Multimodal polyethylene pipe resin composition and preparation method thereof

A technology of resin composition and multimodal polyethylene, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of cracking or cracking, expensive, etc., and achieve the effect of excellent pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

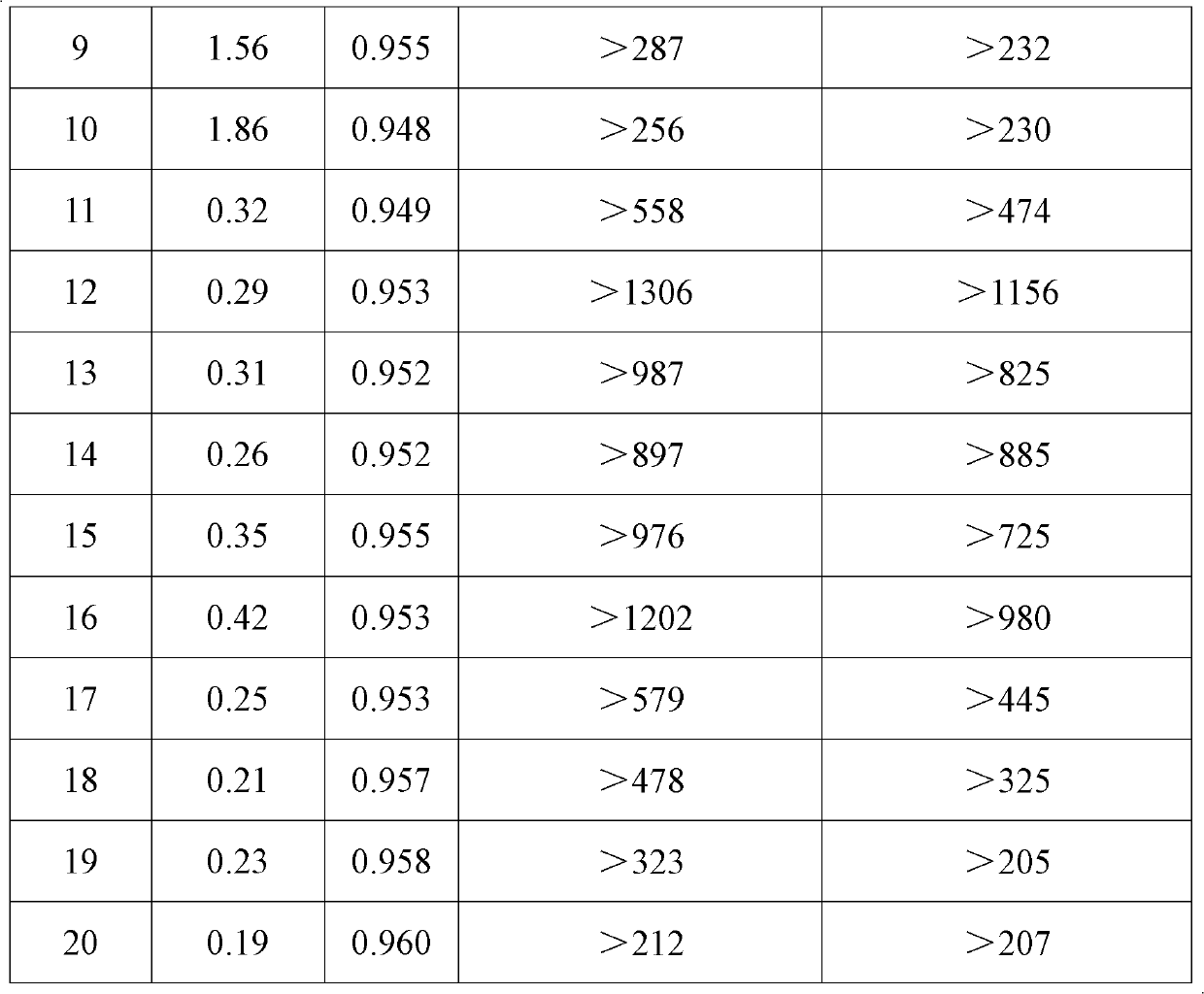

[0037] The multimodal polyethylene pipe resin composition is prepared by three slurry reactors in series polymerization process, adding catalyst Z501, accelerator DDS, Si / Ti is 2, cocatalyst TEA in the first reactor, H2 in the first reactor / C2 (molar ratio) is 2; in the second reactor H2 / C2 (molar ratio) is 0.01, 1-hexene / ethylene (molar ratio) is 0.01; in the third reactor H2 / C2 (molar ratio) is 0,1-hexene / ethylene (molar ratio) is 0.1; the ethylene consumption ratio of the three reactors is 40:30:30. The test results are shown in Table 1.

Embodiment 2

[0039] The multimodal polyethylene pipe resin composition is prepared by three slurry reactor series polymerization processes, and catalyst Z501, accelerator DDS are added in the first reactor, Si / Ti is 4, cocatalyst TEA, and H in the first reactor 2 / C 2 (molar ratio) is 2; H in the second reactor 2 / C 2 (molar ratio) is 0.02, and 1-hexene / ethylene (molar ratio) is 0.02; In the third reactor, H 2 / C 2 (molar ratio) is 0.002, 1-hexene / ethylene (molar ratio) is 0.09; the ethylene consumption ratio of the three reactors is 42:31:27. The test results are shown in Table 1.

Embodiment 3

[0041] The multimodal polyethylene pipe resin composition is prepared by three slurry reactor series polymerization processes, and catalyst Z501, accelerator DDS are added in the first reactor, Si / Ti is 6, cocatalyst TIBA, and H in the first reactor 2 / C 2 (molar ratio) is 2; H in the second reactor 2 / C 2 (molar ratio) is 0.03, and 1-hexene / ethylene (molar ratio) is 0.03; In the third reactor, H 2 / C 2 (molar ratio) is 0.003, 1-hexene / ethylene (molar ratio) is 0.08; the ethylene consumption ratio of the three reactors is 44:32:24. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com