Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Good bite resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

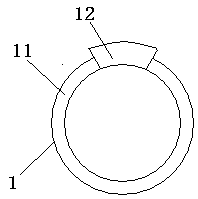

High-temperature metal hard seal ball valve for granular media

ActiveCN102654202AAvoid damageImprove sealingSpindle sealingsPlug valvesMetallic materialsEngineering

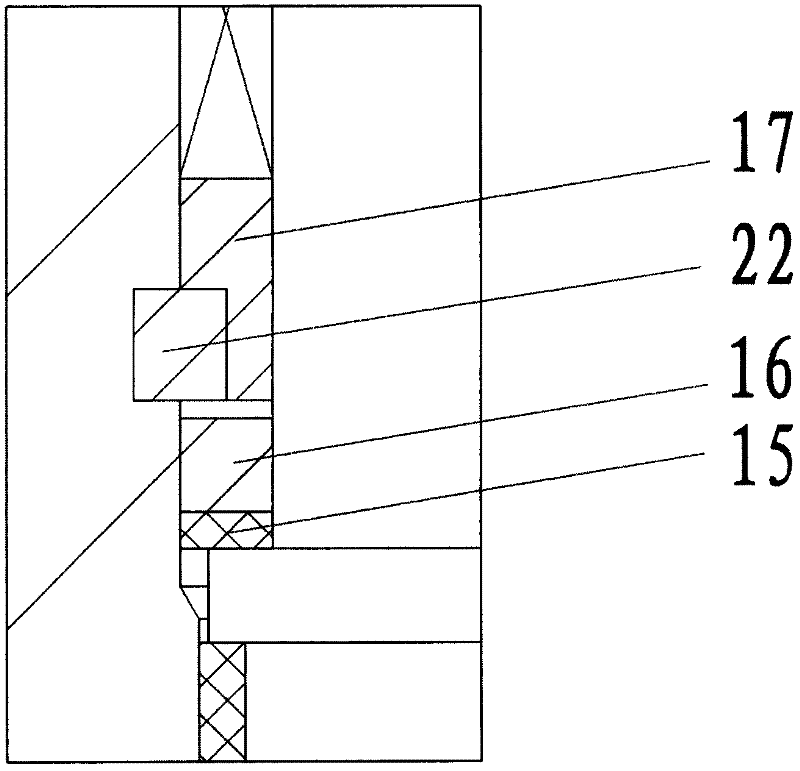

The invention provides a high-temperature metal hard seal ball valve for granular media. The high-temperature metal hard seal ball valve comprises a valve body, a ball body, a valve rod, a valve seat and a bottom cover, wherein the ball body is arranged in a cavity in the valve body, the valve rod connected with the ball body extends out of the valve body through a center through hole at the upper part of the valve body, the bottom cover is positioned at the bottom of the valve body and comprises a bottom cover baseplate and a bottom cover shaft, the bottom cover baseplate is movably connected with the valve body, the bottom cover shaft penetrates through a through hole at the lower part of the valve body and is connected with the ball body in the cavity of the valve body, the ball body and the valve seat are made of metal materials, the valve seat is mounted in the valve body and on the inner wall which is in contact with the ball body, a spring seat is arranged on the outer side of the valve seat, a disc spring is mounted in a groove between the spring seat and the valve seat, a pressure ring is arranged on the outer side of the spring seat, the pressure ring is fixedly mounted on the spring seat through a screw, a pendant collet for playing a sealing role is arranged in the contact position of the spring seat, the pressure ring and the valve body, an O ring is arranged in the groove between the valve seat and the valve body, and the O ring is made of fluorine rubber.

Owner:OVIKO GRP CO LTD

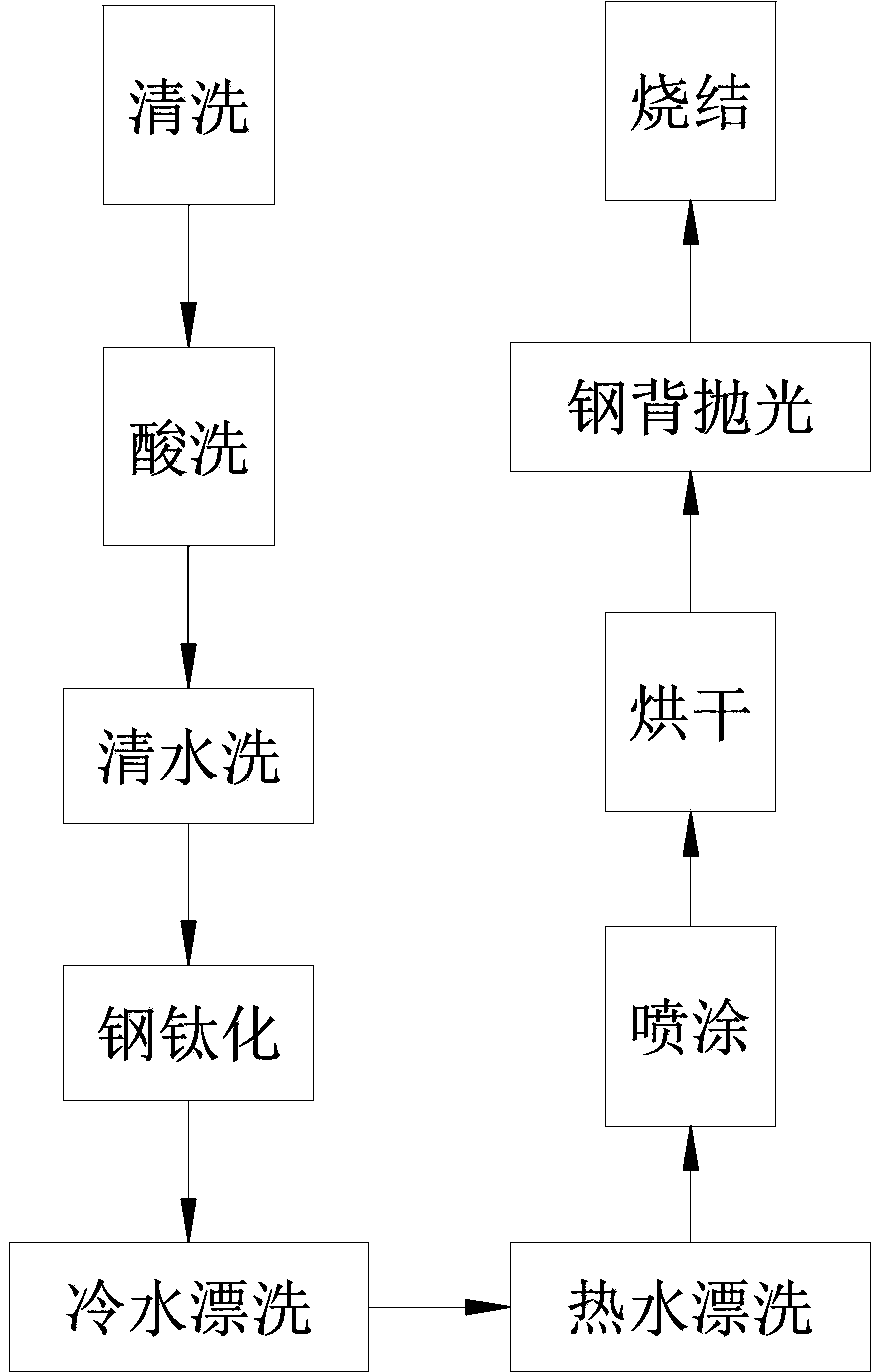

Process for spaying MoS2 on bearing bush without alloy layer

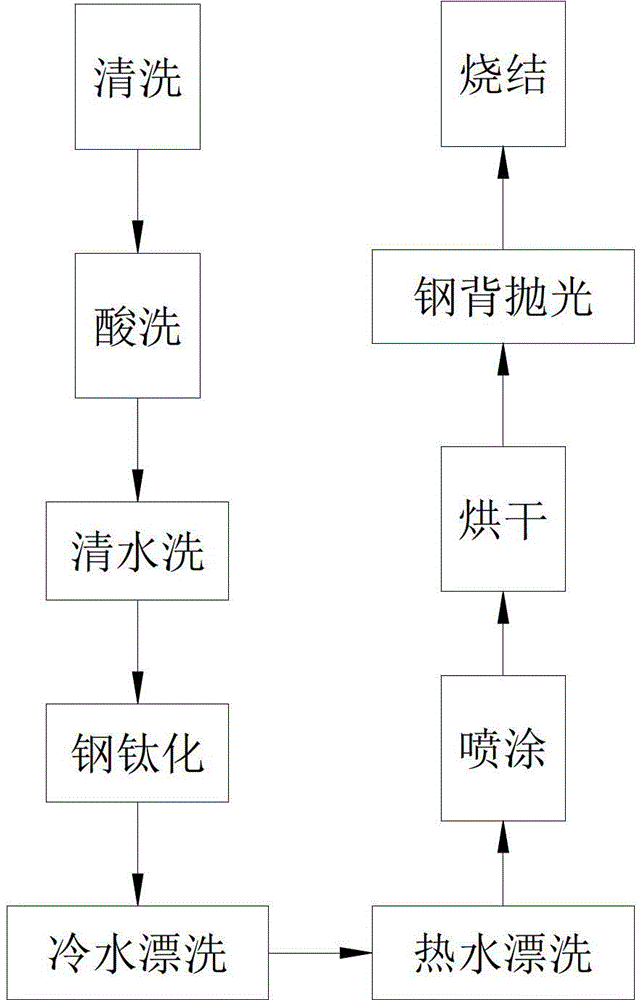

The invention provides a process for spaying MoS2 on a bearing bush without an alloy layer, and aims to solve the problem in the prior art of spaying MoS2 on the bearing bush without the alloy layer. The process comprises the following steps of cleaning, pickling, fresh water cleaning, steel titanizing, cold water rinsing, hot water rinsing, spraying, oven-drying, steel back burnishing, sintering and the like of a steel back layer, wherein before pickling, the steel back layer after being cleaned can be firstly placed in tap water for cleaning; and before spraying, steel back layer after being rinsed by hot water can be firstly placed in an oven for oven-drying. The process is safe and environment-friendly in the implementation process; as galvanizing is omitted, pollution to the environment can be efficiently reduced; and the bearing bush produced by adopting the process has better dry grinding resistance, meshing resistance, corrosion resistance and wear resistance, and can reduce scuffing on the inner surface of the bearing bush in the installation and use process, so that the service lives of the bearing bush and lubricant in the bearing bush can be prolonged.

Owner:YANTAI CHUNSHENG SLIDING BEARING

Processing technology for lubricating wear-resistant coating of bearing bush of engine

ActiveCN109248843ASolve environmental problemsImprove operational reliabilityPretreated surfacesEpoxy resin coatingsThermal sprayingWear resistant

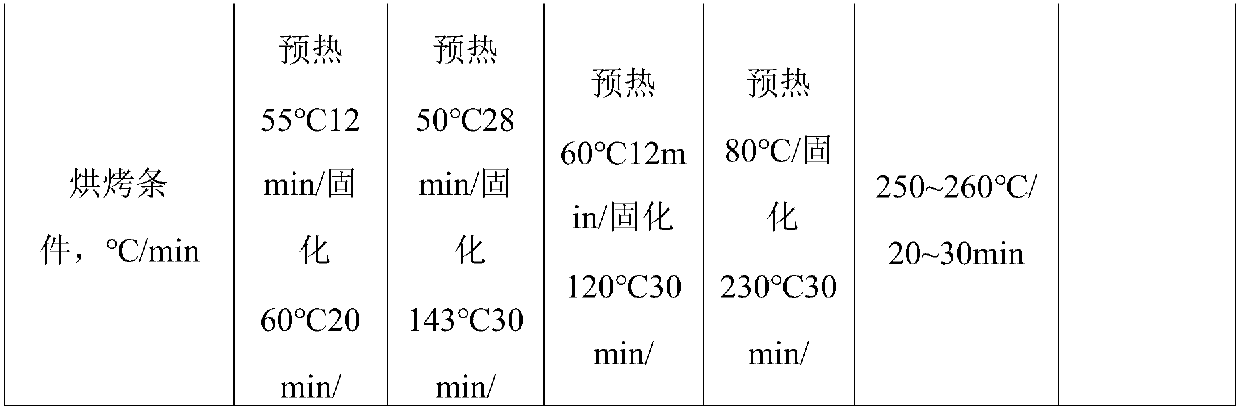

The invention discloses a processing technology for a lubricating wear-resistant coating of a bearing bush of an engine. The processing technology comprises the steps of (1) pretreatment, wherein thesurface of the bearing bush is cleaned, after sand blasting treatment, the bearing bush is placed in a passivation pond for passivation treatment, and after passivation, the bearing bush is cleaned and dried; (2) pre-heating treatment, wherein after pretreatment, the bearing bush is placed in a drying oven and hated to 40-60 DEG C, and the temperature is preserved for 10-30 min; (3) spraying treatment, wherein the bearing bush is taken from the drying oven, and thermal spraying is conducted on the surface of the bearing bush by adopting the wear-resistant lubricating coating; (4) solidifying treatment, wherein the bearing bush is placed in the drying oven and heated to 120-160 DEG C for solidifying, and the solidifying time is 20-30 min; (5) packaging checking. According to the processingtechnology, a spraying mode is adopted for replacing a bearing bush electroplating mode, the environmentally friendly problem is solved, and the production cost is reduced; the processed lubricating wear-resistant coating of the bearing bush of the engine greatly improves the running reliability of the bearing bush of the engine, and the service life is long.

Owner:在邦润滑材料(上海)有限公司

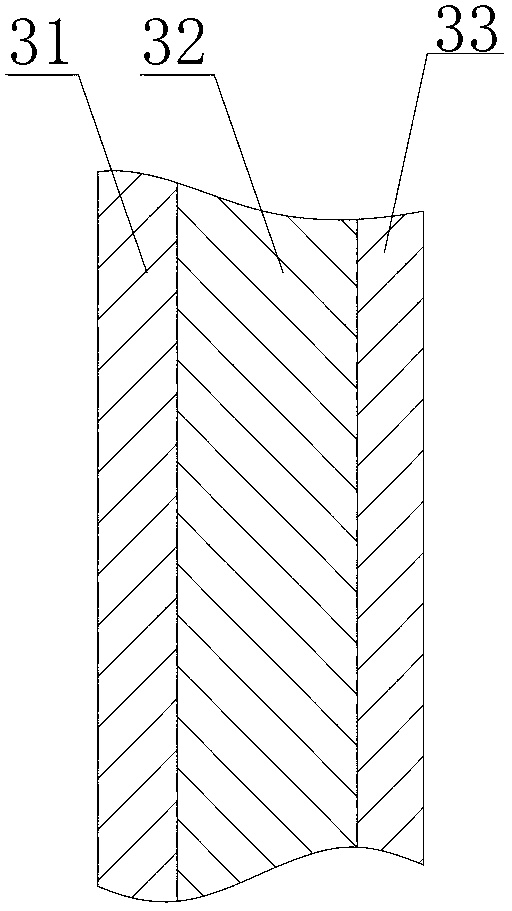

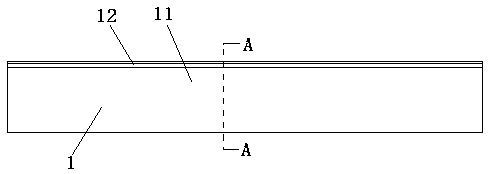

Bearing bush and process thereof for spraying MoS2 on alloy layer

ActiveCN103122937AGood bite resistanceReduce coefficient of frictionPretreated surfacesBearing componentsEnvironmental resistanceParylene

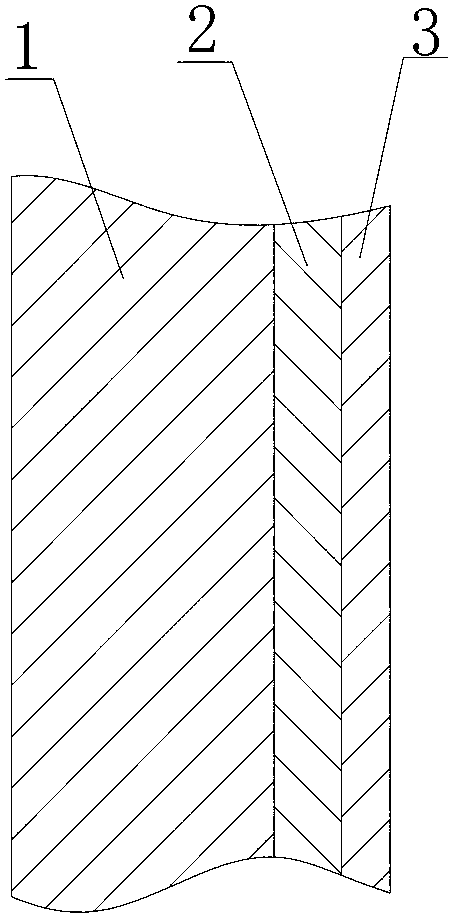

The invention provides a bearing bush and a process thereof for spraying MoS2 on an alloy layer for solving the problem that the alloy layer or the plated layer of the bearing bush peels off frequently. The bearing bush comprises a steel backing layer and the alloy layer fixedly arranged. The alloy layer is provided with a spraying layer fixed with the alloy layer. The alloy layer is one of an aluminum alloy layer or a copper-lead alloy. The spraying layer comprises a PI (Polyimide) resin layer, a MoS2 layer and a PAR (Parylene) lubricating coating sequentially arranged. The PI resin layer is contacted with the alloy layer. The bearing bush can effectively improve the dry grinding resistance, the anti-occlusion performance, the corrosion resistance and the wear resistance through the MoS2 layer by arranging the spraying layer on the alloy layer, the problem that the inner surface of the bearing bush in the installation and use process is scratched is solved, and the service lives of the bearing bush and lubricating oil in the bearing bush are prolonged. The bearing bush is good in practicality, and the whole manufacturing process of the bearing bush is safe and environment-friendly, so that the environmental pollution can be reduced.

Owner:YANTAI CHUNSHENG SLIDING BEARING

Method for preparing aluminum bronze powder by water atomization

An embodiment of the invention discloses a method for preparing aluminum bronze powder by water atomization. The method includes the steps: smelting 90.5-93.5% of Cu and 6.5-9.5% of Al to form alloy liquid under normal pressure at the temperature of 1250 DEG C; performing chemical refining deoxidation and slag raking; measuring and controlling components, adding covering agents into the alloy liquid and keeping the temperature at 1220-1250 DEG C in a standing manner; pouring the alloy liquid into a leakage ladle, atomizing the alloy liquid under the water pressure of 3-5MPa and at the water temperature of 45-50 DEG C by a free-fall nozzle under protection of inert gas to form alloy powder; dewatering and drying the alloy powder; and screening the alloy powder to obtain the aluminum bronze alloy powder with -150-+350 meshes. The aluminum bronze powder prepared by the method can serve as an anti-friction coating material in an engine sliding bearing, and environmental pollution caused by leaded anti-friction coating material is avoided.

Owner:PUJIANG HUIKAI POWDER TECH

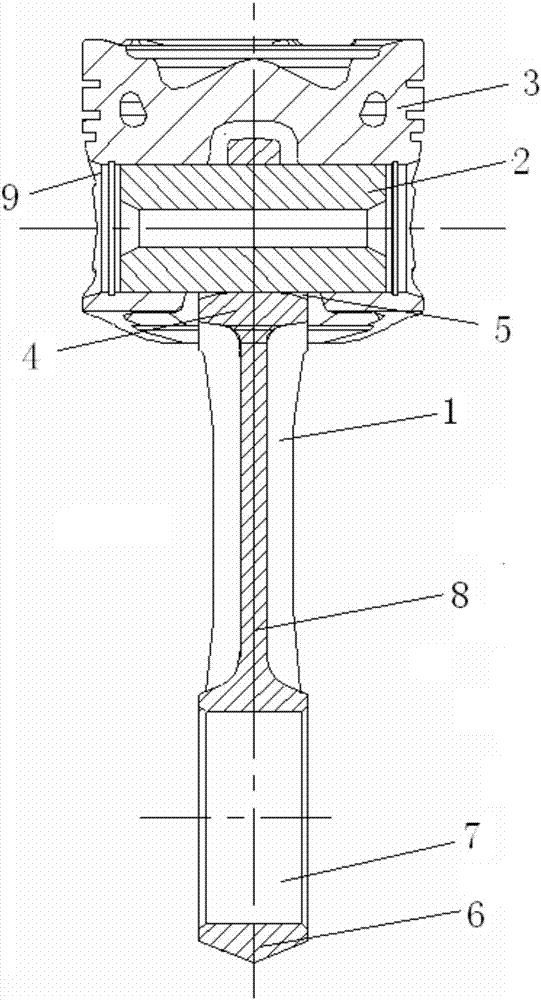

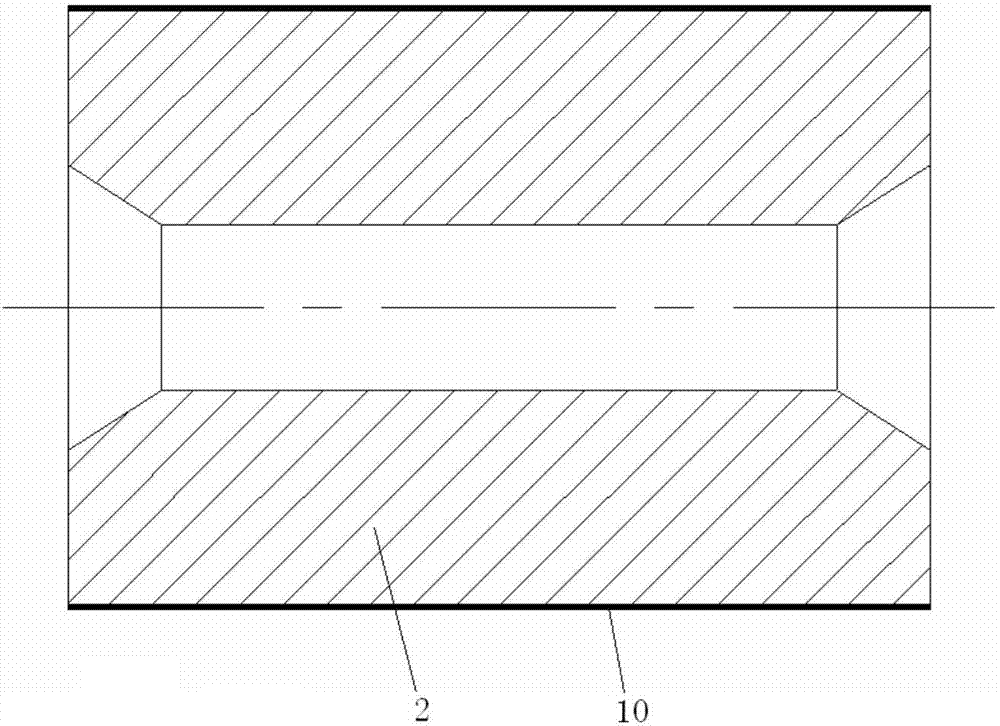

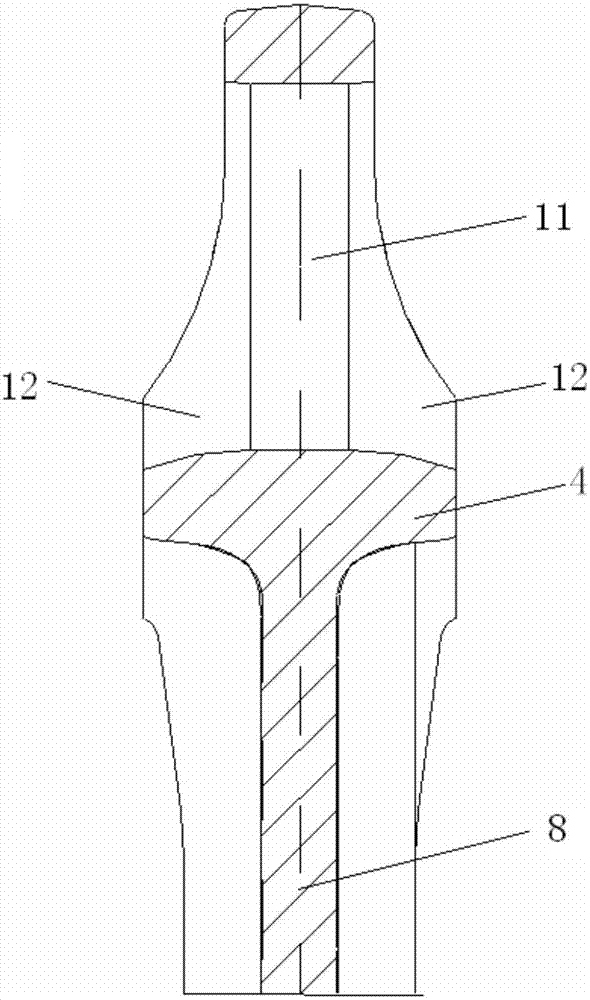

Low-friction bush-free connecting rod-piston pin structure

InactiveCN107120432AReduce in quantityReduce coefficient of frictionPlungersTrunk pistonsHardnessEngineering

The invention relates to a low-friction bush-free connecting rod-piston pin structure, in particular to a structure formed by matching a connecting rod of which a bush is omitted with a piston pin of which the surface is coated with a diamond-like coating material, namely DLC, and belongs to the technical field of connecting rod pistons. The structure comprises a connecting rod, a piston pin and a piston. The surface of the piston pin is coated with the diamond-like coating. A connecting rod small head hole comprises a middle hole section and side hole sections symmetrically formed in the left and right sides of the middle hole section. The generatrix of the middle hole section is axially straight. Each side hole section is a horn-shaped hole with the diameter is gradually increased from the side close to the middle hole section to the other side. The cross section of the connecting rod small head hole is in an oval shape. The diamond-like coating on the surface of the piston pin has high hardness, good abrasion resistance and self-lubricating property, low friction coefficient and good adhesive resistance, and completely adapts to the oil-less lubricating state of the connecting rod small head hole.

Owner:CHINA FIRST AUTOMOBILE

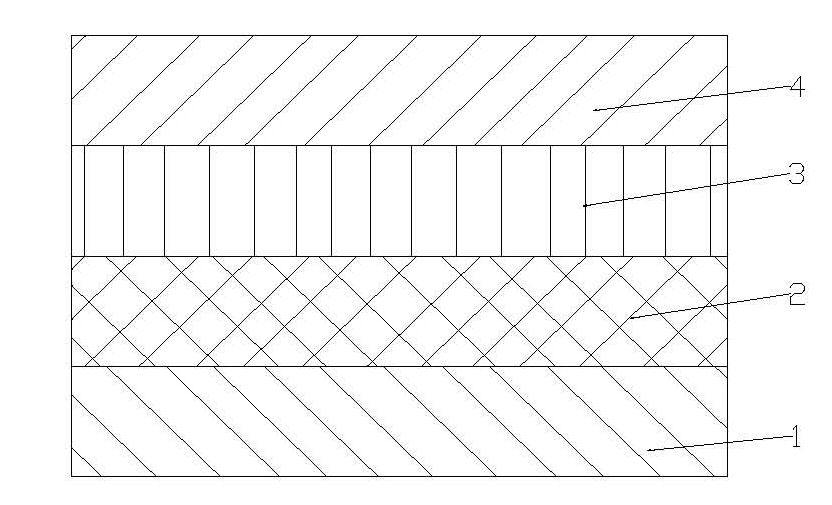

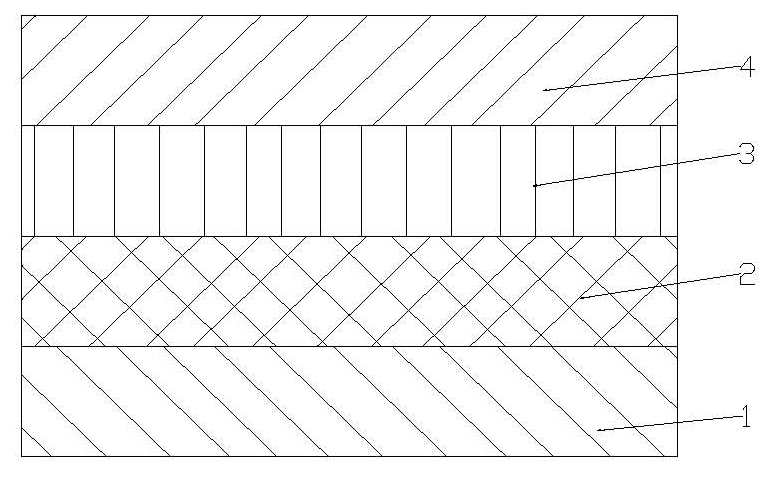

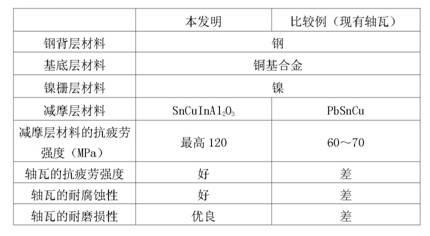

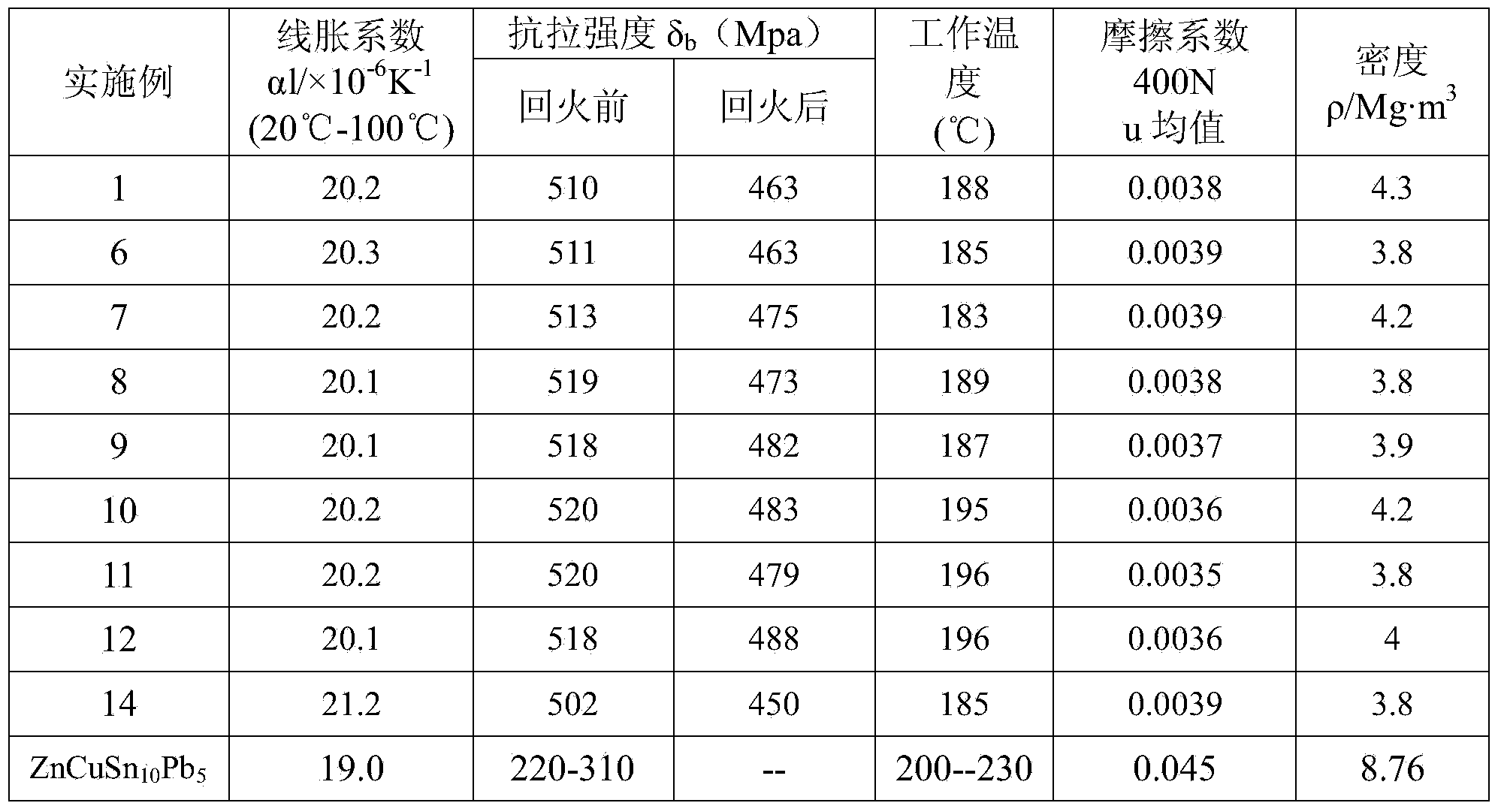

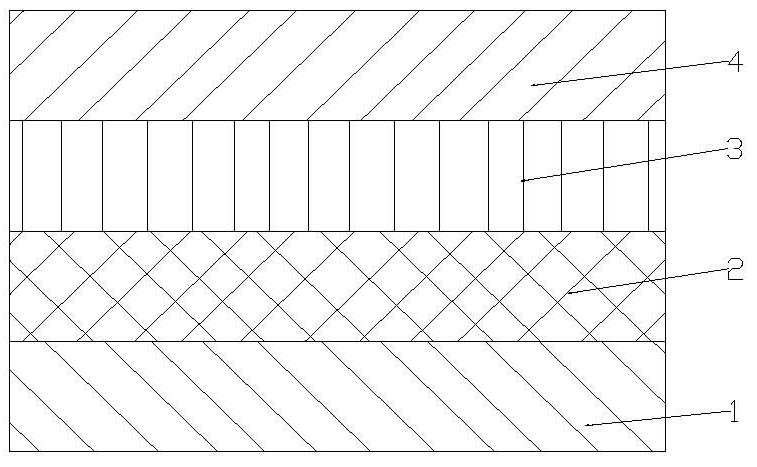

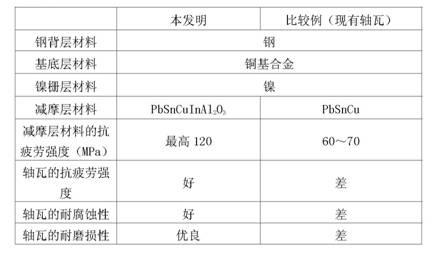

Composite coated bearing shell

The invention discloses a composite coated bearing shell which comprises a steel backing layer, a basal layer, a nickel grid layer and an antifriction layer which are sequentially arranged. The composite coated bearing shell is characterized in that the antifriction layer is made of tin-copper-indium-aluminum oxide alloy, wherein the tin-copper-indium-aluminum oxide alloy comprises the following elements by proportion: 0.7-5% of copper, 2-20% of indium, 0.5-1.5% of aluminum oxide and the balance of tin. The composite coated bearing shell has the advantages of high bearing, wear resistance, seizure resistance, good embedding performance and corrosion resistance, no lead, environment friendliness and the like.

Owner:GUANGZHOU ANDA AUTOMOBILE PARTS

Highly wear-resisting axle-hang free aluminum base alloy and preparation method thereof

InactiveCN103436756AGrain refinementImprove wear resistance and antifriction performanceRheniumManganese

The invention discloses an aluminum base alloy which comprises the following components in percent by weight: 38-40% of zinc, 0.5-5% of silicon, 3.0-5% of copper, 0.5-1% of manganese, 0.3-0.5% of chromium, 1.2-1.8% of rhenium, 1-1.5% of boron, 0.038-0.048% of magnesium, 0.015-0.02% of titanium and the balance of aluminum. The invention further discloses a preparation method thereof. The aluminum base alloy disclosed by the invention has the advantages of high wear resistance, no axle-hang, low expansion rate, self-lubrication, anti-occluding function and high work temperature, and the low expansion rate of the alloy is realized, so that the aluminum base alloy is suitable for manufacturing various precise friction pair parts of mechanical equipment.

Owner:四川超耐磨高科技有限公司

Aluminum tin 40 copper-steel metal bearing material and production method thereof

ActiveCN102935447AGood bite resistanceImprove complianceMetal rolling arrangementsIngotDiesel engine

The invention discloses an aluminum tin 40 copper-steel metal bearing material and a production method thereof. The production method comprises that (1) aluminum tin 40 copper alloy ingots of which two surfaces are roughened and a pure aluminum layer are subjected to the dual-surface composite rolling, the cold rolling is conducted sequentially till the target thickness is reached, the aluminum tin 40 copper alloy ingots are obtained through horizontal continuous casting, the processing rate of the dual-surface composite rolling is more than 50% and the processing rate per cold rolling is in a range from 20% to 35%; and (2) steel plates of which two surfaces are roughened and the aluminum tin 40 copper alloy after being burnished in the (1) are subjected to the composite rolling and the annealing is conducted for 8-10 hours at the temperature of 280 DEG C+ / -10 DEG C. The material has good seizure resistance, adaptability and high-temperature properties and is suitable to diesel engine bearing of medium and low speed ships.

Owner:SHANGHAI HEWEI IND

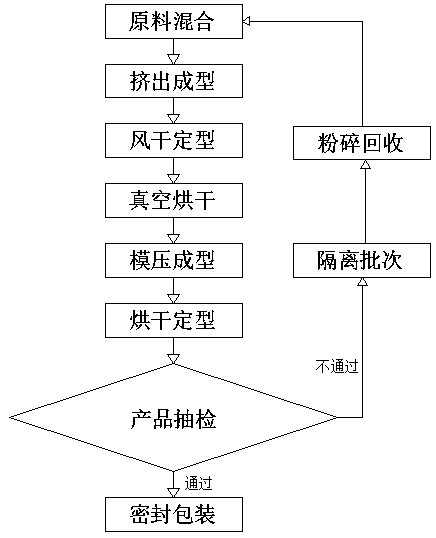

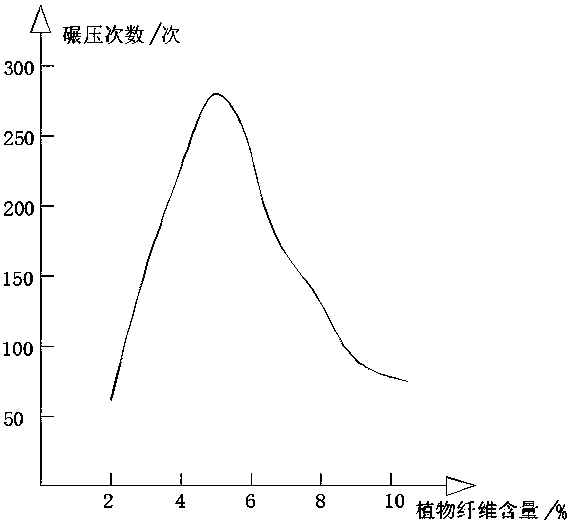

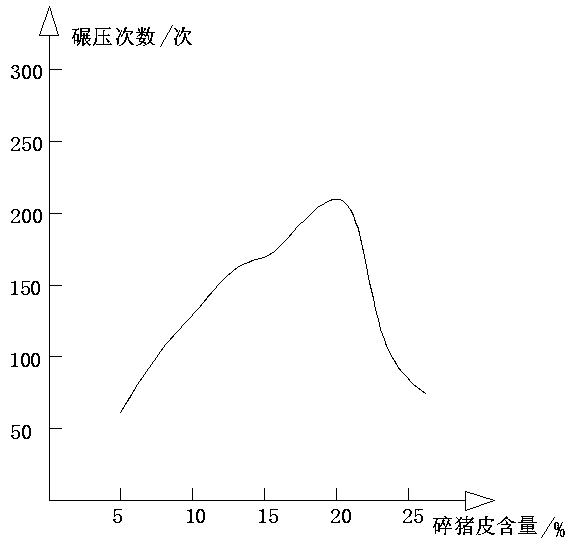

Molding method of chew type pet food

InactiveCN109845893AImprove bite resistanceImprove product qualityAnimal feeding stuffAccessory food factorsWettingAir drying

The invention discloses a molding method of chew type pet food. The molding method comprises the following steps: raw material mixing: mixing 16% of edible gum, 20% of broken pigskin, 40% of broken cowhide, 4% of vegetable protein, 10% of a wetting agent, 5% of plant fiber and 5% of additives by a chopper mixer, and performing mixing by an internal mixer to form raw material paste A; extrusion molding: putting the raw material paste in a food extruder to be extruded into gum strips; air drying and setting: placing a blowing device at a discharge port of the food extruder, performing air dryingon the extruded gum strips; and vacuum drying: placing the gum strips in a vacuum oven for drying at the drying temperature of 53-75 DEG C until the moisture weight content reaches 31%-33%. The chewing resistance of the product can be improved, so that pet food is more durable, the product quality can be improved, by vacuum drying of the extruded rubber strips, the condition that the product sticks to a die during die pressing can be avoided, production is facilitated, and the production efficiency of the product can be improved.

Owner:GUANGDE YOUWEIFANG PET FOOD

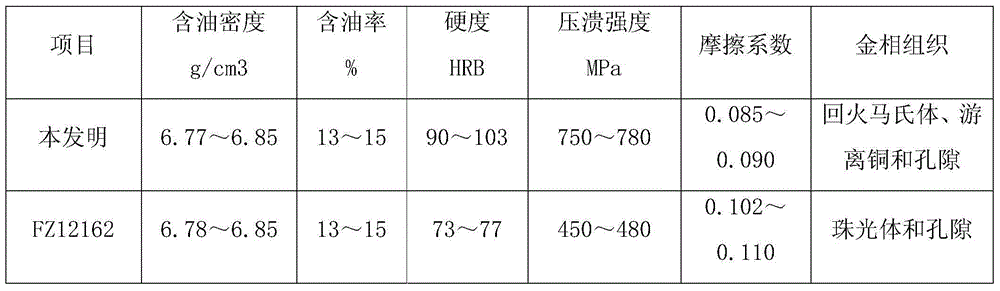

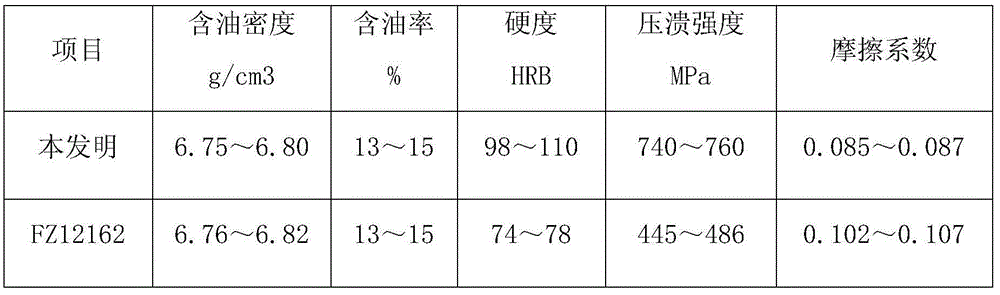

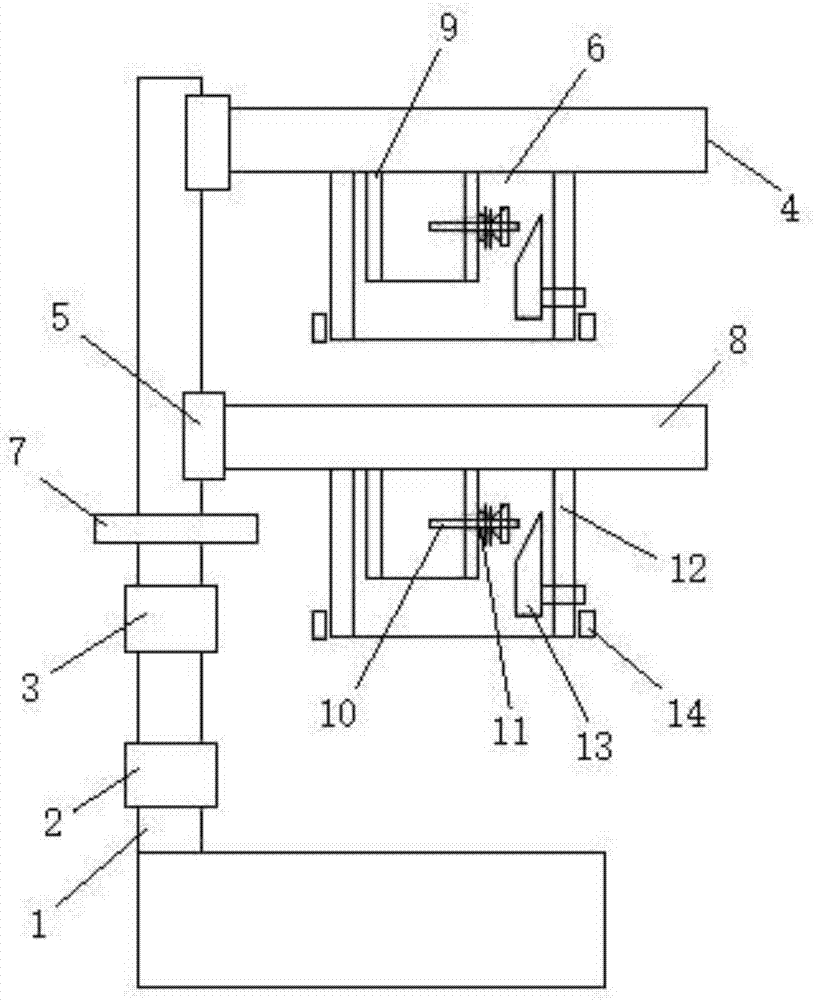

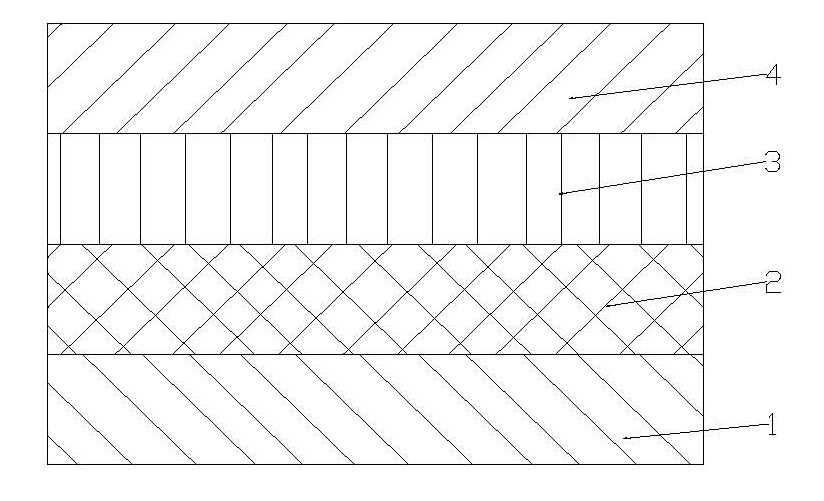

High-strength and wear-resisting iron based powder metallurgic bearing

The invention discloses a high-strength wearproof iron-based powder metallurgy bearing material and a preparation method thereof. The high-strength wearproof iron-based powder metallurgy bearing material is characterized by being composed of the following components by weight percent: 16.0%-18.0% of copper, 0.80%-0.90% of carbon, 0.01%-1.0% of cerium fluoride and the balance of iron, wherein the total amount of impurities is not higher than 2%. The process for preparing the iron-based powder metallurgy bearing material comprises the steps of mixing powder, pressing, sintering, heat treatment and vacuum oil immersion. The iron-based powder metallurgy bearing material provided by the invention has high-strength wear-resisting properties, specifically, the crushing strength of the bearing material ranges from 720 MPa to 780 MPa, the Rockwell hardness of the bearing material ranges from 90 HRB to 110 HRB, the oil length of the bearing material ranges from 13% to 16% and the oiling friction coefficient of the bearing material ranges from 0.08 to 0.09. The material provided by the invention is used as oil cylinder bearings of engineering machinery, such as an excavator and a bulldozer.

Owner:合肥波林新材料股份有限公司

Farmland irrigation device

InactiveCN107079782AAvoid cloggingAvoid damageWater/sewage treatment by irradiationSpecific water treatment objectivesWater storageEngineering

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Alloy coating bushing

ActiveCN101851712AHigh hardnessIncrease the carrying areaBearing componentsCorrosion resistantIndium

The invention discloses an alloy coating bushing which comprises a steel backing layer, a substrate layer, a nickel grid layer and a friction-reducing layer which are sequentially arranged. The friction-reducing layer is made from a lead-tin-copper-indium alumina alloy which is prepared from the following elements in percentage by weight: 4-18 percent of tin, 0.7-5 percent of copper, 2-20 percent of indium, 0.5-1.5 percent of alumina and the balance of lead. The alloy coated bushing has the advantages of high bearing capability, abrasion and interlacement resistance, good embedment and corrosion resistance, low lead content, environmental protection and the like.

Owner:湖北安达精密工业有限公司

Tooth cleaning bone for tooth cleaning/protection of pets and processing method of tooth cleaning bone

InactiveCN109964843AGood tooth cleaning effectImprove palatabilityAnimal feeding stuffAccessory food factorsFiberGlycerol

The invention discloses a tooth cleaning bone for tooth cleaning / protection of pets and a preparation method of the tooth cleaning bone. The tooth cleaning bone consists of a tooth cleaning base material and a tooth cleaning / protection material. The tooth cleaning base material is prepared from, by mass percentage, 15-25% of starch, 15-30% of gluten powder, 2-10% of edible natural plant fibers, 8-15% of plant protein powder, 0.2-1% of sodium tripolyphosphate, 15-25% of glycerol and 15-25% of water. The tooth cleaning / protection material is prepared from, by mass percentage, 25-35% of meat powder, 15-25% of plant protein powder, 10-20% of starch, 0.2-0.6% of sodium tripolyphosphate, 8-15% of glycerol, 0.4-1% of an acidity regulator, 0.01-0.2% of a bacteriostatic component and 15-25% of water. The obtained tooth cleaning bone for pets has good efficacy of cleaning and protecting the teeth, and the preparation method of the tooth cleaning bone for tooth cleaning / protection of pets is moreefficient than the prior art.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

High-palatability combined pet tooth cleaning bone and preparation method thereof

ActiveCN109964842AGood tooth cleaning effectImprove palatabilityFood processingTaming and training devicesPotato starchGlycerol

The invention discloses a high-palatability combined pet tooth cleaning bone and a preparation method thereof. The tooth cleaning bone is composed of a base material and a palatability material; the base material comprises, by mass, 15-25% of meat meal, 10-18% of potato starch, 20-28% of wheat gluten, 5-12% of plant protein powder, 0.4-0.8% of tea polyphenol, 0.6-1.2% of an acidity regulator, 10-20% of glycerol and 12-24% of water; the palatability material comprises, by mass, 91-95% of fresh meat, 0.01-0.05% of vitamin E, 1-5% of water and 2-6% of glycerol. The obtained combined pet tooth cleaning bone has a good tooth cleaning effect and relatively high in palatability, and the preparation method of the high-palatability combined pet tooth cleaning bone is more efficient compared with the prior art.

Owner:GAMBOL PET GROUP CO LTD

Bone protein and preparing technique

ActiveCN101313735AAvoid bending deformationAvoid churnAnimal feeding stuffAccessory food factorsSodium phosphatesPyrophosphate

The invention discloses a bone protein, which comprises a main material and auxiliary materials, wherein, the main material is 65.0 to 72.3 percent of corn starch, and the auxiliary materials comprise 7.0 to 8.0 percent of fresh chicken, 18.3 to 22.0 percent of sorbitol, 0.1 to 0.2 percent of sodium pyrophosphate, 0.04 to 0.05 percent of sodium hexametaphosphate, 0.07 to 0.08 percent of trimeric sodium phosphate, 0.15 to 0.21 percent of sodium dehydroacetate, 0.20 to 0.30 percent of xanthan gum, 0.20 to 0.3 percent of potassium sorbate and 0.4 to 0.7 percent of functional additives. The invention also discloses a technique for manufacturing the bone protein, comprising the following steps: firstly, the main material corn starch is weighed and taken for standby; secondly, the auxiliary materials are weighed and taken for standby; thirdly, liquid auxiliary materials are prepared; fourthly, raw materials are prepared; fifthly, preheating is performed through a bulking machine; sixthly, processing is performed; and seventhly, the bone protein is cooled, cut and packaged in time.

Owner:JIANGSU KANGBEI PET FOOD CO LTD

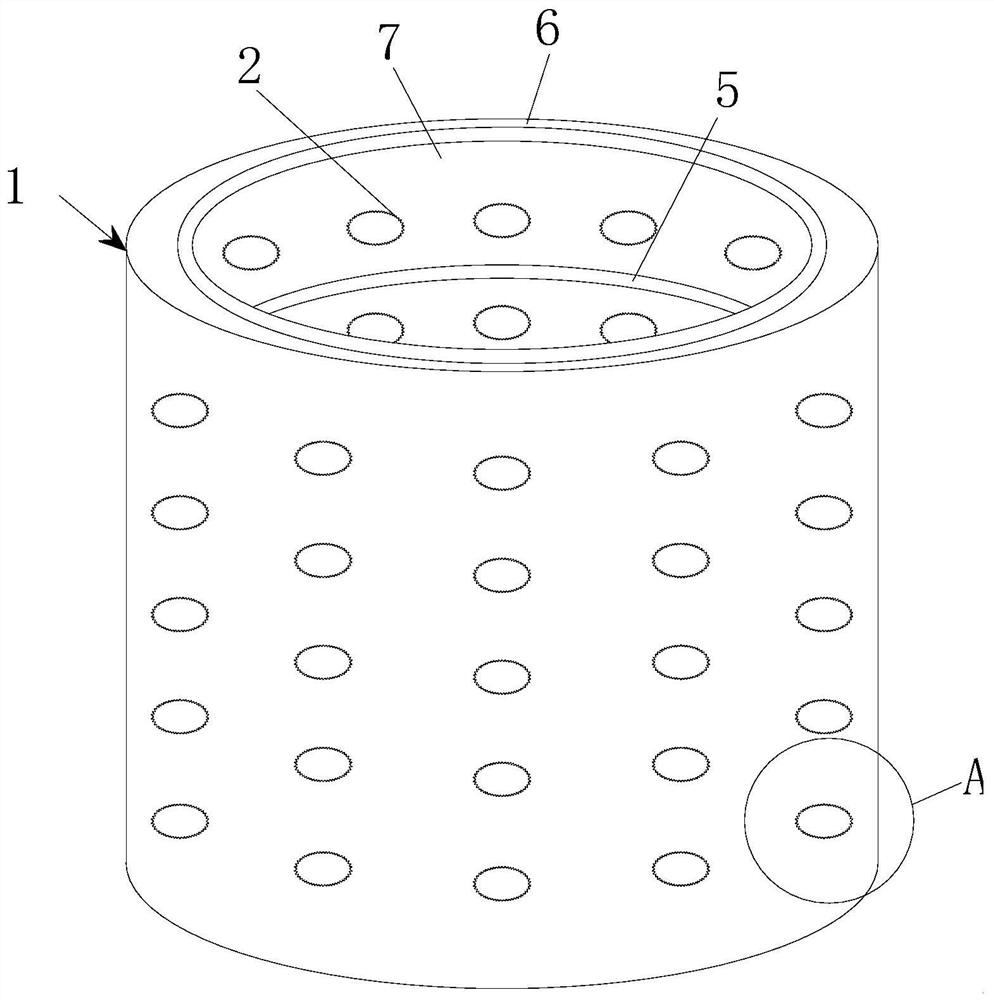

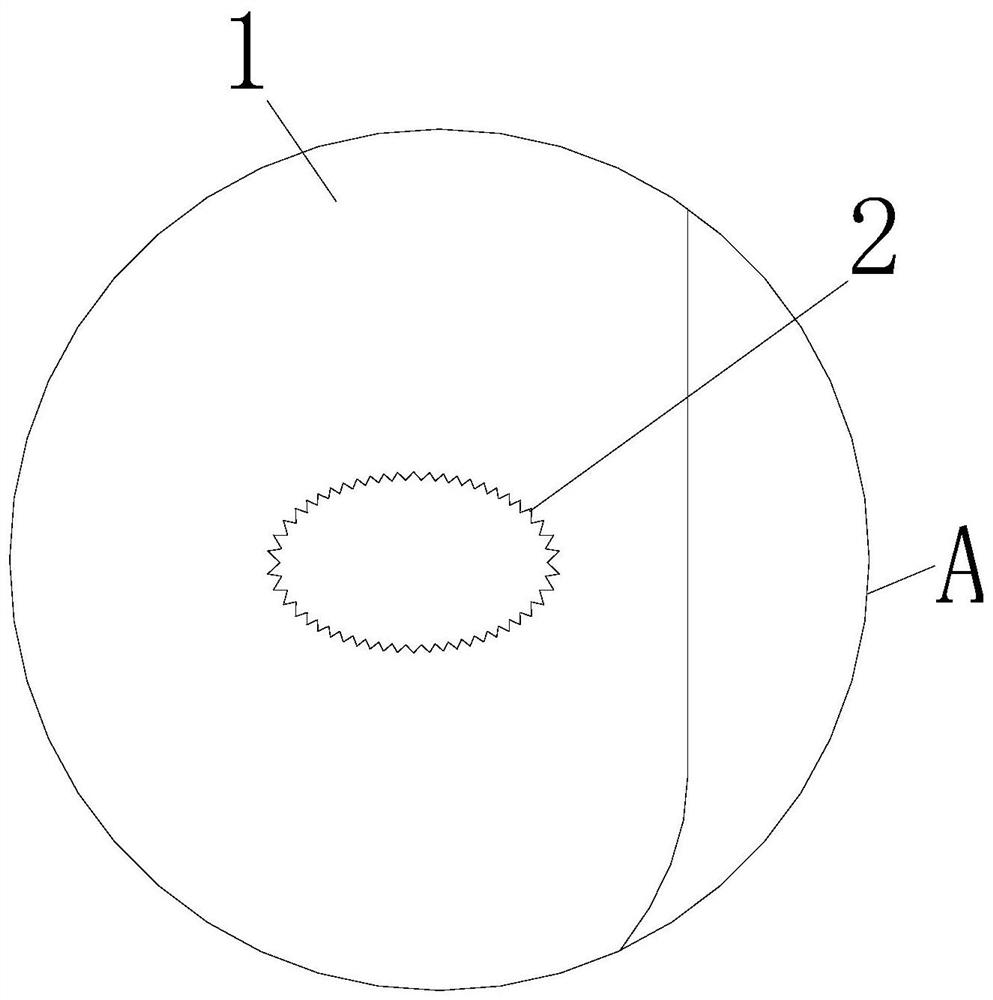

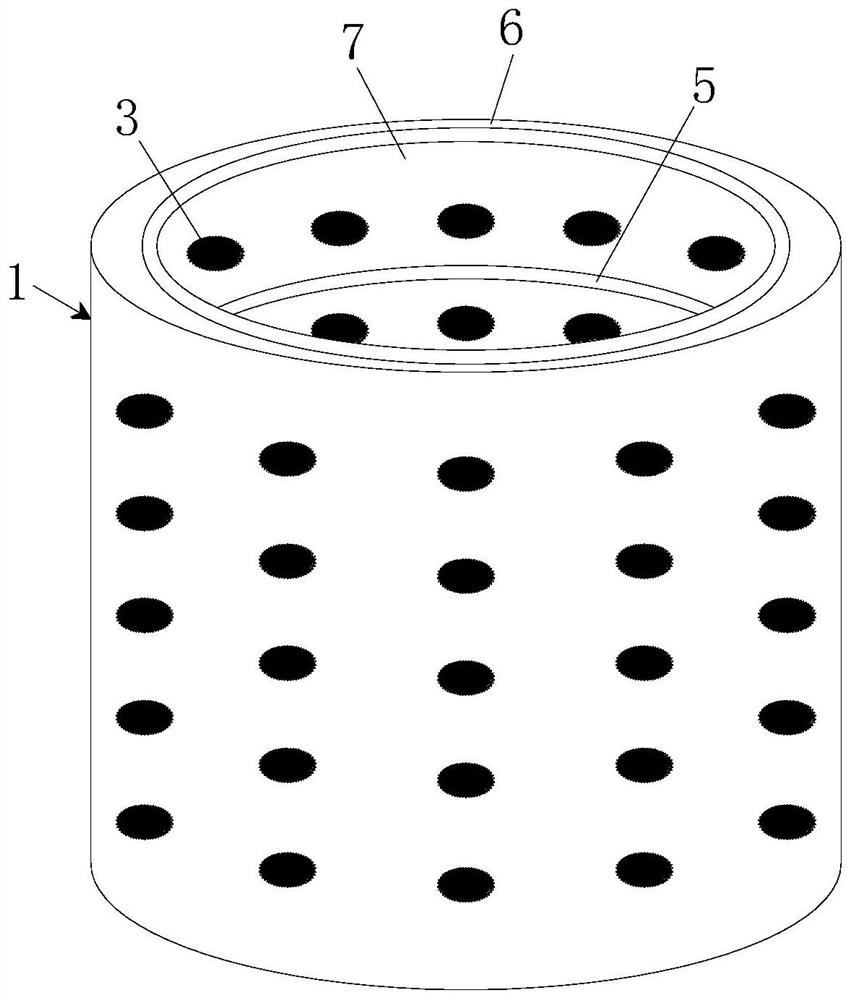

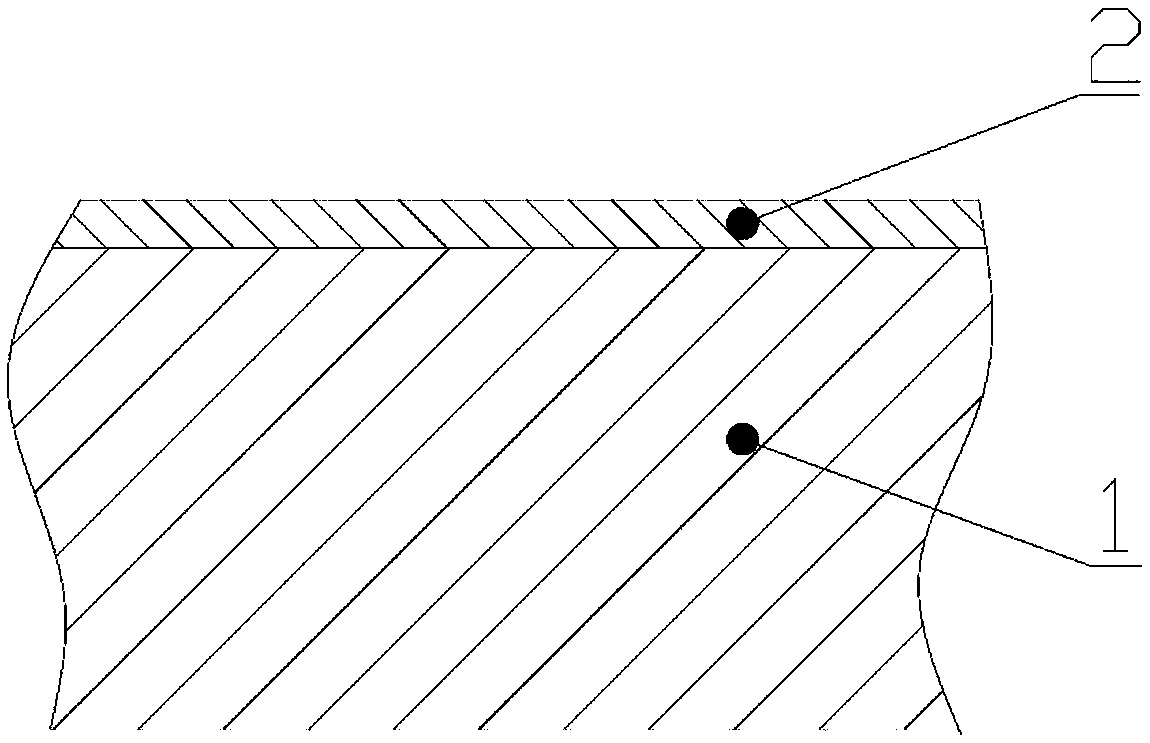

HYB-650 copper-based inlaid solid lubricating bearing and manufacturing process thereof

ActiveCN111795074AIncrease loading capacityGood anti-fatigue propertiesShaftsBearing componentsMetallurgyLubrication

The invention provides an HYB-copper-based inlaid solid lubricating bearing, and relates to the field of bearings. The HYB-650 copper-based inlaid solid lubricating bearing and a manufacturing processthereof comprise a bearing substrate, lace embedded holes and a corrugated solid lubricating column. The bearing substrate comprises a copper-base layer and a sintered layer. The lace embedded holespenetrate through the inner and outer diameters of the bearing substrate. A plurality of lace embedded holes are distributed criss-crossed on the bearing substrate. The HYB-650 copper-based inlaid solid lubricating bearing and the manufacturing process thereof, through special and unique creation of basic mechanism of the solid lubricating bearing, under the premise of not affecting the integrityof the bearing, greatly improves the problem of poor durability of a lubricating oil film of the solid lubrication bearing, and reserves a lubricating strip film which can be used directly for the oilfilm, thereby effectively solves the problem of poor continuous replenishment of a solid lubricant of a general copper-based inlaid solid lubricating bearing, and the problem of the lubrication effect being in a diminishing state when the solid lubricant is not completely consumed.

Owner:HUAYI BEARING TECH JIANGSU CO LTD

Double-layer metal composite material applied to sliding bearings and preparation method of double-layer metal composite material

InactiveCN109296643AGood thermal conductivityPrevent lockShaftsBearing componentsAlloy elementThermal conductivity

Owner:SHANGHAI JIAO TONG UNIV

Pet dental care chews with high palatability and processing method thereof

PendingCN109997720AGood tooth cleaning effectImprove palatabilityFodderTaming and training devicesFiberPhosphate

The invention discloses pet dental care chews with high palatability and a processing method thereof. The pet dental care chews are made with a base material and a palatable material; the base material is made with, by mass, 15-30% of starch, 15-30% of wheat gluten, 2-10% of edible natural plant fibers, 6-10% of phosphate-modified starch, 0.2-1% of sodium tripolyphosphate, 0.4-1% of an acidity regulator, 15-25% of glycerol, and 15-25% of water. The palatable material is made with, by mass, 80-90% of fresh meat, 2-10% of starch, 2-8% of glycerol, 0.2-1% of sodium tripolyphosphate, and 1-5% of water. The pet dental care chews herein have good dental cleaning effect and good palatability; the processing method of the pet dental care chews is more efficient than the prior art.

Owner:GAMBOL PET GROUP CO LTD

Spraying mos2 process of a bearing bush and its alloy layer

ActiveCN103122937BGood bite resistanceReduce coefficient of frictionPretreated surfacesBearing componentsParyleneAlloy

The invention provides a bearing bush and a process thereof for spraying MoS2 on an alloy layer for solving the problem that the alloy layer or the plated layer of the bearing bush peels off frequently. The bearing bush comprises a steel backing layer and the alloy layer fixedly arranged. The alloy layer is provided with a spraying layer fixed with the alloy layer. The alloy layer is one of an aluminum alloy layer or a copper-lead alloy. The spraying layer comprises a PI (Polyimide) resin layer, a MoS2 layer and a PAR (Parylene) lubricating coating sequentially arranged. The PI resin layer is contacted with the alloy layer. The bearing bush can effectively improve the dry grinding resistance, the anti-occlusion performance, the corrosion resistance and the wear resistance through the MoS2 layer by arranging the spraying layer on the alloy layer, the problem that the inner surface of the bearing bush in the installation and use process is scratched is solved, and the service lives of the bearing bush and lubricating oil in the bearing bush are prolonged. The bearing bush is good in practicality, and the whole manufacturing process of the bearing bush is safe and environment-friendly, so that the environmental pollution can be reduced.

Owner:YANTAI CHUNSHENG SLIDING BEARING

Technology of utilizing liquid-solid rolling cladding method to prepare bimetallic bearing

InactiveCN104690555AGood compressive and tensile mechanical propertiesGood fatigue strengthOther manufacturing equipments/toolsSliding contact bearingsComposite strengthZinc

The invention discloses a technology of utilizing a liquid-solid rolling cladding method to prepare a bimetallic bearing. According to the technical scheme, the technology comprises the following steps: adopting the liquid-solid rolling cladding method combining a casting method with a composite method; directly pouring zinc-based aluminum alloy molten metal to a base metal; cooling, solidifying and rolling by water cooled rolls to produce a composite board without larger plastic deformation. The technology disclosed by the invention has the characteristics as follows: the bimetallic bearing alloy prepared by the technology is excellent in compression resistance, tension resistance, mechanical property, friction performance, high-temperature stability performance and casting property; meanwhile, the liquid-solid rolling cladding method is a near net-shape processing method organically combining the hot dip aluminum plating with aluminum alloy cast rolling, so that the method is high in combined strength, low in production cost, less in equipment investment, high in production efficiency, low in energy consumption and high in composite board binding strength, and further has a good market prospect.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

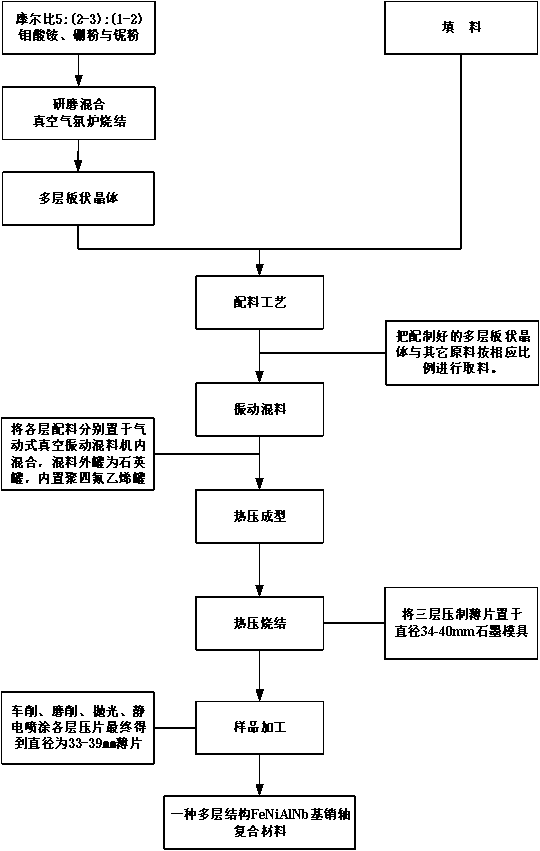

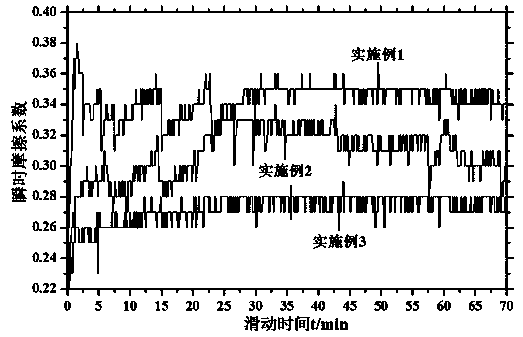

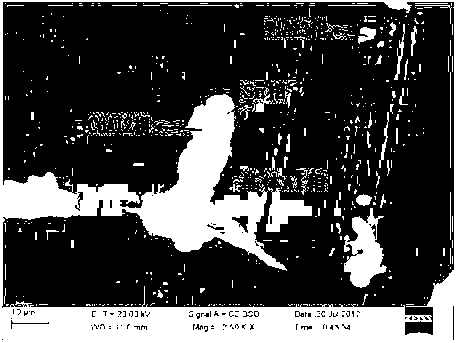

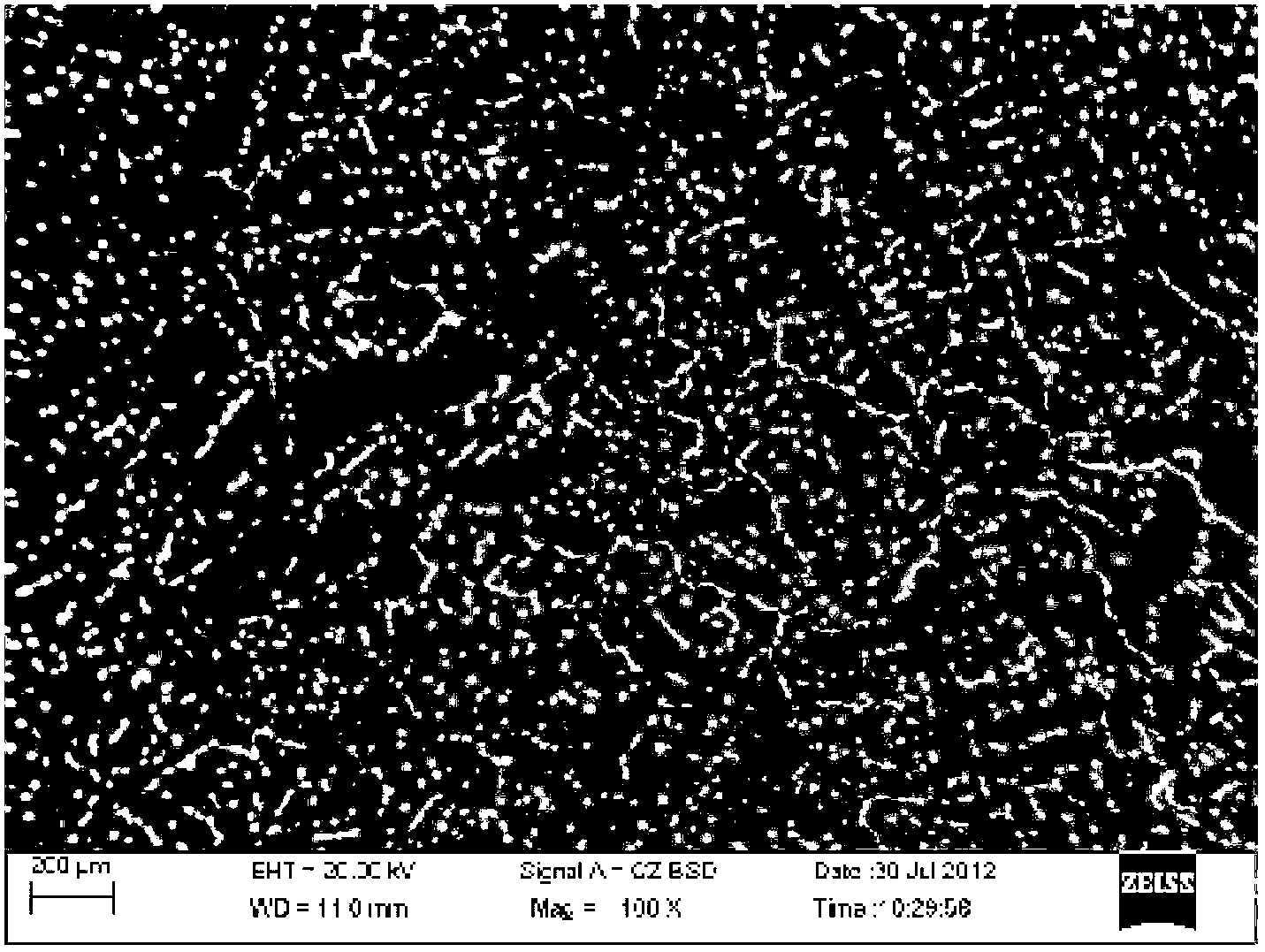

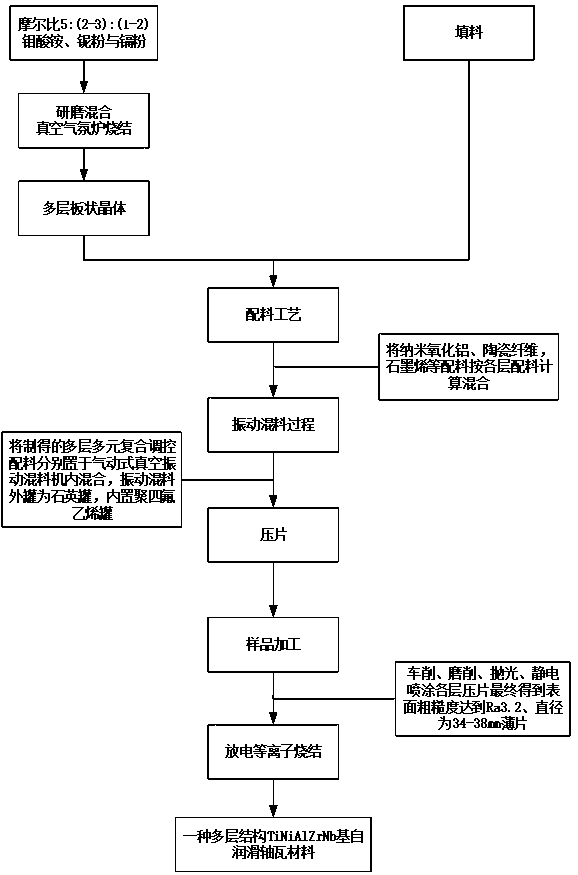

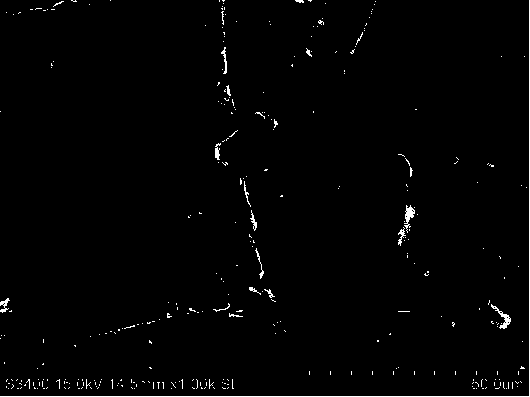

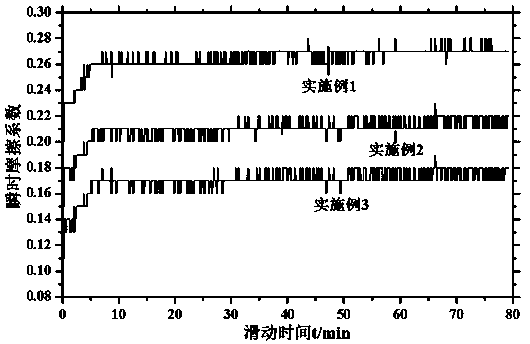

Tribological design and preparation method of FeNiAlNb-based pin shaft multilayer composite structure material

ActiveCN110626016AImprove tribological propertiesModerate coefficient of frictionLamination ancillary operationsLaminationAlloyThermal stability

The invention discloses a tribological design and preparation method of an FeNiAlNb-based pin shaft multilayer composite structure material. A FeNiAlNb matrix, an antifriction agent, an anti-wear agent and a reinforcing agent are adopted as the components, a multi-element tabular crystal is prepared, by means of each layer material component design and computation, vibration mixing, hot press molding, multi-layer structure compounding and subsequent machining procedures, the FeNiAlNb-based pin shaft multilayer composite structure material can be prepared. Through reasonable design and optimalproportioning of the matrix alloy, the antifriction agent, the anti-wear agent and the reinforcing agent on a friction film, a bearing transition layer and a matrix bearing layer, the material utilization rate is improved, the production cost is reduced, and the FeNiAlNb-based pin shaft multilayer composite structure material can meet the friction and wear properties under high-low temperature andhigh-load working conditions while having excellent thermal stability and mechanical properties, and also significantly enhances the use precision and service life of the pin shaft on the premise ofobviously improving the connection strength and bearing capacity of the pin shaft.

Owner:ANYANG INST OF TECH

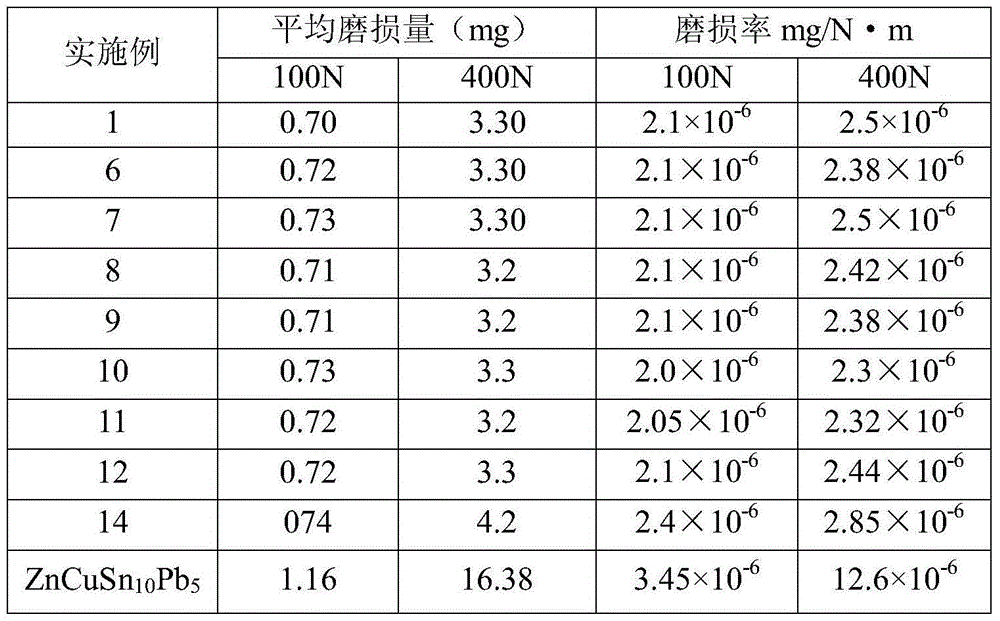

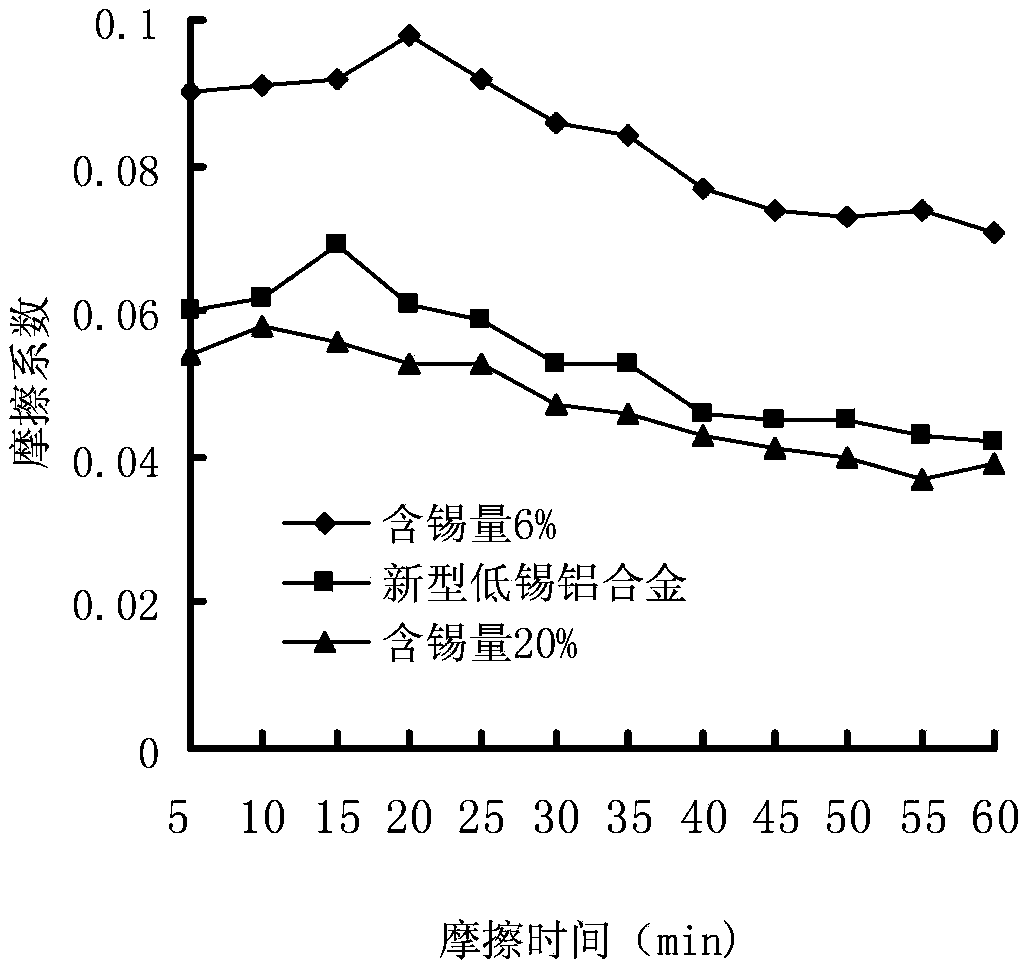

Preparation method for heavy-load high-power vehicle engine high-purity aluminum-tin bearing materials

The invention relates to a preparation method for heavy-load high-power vehicle engine high-purity aluminum-tin bearing materials. The preparation method includes the detailed steps of weighing industrial pure metallic tin, first-level electrolytic copper and special second-level aluminum ingots for re-melting in proportion; weighing first-level potassium fluotitanate; putting the first-level potassium fluotitanate into a constant temperature preheating drying furnace for drying; putting the special second-level aluminum ingots for re-melting into an industrial furnace; adding the industrial pure metallic tin and first-level electrolytic copper after all the special second-level aluminum ingots in the furnace are smelted; sampling and detecting alloy contents; putting the first-level potassium fluotitanate into aluminium alloy melt; and casting. According to the aluminum-tin bearing materials prepared in the method, strength reaches 140-165 megapascals, elongation reaches 15-19 %, brinell hardness reaches 45-51, fatigue strength reaches 90-106 megapascals, abrasion loss reaches 6.7-7 * 10-4 grams, anti-seizure adhesiveness reached the second level, and friction coefficient is 0.038-0.042. Therefore, the prepared bearing materials are high in bearing capacity, are good in abrasion-resistance, antifriction performance and anti-seizure adhesiveness, meet the requirements of a heavy-load high-power vehicle engine, and have broad application prospects.

Owner:GUANGZHOU LIZHONG JINSHAN ALLOY

Multi-layer structure TiNiAlZrNb-based self-lubricating bearing bush material design and preparation method thereof

InactiveCN110614360AImprove working condition adaptabilityGreenTransportation and packagingMetal-working apparatusOil and greaseMaterial Design

The invention relates to a multi-layer structure TiNiAlZrNb-based self-lubricating bearing bush material design and a preparation method thereof. The main component of the self-lubricating bearing bush is composed of a TiNiAlZrNb substrate, a soft metal SnCuZnAg and a multi-element composite regulating agent, the machining process of a TiNiAlZrNb-based self-lubricating bearing bush is prepared bya multi-element plate-shaped crystal, and each layer of material is subjected to design calculation and vibration mixing and hot press molding and sample machining and is compounded with a multilayerstructure. Compared with uniformly distributed block body bearing bush materials, and the TiNiAlZrNb-based multi-layer structure composite materials greatly save the material usage amount on the premise of meeting the performance requirements of the bearing bush materials; meanwhile, the multi-layer structure composite materials can replace oil and grease under working conditions such as high temperature and high pressure to achieve good lubricating effect, and the multi-layer structure TiNiAlZrNb-based self-lubricating bearing bush materials have the advantages of green environmental protection, high use precision, long service life.

Owner:ANYANG INST OF TECH

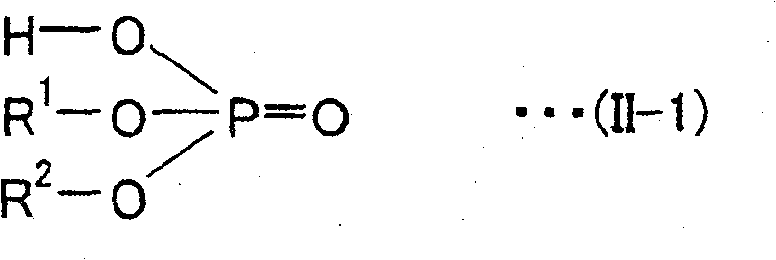

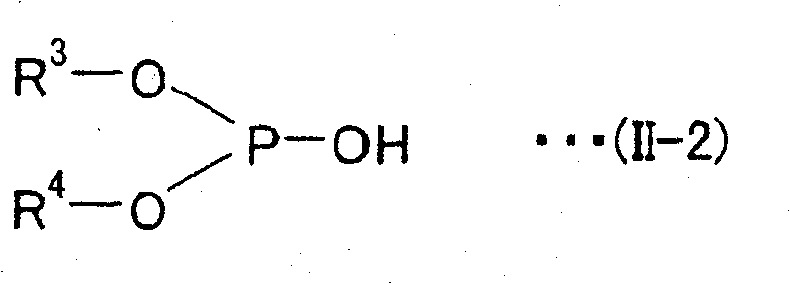

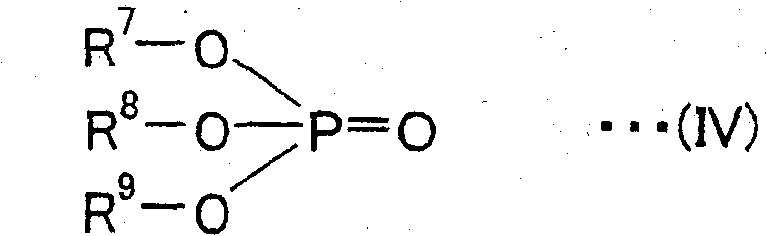

Hydraulic oil composition

ActiveCN101517054BImprove energy savingImprove thermal stabilityThickenersAdditivesFriction reductionAlcohol

A hydraulic oil composition obtained by blending a base oil having a sulfur content of less than 0.03% by mass, a content of saturates of 90% by mass or above, a viscosity index of 80 or above and an absolute viscosity at 40 DEG C of 1 to 1000mPa s with (A) 1 to 20% by mass of a polymethacrylate-type viscosity index improver having a weight-average molecular weight of 10,000 to 50,000, (B) 0.005 to 5% by mass of an acid amide, (C) 0.005 to 5% by mass of (c-1) a specific hydrogenphosphate ester and / or (c-2) a specific hydrogenphosphite ester and (D) 0.005 to 5% by mass of at least one member selected from among polyhydric alcohol esters, alkanolamines, olefin sulfides, and thiocarbamates. The hydraulic oil composition exerts satisfactory and well-balanced properties essential to hydraulic oil which include energy saving, heat stability (sludge resistance), prevention of wear and scuffing, water shedding, and friction reduction in sliding parts.

Owner:IDEMITSU KOSAN CO LTD

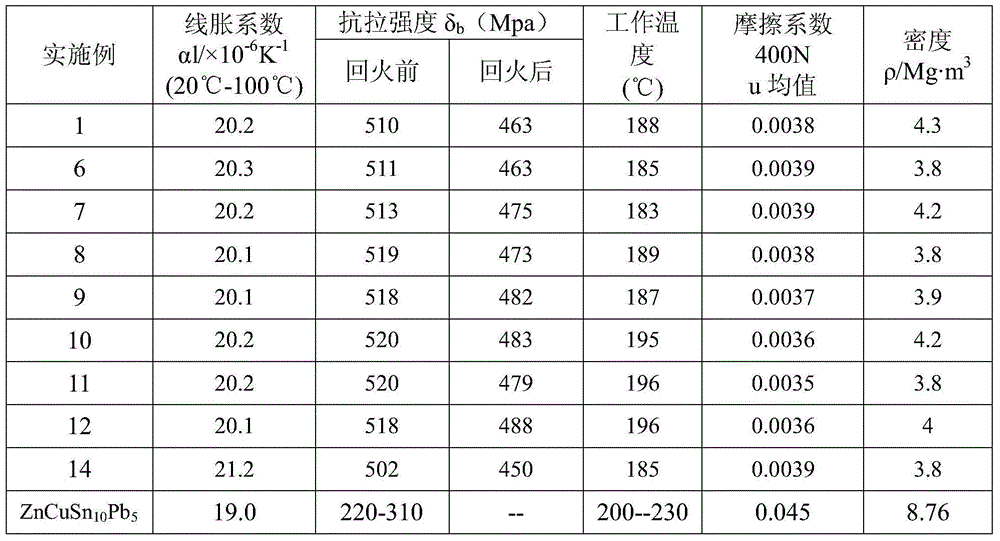

A high wear-resistant shaft-free aluminum-based alloy and its preparation method

InactiveCN103436756BGrain refinementImprove wear resistance and antifriction performanceRheniumWear resistant

The invention discloses an aluminum base alloy which comprises the following components in percent by weight: 38-40% of zinc, 0.5-5% of silicon, 3.0-5% of copper, 0.5-1% of manganese, 0.3-0.5% of chromium, 1.2-1.8% of rhenium, 1-1.5% of boron, 0.038-0.048% of magnesium, 0.015-0.02% of titanium and the balance of aluminum. The invention further discloses a preparation method thereof. The aluminum base alloy disclosed by the invention has the advantages of high wear resistance, no axle-hang, low expansion rate, self-lubrication, anti-occluding function and high work temperature, and the low expansion rate of the alloy is realized, so that the aluminum base alloy is suitable for manufacturing various precise friction pair parts of mechanical equipment.

Owner:四川超耐磨高科技有限公司

Preparation method for heavy-load high-power vehicle engine high-purity aluminum-tin bearing materials

The invention relates to a preparation method for heavy-load high-power vehicle engine high-purity aluminum-tin bearing materials. The preparation method includes the detailed steps of weighing industrial pure metallic tin, first-level electrolytic copper and special second-level aluminum ingots for re-melting in proportion; weighing first-level potassium fluotitanate; putting the first-level potassium fluotitanate into a constant temperature preheating drying furnace for drying; putting the special second-level aluminum ingots for re-melting into an industrial furnace; adding the industrial pure metallic tin and first-level electrolytic copper after all the special second-level aluminum ingots in the furnace are smelted; sampling and detecting alloy contents; putting the first-level potassium fluotitanate into aluminium alloy melt; and casting. According to the aluminum-tin bearing materials prepared in the method, strength reaches 140-165 megapascals, elongation reaches 15-19 %, brinell hardness reaches 45-51, fatigue strength reaches 90-106 megapascals, abrasion loss reaches 6.7-7 * 10-4 grams, anti-seizure adhesiveness reached the second level, and friction coefficient is 0.038-0.042. Therefore, the prepared bearing materials are high in bearing capacity, are good in abrasion-resistance, antifriction performance and anti-seizure adhesiveness, meet the requirements of a heavy-load high-power vehicle engine, and have broad application prospects.

Owner:GUANGZHOU LIZHONG JINSHAN ALLOY

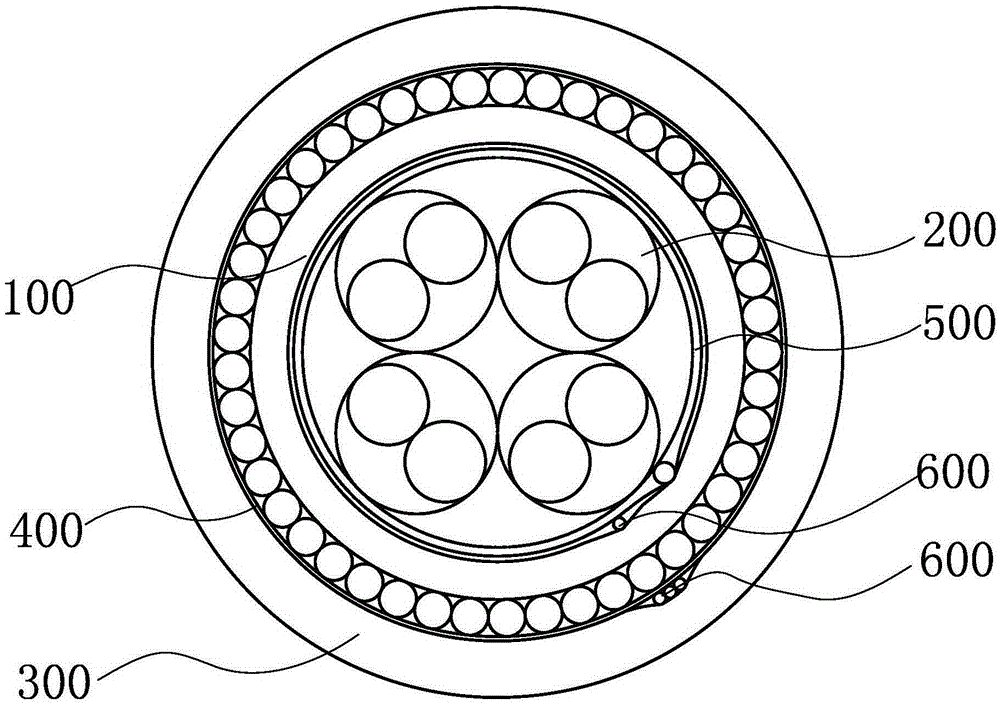

Cable

InactiveCN105304183AHigh tensile strengthIncreased bite resistanceInsulated cablesInsulated conductorsOuter root sheathLanthanum

The invention provides a cable, and belongs to the technical field of cables. The cable solves the problem of low tensile strength of the existing cable. The cable comprises an inner sheath; a plurality of wire cables are annularly arranged in the inner sheath; an outer sheath is arranged on the inner sheath; a reinforcing layer is arranged between the outer sheath and the inner sheath; the reinforcing layer comprises at least one reinforcing rib; the inner sheath is wrapped with the reinforcing rib, and the reinforcing rib is in contact with the inner sheath and the outer sheath, wherein the reinforcing rib is made from a manganese iron alloy; and the manganese iron alloy comprises the following components in parts by weight: 100-300 parts of iron, 200-500 parts of manganese, 50-80 parts of silicon, 20-30 parts of carbon, 20-30 parts of titanium carbide, 10-20 parts of molybdenum, 5-10 parts of scandium and 5-10 parts of lanthanum. The cable has the advantages of high tensile strength and long service life.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Aluminum tin 40 copper-steel metal bearing material and production method thereof

ActiveCN102935447BGood bite resistanceImprove complianceMetal rolling arrangementsLow speedSheet steel

The invention discloses an aluminum tin 40 copper-steel metal bearing material and a production method thereof. The production method comprises that (1) aluminum tin 40 copper alloy ingots of which two surfaces are roughened and a pure aluminum layer are subjected to the dual-surface composite rolling, the cold rolling is conducted sequentially till the target thickness is reached, the aluminum tin 40 copper alloy ingots are obtained through horizontal continuous casting, the processing rate of the dual-surface composite rolling is more than 50% and the processing rate per cold rolling is in a range from 20% to 35%; and (2) steel plates of which two surfaces are roughened and the aluminum tin 40 copper alloy after being burnished in the (1) are subjected to the composite rolling and the annealing is conducted for 8-10 hours at the temperature of 280 DEG C+ / -10 DEG C. The material has good seizure resistance, adaptability and high-temperature properties and is suitable to diesel engine bearing of medium and low speed ships.

Owner:SHANGHAI HEWEI IND

Process for spaying MoS2 on bearing bush without alloy layer

ActiveCN103143487BReduce pollutionReduce scratchesPretreated surfacesCoatingsEnvironmental resistanceWater rinsing

The invention provides a process for spaying MoS2 on a bearing bush without an alloy layer, and aims to solve the problem in the prior art of spaying MoS2 on the bearing bush without the alloy layer. The process comprises the following steps of cleaning, pickling, fresh water cleaning, steel titanizing, cold water rinsing, hot water rinsing, spraying, oven-drying, steel back burnishing, sintering and the like of a steel back layer, wherein before pickling, the steel back layer after being cleaned can be firstly placed in tap water for cleaning; and before spraying, steel back layer after being rinsed by hot water can be firstly placed in an oven for oven-drying. The process is safe and environment-friendly in the implementation process; as galvanizing is omitted, pollution to the environment can be efficiently reduced; and the bearing bush produced by adopting the process has better dry grinding resistance, meshing resistance, corrosion resistance and wear resistance, and can reduce scuffing on the inner surface of the bearing bush in the installation and use process, so that the service lives of the bearing bush and lubricant in the bearing bush can be prolonged.

Owner:YANTAI CHUNSHENG SLIDING BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com