Preparation method for heavy-load high-power vehicle engine high-purity aluminum-tin bearing materials

A vehicle engine, aluminum-tin alloy technology, applied in the direction of mechanical equipment, bearing components, shafts and bearings, can solve the problems of undiscovered patent documents, etc., to refine alloy grains, improve anti-seizure, mechanical properties high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

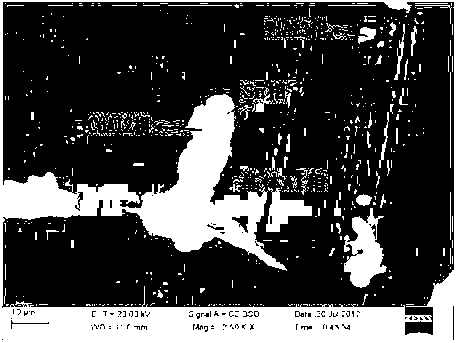

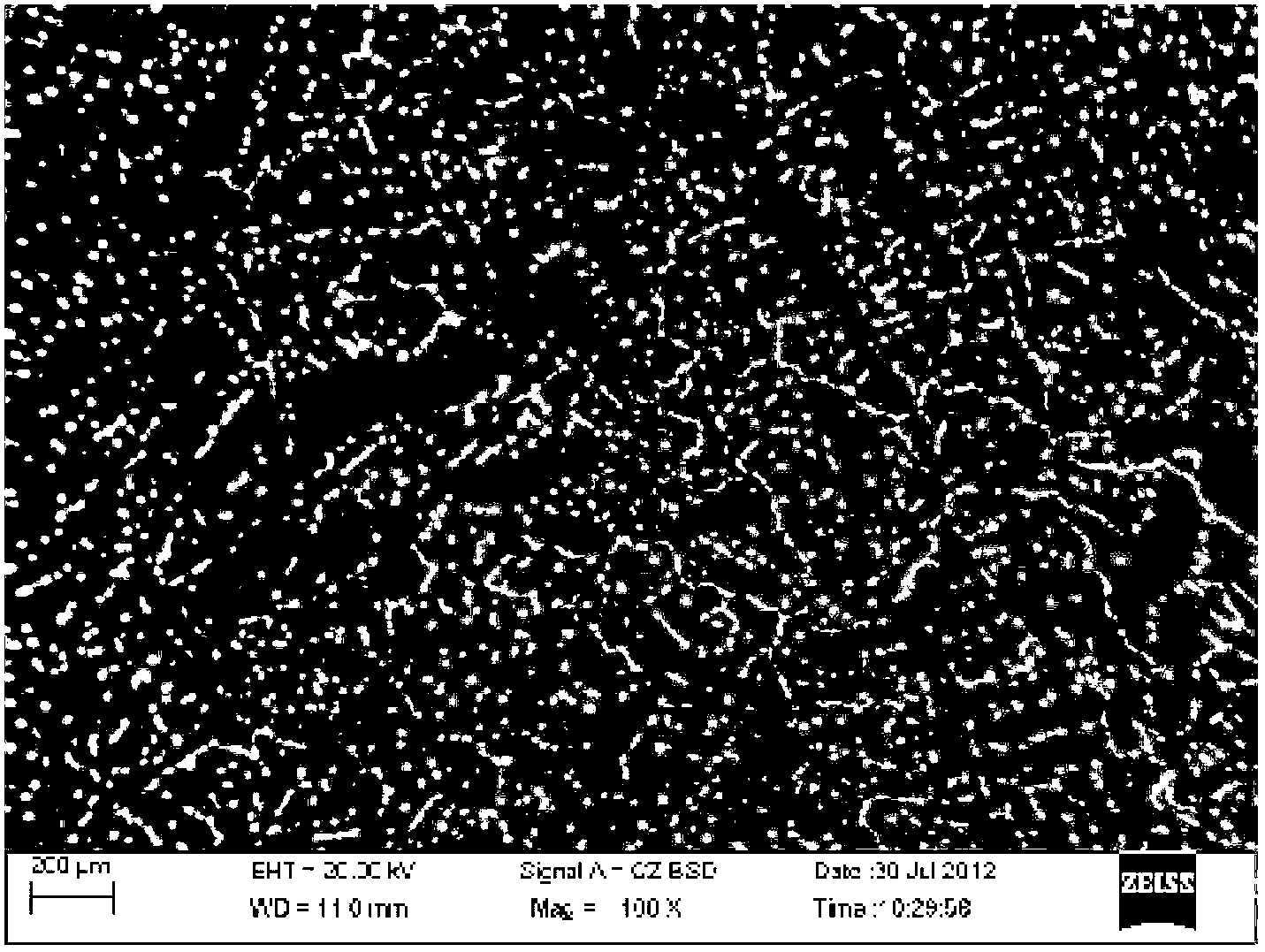

Image

Examples

Embodiment 1

[0027] A method for preparing a high-purity aluminum-tin alloy bearing material for a heavy-duty high-power vehicle engine, the steps are:

[0028] (1) The basic material elements are based on the mass percentage Sn: 3.7%, Cu: 3.5%, and Al is the balance. Specifically, the total weight of this embodiment is calculated according to 80Kg, and 2.9Kg of industrial pure metal tin and 2.8Kg of first-grade electrolytic copper are weighed , 74.30Kg of aluminum ingots for extra-grade remelting;

[0029] (2) Weigh 0.8g of first-grade potassium fluorotitanate;

[0030] (3) Put the industrially pure metal tin, first-grade electrolytic copper, aluminum ingot for extra-grade remelting, first-grade potassium fluorotitanate and casting mold in step (1) and step (2) into a constant temperature waste heat drying at a temperature of 200°C Dry in the oven for 2h;

[0031] (4) Put the aluminum ingot for remelting in step (3) into a CX-GR-150 industrial electric furnace, set the temperature of th...

Embodiment 2

[0041] A method for preparing a high-purity aluminum-tin alloy bearing material for a heavy-duty high-power vehicle engine, the steps are:

[0042] ⑴Basic material elements are based on mass percentage Sn: 3.5, Cu: 3.5, and Al is the balance, specifically: the total weight is calculated as 65Kg, weighing 2.3Kg of industrial pure metal tin, 2.3Kg of first-grade electrolytic copper, and special first-grade remelting Use aluminum ingot 60.4Kg;

[0043] (2) Weigh 0.6g of first-grade potassium fluorotitanate;

[0044] (3) Put the industrially pure metal tin, first-grade electrolytic copper, aluminum ingot for special second-grade remelting, first-grade potassium fluorotitanate, and casting mold in steps (1) and (2) into a constant temperature waste heat drying at a temperature of 200°C Dry in the oven for 2h;

[0045] (4) Put the aluminum ingot for remelting in step (3) into a CX-GR-150 industrial electric furnace, set the temperature of the industrial electric furnace to 800°C, ...

Embodiment 3

[0055] A method for preparing a high-purity aluminum-tin alloy bearing material for a heavy-duty high-power vehicle engine, the steps are:

[0056] ⑴Basic material elements are based on mass percentage Sn: 3.9, Cu: 3.3, and Al is the balance, specifically: the total weight is calculated as 95Kg, weighing 3.7Kg of industrial pure metal tin, 3.1Kg of first-grade electrolytic copper, and special first-grade remelting Use aluminum ingot 88.2Kg;

[0057] (2) Weigh 0.7g of first-grade potassium fluorotitanate;

[0058] (3) Put the industrially pure metal tin, first-grade electrolytic copper, aluminum ingot for special second-grade remelting, first-grade potassium fluorotitanate, and casting mold in steps (1) and (2) into a constant temperature waste heat drying at a temperature of 200°C Dry in the oven for 2h;

[0059] (4) Put the aluminum ingot for remelting in step (3) into a CX-GR-150 industrial electric furnace, set the temperature of the industrial electric furnace to 800°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com