High-strength and high-stability modified PVC and preparation method thereof

A modified and high-strength technology, applied in the field of polymer materials, can solve the problem of difficult to meet the requirements of high strength and high stability of anti-friction strips, and achieve easy large-scale application, low production cost, and good rigidity-toughness balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

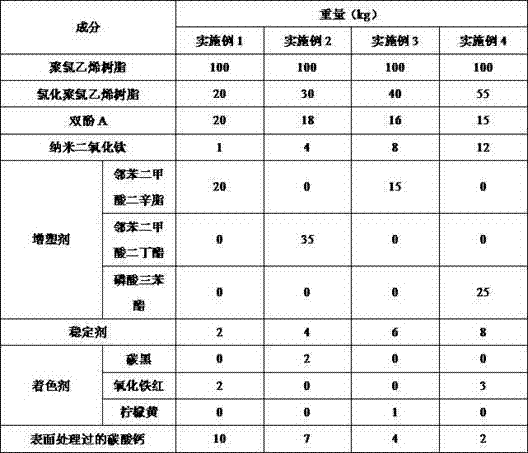

[0027] Carry out proportioning each composition by the weight shown in table 1.

[0028]

[0029] Each component weight of table 1 embodiment 1-4

[0030] Wherein, in embodiment 1-4, the average degree of polymerization of polyvinyl chloride resin is 800-1500; Chlorine content is 65%-70% in the chlorinated polyvinyl chloride resin; , 60nm, 80nm; the stabilizer is an organotin stabilizer.

[0031] The specific method of calcium carbonate surface treatment is: put calcium carbonate into the mixer, heat to 60°C and keep it warm for an appropriate time, then add titanate coupling agent into the mixer and mix evenly, and discharge the material after 10-25 minutes for use , Pay attention to keep the calcium carbonate dry to prevent moisture absorption.

[0032] The preparation process is as follows: S1. Weigh each component according to the weight in Table 1, mix them evenly in a pre-mixer, heat to 70-90°C, and keep warm for 15 minutes;

[0033] S2. Put the mixture obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com