Building template material and preparation method thereof

A technology for building formwork and glass fiber, which is applied in the field of building materials, can solve the problems of further improvement of anti-ultraviolet aging performance and flame retardant performance, and achieve the effects of improving anti-ultraviolet aging ability, easy processing and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

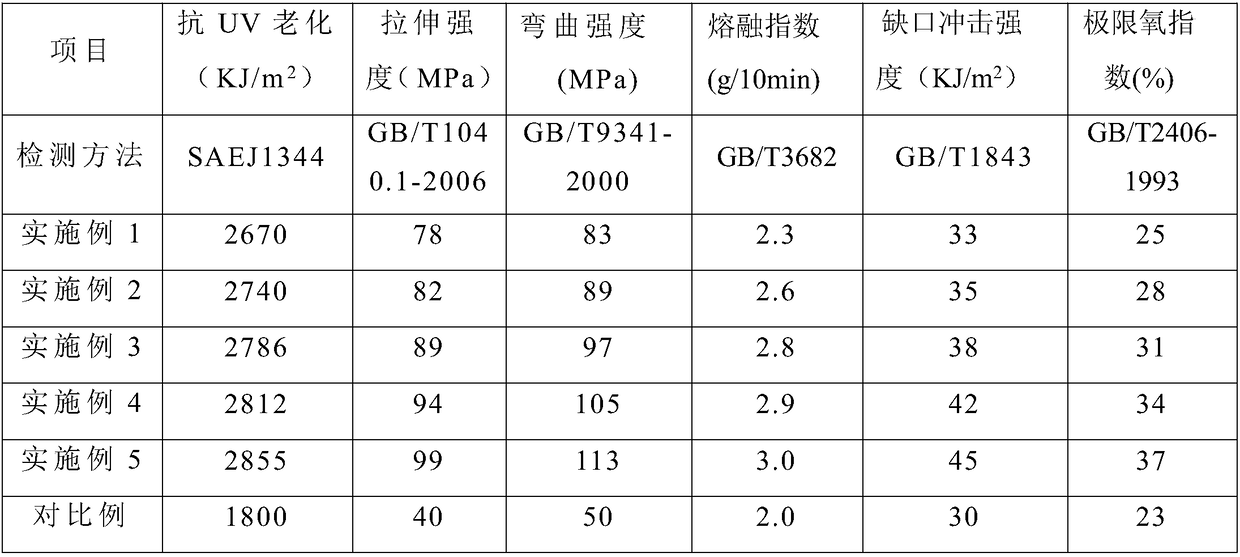

Examples

Embodiment 1

[0031] A building formwork material, made of the following components by weight: 100 parts of glass fiber reinforced adamantane polyamide grafted polyolefin resin, 1 part of polyethylene resin, 2,6-di-tert-butyl-4-methanol 1 part of base phenol.

[0032] The preparation method of described glass fiber reinforced adamantane polyamide grafted polyolefin resin comprises the steps:

[0033] 1) Dissolve 10g of 2,4-diamino-6-vinyl-S-triazine and 18.4g of 1,3-adamantanedicarboxylic acid in 50g of dimethyl sulfoxide to form a solution, and then add 1, 5g of 4-naphthoquinone was placed in a high-pressure reactor, and the reactor was replaced with nitrogen, and then kept at 190°C and the pressure at 2MPa, stirred and reacted for 2h, and then slowly exhausted and decompressed to normal pressure within 1 hour, and at the same time The temperature in the autoclave was raised to 240°C; then, under a nitrogen atmosphere, the temperature was controlled for 8 hours, and then it was precipitat...

Embodiment 2

[0038] A building formwork material, made of the following components by weight: 100 parts of glass fiber reinforced adamantane polyamide grafted polyolefin resin, 2 parts of ethylene propylene rubber, N,N'-bis-(3-(3 , 2 parts of 5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine.

[0039] The preparation method of described glass fiber reinforced adamantane polyamide grafted polyolefin resin comprises the steps:

[0040] 1) Dissolve 10 g of 2,4-diamino-6-vinyl-S-triazine and 18.4 g of 1,3-adamantanedicarboxylic acid in 65 g of N,N-dimethylformamide to form a solution, and then add Add 6g of copper naphthenate to the solution, place it in a high-pressure reactor, replace the reactor with nitrogen, then keep the pressure at 2.3MPa at 195°C, stir and react for 2.3h, then slowly exhaust and reduce the pressure within 1.2 hours to Under normal pressure, the temperature in the autoclave was raised to 250°C; then, under a helium atmosphere, the temperature control react...

Embodiment 3

[0045] A building formwork material, made of the following components by weight: 100 parts of glass fiber reinforced adamantane polyamide grafted polyolefin resin, 3 parts of EPDM rubber, tetrakis [β-(3,5-di 2 parts of tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester.

[0046] The preparation method of described glass fiber reinforced adamantane polyamide grafted polyolefin resin comprises the steps:

[0047] 1) Dissolve 10g of 2,4-diamino-6-vinyl-S-triazine and 18.4g of 1,3-adamantanedicarboxylic acid in 80g of N-methylpyrrolidone to form a solution, and then add phen 6.5g of thiazine was placed in a high-pressure reactor, and the reactor was replaced with nitrogen, then kept at 205°C and the pressure at 2.5MPa, stirred and reacted for 2.6h, and then slowly exhausted and decompressed to normal pressure within 1.6 hours. The temperature in the autoclave was raised to 260°C; then, under a neon atmosphere, the reaction was carried out under temperature control fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com