High-strength and wear-resisting iron based powder metallurgic bearing

An iron-based powder metallurgy and bearing technology, which is applied in the field of high-strength wear-resistant iron-based powder metallurgy bearing materials, can solve the problems of low strength performance, bearing wear, short life, etc., achieve good anti-seizure performance, increase hardness, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

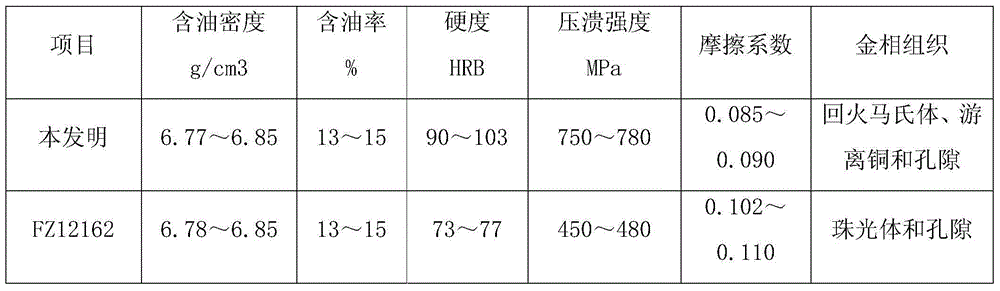

[0023] A bearing for a high-pressure oil cylinder of an excavator is manufactured from the high-strength wear-resistant iron-based powder metallurgy bearing material and the preparation method thereof of the present invention.

[0024] The composition of the high-strength wear-resistant iron-based powder metallurgy bearing material in this embodiment is shown in Table 1.

[0025] Table 1 Bearing material composition (by weight percentage):

[0026] Element

the carbon

Impurities

iron

wt(%)

16.0

0.9

0.01

≤2.0

margin

[0027] The preparation method of the iron-based powder metallurgy bearing material is completed according to the following steps:

[0028] 1. Mixing: Mixing according to the ratio of material components in Table 1, using a V-shaped mixer to mix evenly, and the mixing time is 30 minutes to obtain mixed powder.

[0029] In the raw material powder: the iron powder is an atomized...

Embodiment 2

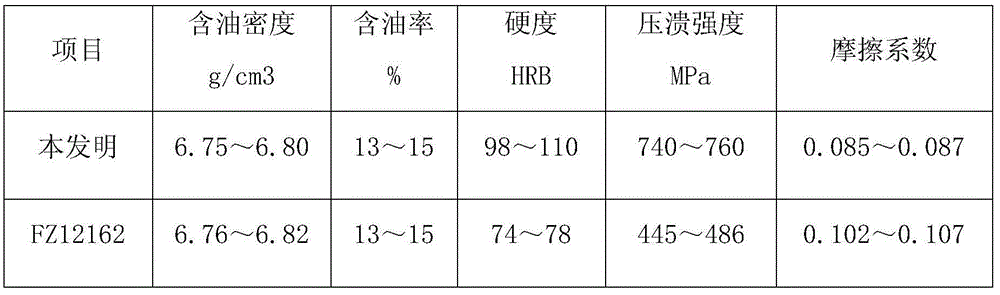

[0039] The utility model relates to a bearing for an oil cylinder of a bulldozer. The composition of the high-strength wear-resistant iron-based powder metallurgy bearing material in this example is shown in Table 3.

[0040] Table 3 Bearing material composition (by weight percentage)

[0041] Element

the carbon

Impurities

iron

[0042] wt(%)

16.8

0.88

0.40

≤2.0

margin

[0043] The difference between this embodiment and Example 1 is that in this embodiment, 0.3wt% zinc stearate and 0.5wt% micronized wax are added; the mixing time is 40 minutes; the pressing pressure is 600MPa; the sintering temperature is 1150°C, and the sintering time The heat treatment temperature is 910°C, the carbon potential is 0.85, the tempering temperature is 190, and the tempering time is 2 hours; after heat treatment, the product is immersed in oil, the oil temperature is 95-100°C, the vacuum pressure ...

Embodiment 3

[0047] The utility model relates to a bearing for a hydraulic cylinder equipped with a suspension device of a construction machinery vehicle. The composition of the high-strength wear-resistant iron-based powder metallurgy bearing material in this example is shown in Table 5.

[0048] Table 5 Bearing material composition (by weight percentage)

[0049] Element

copper

the carbon

Impurities

iron

wt(%)

17.5

0.85

0.70

≤2.0

margin

[0050] The difference between this example and Example 1 is that in this example, 0.3wt% zinc stearate and 0.04wt% spindle oil are added; the mixing time is 60 minutes; the pressing pressure is 550MPa; the sintering temperature is 1120°C, and the sintering time 45 minutes; the heat treatment temperature is 920°C, the carbon potential is 0.80, the tempering temperature is 220°C, and the tempering time is 2 hours; after heat treatment, the product is immersed in oil, the oil tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com