Low-density low-shrinkage high-gloss polypropylene compound as well as preparation method and product thereof

A polypropylene, low-shrinkage technology, applied in the field of low-density, low-shrinkage, high-gloss polypropylene composites and their preparation, can solve the problems of unsightly appearance of products, uneven shrinkage rate, poor surface flatness of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] An embodiment of the present invention also provides a method for preparing a low-density, low-shrinkage, high-gloss polypropylene composite, which includes the following steps:

[0058] The polylactic acid base material and the above-mentioned low-density, low-shrinkage and high-gloss polypropylene composite are mixed into the kneader, and the material is discharged after stirring and mixing for a predetermined time;

[0059] The components in the low-density, low-shrinkage, and high-gloss polypropylene composite according to any one of claims 1-8 are obtained according to the ratio, and the polypropylene, ethylene-octene block copolymer elastomer, nucleating agent, talc Mix powder and coupling agent in a high-speed mixer for 2-5 minutes;

[0060] The mixed material is added to the twin-screw extruder, and the low-shrinkage, low-density and high-gloss polypropylene composite material is obtained by melt extrusion, drying, cooling and pelletizing; The temperature from ...

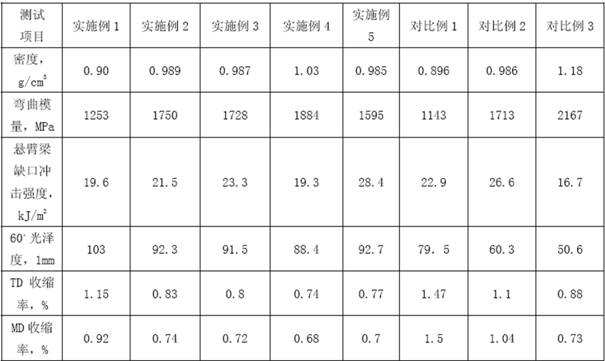

Embodiment 1

[0064] An embodiment of the low-shrinkage, low-density and high-gloss polypropylene composite material of the present invention, the low-shrinkage, low-density and high-gloss polypropylene composite material in this embodiment comprises the following components by weight:

[0065] 35 parts of PP-1 polypropylene, 25 parts of PP-3 polypropylene, 20 parts of ethylene-octene block copolymer elastomer Infuse 9007, 10 parts of talc, 0.1 part of NA-1 nucleating agent, 0.3 part of coupling agent, B225 antioxidant 0.2 parts.

[0066] The preparation method of the low-shrinkage, low-density and high-gloss polypropylene composite material of this embodiment includes the following steps:

[0067] The polypropylene, the ethylene-octene block copolymerized elastomer, the nucleating agent, the talc, and the coupling agent are mixed in a high-speed mixer for 3 minutes, wherein the rotating speed of the high-speed mixer is 600 rpm;

[0068] Add the mixed materials in step 1 into the twin-scre...

Embodiment 2

[0070] In this Example 2, the low-shrinkage, low-density high-gloss polypropylene composite material contains the following components in parts by weight:

[0071] 35 parts of PP-1 polypropylene, 25 parts of PP-3 polypropylene, 20 parts of ethylene-octene block copolymer elastomer Infuse 9007, 15 parts of AH5000 talc, 0.1 part of NA-1 nucleating agent, KH-570 silane coupling agent 0.3 part of joint agent, 0.2 part of B225 antioxidant.

[0072] The preparation method of described low shrinkage, low density high gloss polypropylene composite material, comprises the steps:

[0073] The polypropylene, the ethylene-octene block copolymerized elastomer, the nucleating agent, the talc, and the coupling agent are mixed in a high-speed mixer for 3 minutes, wherein the rotating speed of the high-speed mixer is 600 rpm;

[0074] Add the mixed materials in step 1 into the twin-screw extruder, and perform melt extrusion, drying, cooling, and pelletizing to obtain the low-shrinkage, low-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com