High-flow high-impact transparent polypropylene material produced by adopting hydrogen regulation method and method of high-flow high-impact transparent polypropylene material

A transparent polypropylene, high-flow technology, applied in the field of polypropylene materials, can solve the problems of product quality fluctuation, unplanned shutdown of equipment, vibration, etc., and achieve the effect of improving production efficiency, reducing processing energy consumption, and good rigidity and toughness balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

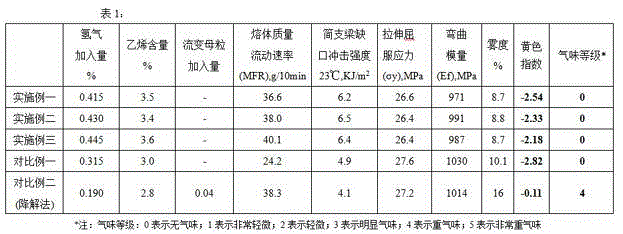

Embodiment 1

[0031] (1) Use propylene and ethylene as raw materials, the ratio of propylene and ethylene is 97:3, put them into the loop reactor, add catalyst, electron donor and antistatic agent, stir evenly, and carry out the reaction. Among them, the amount of DQC-401 catalyst added is 0.8kg / h, the ratio of triethylaluminum flow / propylene flow is 0.16kg / kg, and the ratio of triethylaluminum flow / Donor is 5 kg / kg, the loop reaction temperature is 70 ± 1°C, the reaction pressure is 3.7MPa, and the loop control hydrogen concentration is 0.41 %, polymerized to obtain a weight average molecular weight of 186477, a molecular weight distribution of 5.79, and a melt flow rate controlled at 36.6 g / 10min random copolymerized polypropylene powder.

[0032] (2) Based on the total weight of random copolymerized polypropylene powder, take antioxidant 0.15% , acid absorbent 0.05% , lubricant 0.05%, transparent agent 0.2% Mixed and granulated by extrusion to form a granular composition as a premix....

Embodiment 2

[0034] (1) Use propylene and ethylene as raw materials, the ratio of propylene and ethylene is 96:4, put them into the loop reactor, add catalyst, electron donor and antistatic agent, stir evenly, and carry out the reaction. Among them, the amount of DQC-401 catalyst added is 1.0kg / h, the ratio of triethylaluminum flow / propylene flow is 0.16kg / kg, and the ratio of triethylaluminum flow / Donor is 5kg / kg, the loop reaction temperature is 70 ± 1°C, the reaction pressure is 4.0MPa, and the loop control hydrogen concentration is 0.43 %, polymerized to obtain a weight average molecular weight of 183731, a molecular weight distribution of 6.03, and a melt flow rate controlled at 38.0 g / 10min random copolymerized polypropylene powder.

[0035] (2) Based on the total weight of random copolymerized polypropylene powder, take antioxidant 0.15% , acid absorbent 0.05% , lubricant 0.05%, transparent agent 0.2% Mixed and granulated by extrusion to form a granular composition as a premix. ...

Embodiment 3

[0037] (1) Use propylene and ethylene as raw materials, the ratio of propylene and ethylene is 96.5:3.5, put them into the loop reactor, add catalyst, electron donor and antistatic agent, stir evenly, and react. Among them, the amount of DQC-401 catalyst added is 0.9kg / h, the ratio of triethylaluminum flow / propylene flow is 0.16kg / kg, and the ratio of triethylaluminum flow / Donor is 5 kg / kg, loop reaction temperature 70 ± 1°C, reaction pressure 3.8 MPa, the loop control hydrogen concentration is 0.45 %, polymerized to obtain random copolymerized polypropylene powder with a weight average molecular weight of 181993, a molecular weight distribution of 5.91, and a melt flow rate controlled at 40.1g / 10min.

[0038] (2) Based on the total weight of random copolymerized polypropylene powder, take antioxidant 0.15% , acid absorbent 0.05% , lubricant 0.05%, transparent agent 0.2% Mixed and granulated by extrusion to form a granular composition as a premix. The premix is added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com