive odor control is not effective, etc., to achieve good deodorization Effect, improvement of rigidity, effect of low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

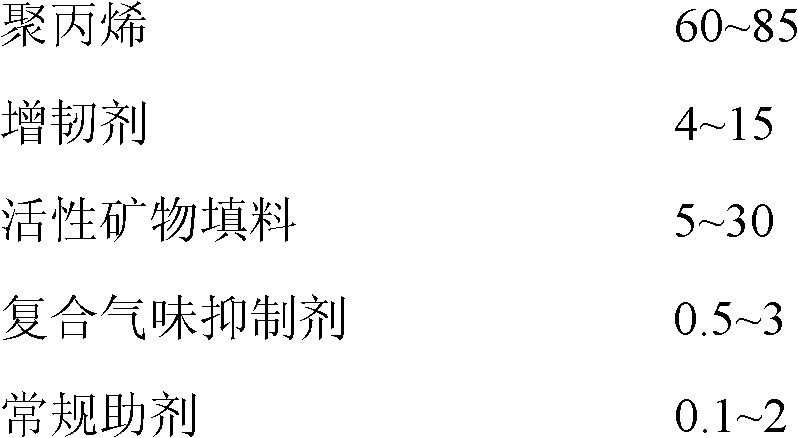

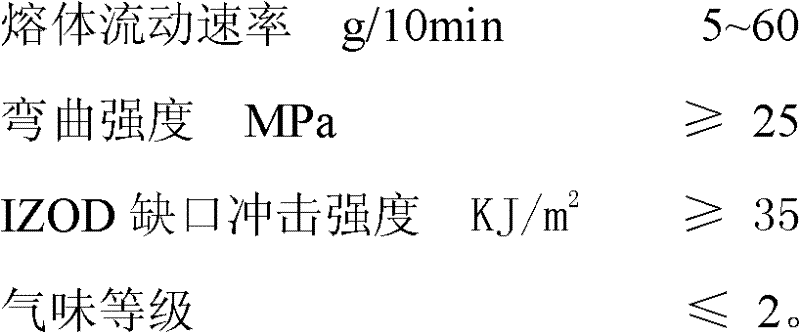

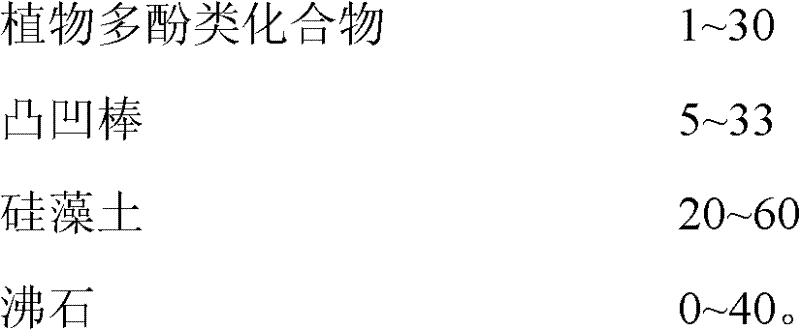

Method used

Image

Examples

Embodiment 1

[0053] The low odor rigid high performance polypropylene composite material of the present invention is prepared according to the following steps

[0054] ①.Ingredient pre-mixing

[0055] According to the proposed formula, accurately weigh 72 parts by weight of polypropylene QP83N, 7.5 parts by weight of toughening agent 8150 produced by DuPont, compound odor suppression (compounded by attapulgite:diatomite:zeolite=1:33:33:33) into) 2 parts by weight,

[0056] Antioxidant 1010 0.2 parts by weight, lubricant AC 0.3 parts by weight, pre-mixed for 5-20 minutes;

[0057] ②.Dry mixing, melt extrusion granulation

[0058] Place the pre-mixed raw materials in step 1 in a twin-screw side feeder, add active wollastonite whiskers 1250 mesh and 18 parts by weight by side feeding, and dry mix for 5 to 20 minutes; then melt Extrusion and granulation; process conditions are as follows:

[0059]

Embodiment 1~ Embodiment 10

[0061] According to the methods and steps of the examples, and according to the formula in Table 1, the low-odor rigid and tough high-performance polypropylene composite material of the present invention was prepared

[0062] Table 1

[0063]

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com