Double-layer metal composite material applied to sliding bearings and preparation method of double-layer metal composite material

A double-layer metal and composite material technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as wear resistance, unsatisfactory temperature resistance, limited thermal conductivity, large-scale equipment failure, etc., and achieve excellent thermal conductivity , excellent bite resistance, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

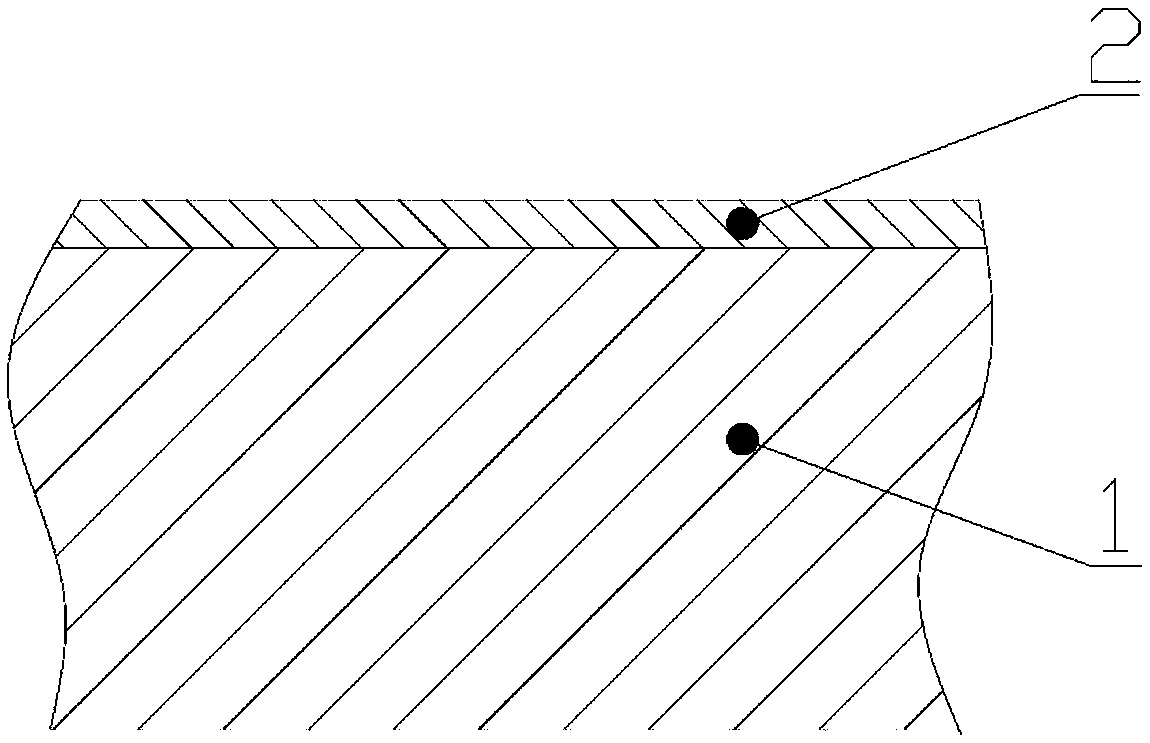

[0029] This embodiment relates to a kind of bimetallic composite material, such as figure 1 As shown, the bimetallic composite material includes a bearing layer 1 and a friction-reducing alloy layer 2 compounded thereon; the bimetallic composite material bearing layer 1 is made of aluminum bronze, and the mass percentage of the main elements of aluminum bronze is 85% Copper element, 10.0% aluminum element, 3.0% iron element, 1.5% manganese element. The anti-friction alloy layer 2 is made of a medium-high tin-aluminum base alloy, the main elements of which are 78% aluminum, 20% tin and 1.0% copper by mass.

[0030] The preparation method of the double-layer metal composite material applied to the sliding bearing in this embodiment:

[0031] The first step is to prepare and process the aluminum bronze material of the bearing layer, and the surface roughness to be surfacing reaches Ra0.8;

[0032] The second step is to put the processed aluminum bronze material of the bearing l...

Embodiment 2

[0037] This embodiment relates to a kind of bimetallic composite material, such as figure 1 As shown, the bimetallic composite material includes a bearing layer 1 and an antifriction alloy layer 2 compounded thereon; the bimetallic composite material bearing layer 1 is made of tin bronze, and the mass percentage of the main elements of tin bronze is 88.5% Copper element, 10.0% tin element, 1.0% phosphorus element. The anti-friction alloy layer 2 is made of a medium-high tin-aluminum base alloy, the main elements of which are 59% aluminum, 40% tin, and 0.5% copper.

[0038] The preparation method of the double-layer metal composite material applied to the sliding bearing in this embodiment:

[0039] The first step is to prepare and process the aluminum bronze material of the bearing layer, and the surface roughness to be surfacing reaches Ra0.8;

[0040] The second step is to put the processed aluminum bronze material of the bearing layer into the acetone solution, and use ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com