High-performance antibacterial spraying-free POM composite material and preparation method thereof

A composite material and spray-free technology, which is applied in the field of polymer materials, can solve the problems of difficult to reproduce the modification effect stably, poor resistance to acid and alkali solvents, and non-prominent characteristic indicators, etc., and achieve good mechanical performance and good performance. Protective effect, effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

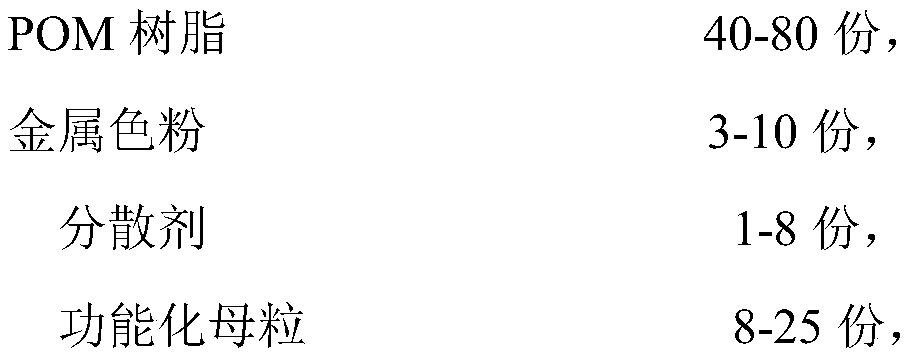

Method used

Image

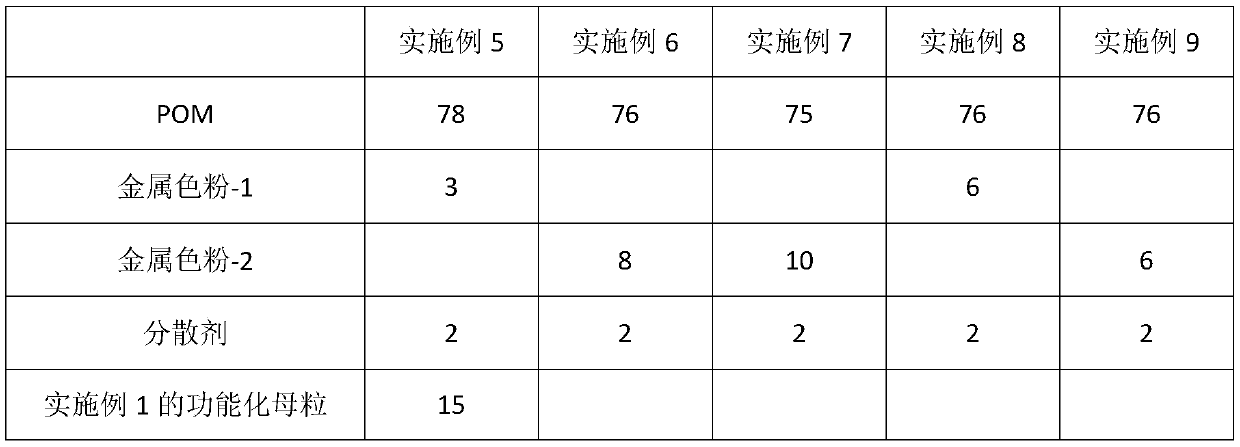

Examples

Embodiment 1

[0042] According to the data of Example 1 shown in Table 1, the elastic ionomer and nano-state airgel were weighed and mixed uniformly to obtain a mixed raw material. ;

[0043] Put the dried mixed raw materials into a closed reaction kettle, vacuumize the reaction kettle and fill it with inert nitrogen to protect it to normal pressure, then heat it to 190°C and keep it at a constant temperature, and stir at a constant speed of 120 rpm for 30 minutes , then add the silver ion antibacterial agent in proportion, continue to stir for 10 minutes, fill with nitrogen and pressurize, export the molten blend from the bottom outlet of the closed reactor, cool, and pelletize to obtain functionalized masterbatch.

Embodiment 2

[0045] According to the data of Example 2 shown in Table 1, the elastic ionomer and nano-state airgel were weighed and mixed uniformly to obtain a mixed raw material. ;

[0046] Put the dried mixed raw materials into a closed reaction kettle, vacuumize the reaction kettle and fill it with inert nitrogen to protect it to normal pressure, then heat it to 190°C and keep it at a constant temperature, and stir at a constant speed of 120 rpm for 30 minutes , then add the silver ion antibacterial agent in proportion, continue to stir for 10 minutes, fill with nitrogen and pressurize, export the molten blend from the bottom outlet of the closed reactor, cool, and pelletize to obtain functionalized masterbatch.

[0047] Table 1 Formula table of functionalized masterbatch (unit: gram)

[0048] Example 1 Example 2 Example 3 Example 4 elastic ionomer 6 6 6 6 Nano state airgel-1 3 2 5 Nano state airgel-2 6 Silver ion antibacterial agent...

Embodiment 3

[0050] According to the data of Example 3 shown in Table 1, the elastic ionomer and nano-state airgel were weighed and mixed uniformly to obtain a mixed raw material. ;

[0051] Put the dried mixed raw materials into a closed reaction kettle, vacuumize the reaction kettle and fill it with inert nitrogen to protect it to normal pressure, then heat it to 190°C and keep it at a constant temperature, and stir at a constant speed of 120 rpm for 30 minutes , then add the silver ion antibacterial agent in proportion, continue to stir for 10 minutes, fill with nitrogen and pressurize, export the molten blend from the bottom outlet of the closed reactor, cool, and pelletize to obtain functionalized masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com