Low-friction bush-free connecting rod-piston pin structure

A piston pin and no bushing technology, applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems that the advantages of mass production cannot be used, the strength of the small head hole of the connecting rod is reduced, and the production cost has no advantages, etc., to achieve Excellent self-lubricating properties, improved work reliability, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

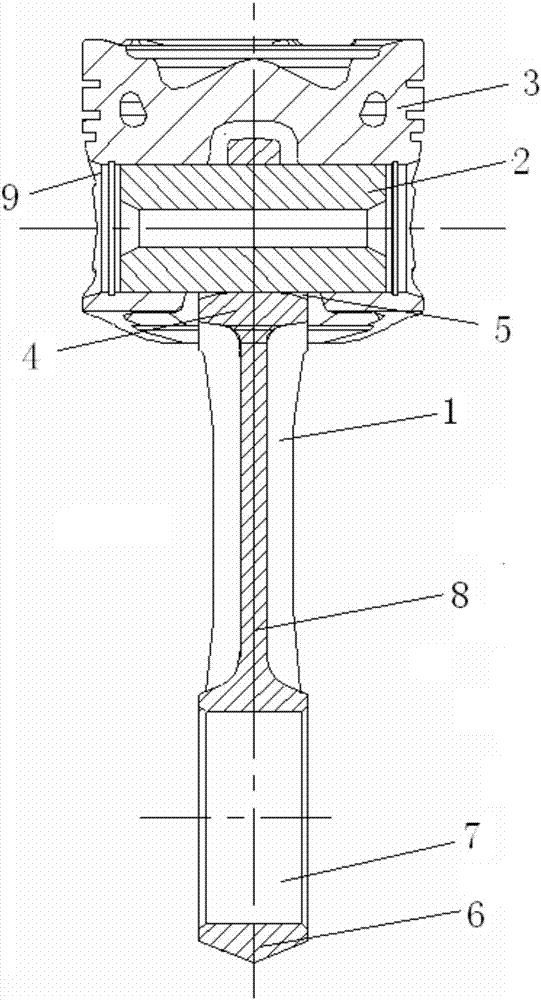

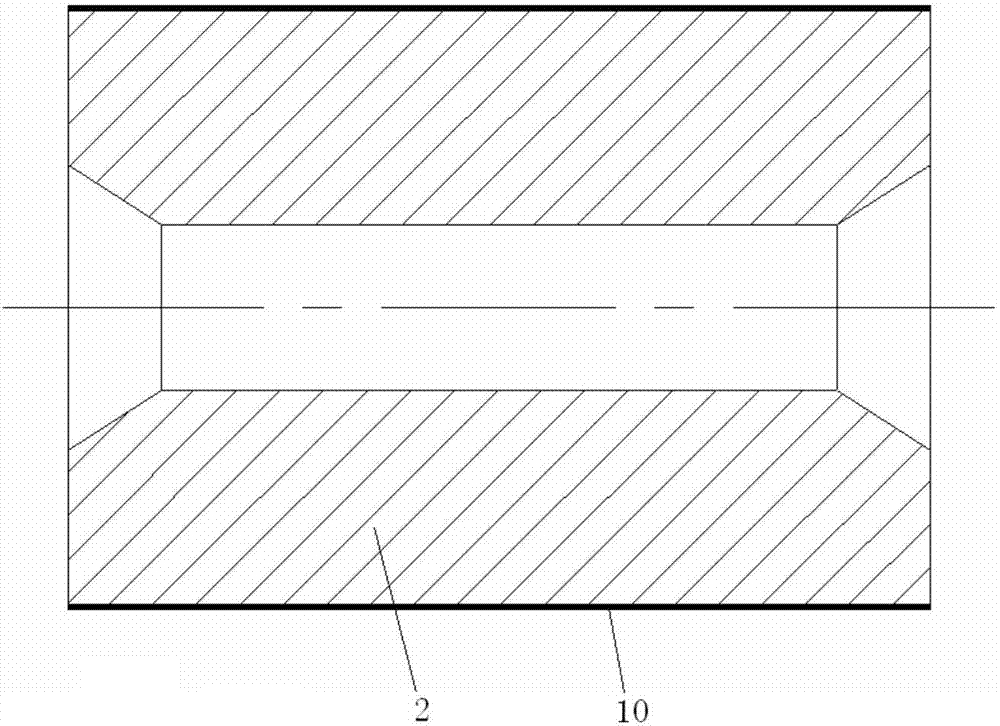

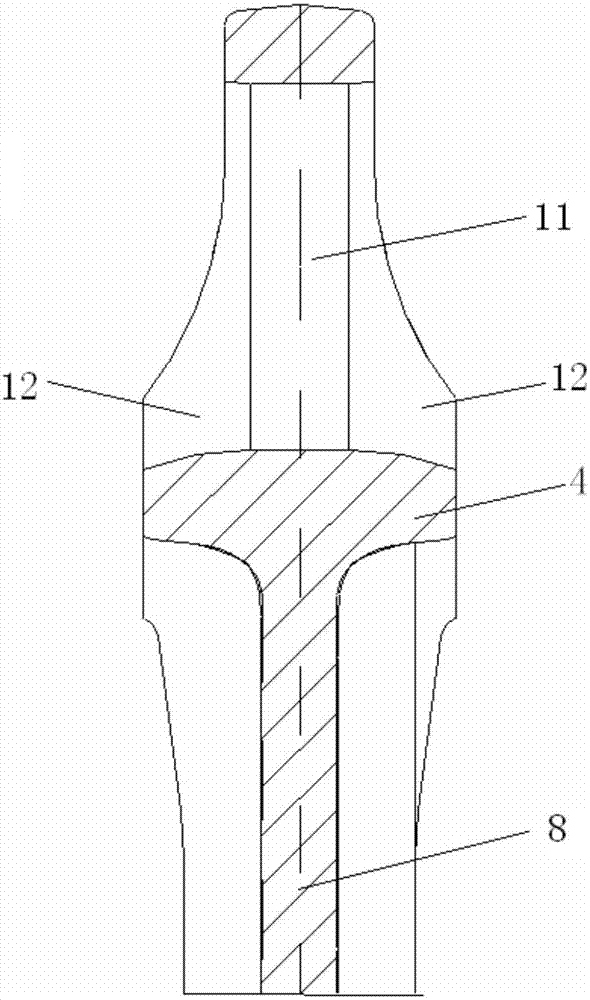

[0024] like Figures 1~5 As shown, the present invention mainly includes a connecting rod 1 , a piston pin 2 and a piston 3 . The connecting rod 1 includes a connecting rod small end 4 and a connecting rod large end 6 , and the connecting rod small end 4 and the connecting rod large end 6 are connected into one body through a rod body 8 . The connecting rod small end 4 is provided with a connecting rod small end hole 5 , and the connecting rod large end 6 is provided with a connecting rod large end hole 7 .

[0025] The piston 3 is provided with a left and right through piston pin hole 9, the connecting rod small end 4 of the connecting rod 1 extends into the piston 3, the piston pin 2 is located in the connecting rod small head hole 5, and the left and right ends of the piston pin 2 extend out of the connecting rod The small head hole 5 extends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com