Medium-alkali glass fiber reinforced regenerated polypropylene composite material as well as preparation method and application thereof

A technology for recycling polypropylene and composite materials, applied in the field of polypropylene composite materials and their preparation, can solve the problems of high formula cost, unsuitable for large-scale promotion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

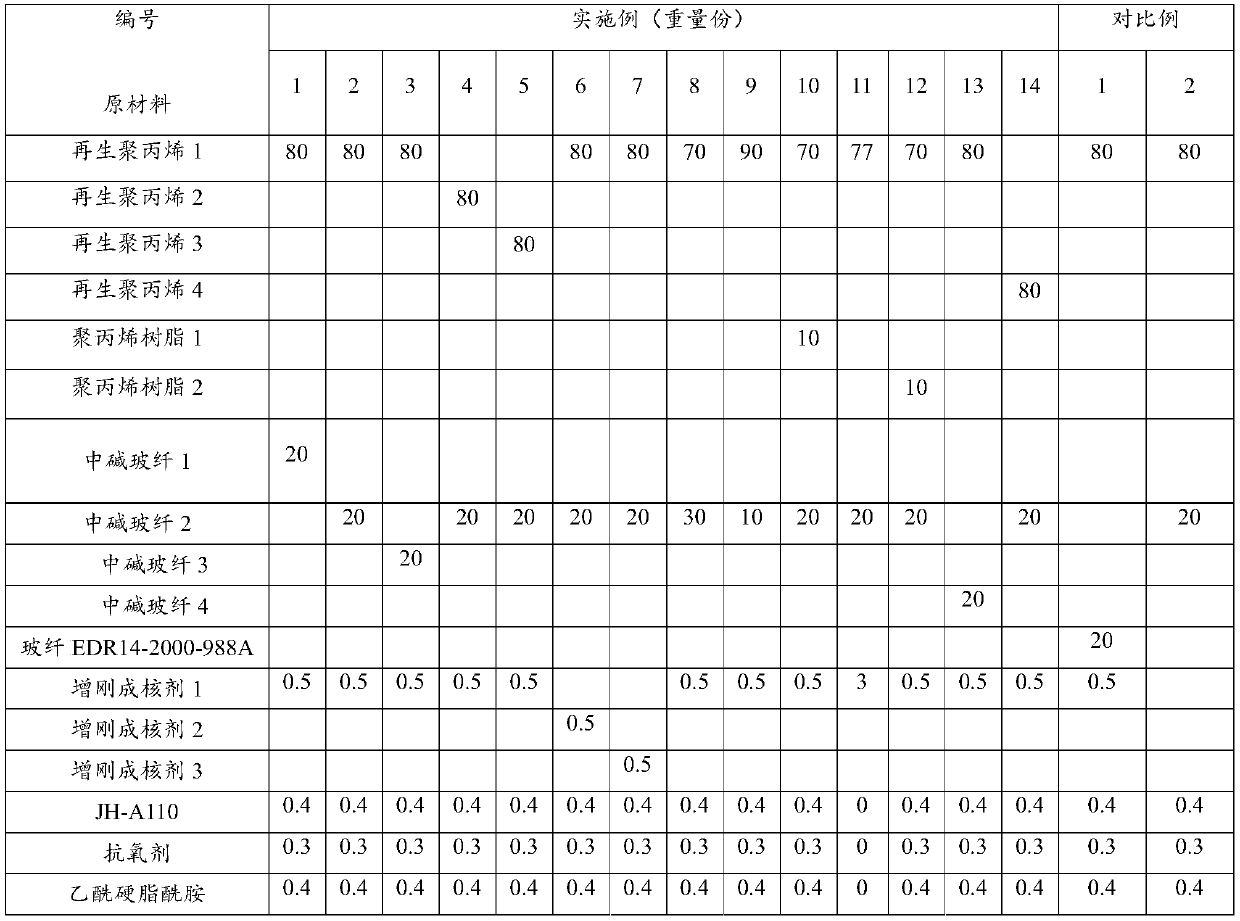

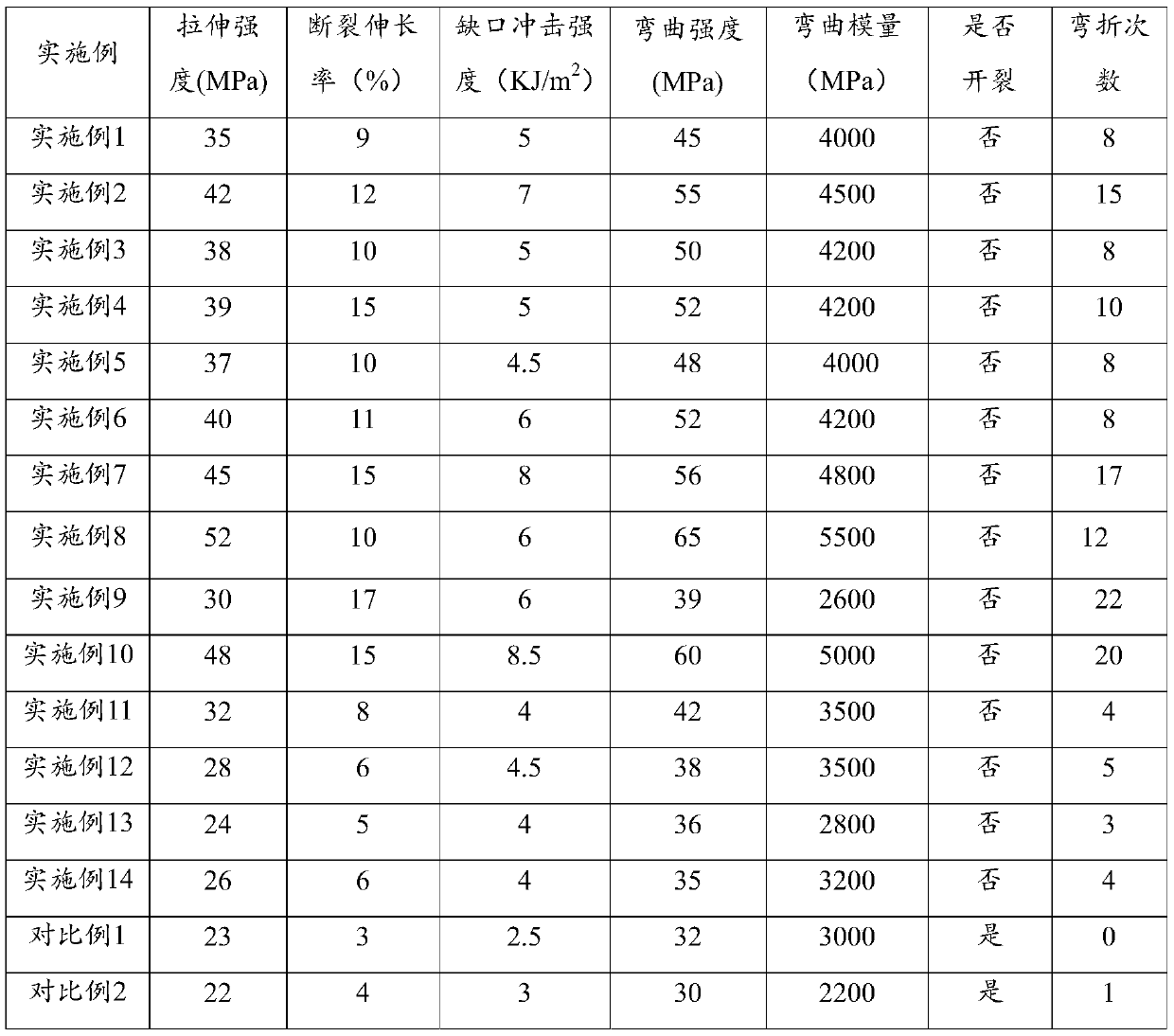

[0024] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0025] The raw materials used in the examples of the present application and the comparative examples are described as follows, including but not limited to these materials, and other unexplained raw materials are commercially available conventional materials:

[0026] Recycled polypropylene 1: The base material is copolymerized washing machine barrel material, MFR (230°C, 2.16kg) is 30g / 10min;

[0027] Recycled polypropylene 2: The base material is homopolymeric tonne bag material, and the MFR (230°C, 2.16kg) is 10.0g / 10min;

[0028] Recycled polypropylene 3: The base material is homopolymer daily miscellaneous materials, and the MFR (230°C, 2.16kg) is 18.0g / 10min;

[0029] Regenerated polypropylene 4: the bottom material is homopolymer daily miscellaneous materials, MFR (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com