Slow-release chemical paraffin removing ball, and preparation method and applications thereof

A wax-removing ball and slow-release technology, which is applied in the field of slow-release chemical wax-removing balls and their preparation, can solve the problems that the wax-removing balls are easily stuck and the wax-removing balls have no anti-wax, etc., and achieves low price and high effect. Stable, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the wax removing ball includes the following steps:

[0036] 1) According to different crude oil properties, weigh a certain quality of sodium stearate, polyoctadecyl acrylate, JFC, Tween-80 or Span-65 according to different formulations, and dissolve the liquid ingredients in the solid ingredients for use.

[0037] 2) Place the EVA in an iron container, heat it on an electric furnace at 150°C-200°C until the EVA is in a fluid state, then mix the medicine prepared in step 1) with the EVA according to the ratio, and heat again at 150°C-200°C Until the mixture is in a fluid state, a high-temperature liquid mixture is obtained.

[0038] 3) Pour the high temperature liquid mixture obtained in step 2) into a spherical mold and cool to room temperature.

[0039] Since the wax inhibitor is evenly distributed inside the wax ball, and sodium carboxymethyl cellulose can slowly release the sodium stearate into the crude oil, after one shot of the ball, when the w...

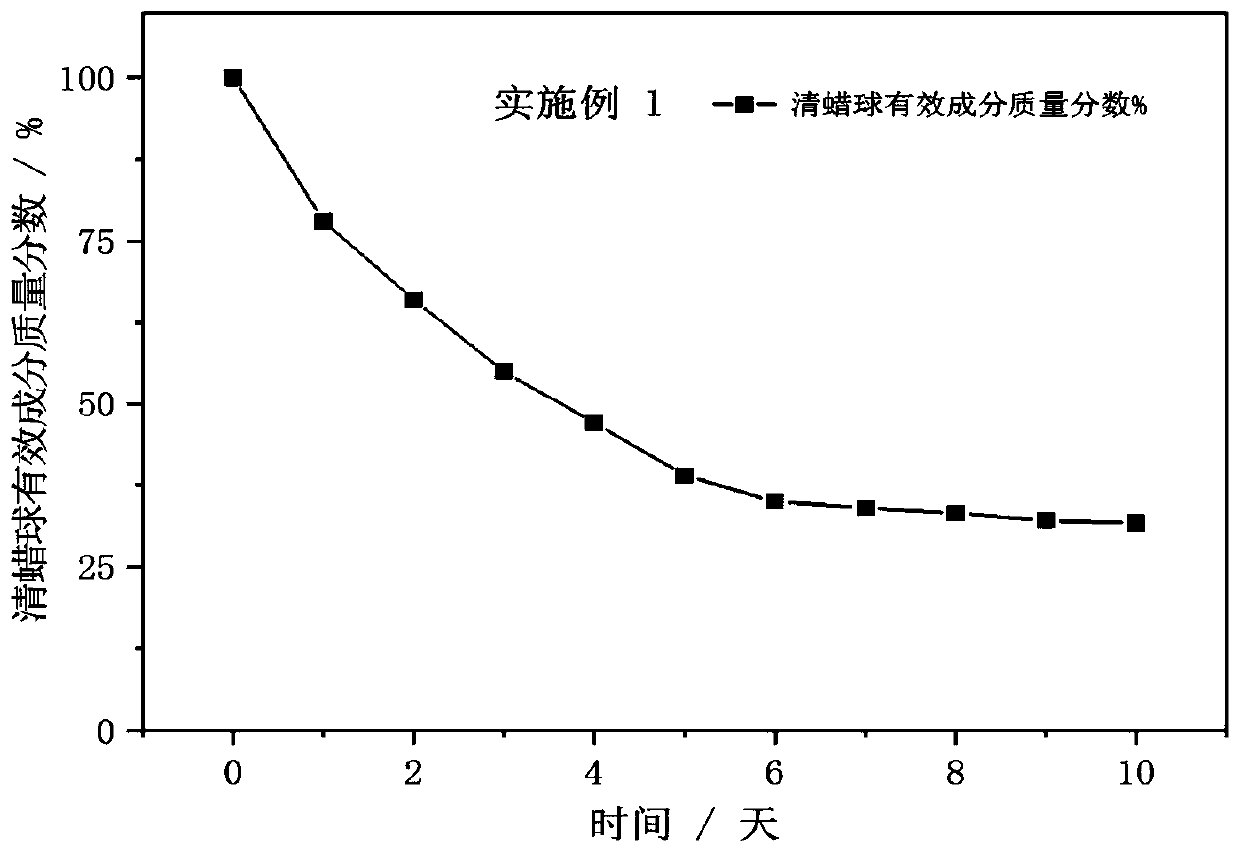

Embodiment 1

[0041] For paraffin-based crude oil with water content below 20%, sodium stearate is selected as the main water-soluble surfactant, polyoctadecyl acrylate is used as a pour point depressant to reduce the precipitation rate of paraffin, and sodium carboxymethyl cellulose is used as a slow release JFC is used as a penetrant, and Span-65 is used as a co-solvent to increase the dissolving effect of the first two drugs. When preparing, melt 40% EVA in a container at high temperature, and then 50% sodium stearate, 1% carboxymethyl cellulose, 3% polyoctadecyl acrylate, 3% JFC and 3% Span- 65 into the beaker and mix well. The uniformly mixed medicine and liquid EVA are mixed uniformly, and the mixture is placed in a spherical mold for cooling and molding.

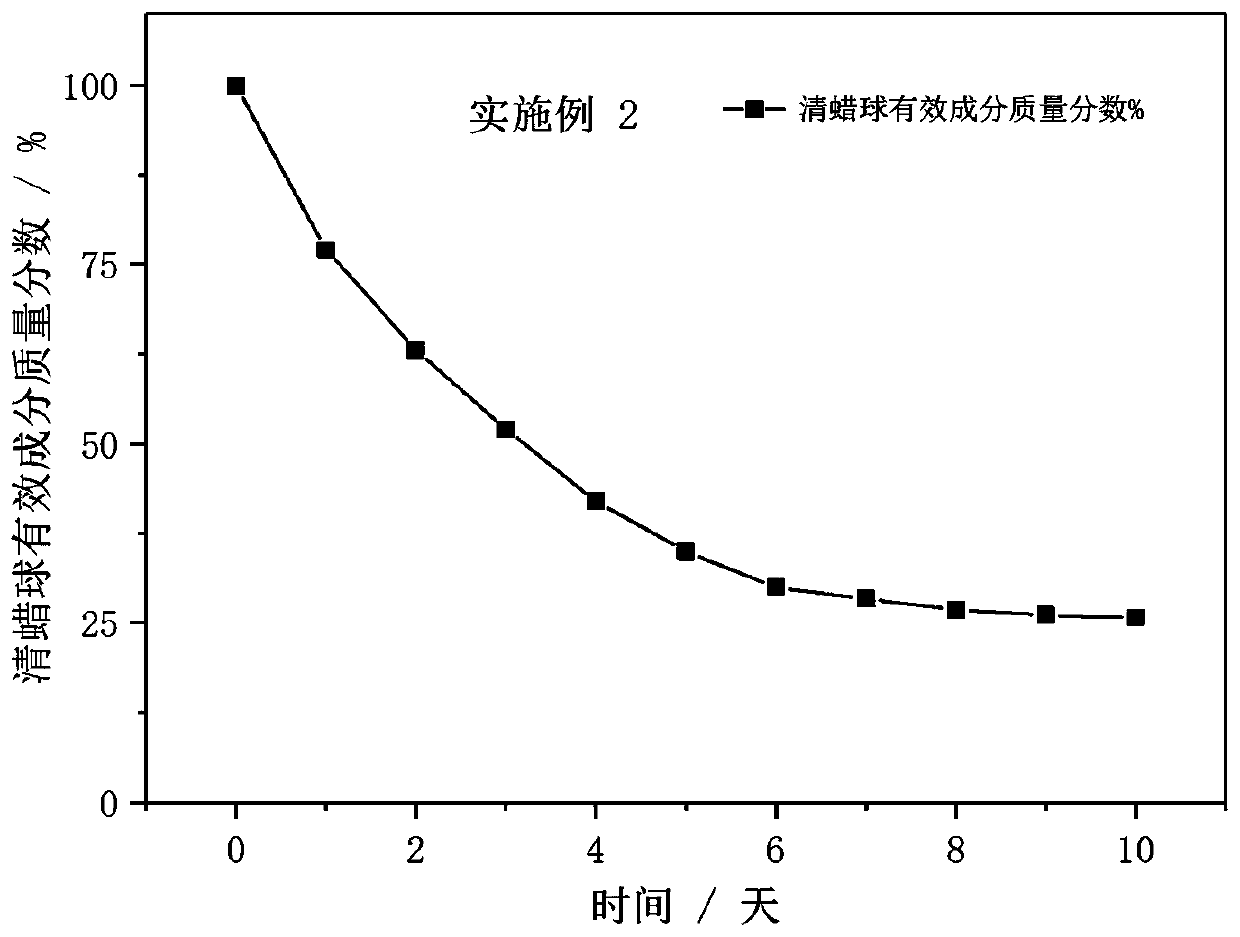

Embodiment 2

[0043] For paraffin-based crude oil with a water content of 20%-50%, sodium stearate is selected as the main water-soluble surfactant, polyoctadecyl acrylate is used as a pour point depressant to reduce the precipitation rate of paraffin, carboxymethyl cellulose Sodium is used as a slow release agent, JFC is used as a penetrant, and Tween-80 is used as a cosolvent to increase the dissolution effect of the first two drugs. When preparing, melt 40% EVA in a container at high temperature, and then 50% sodium stearate, 3% carboxymethyl cellulose, 3% polyoctadecyl acrylate, 2% JFC and 2% Tween- Put 80 into the beaker and mix well. The uniformly mixed medicine and liquid EVA are mixed uniformly, and the mixture is placed in a spherical mold for cooling and molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com