High-yield-strain low-temperature-impact-resistant talcum powder filled polypropylene material and preparation method thereof

A technology of polypropylene material and talc powder, which is applied in the field of high yield strain low temperature impact resistant talc powder filled polypropylene material and its preparation, and can solve the problems that high yield strain materials are rarely reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0053] A preparation method of a high-yield-strain low-temperature impact-resistant talcum powder-filled polypropylene material, comprising the following steps:

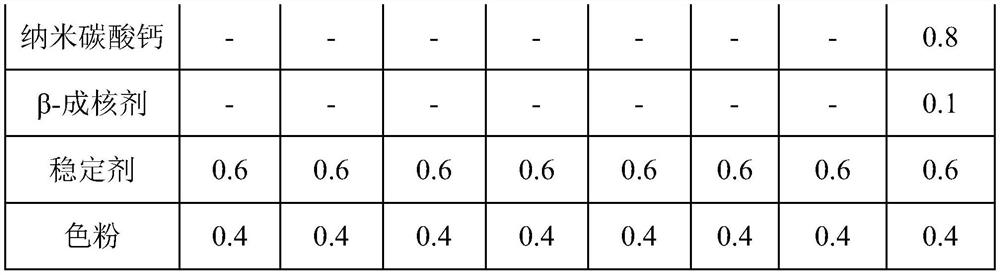

[0054](1) Weigh 79 parts of nano-calcium carbonate, 10 parts of polypropylene resin, 10 parts of β-nucleating agent, 0.8 part of dispersant, and 0.2 part of antioxidant, and place the above components in a high-speed mixer for 3 minutes after mixing , put it into a twin-screw extruder to extrude and granulate, and get the composite nucleated masterbatch after drying. The temperature of the feeding section of the twin-screw extruder is 120°C, the temperature of the conveying section is 160°C, and the temperature of the melting section is 190°C. The temperature is 180° C., and the screw speed is 150 rpm.

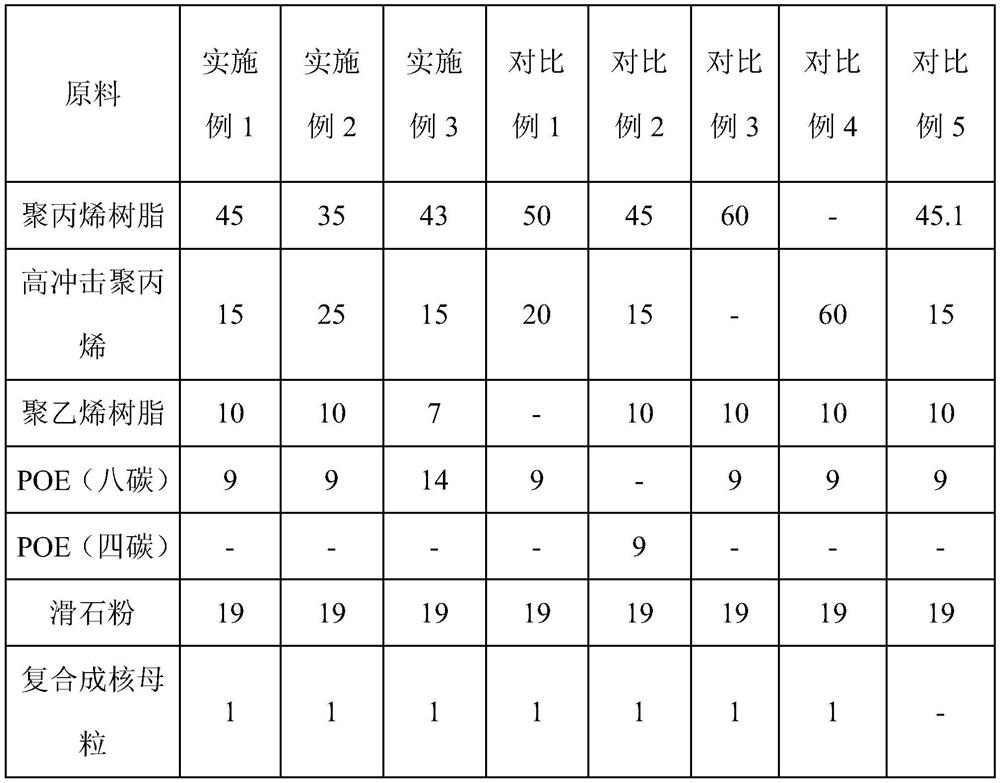

[0055] (2) Put polypropylene resin, polyethylene resin, polyolefin elastomer (POE), talcum powder, composite nucleating masterbatch, stabilizer and toner into the high-speed mixer in the parts by weight shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com