Multi-layer structure TiNiAlZrNb-based self-lubricating bearing bush material design and preparation method thereof

A multi-layer structure, lubricating shaft technology, used in metal processing equipment, chemical instruments and methods, layered products, etc., can solve the problem that the working state of the bearing pad cannot meet the fluid lubrication conditions, the lubricating film on the bearing pad surface is incomplete, and the friction surface is high. temperature and other issues, to achieve the effect of improving compatibility and bonding performance, outstanding anti-seizure performance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

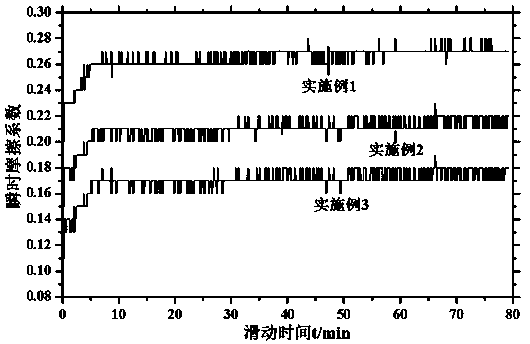

Embodiment 1

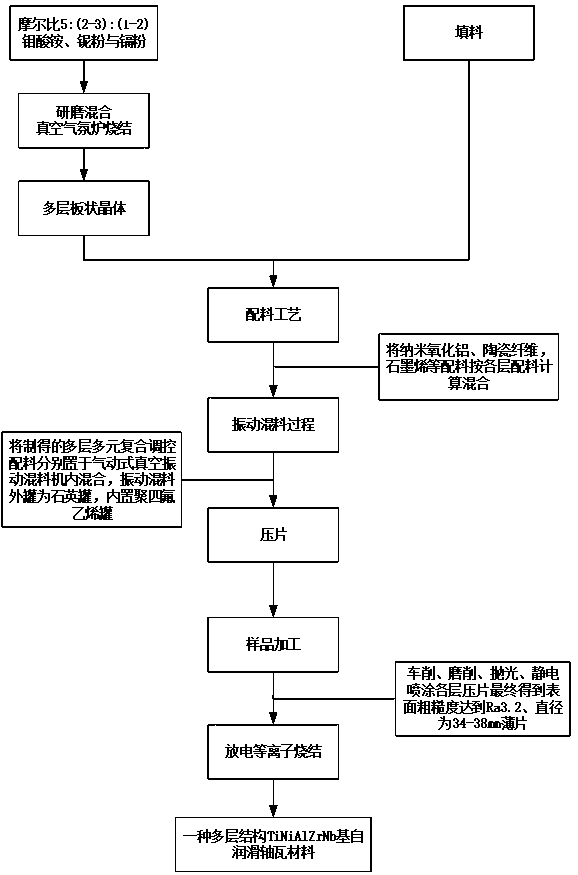

[0035] Such as figure 1 As shown, the main process of a multilayer structure TiNiAlZrNb-based self-lubricating bearing material design and its preparation method has the following steps:

[0036] 1) Weigh ammonium molybdate, niobium powder and cadmium powder at a molar ratio of 5:2:1, grind and mix the ammonium molybdate powder, niobium powder and cadmium powder to obtain a mixed powder with an average thickness of 25 μm; then vacuum atmosphere Furnace sintering, the sintering temperature is 650°C, the holding time is 3.5h, the protective gas is argon, and the reaction is enhanced by feeding oxygen during the sintering process. The oxygen feeding rate is 65ml / min, and a multi-layer plate crystal MoNbCrO is obtained. figure 2 It is the electron micrograph of the multilayer plate crystal MoNbCrO powder prepared in embodiment 1.

[0037] 2) Combine step 1) obtained multilayer plate crystal MoNbCrO with nano-alumina, ceramic fiber, graphene, aramid fiber, glass fiber, carbon fib...

Embodiment 2

[0047] Such as figure 1 As shown, a kind of multi-layer structure TiNiAlZrNb base self-lubricating bearing material design and its preparation method in the main process in embodiment 2 have the following several steps:

[0048] 1) Weigh ammonium molybdate, niobium powder and cadmium powder according to a molar ratio of 5:3:2, grind and mix the ammonium molybdate powder, niobium powder and cadmium powder raw material powder, and the average particle size is about 28 μm; then vacuum Sintering in an atmosphere furnace, the sintering temperature is 750°C, the holding time is 4.5h, the protective gas is argon, and the reaction is enhanced by feeding oxygen during the sintering process. The oxygen feeding rate is 175 ml / min, and a multi-layer plate crystal MoNbCrO is obtained.

[0049] 2) Combine step 1) obtained multilayer plate crystal MoNbCrO with nano-alumina, ceramic fiber, graphene, aramid fiber, glass fiber, carbon fiber, nitrile rubber powder, silicone resin, serpentine, no...

Embodiment 3

[0059] Such as figure 1 As shown, a kind of multi-layer structure TiNiAlZrNb base self-lubricating bearing material design and its preparation method in the main process in embodiment 3 have the following several steps:

[0060] 1) Weigh ammonium molybdate, niobium powder and cadmium powder at a molar ratio of 5:3:2, grind and mix the ammonium molybdate powder, niobium powder and cadmium powder powder raw materials to obtain uniformly mixed plate-like crystals with a thickness of 30 μm The original ingredients are then sintered in a vacuum atmosphere furnace, the sintering temperature is 750°C, the holding time is 4.5h, the protective gas is argon, and 175 ml / min oxygen is introduced during the sintering process to obtain a multi-layer plate crystal MoNbCrO.

[0061] 2) Combine step 1) obtained multilayer plate crystal MoNbCrO with nano-alumina, ceramic fiber, graphene, aramid fiber, glass fiber, carbon fiber, nitrile rubber powder, silicone resin, serpentine, nodular cast iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com